Warping is an all too common issue in fused deposition modeling (FDM) 3D printing. If you’ve ever experienced the edges and corners of your 3D prints curling off the print surface, you know just how annoying warping can be. This problem can singlehandedly ruin otherwise perfect prints, making them deformed and dimensionally inaccurate.

Warping is caused by thermal contraction. As the extruded plastic cools, it contracts. Since the first layer of the 3D print adheres to the build surface, it doesn’t contract with the rest of the model’s layers. Instead, the forces begin to bend the bottom of the print upwards.

ABS suffers heavily from warping, as it remains solid up to around 100 °C. This means that the extruded plastic quickly solidifies during printing, leaving it vulnerable to warping forces.

To combat this pesky problem, you will need to reduce these contracting forces and keep the first layer firmly stuck to the print surface. In our general guide on warping, we cover basic tips that can be used for a variety of filaments. In this article, however, we’ll focus specifically on ABS and how to prevent it from warping. Let’s dive in!

Clean the Print Surface

Whether from dust, greasy fingers, or adhesive residue, your print surface will likely collect a layer of grime over time. This will prevent the first layer of your 3D print from adhering properly, increasing the chances of ABS warping.

Remember to clean your print surface regularly. A quick wipe-down with a paper towel and some isopropyl alcohol (IPA) will do the trick for PEI sheets. If you have a glass bed, you can use a scraper to remove excess residue. With that, the print surface will do a better job of holding down the first layer.

Keep in mind that not all cleaning agents can be used for all kinds of surfaces, as they can react differently and end up ruining them.

Tune Your First Layer Settings

Another explanation for warping is that your first layer print settings aren’t properly tuned. This includes the temperatures, layer height, line thickness, and more. For a general overview of these settings, check out our first layer problems guide.

For ABS, try starting with these reference settings:

- Nozzle temperature: 235 °C

- Bed temperature: 110 °C

One specific concern with ABS is that your bed temperature isn’t high enough to keep the first layer held down. This is due to ABS’s incredibly high temperature resistance, which prevents anything below 100 °C from having much of an effect on it.

In general, you want a high bed temperature to keep the material warm and adhered to the bed while keeping the nozzle temperature as low as possible. A sufficiently high nozzle temperature is necessary for proper layer adhesion and strong prints, but shooting too high may exacerbate the effects of thermal contraction. This is due to the increased temperature difference between the nozzle and the bed.

Based on how your prints turn out, tweak the nozzle and bed temperatures by increments of 5 °C to find the balance between print strength and warping.

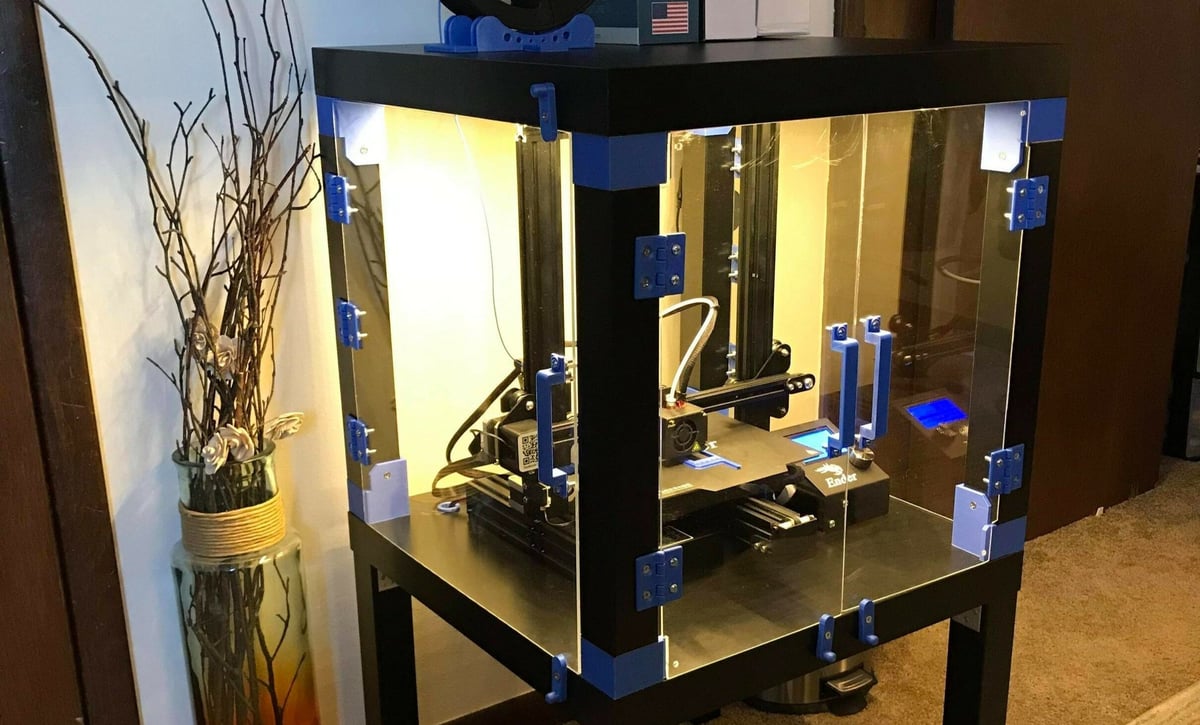

Print in an Enclosure

As mentioned previously, ABS’s resistance to temperature makes it extremely prone to warping. To mitigate these effects, try printing in an enclosure to raise the ambient temperature. This decreases the forces created by thermal contraction.

