HDPE stands for “high-density polyethylene”. While that may be helpful for the chemists among us, most of us know HDPE as the recyclable plastic used to store household products such as milk, laundry detergent, and soda.

HDPE is commonly used in packaging and other commercial applications because it’s recyclable, waterproof, buoyant, and considered food safe. It’s worth mentioning that while the material is food-safe, the 3D printing process is not, and additional steps need to be taken beyond simply having the right material.

In addition to being a popular choice for liquid containers, HDPE is used to make “synthetic lumber” for weatherproof furniture, corrosion-resistant pipes, and medical equipment.

But if it’s a great option to reduce plastic consumption and waste, why hasn’t it become a must in every 3D printing workshop?

In this article, we’ll take a look at objects that can benefit from being printed with HDPE, the advantages and disadvantages of the material, some tips on working with it, and finally where you can find it.

What to Print

There are more than a dozen different kinds of materials available for fused deposition modeling (FDM) printers, each with its own advantages and drawbacks. For example, PLA is affordable and easy to work with. It’s great for small models, desk accessories, and even practical objects that won’t experience too much stress. PETG is another common filament, and it’s a great choice for printing protective covers and useful parts that will need to stand up to some wear and tear.

With that in mind, here are some applications you might consider using HDPE filament for:

Objects that Float

Since HDPE is waterproof and buoyant, it’s well-suited for printing objects such as keychain buoys, pool and bath toys, and fishing bobbers. With a big enough printer and enough patience, you could even print yourself a boat (or one for your Lego).

Recyclable Supports

If you’re trying to make your 3D printing more environmentally friendly and are running a dual-extruder printer, you could print your supports out of recyclable HDPE to minimize waste.

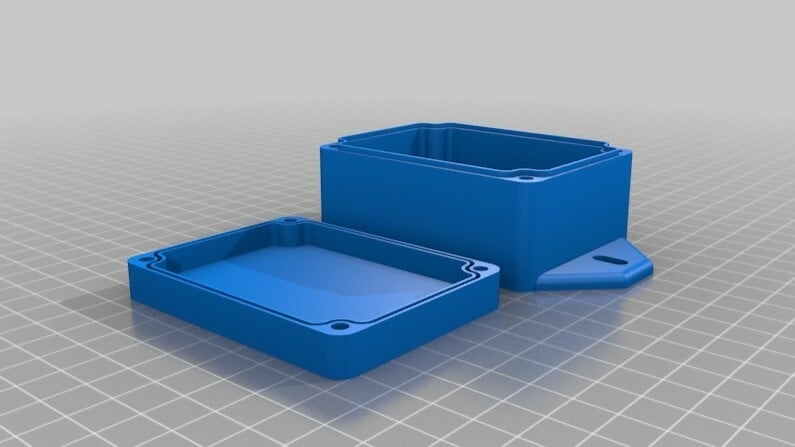

Containers for Some Types of Chemicals

Chemistry is messy, and combining the wrong chemicals can have dangerous consequences. HDPE filament doesn’t react when it comes in contact with many household chemicals that may be caustic to more common filament types. You can use HDPE in projects that will come into contact with, for example, laundry detergent, bleach, antifreeze, and gasoline.

Let’s take a closer look at the advantages and disadvantages of 3D printing HDPE.

Advantages

As a 3D printing material, HDPE offers a few advantages, with one already mentioned above. Here are a couple of others to consider:

Recyclable

HDPE’s most notable advantage is how easy it is to recycle. Recycling old products into filament creates a new use for the millions of tons of plastic waste. Plus, when you use HDPE for 3D printing filament, you can recycle your unused filament and finished objects after they’ve served their purpose.

Watertight

HDPE is often used as a container for liquids because it’s not soluble in water, and, meeting a few design requirements, you can have watertight models. This is true whether the container is made with traditional manufacturing methods or 3D printing.

Temperature-Resistant

HDPE can be used to hold liquids up to 120 °C for short periods, although warping is likely under sustained heat.

While HDPE has significant advantages, there are quite a few drawbacks, which we’ll go over next.

Disadvantages

With HDPE being a strong and environmentally-friendly material, you might be wondering why it isn’t used more in 3D printing. Unfortunately, as a 3D printing material, HDPE currently leaves a lot to be desired.

