Hot ends are crucial for successful FDM 3D printing, and British manufacturer E3D is a beloved name in the game. Having their models shipped with printers from brands like Prusa and Ultimaker, their designs are among the most widespread.

At the core of their lineup is the concept of the V6 ecosystem: A mix of standardized dimensions and recurring features allow some parts to be swapped and reused across different models. Not only does this simplify the maintenance process, but it also saves the end user money and the stress of looking for compatible parts.

The vast number of compatible third-party products means you’re not locked up in a proprietary bubble. You can oftentimes mix-match an original E3D nozzle with a compatible heatblock and heat break.

And since there’s no “hot end to rule them all”, having a pool of options and alternatives to choose from helps unlock new possibilities and reach higher printing peaks. In this article, we’ve compiled a list of our favorite E3D hot ends as well as other alternatives. Each pick is labeled so you’ll know exactly what you’re looking at, and we also explain why we recommend it.

Considerations

While E3D’s lineup might not appear confusing, the alternatives present on the market surely are. When researching for this list, we set a few rules:

- V6 compatible: The hot end must be at least partially compatible with the original ecosystem, either by sharing nozzle dimensions, mounting hardware, or other specs.

- Product life: Since the hot end runs on consumables (i.e. nozzles) and might require spare parts, it must be actively supported by the manufacturer. End-of-life models are therefore omitted.

- Not a clone: Assessing the quality of a cloned, off-brand model isn’t straightforward. Oftentimes, the considerations can’t even be extended to the other units of the same batch due to poor quality control. Therefore, we’ll not include them in the list.

Alternatives vs. Clones

Because E3D is an open-source hardware manufacturer, they’ve also inspired dozens of imitators. Alternatives are hot ends that are made for the same type of usage as E3D hot ends but aren’t constructed from the same design. They may not necessarily be less expensive, but they offer different features that might suit your use case better.

Clones are exact replicas of E3D’s designs made and sold by other brands, often at lower price points. Of course, the overall quality might be subjected to changes and oscillate between indistinguishable from the original and cheap knock-off. We don’t recommend going for anything other than the original.

In this article, we’ll present a few alternatives to E3D hot ends, but as we said above, clones will be excluded.

