Ever thought about using a 3D printer to help improve your design process? Wondering if it’s right for you? Additive manufacturing is making its way into the field of architecture in ways we never before imagined. From creating early iterations of concept designs to constructing full-scale buildings right on site, 3D printing has many things to offer to architects.

The benefits of having a 3D printer at your disposal are plenty. Modern printers have become very affordable, making it much easier to build complex and intricate models quickly and accurately and work the kinks out of your project early on. As a tool, 3D printing saves you time, money, and manpower compared to traditional model-building techniques. Winning clients over with the beauty of your design just got so much easier.

There are a lot of printers out there, so how do you know which one is right for you? We’ve picked out some of the best 3D printers for architects needs, to help you make your choice. Whether you’re looking for something easy to use, with a specific print size capacity, one that works with a specific material or a choice of different ones, here are some tools to help you decide which machine is right for you.

| 3D Printer | Technology | Print Area (mm) | Difficulty | Dimensions | Weight | Market Price |

|---|---|---|---|---|---|---|

| Bambu Lab X1 - Carbon | FDM | 256 x 256 x 256 | Advanced | 389 x 389 x 457 mm (without AMS) | 14.15 kg | $1,149 ($1,449 with AMS) |

| Original Prusa MK4 | FDM | 250 x 210 x 220 mm | Medium | 500 x 550 x 400 mm | 7 kg | $799 (kit) $1,099 (assembled) |

| UltiMaker S3/S5 | FDM | 230 x 192 x 200 mm (S3), 330 x 240 x 330 mm (S5) | Simple | 394 x 489 x 637 mm (S3), 495 x 585 x 780 mm (S5) | 14.4 kg (S3), 20.6 kg (S5) | $4450 (S3), $6950 (S5) |

| Budget Pick: Anycubic Kobra Max | FDM | 400 x 400 x 450 mm | Medium | 715 x 720 x 665 mm | 16 kg | $499 |

| Zortrax Inkspire 2 | SLA | 192 x 120 x 280 mm | Plug and Play | $4380 | ||

| Formlabs Form 3+ | SLA | 145 x 145 x 185 mm | Plug and Play | 405 x 375 x 530 mm | 17.5 kg | $2,499 |

| Anycubic Photon M3 Max | SLA | 298 x 164 x 300 mm | Medium | 596 x 400 x 408 mm | 26 kg | $869 |

| Budget Pick: Elegoo Saturn 2 | SLA | 219 x 123 x 250 mm | Advanced | 306 x 273 x 567 mm | 11 kg | $350 |

Before Buying a 3D Printer for Architects

If you’re tasked with purchasing the most useful 3D printer for your architecture firm, and you’re new to 3D printing yourself, this can be a daunting task. Fortunately, 3D printer manufacturers offer a wide range of resources and, of course, All3DP has thousands of articles covering printers, technologies, software, and troubleshooting to make you an expert in no time.

But first, let’s cover a few things you should look for when making a 3D printer purchase.

Budget: The cost of the machine itself is only the beginning. Keep in mind, you’ll need to buy printing materials, just like you need toner and paper for your 2D printer. Carefully consider your needs. Will you be printing quick mock-ups to look at scale and proportion, or will you need presentation grade outputs? Monolith models or multiple colors and materials? What size models? Each printer has its advantages and limitations. Knowing your needs will help you get the most bang for your buck. Don’t assume you’ll need to spend a fortune, we’ve thrown in a couple of high quality budget printers in our list to fit every price range.

Materials: Some printers only print with their own proprietary materials, while others work with a wide range of materials. You may be able to find more affordable material for the open printers, but cheaper isn’t always the best choice. Make sure you look through the selection of materials provided by the manufacturer before you invest to see if it can do everything you need it to do. Are the filaments affordable and easily available? Do they come in a variety of materials in terms of strength, flexibility, color to fit your needs?

Print Quality: What kind of resolution are you looking for in your prints? Things like layer height and resolution will affect your final model. How detailed are your designs? How fast do you need the machine to print? How big do you imagine your models will need to be? Pay attention to product build size and print speeds, as well as types of materials the printer works with.

Emissions & Space: All 3D printers produce some sort of emissions while in use, even those that use non-toxic PLA. Some of them are harmless off-smells from heated materials, but others have been linked to health risks. Evaluate how ventilated your printer setting can be and if you should have an enclosure and HEPA air filter.

Software: Most printers use STL file formats which are compatible with the software most architects use. You’ll also find printers that use formats, such as OBJ, AMF, and 3MF. After you have your file, you’ll need to use Slicer software to prepare it to print. This essentially determines how the model will be built and tells the printer how to construct it, and typically comes with the machine.

