Goddess-like Extrusion

E3D is a company that makes premium, high-quality hot ends, extruders, nozzles, and other 3D printing accessories, having had particular success with their V6 hot end and Titan extruder. Many of their available components are compatible with a wide range of printers and some stock 3D printers have included E3D components, like the Prusa i3 MK3S+ with its E3D nozzle and heat break.

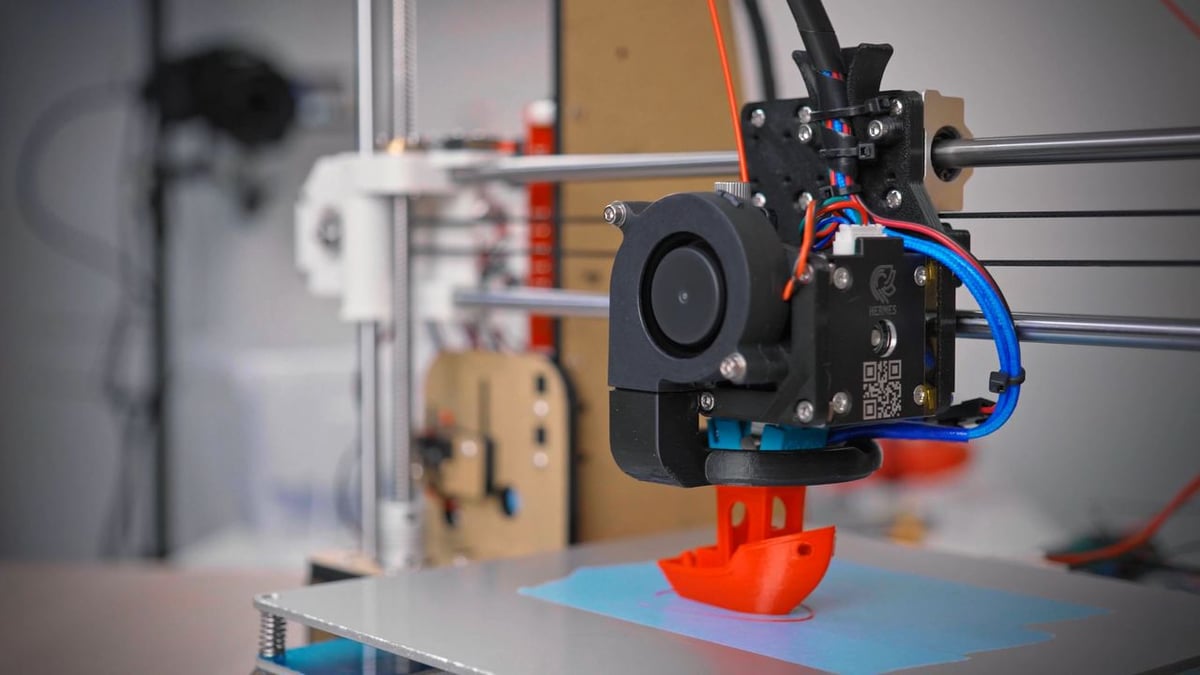

One of E3D’s latest innovations is the new and revised E3D Hemera extruder, originally known as the E3D Hermes (the name was changed due to licensing issues). Hemera is the goddess of daytime in Greek mythology, so hopefully, with the Hemera, you can keep your machine printing all day long.

