A slicer is a program that converts digital 3D models into printing instructions for a given 3D printer to build an object. In addition to the model itself, the instructions contain user-entered 3D printing parameters, such as layer height, speed, and support structure settings.

Every 3D printing technology creates 3D objects by adding material layer by layer. Slicer software is therefore appropriately named because it virtually “cuts” 3D models into many horizontal 2D layers that will later be printed, one at a time.

In this article, we’ll discuss the role of slicers in 3D printing, detail how 3D slicing works for FDM and resin, and finally finish up with slicing in other 3D printing technologies. Let’s get started!

What Does a Slicer Do?

In a nutshell, a slicer serves as a bridge between a digital 3D model (produced through computer-aided design, or CAD) and a manufacturing system by translating the design into instructions for – in this case – a 3D printer to perform.

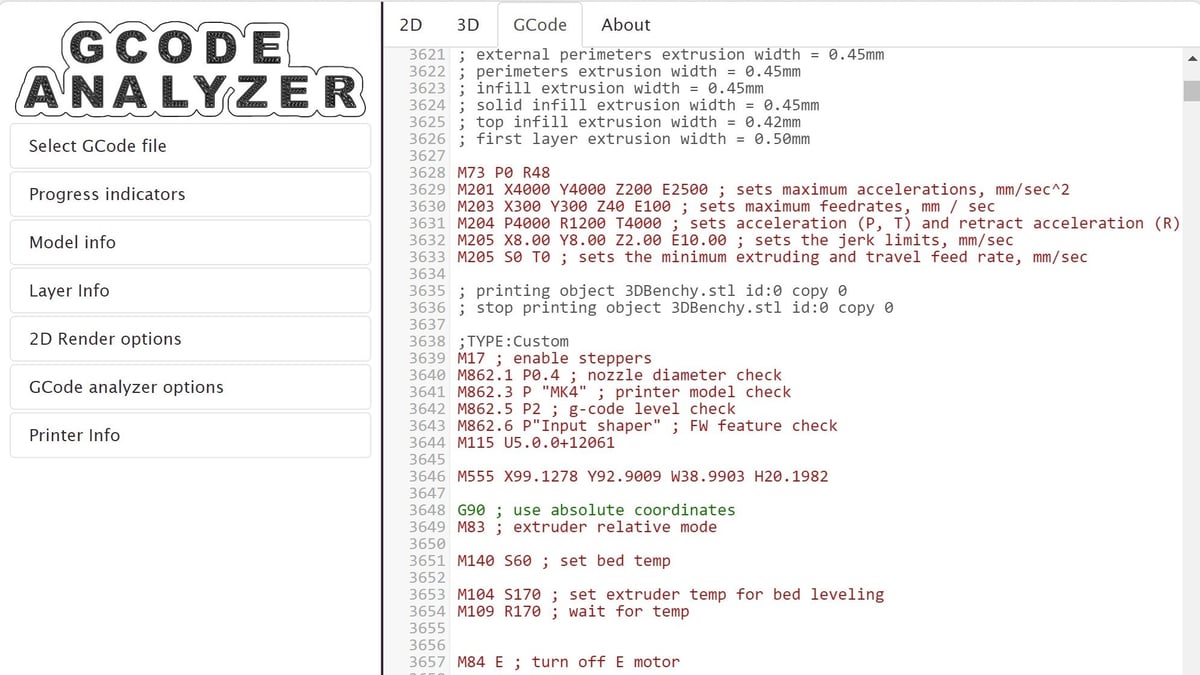

These instructions are transmitted in the form of command lines, usually referred to as computer numerical control (CNC). As the name implies, inputted commands control all the printer’s aspects, including movement speeds and temperatures, among many others. A distinction can be made between 3D printers and other CNC machines, like those dedicated to milling, plasma cutting, and turning. 3D printers are, as explained, operated through CNC instructions, yet they aren’t the most common example when users think of the term.

In any case, while there are many different ways to “talk” to these machines, the predominant language is G-code, which is used across different kinds of manufacturing systems – and understandably, there are specific commands for different technologies. G-code, as seen above, details, line by line, what the 3D printer has to do.

3D slicing procedures might look straightforward for anyone who’s printed a 3D model. But what really happens behind that tidy user interface? Let’s take a look at what we need to have a successful slicer experience.

