Creality’s Ender 3 made it possible for many DIY enthusiasts to get their hands on 3D printing. Later, the Ender 3 Pro and Ender 3 V2 were released, and like the first generation Ender, they were a hit. Despite their popularity, one issue that persists across the Ender 3s is the tendency for the extruder to skip, producing a distinctive clicking noise.

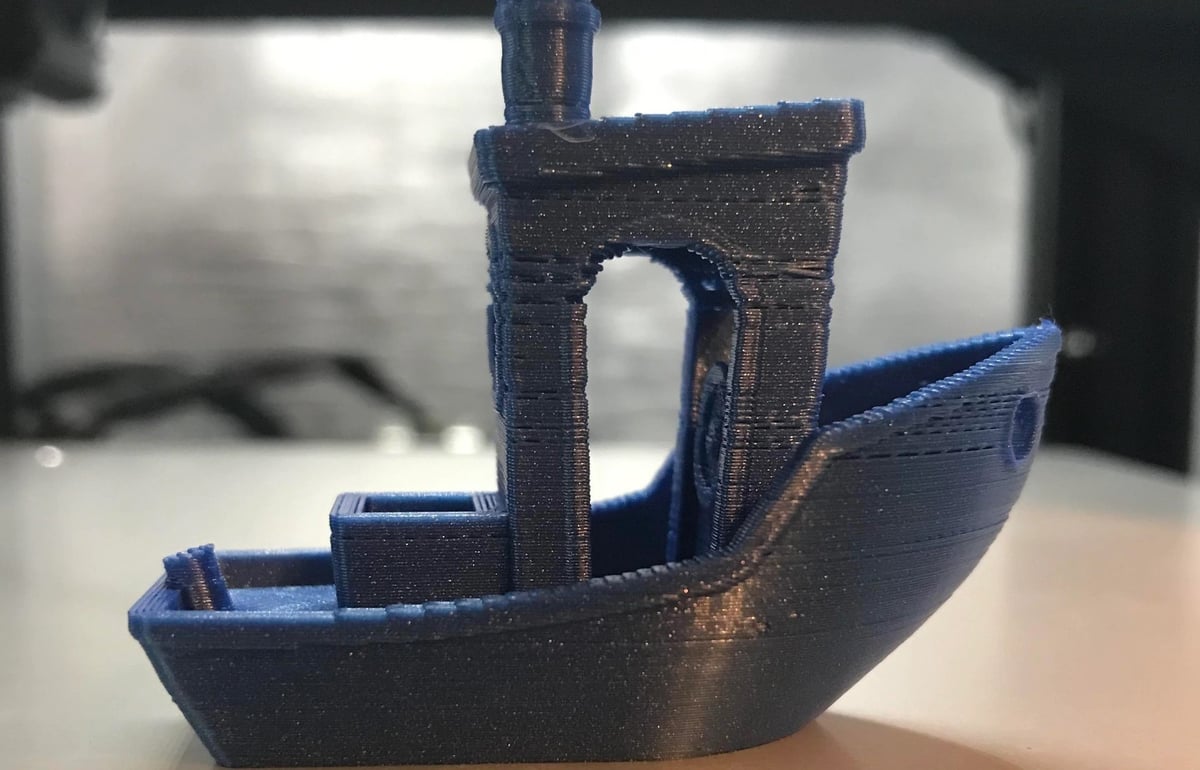

Skipping occurs when the extruder’s stepper motor is, for whatever reason, unable to turn the gear that advances the filament. It then skips back on itself, relieving pressure. This problem, and its underlying issues, can lead to severe 3D printing defects, such as under extrusion.

In this article, we’ll go over a number of solutions you can try to help fix an Ender 3’s skipping extruder. To begin, we’ll cover basic printer setup and maintenance tasks that should be done regularly on all three machines. Later, we’ll move on to special solutions that can be employed when all other issues can be ruled out.

We’ll note when special considerations should be taken, given that the three printers aren’t identical.

Now, onto the solutions!

Tip #1: Level the Bed

Before doing any printing, one should always make sure the bed is level because an unlevel bed can lead to many issues, including extruder skipping. The Ender 3 comes with a bed that needs to be leveled manually. Apart from ensuring the correct tilt, this process also sets the correct gap for the filament to flow between the nozzle and all points of the print surface.

