If you’re looking to 3D printing a part to fix your plumbing or create a water feature, why not 3D print in the same material that typical plastic pipes are make from: PVC.

This plastic has been used for household plumbing since the 1950s as an alternative to traditional materials like iron and copper. The advantages of PVC pipes include their light weight, durability, resistance to corrosion, and low cost. Today, PVC is the standard material for water supply and drainage systems in residential, commercial, and industrial buildings.

PCV or polyvinyl chloride (also called Vinyl) is a versatile material with a range of applications, including vinyl records (remember those?), vinyl flooring and siding, and synthetic fabrics. And you can 3D print with it as long as you take the safety precautions seriously.

Features & Advantages of PVC

PVC has a relatively unique combination of features making it particularly useful in certain applications, such as plumbing and outdoor projects involving water (rain) and UV light (sun).

PVC Characteristics

- Flame retardant

- Chemical resistance (to oils, salt solutions and water)

- High impact resistance

- Good mechanical properties (functionality, toughness, rigidity)

- Suitability for use in electrical devices

- Flame retardant and resistant

- Low moisture absorption

The technical specifications of PVC are also impressive.

- Tensile strength: 45 – 55 MPa

- Tensile modulus: 2000 – 4000 MPa

- Tensile elongation: 13%

- Flexural strength: 60 – 80 MPa

- Flexural modulus: 1500 – 3000 MPa

- HDT (0.45 MPa): 60 – 80°C

- HDT (1.8 MPa): 50 – 70°C

Materials for 3D Printing PVC

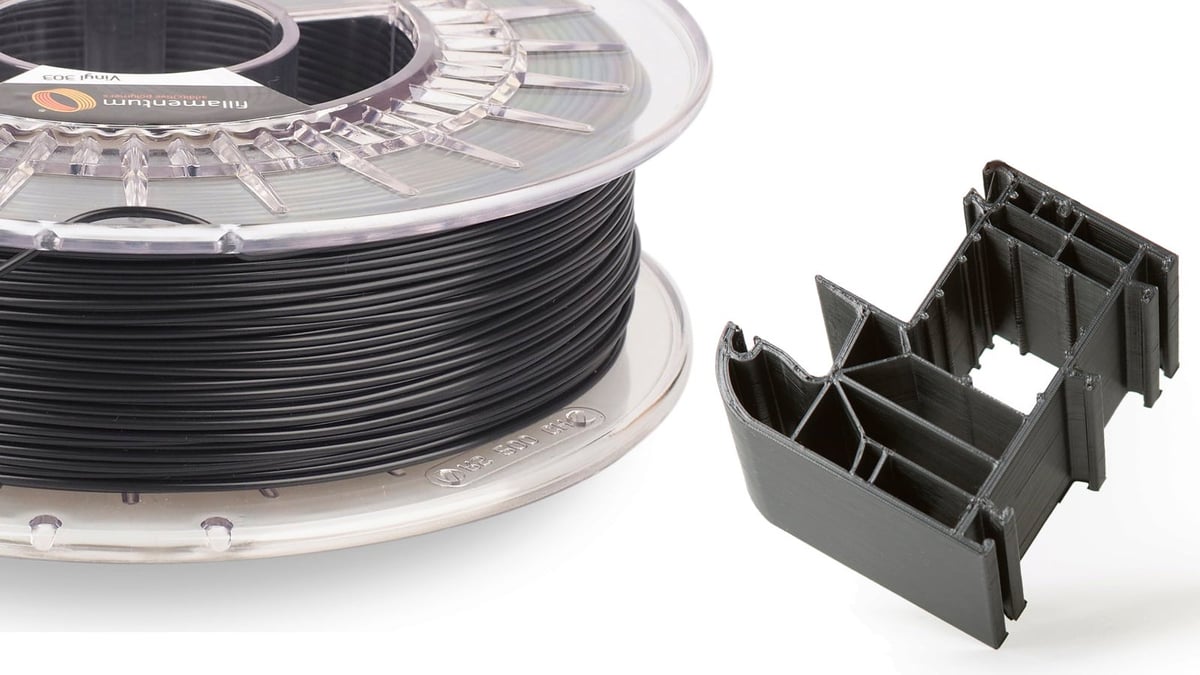

Despite the benefits it produces in final 3D printed parts, you’ll typically find only one PVC brand of filament on the market today: Fillamentum’s Vinyl 303. Why? Emissions.