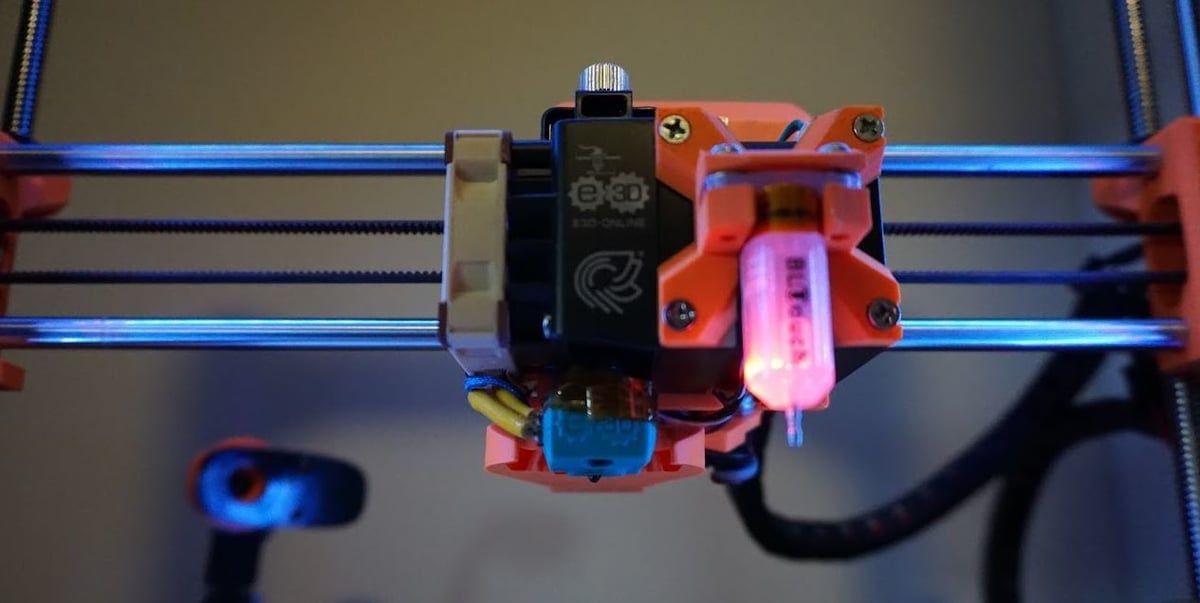

The E3D Hemera is a dual-drive extruder compatible with many E3D hot ends or the E3D Bowden coupler attachment, also known as the “Bowdapter”. The extruder comes with the V6 hot end, but as we said, you can attach other hot ends like the E3D Volcano or SuperVolcano. However, the Hemera’s main feature isn’t its compatibility, but rather its dual-drive setup, along with the special motor that allows for such a compact assembly.

In this article, we’ll go over the E3D Hemera and outline its unique features. Because the extruder is comparable to the E3D Titan Aero, we’ll then compare the two to further display the strengths of the Hemera.

Features

The E3D Hemera has many features, in spite of its small size. Many of its features aren’t unique, like its extruder tensioner knob or attached fan, but still, they contribute to the extruder’s worth. Below, we’ll go over some of the more notable features of the Hemera.

Included V6 Hot End

When you buy the E3D Hemera from E3D Online, it comes with a few different parts that some resellers may not include. Besides the extruder, another significant part is the genuine V6 hot end; well, the heating block of the V6 at least. Like with the Titan Aero, the Hemera has its own special heat sink, so the E3D V6’s heat sink isn’t necessary.

The E3D V6 hot end can reach temperatures up to 285 °C, so you can print almost any consumer 3D printing materials, from the standard options of PLA and PETG, to more challenging filaments like ABS, nylon, PC, PMMA, and so many more. Furthermore, the V6 heater block and throat included with the Hemera are all-metal and don’t have a PTFE liner, which would limit the temperature range to prevent it from burning.

The Hemera includes the V6’s high-power heater cartridge and a highly-resistant thermistor (temperature sensor), as well as a standard E3D brass nozzle and silicone sock.