If the gap is too small, the filament won’t flow properly, causing a buildup of pressure in the system. Once the pressure exceeds the stepper motor’s limit, it’ll start slipping, leading to the clicking noise. So, before you begin a 3D print, you should manually level the bed using the card trick or by using feeler gauges.

Another thing to look out for is the Ender 3’s bed springs. These springs are cheaply made and might lose their tension over time. Consider upgrading your springs to the yellow compression-molded spring, which results in a much more stable bed during long prints.

Tip #2: Clean the Nozzle

On any FDM printer, it’s normal that the nozzle gets a little dirty from time to time. Normally, this is caused by the gradual buildup of molten filament residue and particles from the surrounding environment. Regardless, if not cleaned up, it can result in a number of problems.

The filament exits the entire extrusion system through the small orifice in the nozzle. For that reason, it’s possible that even a small piece of debris can easily clog the nozzle. A clogged nozzle won’t let the filament flow through, and the resulting buildup of pressure can affect the extruder.

The easiest way to fix this is to simply clean the nozzle using the appropriate needle, one of which comes with the Ender 3. It should clear the orifice enough to let filament flow evenly. Another method to try is a cold or “atomic” pull, which involves yanking partially cooled filament (along with the unwanted debris) out through the top of the hot end.

If the issue persists, you should replace the nozzle entirely. Stock brass 3D printer nozzles are cheap, and replacing them can be an easy solution.

Tip #3: Print Slowly

Print speed can be a major factor contributing to an Ender 3’s clicking extruder. Printing at too high a speed may not give the filament enough time to absorb heat and melt properly. This can lead to improper flow of the filament and perhaps even jamming of the hot end. Because there’s nowhere else for the filament to go, it exerts back pressure, possibly leading to a clicking extruder.

An easy fix is to print at lower speeds. In fact, printing slower is a general remedy to many printing issues. A lower speed ensures that the filament has enough time to melt properly, leading to a good and improved filament flow. You may also notice that printing at lower speeds leads to an overall improvement in print quality.

Tip #4: Check the Temperature

Just as a higher print speed may lead to a partially clogged hot end, a low printing temperature can jam it. In order for the filament to melt and flow properly, you need to heat it the right amount before it exits through the nozzle. If you feel that the temperature is low, try increasing it incrementally, by 5 °C, until you see better results.

Additionally, the heater cartridge on any of the Ender 3s is held in place with only a single small set screw. If this screw loosens, it may cause the heater cartridge to lose contact with the heater block, which will result in insufficient heating of the filament. To address this, check that the heater cartridge is not loose.