All plastic filaments for 3D printing have emissions but some are more concerning than others. One of the primary problems associated with PVC production is the release of chlorine gas. When you 3D printing with PVC, there is less chlorine emissions then when the material is first produced but it should always be used with an enclosed 3D printer is a well ventilated environment. If vapors are accidentally inhaled, move to fresh air, or if necessary, apply artificial respiration or oxygen. If you feel unwell, seek medical advice.

Fillamentum, in the 9-page safety sheet that accompanies your Vinyl 303 purchase says:

- Vinyl has acute toxicity to skin and if ingested.

- Do not use in lighting fixtures

- Ensure good ventilation of the work place. If ventilation is insufficient, use self-contained breathing apparatus.

- Vinyl may cause damage to organs through prolonged or repeated exposure

- pregnant women should stay away when Vinyl 303 is processed

A HEPA filter on your enclosed 3D printer is not enough to protect you from PVC’s fumes. Activated carbon or similar gas filtration is required to mitigate the chlorine gas.

It’s also a good idea to wear a mask and protective gloves when working with PVC, wear a type of lab coat that you take off and wash after you’re done printing, and wash exposed skin with soap after printing.

Because 3D printing with PVC is rare you won’t find print provides for this material, which will likely lead to some initial failed prints before you get the setting dialed in just right. The only guidance on printing with the material from the maker are these:

- Nozzle Temp: 215 – 230°C

- Bed Temp: 80°C

- Only use a brass nozzle

- Speed: 40–60 mm/s

- Part cooling fan: 0– 50 %

- Heated bed surface: PEI plate, mirror /glass

- Adhesive: Magigoo, PVA based glue

- Brim 10 mm/ raft

- Enclosure: recommended

- Printing bridges could be challenging, therefore, we recommend using supports as it really helps and avoids print fails.

- Stronger parts can be achieved by using temperature around 230°C and part cooling fan off, where layers adhere more.

- Printing very small features is hard. It is recommended to avoid it in the models, because printing small detail can cause clogging due to small flow off material.

Sustainability & Alternatives

PVC isn’t a commonly used material in 3D printing due to its toxic emissions and the fact that it will corrode stainless steel nozzles (always use brass). There are safer materials to use no matter what application you have in mind.

In fact, when considering the environmental impact of PVC, it’s essential to evaluate the entire life cycle, including raw material extraction, production, use, and end-of-life disposal. PVC can be recycled, and recycling efforts help mitigate some of the environmental concerns associated with its production and disposal, but the disposal of vinyl products has raises concerns about environmental impact. As a result, there have been efforts to find more environmentally friendly alternatives..

Several alternative plastics are commonly used in place of PVC for various applications, especially when environmental concerns or specific material properties are priorities. Here are some alternatives:

- HDPE (high-density polyethylene) is a common PVC alternative for outdoor uses and water pipes due to its durability and resistance to corrosion. It can withstand exposure to harsh weather conditions, making it suitable for outdoor applications. HDPE is a flexible material, which can be advantageous in situations where some flexibility is required, such as in water pipes that need to accommodate ground movement. This plastic is also lighter than PVC, which can simplify handling and installation.

- PP (polypropylene) is a versatile plastic used in a range of applications, including packaging, textiles, and automotive components. It is known for its high melting point and resistance to chemicals.

- PC (polycarbonate) is a transparent and durable plastic known for its impact resistance and optical clarity. It’s commonly used to 3D print lighting fixtures.

- PETG (polyethylene terephthalate glycol) is commonly used for high-strength applications and has relative flexibility and temperature resistance.

- Thermoplastic Elastomers (TPE) combines the characteristics of rubber and thermoplastics. It’s used in applications where flexibility and elasticity are required, such as in automotive components and medical devices.

Final Thoughts

Evidently, printing PVC is possible, but so far it seems there hasn’t been enough development to make it widely available. This could be because PVC products can be bought at very competitive prices, and so the time, filament, and electricity that would be needed for printing with it may not be worth it for now.

It could also be that the safety standards required for this material are almost unattainable when using ordinary hobbyist printers – toxic fumes being one of the biggest hazards. Plus, for most projects there are plenty of alternatives.

For now, it’s clear that more work still needs to go into modifying 3D printing technology with PVC to make it easily printable and ready for commercialization.

Lead image source: Fillimentum Vinyl 303 natural filament and a part designed by Ivo (Source: Fillamentum)

License: The text of "3D Printing with Vinyl / PVC Filament: All You Need to Know" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.