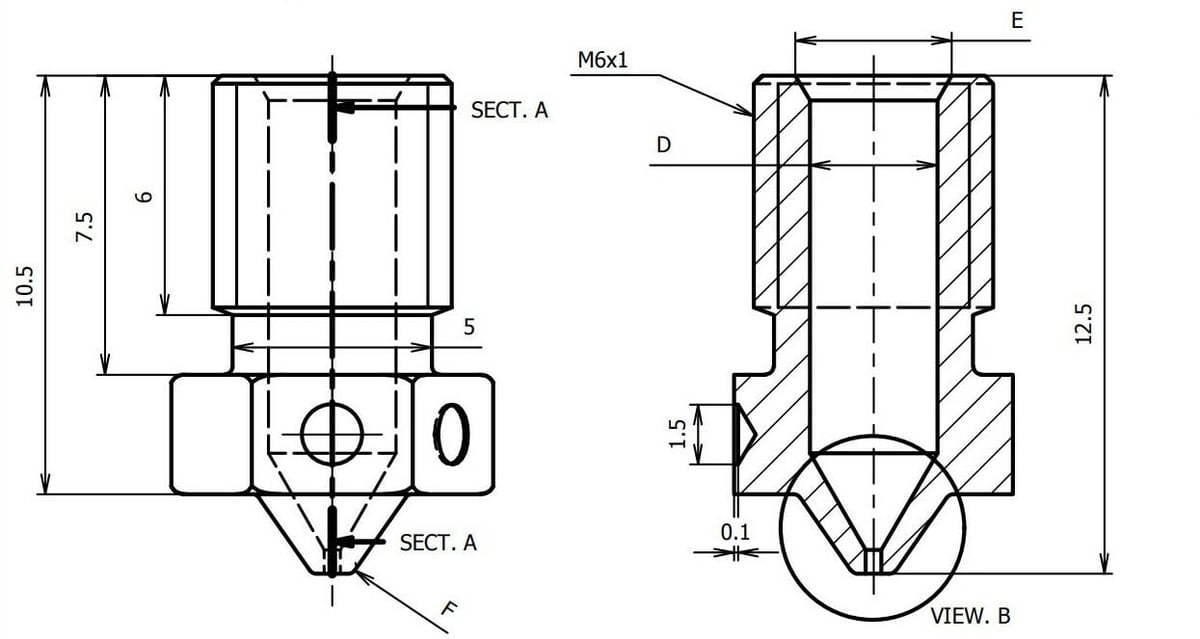

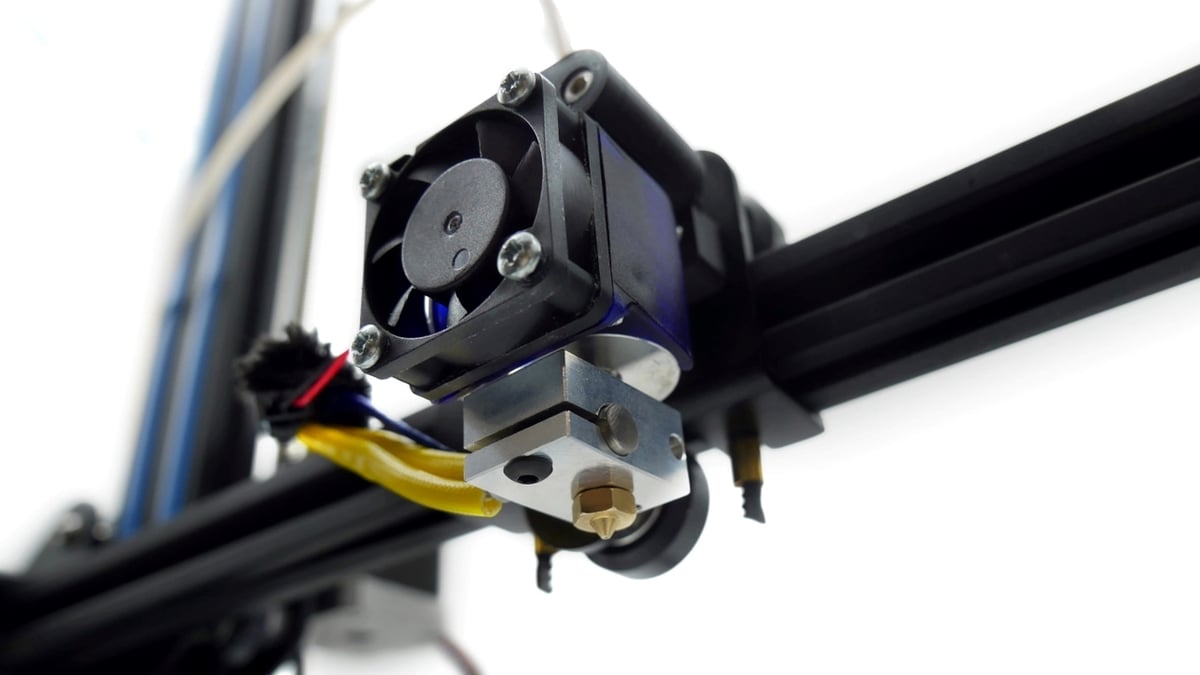

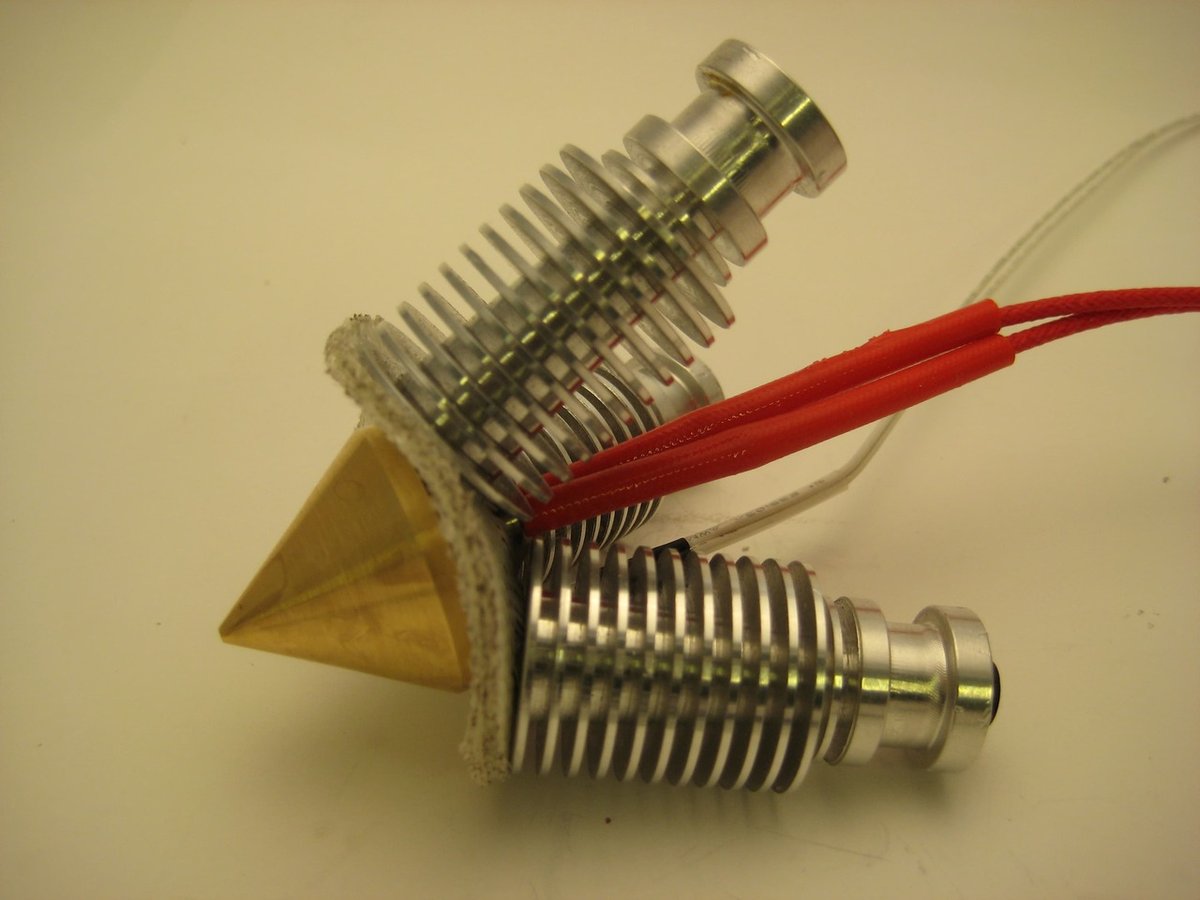

E3D V6

The E3D V6 hot end is probably one of the most recognizable models in the 3D printing community. It’s an upgrade you can add to almost any FDM 3D printer for higher heat resistance, thermal dissipation, and all-metal capabilities. The wide range of options for nozzles, heating cartridges, temperature sensors, as well as heat breaks and blocks, makes upgrading extremely easy.

On the downside, it hasn’t aged well. 3D printing in 2014 (the year it was launched) was quite different from what we’re experiencing now. High-flow hot ends were virtually non-existent because printing speeds were still extremely conservative. Further, nozzle sizes didn’t vary as much as they do nowadays.

In today’s world, the V6’s circa 15 mm3/s volumetric throughput might not be sufficient. For instance, printing 0.2-mm layers with a 0.4-mm nozzle will limit you to a print speed of 185 mm/s.

Of course, the flow rate is affected by many other factors such as material, temperatures, flow multiplier, nozzle geometry, extruder capabilities, and so on. The 15 mm3/s is more of a reference than a strict limit.

- Classification: Original E3D product

- Printing temperature: Up to 485 °C (without the silicon sock, with an E3D PT100 sensor and appropriate nozzle)