Requirements

In order to successfully prepare a model for 3D printing and generate the G-code, the slicer requires two different inputs: the 3D model itself and the set of printing parameters that tell the machine how the actual printing must be done.

3D Models

You can create digital 3D models using a wide variety of CAD software, ranging from the open-source and artistic Blender to the professional and highly technical SolidWorks. The problem is that any digital file created with a specific CAD tool has a particular format, like “Blend” (.blend) for Blender and “part” and “assembly” (.sldprt and .sldasm) for SolidWorks.

Alternatively, you can find models created by others on repositories. These might be available in a variety of formats depending on, for example, whether they’re meant to be printed by multi-material units or if they’re including more manufacturing settings.

If 3D slicers were to process all of these different formats, they would require a huge support base, and even so, they surely couldn’t cover all the modeling software out there. For this reason, a standardized file format is used. The most common associated with 3D printing is STL (.stl), which is exported by most 3D modeling software. You needn’t panic if your program doesn’t export this file type – there are plenty of STL file converters.

3D Printing Parameters

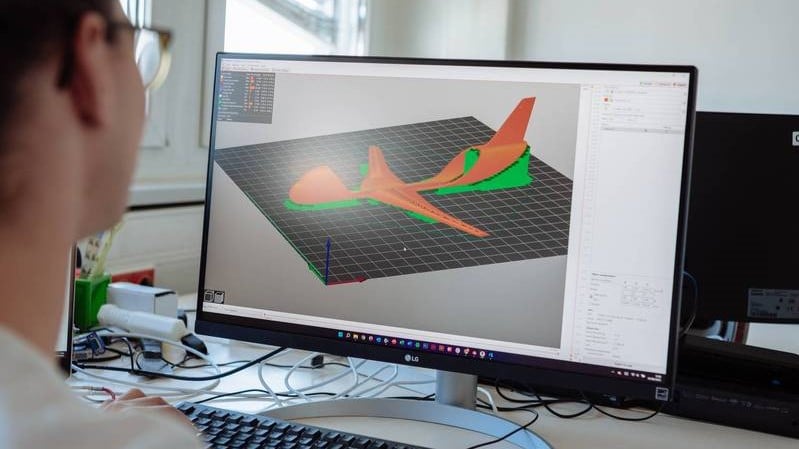

After your 3D model is in a format that the slicer can understand, the next step is to provide printing details, like layer height, speed, part positioning, and several other manufacturing-related settings. These user-entered values are defined prior to printing.

The 3D model can also be partially modified during this step. You can change dimensions through scaling features, and parts can be partially or entirely hollowed, filled with infill patterns, and provided wall-thickness values. This step also includes enabling support structures, which is one of the most practical features of a 3D slicer.

The 3D printing parameters will differ depending on the type of technology (FDM or resin-based) as well as on the type of material (different kinds of filaments for FDM require different settings, for example), the object to be printed, and its intended use. So let’s see what comes into play for each.

FDM Slicing

Fused deposition modeling (FDM) is a material extrusion technique where a printhead moves across two different directions (X- and Y-axes) while plastic filament is melted and pushed through the nozzle to create a 2D layer. This process is repeated until, layer by layer, the 3D object is complete.

FDM printers depend heavily on movement to build a 3D object, with fine, multi-axis control required for an accurate print. As mentioned, different materials will have different settings, from varying temperatures to speeds, and depending on the model, support structures might also come into play.

Once the 3D model and the print settings are defined, the slicer will process these inputs and generate a G-code file that’s then uploaded to the 3D printer.

The final step is done entirely by the 3D slicer’s internal algorithms, which means that it’s not user-related and that each slicer will do this differently. For simple models, any differences between slicers might go unseen, but for the more complex ones, they’ll surely be noticeable. Certain slicers may perform better with certain 3D printers, but there’s no hard-and-fast rule to know which one will work best for you.

Many 3D slicers are available for FDM, several of which are free. Cura and PrusaSlicer are among the most popular within the open-source community, while there are proprietary options such as Bambu Lab’s Bambu Studio, and Simplify3D is a premium (and costly) choice.