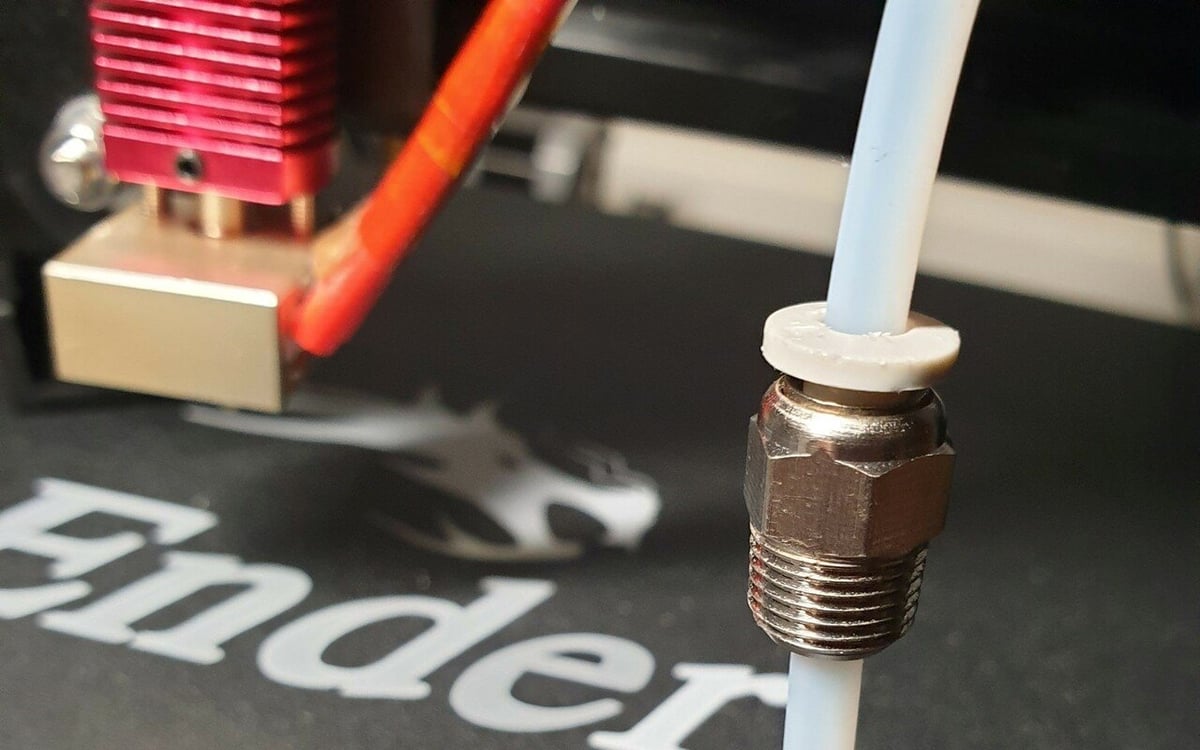

Tip #5: Check the Bowden Setup

The Ender 3s’ Bowden style setup has PTFE coupling at both ends: one at the extruder and one at the hot end itself. If either of the couplings fails, it can cause the PTFE tube to slide at the ends. If the PTFE tube in the hot end slides, it could cause a gap between the tube and the nozzle.

In this case, the molten filament can fill this gap and disrupt material flow. This, too, can generate pressure in the system, possibly resulting in the extruder’s clicking. As such, be on the lookout for any loose couplings and replace them when necessary.

Tighter tolerances and any dirt or debris in the PTFE tube itself might also increase the friction between the tube and the filament. If this friction exceeds the stepper motor limit, it will cause it to slip. Clean the tube regularly and also check its resistance by pushing the filament through manually. If nothing works, replacing the tube entirely is a good (and cheap) idea.

Makers on printing forums and other similar platforms often recommend Capricorn’s PTFE tubes and couplings.

Tip #6: Replace the Extruder

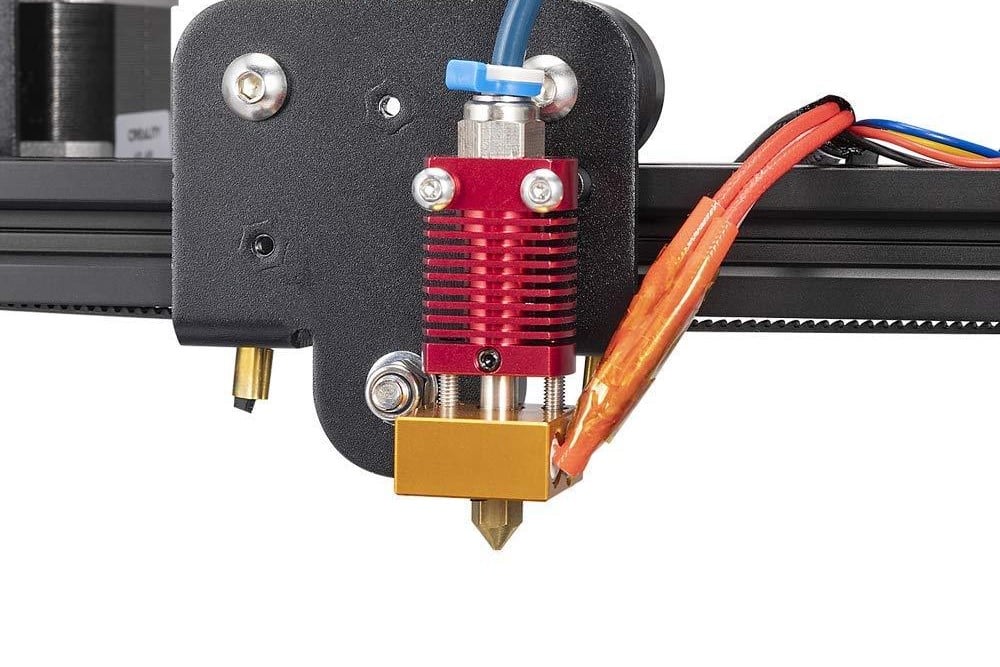

Extruder Gears

With any of the Ender 3s, the extruder employs a single gear and pulley system. The gear is made of brass, which is a relatively soft material, and after long hours of 3D printing, the gear’s teeth are sure to wear. This results in filament grinding, a separate but equally annoying extruder issue where the gear turns but the filament isn’t pushed forward. Instead, the gear just wears down the filament.