Dual-Drive Extruder

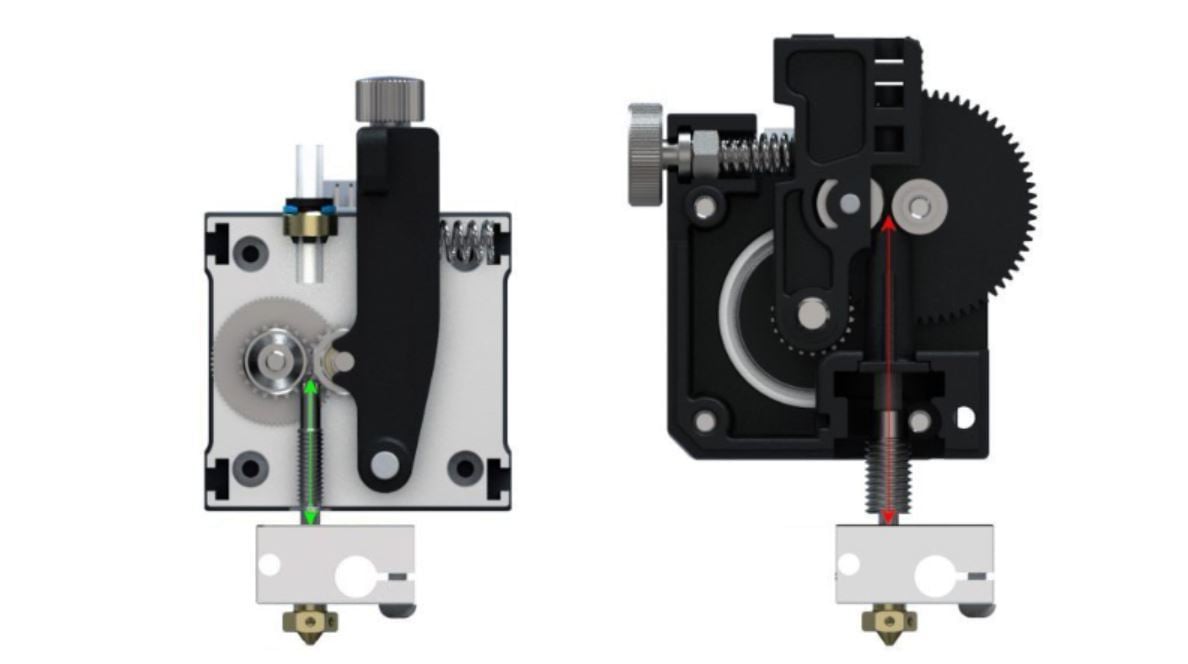

One of the most notable features of the E3D Hemera is its dual-drive extruder. Dual-drive extrusion involves a motor with one spinning axis moving two teethed extruder gears that essentially “hug” the filament from both sides. This provides additional torque and power in the extrusion of filament and the Hemera has 10 kg of pushing force; in other words, it’s super powerful. Dual-drive is also very useful for printing flexible filaments, and E3D claims in their Hemera feature video that with the dual-drive system, you can print flexibles at nearly the same speed as PLA (50 mm/s for TPU).

As we’ve mentioned, the E3D Hemera can serve in both a Bowden or direct drive setup. A Bowden setup is where the extruder and hot end are separated by a PTFE (Bowden) tube, and while this reduces ringing, it can increase the likelihood of extrusion issues. A direct-drive setup is where the extruder is positioned directly over the hot end and does the opposite of a Bowden system (increases ringing and decreases extrusion errors), but is more suited to printing flexible filaments.

The extruder functions on a special E3D Hemera-specific motor with a current rated 1.33 A and a 1.8° step angle. Overall, the Hemera’s dual-drive setup and direct-drive capabilities make it an excellent choice for printing flexible filaments.

Optimized Heat Sink

Another distinguishing aspect of the E3D Hemera is its specially-designed heat sink, which provides excellent hot end cooling. E3D points out in their feature video that many hot end cooling fans (which are different from part cooling fans) provide uncontrolled and unintentional cooling to parts. Any uncontrolled cooling could cause warping, especially with temperature-sensitive materials like ABS.

The E3D Hemera’s heat sink is positioned so that a hot end cooling fan is above it. The fan pushes air to the heat sink, and the heat sink’s special design guides airflow above the assembly rather than downwards to the print. However, this airflow movement won’t prevent the hot end from receiving proper cooling to prevent any unwanted melting, which might cause heat creep jams.

Compact Assembly, Compatibility, and More

The E3D Hemera uses a specially-designed, Hemera-specific stepper motor with a custom motor faceplate. The faceplate connects the stepper motor with the other components on the assembly and allows the Hemera to be as small as possible. While this may mean having a fiddly design, it does reduce the amount of space you lose on your print bed due to the extruder’s footprint.

The assembly is also very compatible; however, some components, like standard NEMA 17 stepper motors, won’t fit on the Hemera. The assembly has a few extruder T-slot endcaps along the side, which are meant to make mounting this extruder to your printer, or adding other attachments like a BLTouch sensor, a breeze. For these reasons, the Hemera works on a large array of printers like the Creality Ender 3, Anet A8, Prusa i3 MK3, LulzBot TAZ 6, and more.

The Hemera also has other, smaller features worth mentioning. These include the adjustable extruder tension knob, high-quality CNC mounting plates, revised material selection to cut down on weight, and more. You can check out the E3D Hemera product page to learn more.

Hemera vs. Titan Aero

As we’ve mentioned, the E3D Hemera is comparable to another of E3D’s offerings, the Titan Aero. The Titan Aero contains a specially-mounted E3D Titan extruder placed over an E3D V6 hot end and heat break throat, like the Hemera has.

The two extruder and hot end combinations are similar in that they both can be used for a direct-drive system and are great for printing flexibles. However, the Hemera is more adaptable and can be used in a Bowden setup, where the Titan Aero cannot. While the Titan Aero, as an only-direct-drive extruder, may be suited for printing flexible filaments, the Hemera is even better because of its dual-drive extruder mechanism.

Both setups incorporate a V6 all-metal hot end and have mounting screws and other pro-compatibility aspects. Unfortunately, the Hemera only functions with the stock E3D motor, while the Titan Aero can work with a variety of NEMA 17 stepper motors (pancake and standard). The Hemera does have the advantage of T-slot mounting screws on the side, which the Titan Aero doesn’t have.

Additionally, the Titan Aero has a CNC-machined heat sink with a fairly standard shape (horizontal lines), while the Hemera has a specially-designed one for improved cooling, made in a lighter material to reduce ringing. Another obvious difference between the two extruders is that the Hemera’s extruder tension knob is pointing up, while the Titan Aero’s is pointing to the side. Lastly, as seen in the image above, the Hemera takes up a lot less space than the Titan Aero, which might be helpful in conserving print space.

All in all, the E3D Hemera is a great option for an extruder and you can tell (not just by the major production delays) that E3D spent a lot of time designing this extruder to be one to remember. The versatility of the Hemera, its compact assembly, flexible printing capabilities, and optimized heat sink all contribute to this extruder’s shine.

Lead image source: calitri-san via Reddit

License: The text of "E3D Hemera: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.