Options include DIY enclosures as well as commercial solutions. Some of the enclosures available for purchase even actively heat the air in the chamber, although this is often unnecessary. Usually, the heat from the heated bed is enough to maintain an appropriately toasty temperature. Or, if your budget allows for it, just simplify things and go for an enclosed 3D printer.

No matter which type you go for, test out the enclosure beforehand to ensure that the electronics and printed components of your printer aren’t damaged.

Use an Adhesive

If an enclosure doesn’t help, or if you simply don’t want to bother with one, you may need a little help from an adhesive. This will give the first print layer a little more to grab onto, preventing it from curling up and spoiling your print.

Common adhesives include regular household hairspray and glue sticks, as well as commercial solutions, like Magigoo (pictured above). For ABS specifically, ABS juice, a solution of ABS and acetone, is also a good option.

Regardless of the adhesive you use, make sure to apply only a thin layer at a time and reapply as necessary. If you use this solution, you’ll definitely need to clean your print surface from time to time, as we discussed previously.

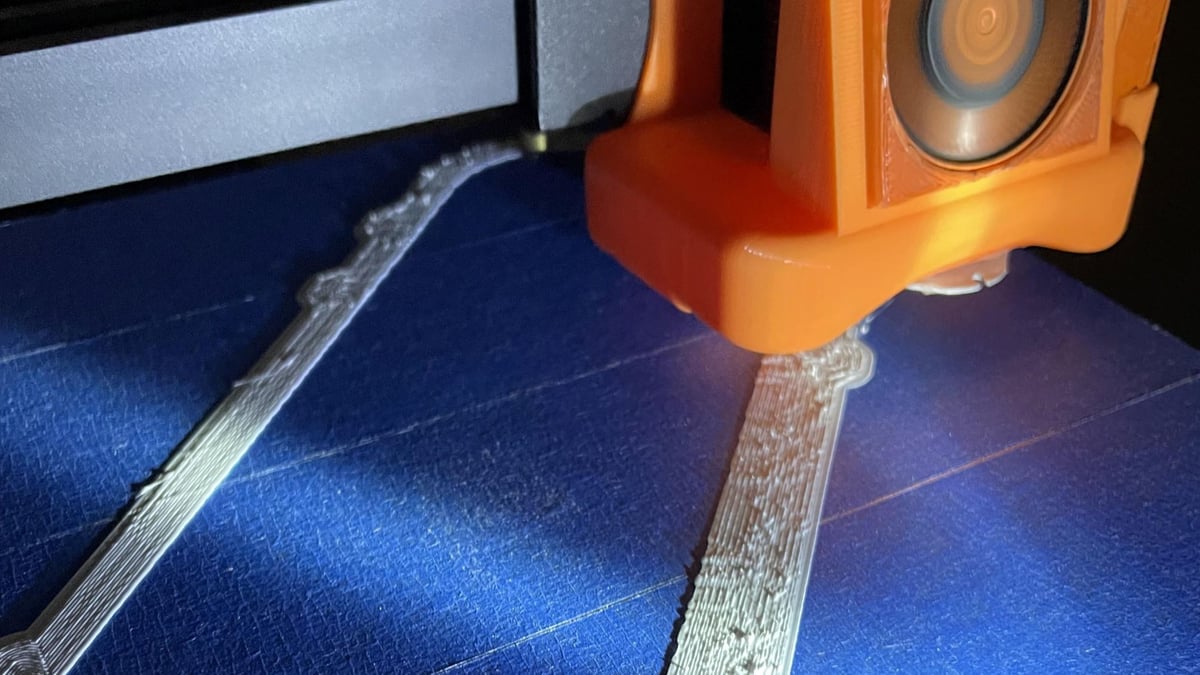

Use a Brim or Raft

As a last resort, you may have to use a brim or raft. Brims expand the first layer with extra perimeters (as seen in the image above), while rafts add extra layers onto which models are then printed. These will aid print adhesion by increasing the surface area in contact with the print bed. Rafts can also compensate for poor bed leveling.

Try the other tips before turning to these, as brims and rafts will increase print time, consume more plastic, and make post-processing 3D prints more tedious. However, if your model has many small features in contact with the print surface, they may be necessary to prevent them from dislodging.

License: The text of "ABS Print Warping: How to Stop It" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.