Technology Type: SLA? FDM? Material Jetting? Powder Bed? How do these technologies work and which one is best for you? Understanding the different types of printers will help you choose the best kind for your business. SLA or Stereolithography was the first type of 3D printing technology developed. It uses UV light to cure and solidify layers of photopolymer resin. FDM (Fused Deposition Modeling) or FFF (Fused Filament Fabrication) involves feeding one or more filaments through a heated printer nozzle, softening the material and allowing it to be deposited in layers to create the desired form. Material Jetting uses drops of material, either liquid photopolymers or casting wax to build up layers onto a build plate. This type of printer allows for different colors and textures in the final product. Powder Bed Fusion (PBF) uses layers of powder which are fused into the desired shapes by a heat source, generally lasers or electron beams. These are only a few of the different types of printers available on the market. For more in depth information on types of machines and how they work, check out our article here:

While compiling our list of the best 3D printers on the market for architects, we’ve focused on SLA and FDM printers. We’ve tried to pick out printers for every price range, and even included a low budget pick that even less established firms can afford.

Bambu Lab X1 - Carbon

If you have the budget, the Bambu Lab X1-Carbon FDM printer is a great option for its speed, ease of use, and multi-color offering.

This printer burst onto the 3D printing scene in late 2022 and is an All3DP printer lab favorite. It delivers a well-connected, beautifully designed user experience that makes printing easy and immensely enjoyable, and did we already mention fast? A standard Benchy (the standard in benchmarking tools) takes just 17 minutes to complete. Fast and beautiful. When compared to the other machines out there, the X1 Carbon is definitely one of the better looking ones. A definite asset to any design office.

This large and fully-enclosed printer comes with a high-temperature extruder making it perfect for using more exotic materials. Bambu Lab has delivered pretty impressive software and as its slicer (Bambu Studio) is based on PrusaSlicer and its offshoot, SuperSlicer, it should also feel pretty familiar those of you with previous experience using 3D printers. Bambu Handy is the mobile app that enables you to control the printer’s main functions from more or less anywhere, monitor the status of prints, visually inspect the print chamber via the X1 Carbon’s in-built camera, and even trigger support requests.

The Bambu Lab X1 even comes complete with AI that checks out the current print and lets you know when something has gone wrong. It features “spaghetti detection”, which looks out for a totally wild and out-of-control print getting, well, wild and out of control, and it also inspects your first layer. If it’s too high or too low, the X1’s brain should notice and inform you via a notification.

Something unique on our list of printers is the X1’s automatic material system (AMS) which usually goes for an additional $349. This enables you to use print with four spools for multi-color print and you can even link four AMS’ together via a hub for the option of 16 different materials for your prints. The AMS reads and automatically knows which filament you have loaded into it. It’s a nice touch and certainly adds to this machine’s overall slick usability.

For more detailed review of this printer, check out our review here:

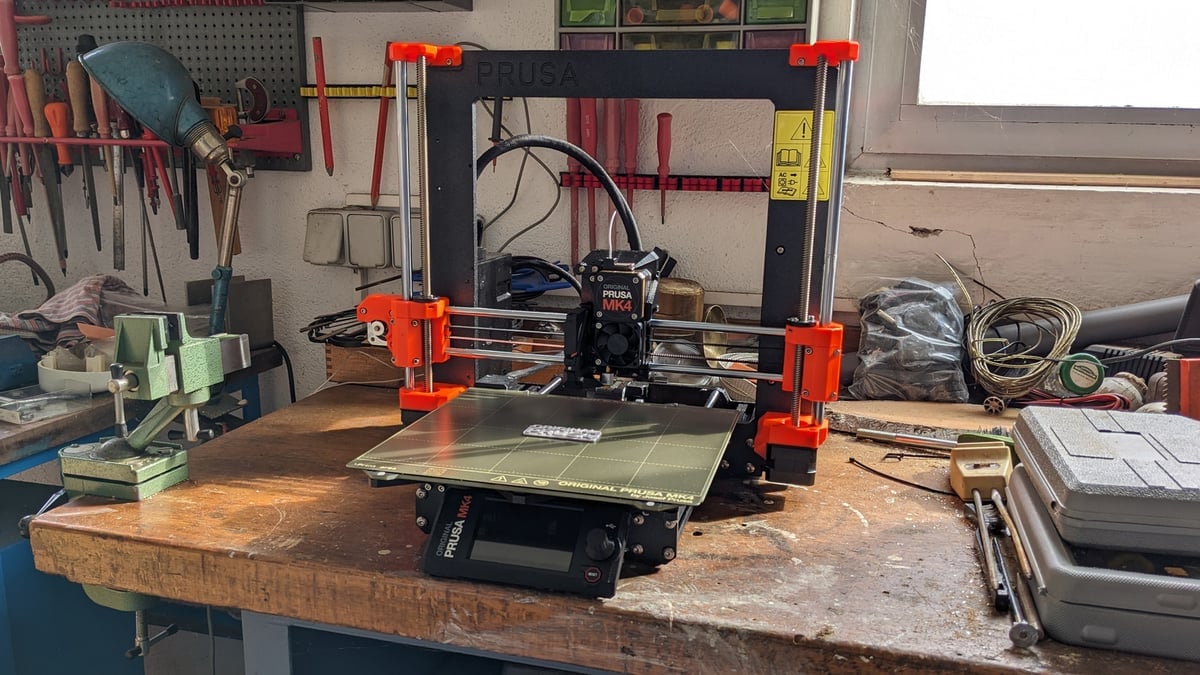

Original Prusa MK4

Looking for a foolproof, highly reliable FDM printer with 24/7 tech support? The Original Prusa MK4 might just be the machine for you.