- Filament size: 1.75 mm, 3.0 mm

- Price: ⁓$55

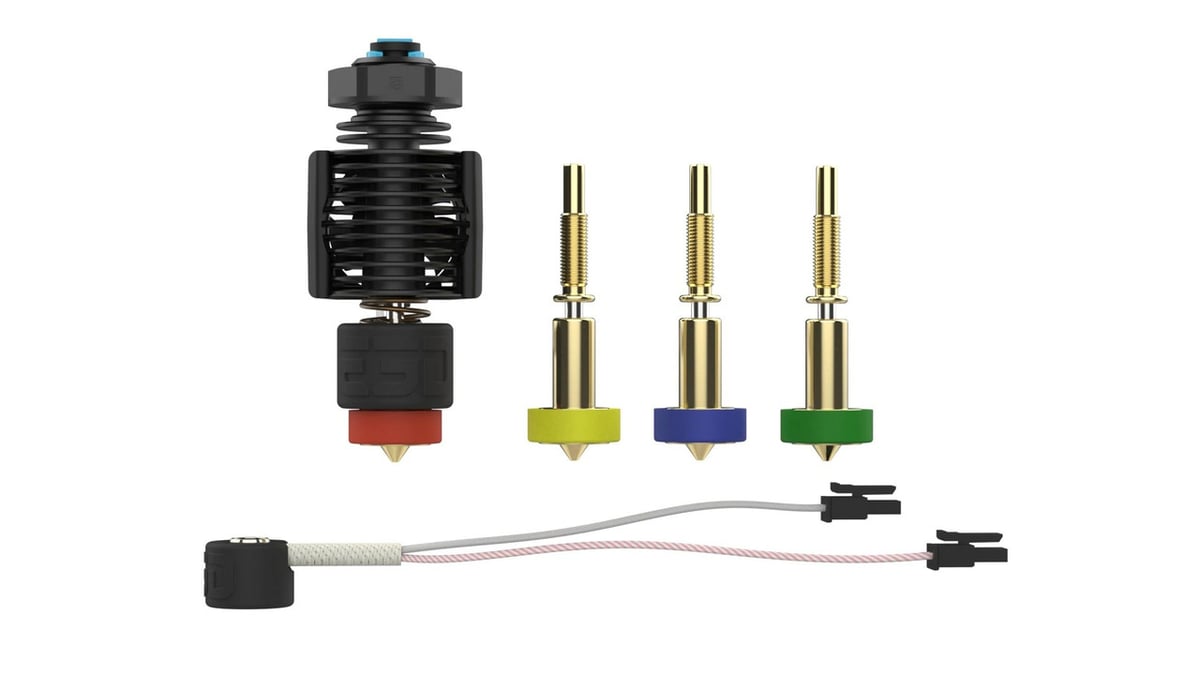

E3D Revo Six

Built directly on the V6 ecosystem, the Revo Six is the latest addition to E3D’s lineup. It fuses the heat break and nozzle in a single screw-in block that can be easily removed. This allegedly reduces the chances of the filament clogging the nozzle or leaking from the assembly.

The thermistor and heating elements are also built-in in a single cylindrical block. The clear advantage here is the ease of repair and the rapid nozzle change feature.

Compared to the V6, the Revo Six is less of an open design. There’s only one type of nozzle that fits it, and the mix-match options available with the V6 are not here yet. As the nozzle and heat break are one single part, you’ll need to buy two different assemblies if you want two different combinations

- Classification: Original E3D product

- Printing temperature range: Up to 300 °C

- Filament size: 1.75 mm

- Price: ⁓$90

Mosquito

Slice Engineering created the Mosquito as a solution to a few typical but frustrating issues they kept finding in high-heat 3D printing processes. It rivals E3D’s V6 in performance and surpasses it in ruggedness, withstanding temperature heights that easily warp lesser hot ends.

Slice outfits the Mosquito with copper instead of the typical aluminum used in hot ends, and that makes a big difference. This will ultimately decrease the risk of heat creep and will allow for a more uniform thermal conduction. The bi-metal heat break stops heat surges and effectively separates the hot zone from the cold zone. Nozzle changes are also easier to perform, even one-handed.

It does come with a higher price tag, though. If you haven’t found a hot end that can hold up to your imagination, the Mosquito may be exactly what you need.

- Classification: Alternative

- Printing temperature range: Up to 500 °C

- Filament size: 1.75 mm

- Price: ⁓$145

Dragonfly BMO

The Dragonfly BMO by Phaetus is a V6-compatible all-metal hot end with true high-temperatures capabilities and an improved cooling design. It’s a direct replacement for the V6, meaning that the old thermistor, heating cartridge, and nozzle can be reused.

Capable of printing upwards of 500 °C, the Dragonfly can withstand literally every filament, even PEEK and Ultem. The very low inner roughness of the heat break allows for a smooth flow without additional drag.

Disassembly might be a bit tricky due to the additional screws, but nozzle changes remain pretty much unchanged.