Brass also restricts the ability to print harder materials. For more consistent and long-term performance, you should consider a steel gear extruder. Creality’s CR-10 has a metal dual gear extruder setup that’s among the best extruder setups that you can get for your Ender 3. It provides a far better grip and is less likely to fail.

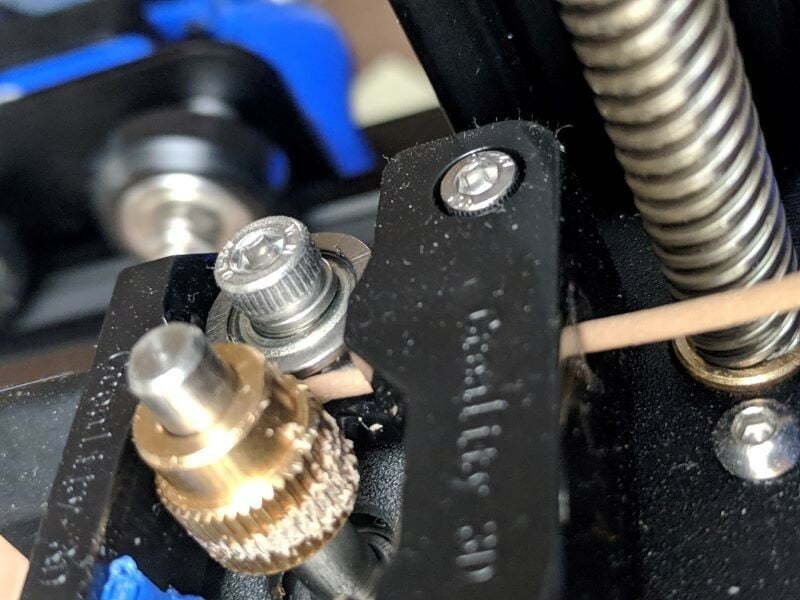

Extruder Arm & Spring

The plastic extruder arm on all the Ender 3s is one of their most significant flaws. The arm is subjected to continuous forces, and the plastic material tends to not hold up for long. The arm eventually develops cracks or breaks away completely, leading to a loss of pressure needed to grip the filament.

If the arm isn’t to blame, it could be the spring that applies the arm’s pressure. A loss of tension – after many hours of use – will lead to a loss of grip on the filament. This again leads to filament grinding. On the other hand, if the spring tension is too high, you could have the same clicking problem.

There are quick fixes to extruder arm or spring spacer issues available on Thingiverse. However, for a more reliable and permanent solution, replacing the Ender 3’s extruder with a metal one is always better.

Tip #7: Check the Stepper Drivers

The Ender 3s come with NEMA 17 stepper motors that run with A4988 or TMC 2208 stepper motor drivers. Neither the stepper motors nor the drivers are actively cooled. So, during long continuous hours of 3D printing, the drivers can heat and send erratic signals to the stepper motors. This issue is clearly noticeable with the Ender 3 V2, in which faulty stepper motor drivers lead to extruder clicking, which eventually results in layer shifting issues.

Most of the time, the stepper drivers are at fault, especially if they are faulty or not tuned correctly. However, if you’ve tried all the other fixes and the extruder is still clicking, you might want to try upgrading your Ender 3’s motherboard to a newer version and then swapping out the stepper motor itself.

It’s important to note that, depending on when and where you bought your printer, you may have a different mainboard. For example, the V2’s 32-bit V4.2.2 is silent, whereas the 3’s and Pro’s aren’t, and the mainboard in Korea is V4.3.1 – which is silent for the v2, but not the 3 and Pro. So, depending on the 3D printer you’ve got and what mainboard it was shipped with, you’ll need to be on the lookout for specific considerations.

License: The text of "Ender 3 (V2/Pro) Extruder Skipping: 7 Tips to Fix It" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.