Resin Slicing

Vat polymerization uses UV light in different forms to cure and solidify liquid resin into layers. Once a layer is solidified, the build platform moves to allow fresh resin to fill and form the next layer until the 3D part is created.

This 3D printing technique relies less on movement when compared to FDM. For “true” SLA printers, a deflecting mirror rotates to direct a UV laser beam at the resin, outlining and forming each 2D layer. For DLP and LCD (or MSLA) 3D printers, the only real movement is done by the build plate, which travels exclusively along the Z-axis during the entire printing process.

One difference from the FDM printing process is that resin printers don’t use G-code in their output files. In fact, most desktop resin 3D printers use their own proprietary format, and therefore, their own slicer software. Still, there are some third-party resin slicers available, like Chitubox, FormWare, which are compatible with many desktop printers.

Slicing for resin is somewhat similar to FDM, but the 3D printing parameters differ. Rather than nozzle temperature or cooling, resin settings include exposure time and lifting speeds. However, layer height and features like support structure allocation are also present in resin, just as they are in most 3D printing technologies. And as happens with the different filaments, depending on the type of resin you opt for, settings will have to be adjusted accordingly.

A Slice from the Rest

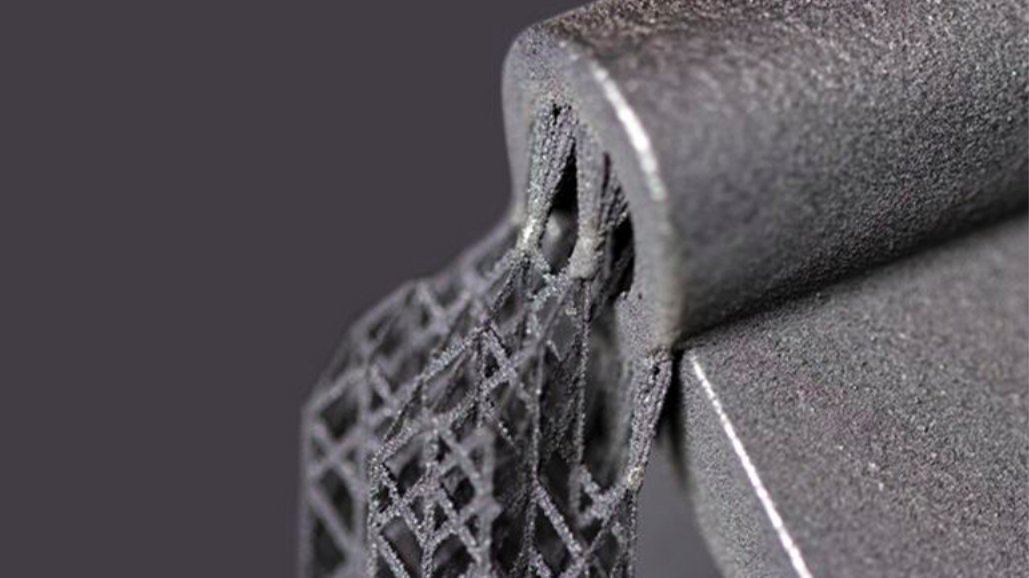

Other 3D printing technologies like SLS, SLM, or even EBM and binder jetting require specific slicers due to the extra complexity and diversity of their processes. For instance, an SLS system from one manufacturer won’t function the exact same way as its competitor, which is why most of these machines use slicer software from the official manufacturer.

Even so, there are some alternatives. Software company Materialise offers a suite of tools for preparing and optimizing 3D models for printing across 3D printing technologies. This software includes various post-processing modules, including the Build Processor, that prepare digital parts for printing on a wide range of 3D printer brands, including HP, EOS, Desktop Metal, and BLT.

Some CAD programs, such as Autodesk’s Fusion 360, can perform build prep operations and send print jobs directly to 3D printers that use FDM, SLA, SLS, SLM, or hybrid technology. With Autodesk’s Netfabb, you can send print jobs directly to 3D printers, including EOS, Formlabs, Arcam, HP, Sinterit, and SLM.

Another CAD program with direct integration to 3D printers is NX, from software giant Siemens. The NX for Manufacturing software is an integrated system to program CNC machine tools, control robotic cells, drive 3D printers, and monitor product quality.

License: The text of "What Is a 3D Slicer? – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.