- Classification: Alternative

- Printing temperature range: Up to 500 °C

- Filament size: 1.75 mm

- Price: ⁓$70

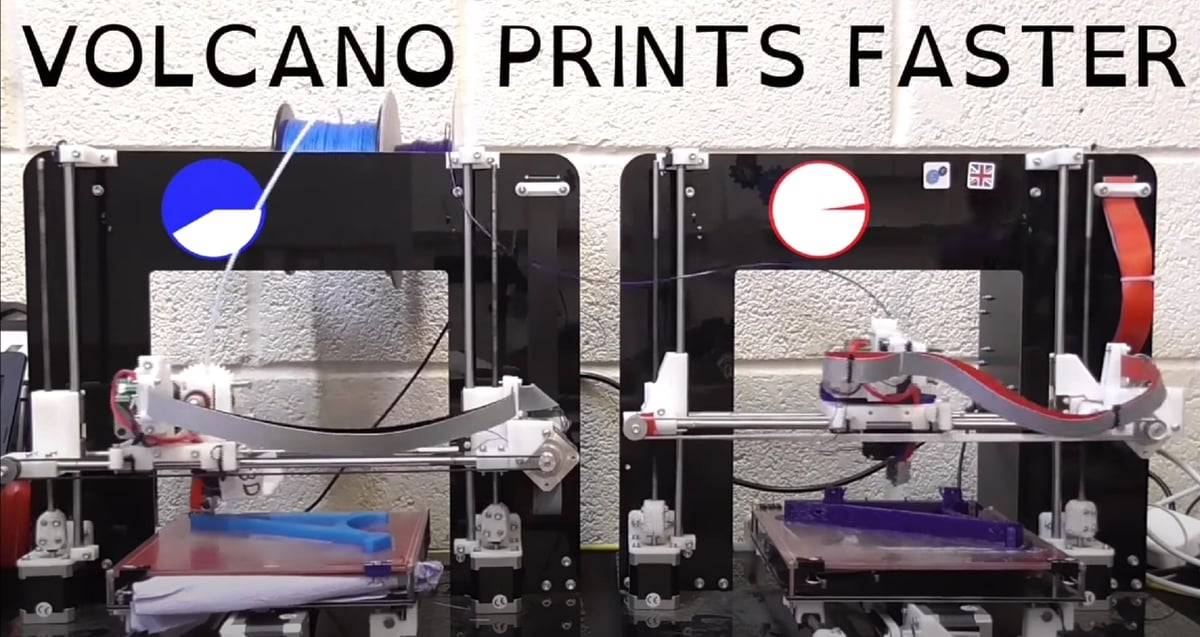

E3D Volcano

For those chasing ever faster speeds, the E3D Volcano is a V6-compatible drop-in replacement that triples the volumetric throughput. Since the flow rate is a function of how fast the hot end can melt the filament (among other factors), this clever design solves this issue.

Instead of using a different heating element, the Volcano features a longer block where the cartridge is inserted vertically, effectively increasing the melt zone length. This allows the filament to start melting earlier in the path and get to the nozzle already melted, even at higher feed rates.

The great advantage is that the heating cartridge and temperature sensor remain the same as the V6. You’ll only need a new Volcano block and nozzle, with the latter coming in a range of nozzle sizes from 0.6 to 1.2 mm.

It’s important to keep in mind, however, that the retraction performance is decreased due to the longer melt zone. This makes the Volcano more prone to stringing and oozing. The longer nozzle will also limit your max Z-axis dimension. On top of that, the stock part cooling fan ducts will no longer blow air on the nozzle tip and will need a replacement.

- Classification: Original E3D product

- Printing temperature range: Up to 285 °C (without the silicon sock, with an E3D thermistor fitted)

- Filament size: 1.75 mm, 2.85 mm

- Price: ⁓$60

E3D SuperVolcano

The SuperVolcano pumps the flow rate of the V6 by an incredible factor of 11. Going from 15 to 110 mm3/s, the hot end needs a total redesign. The comically long heat zone is brought up to temperature by an 80-W, 47.5-mm long heating cartridge. The nozzle is 51.5 mm long from tip to top and comes in sizes of 0.8, 1.0, 1.2, and 1.4 mm. This means that it can print with a 1-mm layer height and a 1.2-mm nozzle at an incredible 85 mm/s.

With great power comes great responsibility too! That’s why the stock heatblock is made out of a plated copper alloy. The high thermal capacity allows the block to sustain the intense load of the heater without melting. This means, of course, that the block itself will take longer to cool down.