For one thing, it produces superb prints. In the end, isn’t that what is most important? As with prior iterations, the hardware really does sing, and prints are put down on the bed in an almost painterly-like fashion. Besides the excellent print quality, this machine has a lot going for it. It features truly automatic bed leveling, it’s basically operable from the minute you open the box, and it’s loaded with QoL trimmings to make your user experience so much more enjoyable.

Print preparation using the company’s open-source slicing software, PrusaSlicer, is at its easiest when you’re using one of the company’s own machines, and the MK4 is no exception. There’s a wide variety of print quality options available to you and a broad material profile section, too. You can, generally, get by without having to dive into any deeper settings by using these quality profiles with the generic materials profiles alone.

The Prusa MK4 is no slouch but, by today’s standards, it is slow. Its design doesn’t necessarily lend itself to super-duper high-speed printing, but there are ways to push things harder without much of a hit to print performance.

The MK4 is an open format printer, so it has a more industrial look to it. If you’re not a fan of this, an official enclosure can be added for a whopping $349! To be fair, the enclosure does a few things more than make the machine look pretty. It reduces noise and fumes from escaping, as well as keeping dust away from the print, which is an important consideration depending on how your office is set up. You don’t want the scent of melting plastic wafting through your office during a crucial client meeting. Possibly more importantly, the enclosure creates a balanced environment by maintaining temperatures, which comes to play when using certain more robust materials that may warp while cooling.

The MK4 is convenient to use. Customizable quick icons let you place the information you care about most at your fingertips. The last sliced file on the USB stick automatically loads for you to one-click print. When you load a material, the machine remembers what it is and automatically knows the temperature it should heat to when unloading it. It’s small touches like this that elevate the experience of the MK4 over many other desktop 3D printers.

Besides the UI, the MK4 is a little smarter at detecting when something is off and triggers safety shutdowns. The company’s new self-developed mainboard, plus a variety of thermistors, take all manner of electrical readings into consideration and trigger safety shutdowns when things are off. This isn’t something we have the tools to test thoroughly, but it is worthwhile noting the transparency around safety and the systems in place.

While not strictly an integrated part of the printer, the MK4 ships with its optional ESP Wi-Fi board attached. Hidden away behind a small 3D printed shroud on the rear of the machine, this small chip lets you hook your MK4 up to your Wi-Fi network for remote monitoring and control via the PrusaConnect web browser interface.

The process for setting your printer up on your network is needlessly complicated, however, requiring you to first create a configuration file on a USB thumb drive using the printer, then update it with a text editor on your computer before reinserting it into the printer. As far as experiences go with connected devices, it’s not particularly elegant. Alternatively, there is an Ethernet port for wired connection to the MK4.

All in all, the MK4 is a good, competitive 3D printer. There’s no denying that it’s a pricey machine, though. But, no one ever bought a Prusa because it was the budget option – you’re paying for a meticulously designed product built in Europe with a well-developed support ecosystem. If you can manage to assemble it from a kit, you can save $300.

Want to know more? Here’s a more detailed review:

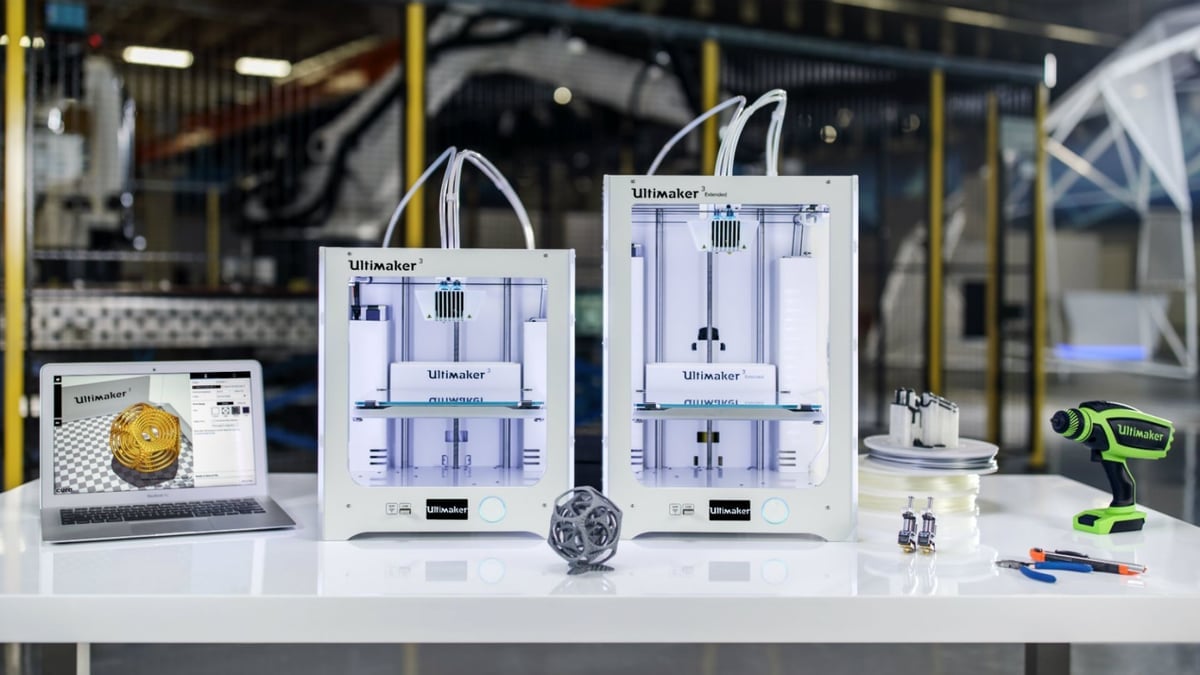

UltiMaker S3/S5

We’re including both the UltiMaker S3 and S5 FDM 3D printers on our list because really, the only fundamental difference between the two is the build size. This does lead to some small differences in the machines, but over all, they share the same components and technologies. They are clean, slick machines, that can print multi-materials straight out of the box (including soluble support structures), and can be fully enclosed with an air-filtration add-on to keep those nasty fumes at bay.

These printers are priced at the higher end of the market with the S3 retailing for $4,450 and the S5 for $6,950, so they may not fit everyone’s budget. In exchange however, you are rewarded with a professional 3D printing experience that results in fast prototypes and complex designs. The defining feature of these two UltiMaker machines is their ability to print two materials in the same job. This allows for more striking models to highlight the quality of your designs. An unsung perk to the system is that UltiMaker has virtually eliminated wastage from material purges when printing. Less waste adds up to more savings in the long run.

In addition, the S5 can be further expanded with UltiMaker’s Material Station and Air Manager units, which altogether are known (and sold) as the UltiMaker S5 Pro Bundle. The units, respectively, allow you to load up to six spools of material for seamless material switching or reloading between and during prints and stabilizes the print chamber temperature and filters airborne particles by way of a HEPA filter. At ~$9,550, it is UltiMaker’s costliest offering, but it’s also the company’s most advanced. If your aim is to print detailed, multi-color designs in a controlled setting, and you have the budget, this may be the machine you’re looking for.

Out of the box, the UltiMaker is compatible with a great number of filaments, both third-party and UltiMaker’s own brand. There are three different classifications of materials, each offering a different degree of ease of use: those produced by UltiMaker, which come on NFC-chipped spools that the printer can “read”; UltiMaker Material Alliance materials, which are those produced by manufacturers that have verified optimal print settings and provided material profiles for use when slicing; and lastly those that are neither, they can work in the printer but require manual set up.

One of the great things about the UltiMaker is its ease of connectivity through the company’s Cura Connect portal. These UltiMaker printers can connect to Cura over your WiFi network, allowing for wireless sending of print jobs, remote viewing of the print in process using an embedded camera, and print queue management.

Further to the connectivity options above, the S3 and S5 also benefit from direct CAD/CAM integration with SolidWorks, Siemens NX, and Autodesk Inventor thanks to plugins available on the Cura Marketplace. In all, it positions both printers as incredibly sophisticated tools that actually require very little time to be spent hands-on working with the printer.