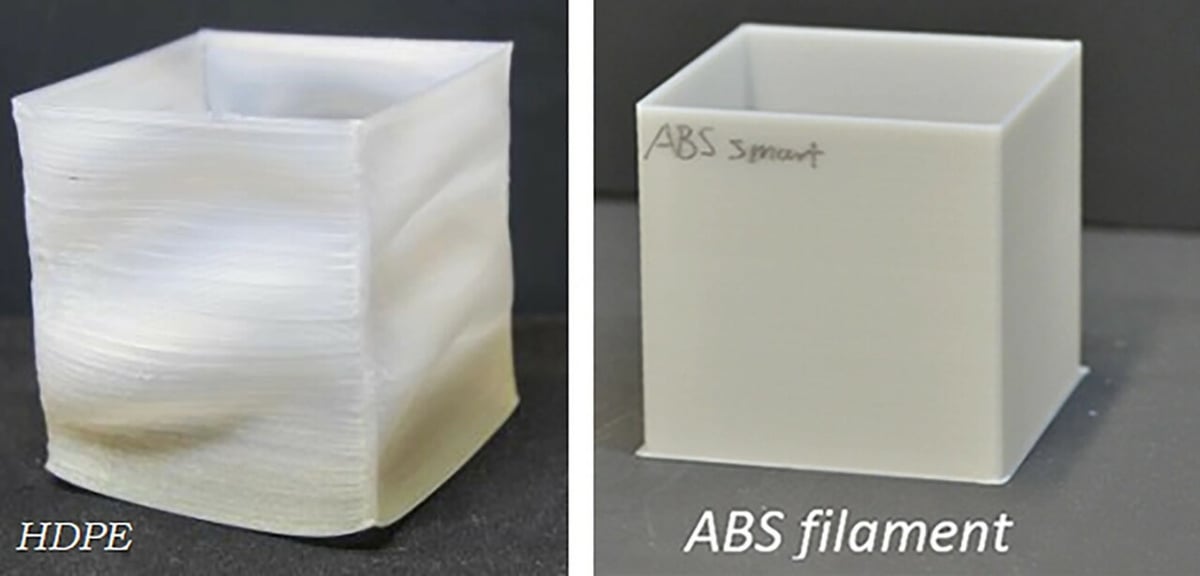

Warping

HDPE has a tendency to warp while printing, leading to imprecise final objects. Unfortunately, while we can mitigate warping, it’s not avoidable as the issue stems from the chemical structure of HDPE. In simple terms, HDPE is composed of two different microstructures that don’t cool at the same rate, and this uneven cooling leads to warped prints.

Shrinkage

HDPE shrinks as it cools. If you don’t account for this during the design phase, you may end up with an object too small for its intended purpose. You can print a test object with HDPE, measure the shrinkage, and adjust your design upward accordingly, but this is still a less-than-ideal solution. This makes HDPE impractical for prints that need to fit together precisely, since you’ll have less control over the final shape than you would with other filaments.

Poor Self-Adhesion

While HDPE forms strong chemical bonds, that doesn’t equate to strong layer adhesion when printing, which will significantly impact the overall strength of the print. Several great 3D printer fillers can smooth out the rough layer lines and help with delamination, but be aware that by introducing new variables to an HDPE print, you may be affecting things like its buoyancy, watertightness, chemical resistance, and recyclability.

Not Readily Availability

At time of writing, no international commercial seller carries HDPE filament. Given the availability of the raw material and the relative ease of turning it into filament, there might just be a lack of demand among 3D printing enthusiasts for it.

Potentially Hazardous Fumes

Printing with HDPE requires similar print settings to those of ABS, including a hot end capable of reaching temperatures of 260 °C. Due to studies on the health risks of 3D printing, a proper enclosure is a requirement when printing HDPE.

3D Printing with HDPE

If the challenges of HDPE haven’t scared you off, there is some good news. You probably already own a machine capable of handling HDPE printing. If your printer can handle ABS, odds are it handle HDPE as well.

There are three basic things you need to print with HDPE:

High Nozzle Temperature

HDPE requires a temperature between 230 °C and 260 °C to flow consistently.

Heated Print Bed

Due to its adhesion and shrinkage issues, HDPE filament works best when printed on a heated bed. This keeps the material stable and warm enough to retain its shape throughout the printing process. It also gives the object better adhesion to the print surface.

Enclosure & Ventilation

Due to the high printing temperatures required, HDPE should be printed in an enclosure with a fume exhaust fan.

Now that all the requirements are met, we’ll go over how you can add some HDPE filament to your 3D printing setup.

Where to Get It

As mentioned, at time of writing there are no commercial sellers of HDPE filament, with Filaments.ca having an “Out of stock” notice. So, if you want to try printing with it, you’ll need to make your own, and there are two routes you can go.

The Filabot EX2 is a filament maker that will turn plastic pellets into filament. The downside is that it costs around $2,600. Another option includes ReDeTec’s ProtoCycler+, which comes with a heftier price tag of close to $4,000, although material compatibility needs to be confirmed.

You can also take the DIY route and build your own filament recycler. While you’ll probably be able to complete this project for less than the price of the Filabot EX2, it won’t be without its own costs and challenges.

While the 3D printing community may be gearing toward a more environmentally-friendly path, whether HDPE becomes a fixture in it or not is to be seen.

License: The text of "HDPE Filament: 3D Printing Basics" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.