While it remains fully compatible with the V6 heatsink and heat breaks, the radical changes come with some drawbacks. The 80-W heater consumes double the current of the standard 30-W and 40-W cartridges. If the total power consumption of the printer exceeds the rated wattage of the power supply, a more powerful unit is needed. For 12-V systems, a dedicated MOSFET is also recommended, as the control board’s extruder connector isn’t designed to handle 6+A. Fortunately, one is included in the 12V model.

Just like the Volcano, a longer fan duct is a must. Due to the high volumetric throughput, stock fans might not provide sufficient cooling. The 3D Print General has a great video on how to set it up correctly.

- Classification: Original E3D product

- Printing temperature range: Up to 485 °C (without the silicon sock, with an E3D PT100 sensor and appropriate nozzle)

- Filament size: 1.75 mm, 2.85 mm

- Price: ⁓$100

Rapido

Phaetus’ Rapido hot end is ideal for high-flow applications. It comes in two variations: the High Flow (HF) and Ultra High Flow (UHF). The UHF model features a longer heat core, as well as the support for Volcano nozzles.

It’s really similar to the Revo Six in terms of aims and capabilities but doesn’t adopt the nozzle-heat break combo approach. Instead, it supports the V6 and Volcano nozzles with adapters available to mix-match them across the two models.

Like the Revo Six, the heating element embraces the nozzle with a ceramic core, allowing for more uniform heating. The thin heat break is designed to avoid heat creep and prevent heat surges. Phaetus claims a volumetric throughput of 45.82 mm³/s.

- Classification: Alternative

- Printing temperature range: Up to 280 °C

- Filament size: 1.75 mm

- Price: ⁓$110 (HF), ⁓$120 (UHF)

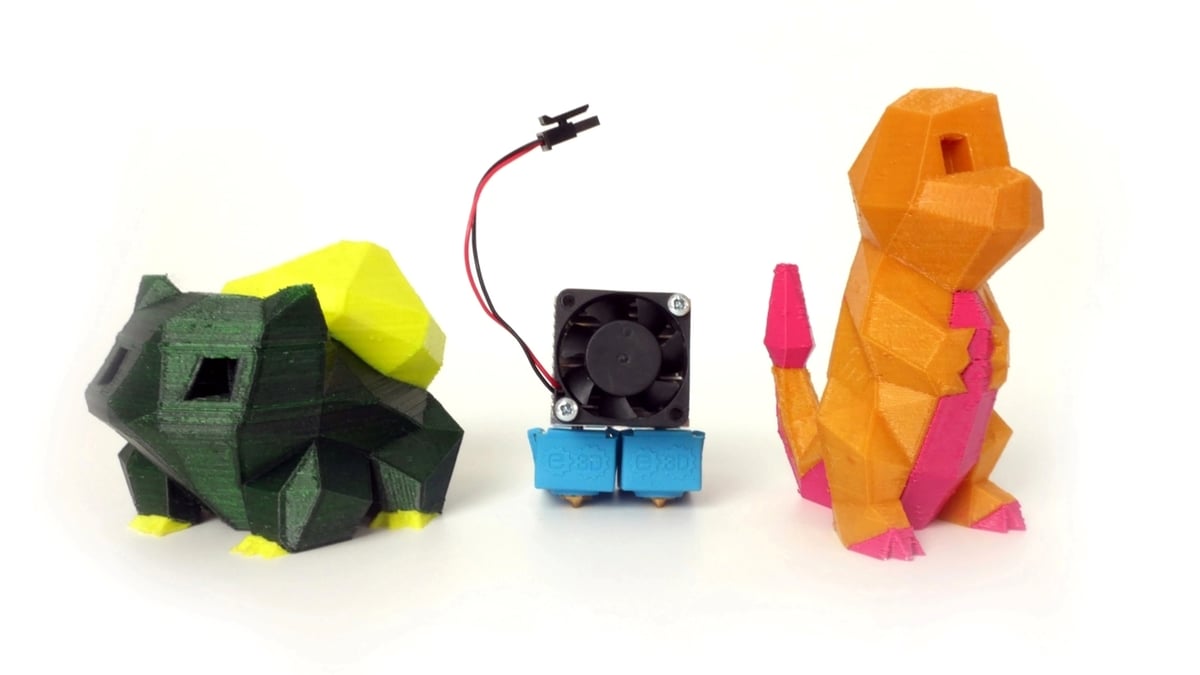

E3D Cyclops+

E3D designed the Cyclops+ as a straightforward solution for multi-filament printing. The base concept is simple: Two filaments are fed by two separate extruders into a single nozzle. It’s oftentimes referred to as a 2-in-1 hot end. This allows dual-color prints as well as color mixing.