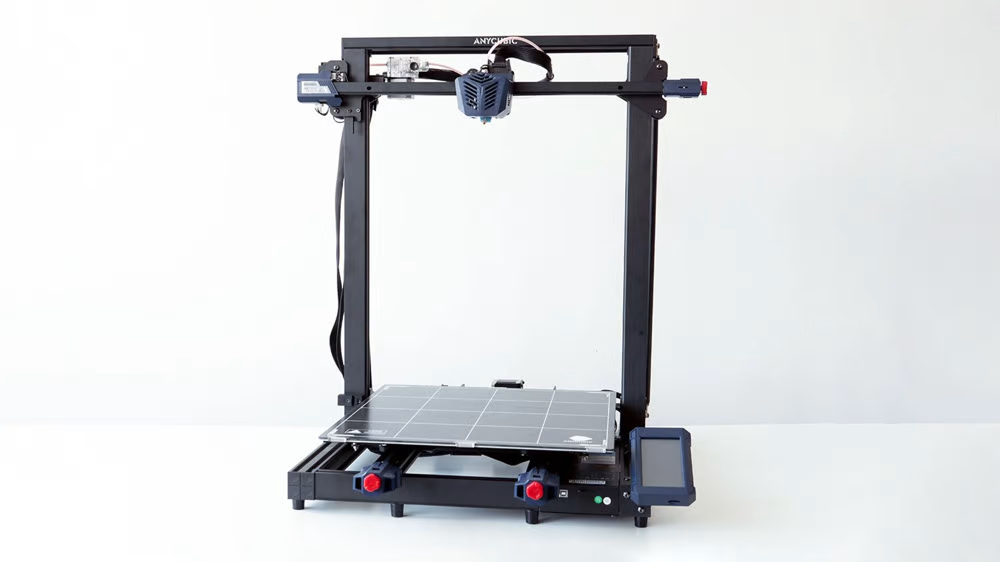

Budget Pick: Anycubic Kobra Max

Priced under $500 the Anycubic Kobra Max FDM printer is our budget pick for the list. But don’t let the price fool you, you get a lot for your money with this machine, as long as you’re a little bit handy. Be forewarned, the Kobra Max comes semi-assembled. You’ll first need to attach the gantry with four bolts, install the Z-axis braces, clip the print bed into place, and then, voilà you’re ready to start printing. This printer works with third party filaments, so you have a wide range of materials to choose from to get your designs looking exactly how you like them.

With a massive build volume of 400 x 400 x 450 mm, the Kobra Max allows for huge prints. Whether you want to 3D print life-sized details or scale up your favorite models, the Kobra Max offers ample build volume to let your creativity run wild. It’s big, though. The footprint of the Kobra Max is 720 x 715 x 665 mm, but you will actually need even more room as the bed travels on the Y-axis and exceeds the frame’s footprint.

Considering the open format of the printer, the printer is pretty silent given its size. As always, it’s the cooling fans that make the most noise during printing. Something to keep in mind, if you are working in a small office.

As far as print quality goes, thanks to its automatic leveling system, LeviQ, and its carborundum glass bed, first layers and print adhesion are superb and, once set up, require no adjustments between prints. Combined with the printer’s robust chassis, its dual geared extruder, and Volcano-style hot end, the Kobra Max has almost all the tools for large 3D printing. What’s missing, if you want to be picky, is a larger spool holder and larger bore nozzles that would help speed up printing times.

The printer is controlled via a 4.3-inch touchscreen. The control menu is clearly arranged, and you can access print and fan speed as well as temperature settings mid-print.

Designs are fed into the Kobra Max by a microSD. Be careful not to get mixed up: the printer and the touchscreen both feature a microSD card slot. It is the printer you want to feed, though, not the touchscreen. Otherwise, you will be left wondering why nothing loads up.

One of the downfalls of the Kobra Max is the speed. One of the hindrances for this is the nozzle size. The nozzle has a bore of 0.4 mm — standard for most smaller printers. For a printer the size of the Kobra Max, larger diameter nozzles, say 0.6, 0.8, or even 1 mm, would absolutely shred print times down to hours, instead of days.

With the slow speed however, you get precision, repeatable results, and trouble free operation. If you don’t mind the open format industrial optic – and all the noise and smells that go along with that, this might be the machine for you. Priced at $499, the Anycubic Kobra Max poses as an affordable entry into the niche that is large format 3D printing. You will have to look far and wide to find a similarly sized and specced alternative if you’re aiming for big projects and ideas.

For a more detailed review of this printer, check out our article here:

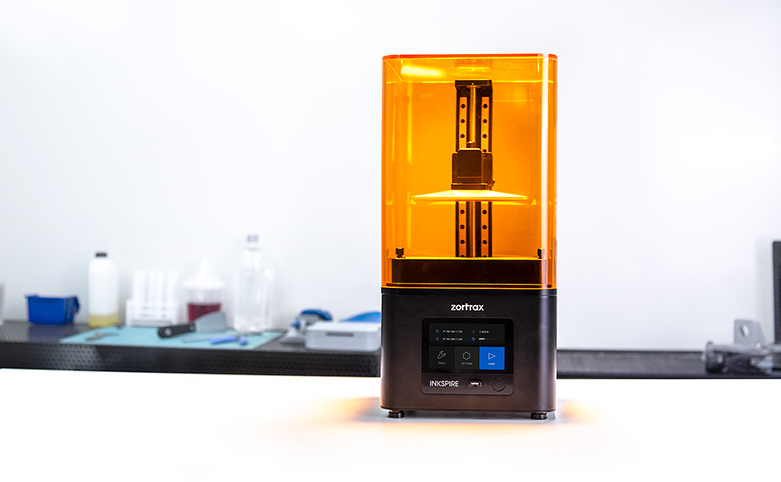

Zortrax Inkspire 2

Zortrax’s Inkspire 2 is a larger, more powerful, and more expensive version of its resin-based predecessor. This SLA printer features liquid-crystal display (LCD) technology with an array of LEDs shining through the LCD screen, not a projector like some printers, to cure the resin print. The screen is a mask, revealing only the pixels necessary for the current layer and blacking out the rest. This technique is often referred to as “masked SLA” or MSLA, a slightly different kind of SLA printer.