Unfortunately, this design has a few flaws. Retraction performance isn’t great, since the molten filament has to go through several right angle curves to get to the nozzle. If printing with one extruder only, the viscous material will flow back through the other heat break. A prime pillar, or prime tower, is a must to avoid color fading.

The Cyclops+, however, isn’t suited for multi-material printing; the two filaments must be made out of the same material. If you’re looking specifically for multi-material printing, you could always keep your current setup and try doing a mid-print filament change. Here’s how to do it on an Ender 3 (Pro/V2).

- Classification: Original E3D product

- Printing temperature range: Up to 300 °C

- Filament size: 1.75 mm

- Price: ⁓$105

Diamond

The Diamond hot end most closely resembles E3D’s Cyclops. However, as the name implies, you can feed three distinct filaments through it at the same time. If you’re eager to get started 3D printing with multiple colors, the Diamond Trippe hot end gives you more options. Check out RepRap’s demo or this fun dual-color die print from Gilles Bouissac to get a sense of how the Diamond hot end works.

Unfortunately, the Diamond hot end doesn’t really improve on the Cyclop+’s design, ultimately sharing (and sometimes increasing) the latter’s drawbacks. An alternative, and probably less complicated, way of doing multicolor prints would be the Palette 2 Pro.

- Classification: Alternative

- Printing temperature range: Up to 300 °C

- Filament size: 1.75 mm, 2.85 mm

- Price: ⁓$43

E3D Chimera+

Building on the basic premise of the Cyclops, the E3D Chimera+ has two extruder nozzles in addition to two hot ends for filaments to feed through. If you want to combine different types of filament, the Chimera+ has your back.

The true multi-material compatibility unlocks a new level of printing quality: water-soluble supports, different materials for the infill, dual-color prints without a prime tower, and a lot more. For higher temperatures or enclosed printers, a water-cooled variant is available.

The Chimera+ has some drawbacks, though. Using only one extruder at a time, the other nozzle will start leaking and fill the walls of the print with blobs and zits. Reducing the standby temperature will help, but will also ultimately increase the printing times. Compared to an independent dual extrusion (IDEX) machine, it’s surely a bit messier. It will also need a board capable of supporting two separate heaters.

An actual dual extruder printer would probably be a better bet if you plan to be doing a lot of multi-material printing. But if you’re still interested, check out how to convert your Ender 3 now.

- Classification: Original E3D product

- Printing temperature range: Up to 300 °C

- Filament size: 1.75 mm

- Price: ⁓$120

E3D Hemera

The Hemera is a direct drive extruder and hot end combo. The dual drive extruder is right above the hot end, allowing for a relatively more precise extrusion. The extruder block and hot end heatsink are also fused together, saving space and improving heat dissipation. It’s fully compatible with V6 blocks and nozzles, as well as the Volcano and SuperVolcano ones. A Revo Six variant is available too.

While the Hemera benefits from all the perks of a direct drive (less retraction needed and easier printing of flexible filaments, for example), the motor is custom made, making it impossible to swap for a lighter model. Being an extruder-hot end combo, it’s harder to install if coming from a V6 or other Bowden configurations. An adapter mount will be needed. The increase in weight might introduce ringing at higher velocities, effectively limiting the maximum printing speed.

- Classification: Original E3D product

- Printing temperature range: Up to 285 °C

- Filament size: 1.75 mm

- Price: ⁓$110

J Head

The J Head is the closest you’ll get to a lot of the E3D line. Its thin construction makes it great for a Bowden setup. The collar doesn’t share the same dimensions as the V6, making it unusable with existing mounts.

Being made out of PEEK, it can’t quite get up to the temperature a V6 can, but it still suffices for PLA. The main advantage here is obviously the lower price.

- Classification: Alternative

- Printing temperature range: Up to 247 °C

- Filament size: 1.75 mm, 2.85 mm

- Price: ⁓$25

License: The text of "The Best E3D Hot Ends & Alternatives of 2022" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.