Developed entirely in-house by Zortrax, the proprietary light engine provides a consistent UV exposure across the entire build platform to achieve consistent print quality regardless of the position of the models, the company says. Compared to the original Inkspire, introduced in 2018, the new version boasts 40% more uniform light distribution.

Zortrax says its light engine is powerful enough to work with high-grade engineering resins (those cured by light with 405 nm wavelength) that used to be supported only on industrial digital light processing (DLP) machines. Inkspire 2’s UV light engine is seven times more powerful than the previous Inkspire and is compatible with some DLP resins. (DLP technology uses a digital light projector and a digital micromirror device to selectively direct light.). So if you’re looking to print super complex and detailed objects, this is definitely a machine to consider.

The Inkspire 2 is also noticeably larger than its predecessor with four times the build volume, measuring 192 x 120 x 280 mm. The layer height at 25 microns, and an XY resolution of 50 x 50 microns remain the same as the previous model.

Although all 3D printers produce some sort of emission while in use, SLA printers produce from 3 to 6 times more volatile organic compounds (VOCs) than FDM printers. Make sure your office is equipped with a well ventilated area and appropriate filters to house this kind of machine.

Zortrax uses durable engineering resins from BASF Forward AM and Henkel/Loctite, which the company says are functional equivalents of high-performance filaments. Four resin lines are dedicated to the Inkspire 2: elastomeric resins, rigid or tough resins, castable resins, and basic resins, with room for expansion in the future. This results in the ability to print objects that are flexible, rigid, resistant to high loads, and those that are heat resistant, allowing for quite a variety for your printing needs.

Zortrax has developed its own software to enable real-time, remote management of all its printers. Prints can be uploaded, started, and paused on each machine connected to the Zortrax inCloud account. The inCloud software even has built-in staff management functionalities enabling users to be organized into teams with assigned 3D printers.

Definitely on the higher end of the spectrum, priced at over $4300, this machine is not for everyone’s budget. That being said, the Inkspire 2 is much more advanced and more automated than most printers on the market. Features such as closed air circulation, HEPA filters, a blackout response system that shuts down in the event of a power outage and finishes the printing process once the power is back on. There’s an automatic wiper that prevents resin sedimentation during longer prints, and, when the printing is done, the Inkspire 2 can transfer the remaining resin back to the bottle. A sensor shuts down the UV lamps when the door is open.

Adding to this price are the new washing ($3,800) and curing ($4,400) devices to accommodate the printer’s large volume. These aren’t absolute necessities, as these can be performed with over the counter tools and supplies, but it does simplify the post-printing process if you have the budget.

For a more detailed review of this printer, check out our article here:

Formlabs Form 3+

The Form 3+ 3D printer from Formlabs is not just the company’s latest upgrade, it is also its fastest resin printer to date. Back in 2020 we named the Form 3 the best resin 3D printer of the year for its ease of use and reliability. Since then, The Form 3+ has made many important changes to make the design even better.

Designs can be uploaded using Wi-Fi, USB, or an ethernet cable. Once the printer is on your network and you have opened an online account with Formlabs, you gain access to a web-based Dashboard where you can tap into your printer’s status, job history, active resin cartridges and resin vats.

Priced at under $2500, the Form 3+ is less than the heftier priced Inkspire, but still pretty high up on the cost scale. Formlabs also makes its own washing and curing stations. These don’t quite break the bank, though. The Form Wash is priced at $650 and the Form Cure goes for $750. To save money, these can be bought along with the printer as a bundle or in a monthly payment plan. A complete package, which runs around $4,250 includes the Form Wash and the Form Cure, in addition to the printer as well its Pro Service Plan for a full year (immediate replacement parts, print support, online training and other services).

There is a lot of value packed into this machine. Brimming with sensors and processes, and complemented by software that completely takes the “3D printing” out of 3D printing, printers made by Formlabs are the easiest to use and most reliable machines we’ve gone hands-on with yet. Print quality depends a lot on the quality of the resins used, and Formlabs proprietary resins don’t disappoint.

Formlabs resins are made specifically to work with settings in their own printers. Third party resins are not likely to produce a successful print. That being said, the 40+ library of materials available to use are intelligently handled by their printers. There’s no expectation on the user to configure — simply plug the resin cartridge into the back of the printer and the only option you are presented only with is to choose the layer resolution. Everything else is taken care of. To date, Formlabs’ in-house-developed material library caters to the specific demands of a broad stretch of industries, with prices typically reflective of the specialty and output; a standard resin runs at $149, whereas more industry-specific resins can run up to $399 for a cartridge.

What you get in detail, unfortunately, does not translate to scale. The Form 3+ has a build size of 14.5 x 14.5 x 18.5 cm which is small for SLA printers, not to mention the sizes you can achieve with some FDM printers, something to keep in mind if your aim is to print large-scaled models.

As with all SLA printers, the resins used to print will undoubtedly produce fumes. However, The Form 3+ printer and Form Wash, are well sealed, and when used with the hoods properly in place, produce very little smell. That being said, due to the toxicity of the materials, always use the machine in a well ventilated area.

For a more detailed review of this printer, check out our article here:

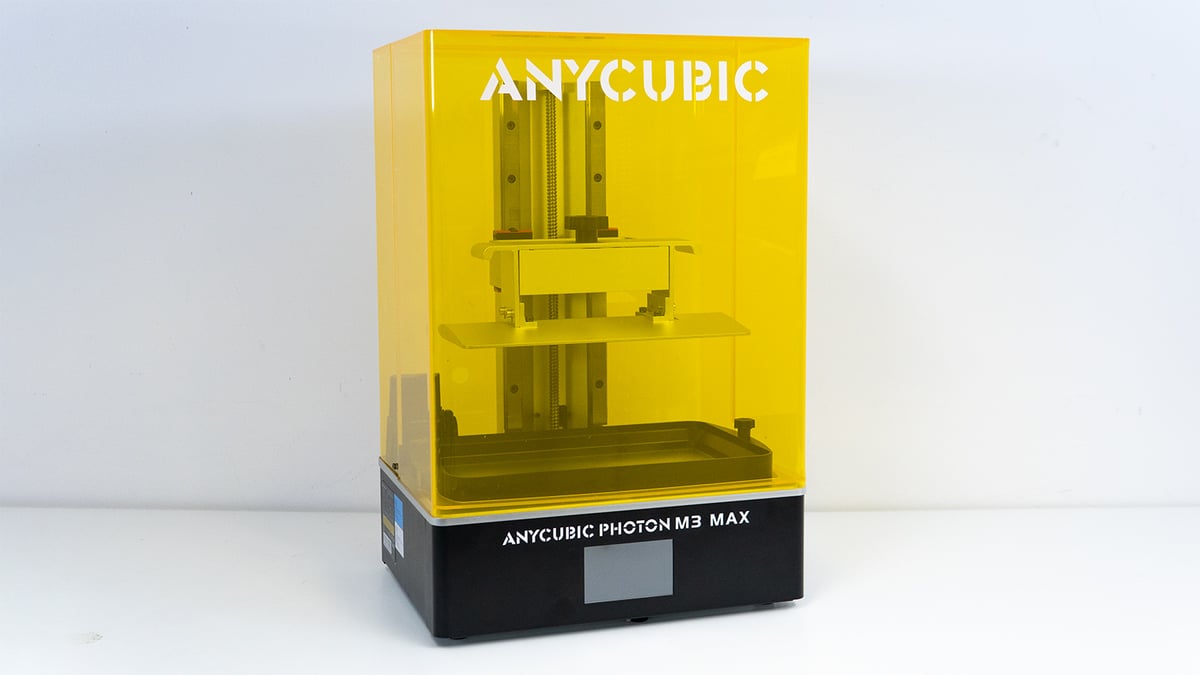

Anycubic Photon M3 Max

The Anycubic Photon M3 Max is a large resin 3D printer capable of producing high-detailed models. It is the largest of the three M3 (third-generation) Anycubic Photon resin printers and Anycubic’s first venture onto the large resin 3D printing turf. On the one hand, it sports a large build volume, affordability, and great performance. On the other hand, it also has a vat that is tricky to handle, limited UI, and a print speed that is on the slow side.

That being said, the Anycubic Photon M3 Max is one of the best large-format resin 3D printers you can purchase right now. In fact, with the Photon M3 Max, Anycubic managed what other manufacturers set out to achieve but seemingly failed due to price creeps: provide a large volume resin 3D printer at an affordable price.

Currently priced at well below $900, this printer undercuts the comparable large-capacity consumer printers out there by a stretch. If you want to get into large resin 3D printing without breaking the bank, the M3 Max should be high on your list. As it is on ours; it is currently our Budget Pick in our Best Large Resin 3D Printers Guide.

Compared to the first two SLA printers evaluated in this article, you may be wondering what you get for your money. With a build volume of 298 x 164 x 300 mm and XY resolution of 46 microns, thanks to its 7K mono screen, you can print truly large and highly precise prints. Our model test prints came out with great detail and little effort and the 7K display rendered every feature crystal clear and distinct. One of the big benefits of having such a large build plate and volume is that you can also print a lot of models simultaneously. Whether we printed one large model or a batch of smaller parts, the M3 Max handled it all. Beware though, printing large is kind of a different beast; it is less forgiving. If you make the same mistake as us and not set up the auto feed, you may run out of resin as we did and mess up the model and support placing.

This printer uses 405 nm UV resin and allows for the use of third party materials, allowing for a large range of resins to choose from and a lot of different sized budgets. The printer also has an auto resin filler that automatically feeds resin into the vat without opening the cover – a novel feature at this price point.

As its name suggests, the M3 Max is the largest of Anycubic’s M3 series, with a footprint of 400 x 408 x 596 mm and a weight of 26 kg. Its half-lid front cover allows for easier access in tight settings, compared to its hinged door competitors. Access to the prints, that is. Anycubics auto-refill system, located in the back of the printer, is a bit cumbersome to reach, so you’ll still need a decent sized work area designated to house this machine.

Designs are fed in through the use of a USB port located on its base. Anycubics proprietary slicing software is provided with the printer. It has fun features like a head scanner that can produce a 3D model of a head from a few photographs but feels a little cumbersome compared to other slicer alternatives out there. You can use the M3 Max with Lychee or ChiTuBox Slicer as well.

The M3 Max’s two-piece acrylic enclosure, which does not look as sophisticated as the metal enclosures you’ll find on competitors, is also a bit wonky at times. What it lacks in stability, however, it makes up for with accessibility, especially when wielding that massive printed model. If you are still concerned about the smell of resins in your office, Anycubic’s AirPure air purifier lists at just under $25. Definitely worth the investment to keep fumes at bay.

For a more detailed review of this printer, check out our article here:

Budget Pick: Elegoo Saturn 2

For our Budget pick for SLA printers, we went with the Elegoo Saturn 2. Priced at just below $350, this is the cheapest 3D printer of any included on our list. But, don’t let the price fool you. The Elegoo Saturn 2 is the best mid-sized resin 3D printer you can buy right now. With its 8K screen and formidable 219 x 123 x 250 mm build volume, the Saturn 2 is among the first wave of a new era in resin 3D printing: no more having to choose between build volume or resolution.

Not only that, the Saturn 2’s new design is also an undeniable eye-catcher. The head-to-toe redesign starts with the acrylic hood, which now comes in a more modern and ergonomic design – a slick look if we ever saw one. Elegoo’s identity remains with flashes of dark red and a deep red cover. The design change seems primarily aesthetic, but thanks to the edged shape, the cover is easier to handle and sturdier than other box-shaped lids.

The Elegoo Saturn 2 has pixels. A lot of them. Explaining how and why this is significant starts with the 10-inch high resolution 8K LCD. 7680 x 4320 pixels are packed into the Saturn 2’s new 10-inch masking LCD. This equates to an XY accuracy of 28.5 microns, which more than triples the resolution of the original Saturn. So, if you are hunting for ever more detailed prints, this jump in resolution, combined with the larger build volume, is significant.

Prints from the Saturn 2 are stunning. The printer’s resolution can render the tiniest of features in lifelike detail. You won’t see a night-and-day difference at an arm’s length, mind, but look closely, and the intricate details are more pronounced and less hazy.

Pixels aren’t the only thing the Saturn 2 went all out on. It finally made the much-needed jump in size, now holstering an impressive 219 x 123 x 250 mm volume. The Saturn 2 is tall, too. Anyone upgrading from the original will immediately notice the difference, with the increase in build volume height and the rearranged base running taller too. Combined, they make the Saturn 2 quite the beanpole. The Z-axis runs on two linear rails, so it is safe from twisting or any uneven motion that could lead to layer separation. It’s all rock solid.

Our common gripe against Elegoo’s resin 3D printers is the lack of resin profiles. While most resins print okay with the slicer-default settings, we would appreciate a little nuance to achieve better or more specific print characteristics. Beyond Elegoo’s materials, there’s also a world of third-party resins. While we wouldn’t expect Elegoo to map the ideal settings for every possible resin that could work in its machines, it wouldn’t be a stretch for the company’s materials to be mapped better for users.

It’s becoming commonplace for resin 3D printer manufacturers to include some air filtration units to counter the unpleasant toxic fumes given off by the resin the printers require. In the case of the Saturn 2, Elegoo decided to go with a replaceable activated carbon filter we’ve already seen on the Jupiter and Saturn S. The filter is USB powered, plugging into a dedicated port at the rear of the printer’s main chamber.

Unscientifically using our noses as a measuring tool, we can say having this small box hum away in the back does make a difference. It does not entirely irradicate the stink, nor will it effectively filter out all the harmful emissions from the resin. It’s not a complete safety solution, so best to still take appropriate protective measures, including ventilation and PPE.

The USB slot – the sole means to load print jobs onto the printer – sits on the side of the printer. There’s no Wi-Fi on the Saturn 2. And while the first-generation Saturn had an Ethernet port, it’s absent here. Judging the mood online, no one misses it, though it speaks to a lack of networkability in resin 3D that others are working on addressing.

As far as slicing software goes, Elegoo provides a copy of ChiTuBox Basic with the Saturn 2, although the free third-party Lychee slicer is an equally capable alternative. Both have printer profiles for the Saturn 2 ready to go, making light work of the setup. Other slicers are available; it’s mostly a matter of personal preference. There are premium versions of ChiTuBox and Lychee. Both offer more advanced settings, but the basic free versions are enough for most users.

Want to know more? Here’s a more detailed review:

Lead image source: Stratasys Direct

License: The text of "The Best 3D Printers for Architects of 2023" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.