The hot end is one of the most important components on a 3D printer, as it heats the filament and pushes it through the attached nozzle. Hot ends are usually a durable, conductive metal assembly consisting of a few elements, including a heating block, throat, PTFE liner (optional), and PTFE coupler.

The hot end is a critical component of a 3D printer, and issues in this area can have significant effects on a print. The most common issue with the hot end is a clog, which can lead to incorrect extrusion or no extrusion at all. The better the hot end is at containing heat and establishing a constant “melt zone”, the less likely it is to clog.

In this article, we’ll look at some of the best 3D printer hot ends, discussing their features, price, compatibility, and more. Before we get into the products, though, we’ll review some aspects to keep in mind when you’re looking for hot ends.

Considerations

When shopping for a hot end, there are a few things that you should keep in mind:

- Compatible materials (maximum temperature): Different 3D printer materials require different hot end temperatures. You should think about what materials you want to print with and make sure your hot end can reach these temperatures.

- Printer compatibility: As 3D printer hot ends aren’t universal, you’ll probably need a custom mount (usually 3D printed) to attach your hot end to your 3D printer. You should consider if a hot end has any mounting features that may help you. Additionally, some extruders come with a complete filament drive system, while others only have the heating elements, such as the heat block and heat sink. For this reason, it’s important to make or buy all the parts that an extruder needs in order to be compatible with your printer.

- Nozzle compatibility: While the nozzle screws into the heater block of a hot end, it can be removed and sometimes needs to be replaced. When purchasing a hot end, make sure that the compatible screw size (e.g. M6) matches that of your preferred nozzle type.

- Heat containment: Heat creep refers to when heat climbs beyond the “melt zone” of a hot end, melting the material too early and blocking the filament path. It’s one of the most common issues for hot ends. Higher quality hot ends will contain heat better, even when printing for an extended period or with high temperatures (such as required by materials like PC). Looking at available heat demonstrations or customer reviews can help confirm this information.

- Durability: The highest quality hot ends are made out of the most durable materials. Durable hot ends last longer and are more likely to survive accidental bumps with other parts of your printer. While it’s hard to evaluate durability for hot ends, you can check the material composition of the assembly.

Now that you know what to look for in a hot end, let’s get to the choices!

Micro Swiss

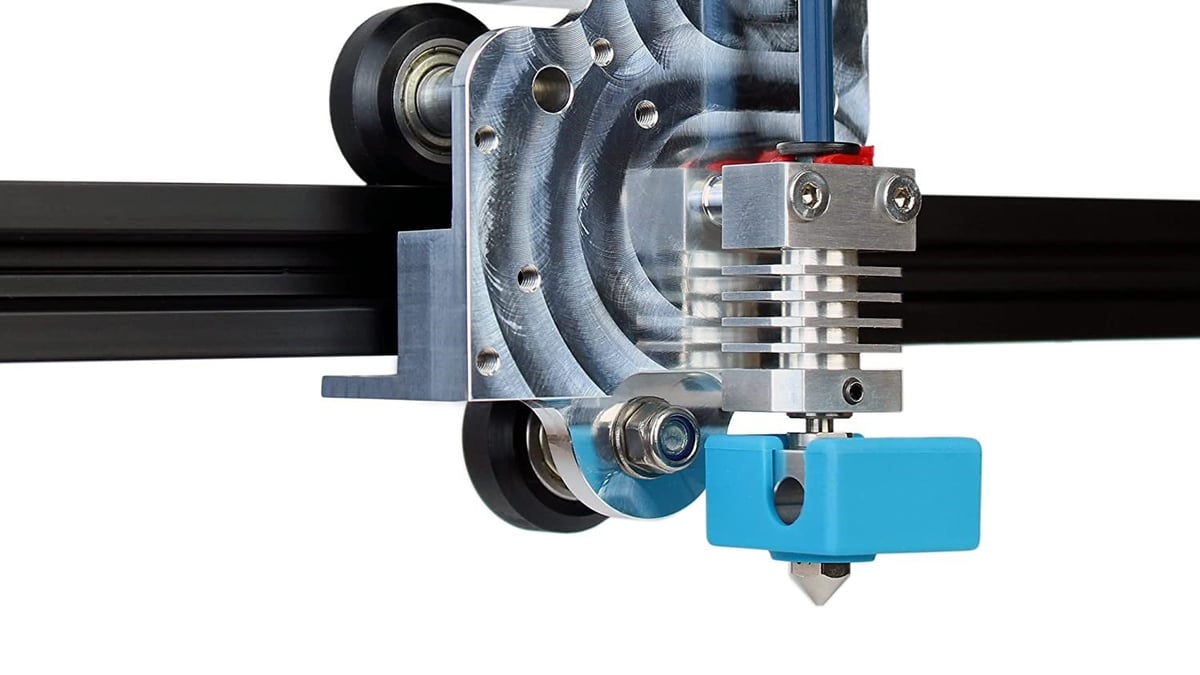

The Micro Swiss all-metal hot end is an excellent choice for those looking to use materials with high printing temperatures. It’s available with or without a filament drive mechanism, depending on where it’s purchased, meaning it can be a quick substitute if you need to replace your hot end or the entire extruder.

At a glance, the heatsink may look similar to the stock hot end on Creality CR or Ender-series printers. The parallel structure makes mounting the Micro Swiss hot end onto these printers a breeze, but besides their shape, the two are very different.

As an all-metal hot end, the Micro Swiss lacks a PTFE liner, which allows it to reach high temperatures of around 280-300 °C without producing toxic fumes from burning the PTFE tube. However, it’s worth mentioning that the increased temperature capabilities also make it more prone to clogging due to heat creep.

The Micro Swiss also features an all-metal throat made of Grade 5 titanium alloy, which connects the heatsink to the heating block. Titanium is not only a highly durable material, it also has great heat isolation properties. According to Micro Swiss, this material offers three times lower thermal conductivity than stainless steel, the typical material of choice for hot end throats.

- Filament diameter: 1.75 mm

- Supported 3D printers: Fits on most FDM printers (e.g. CR-10, Ender 3, Tevo Tornado)

- Price: ∼$65, ∼$120 (direct extrusion)

E3D V6

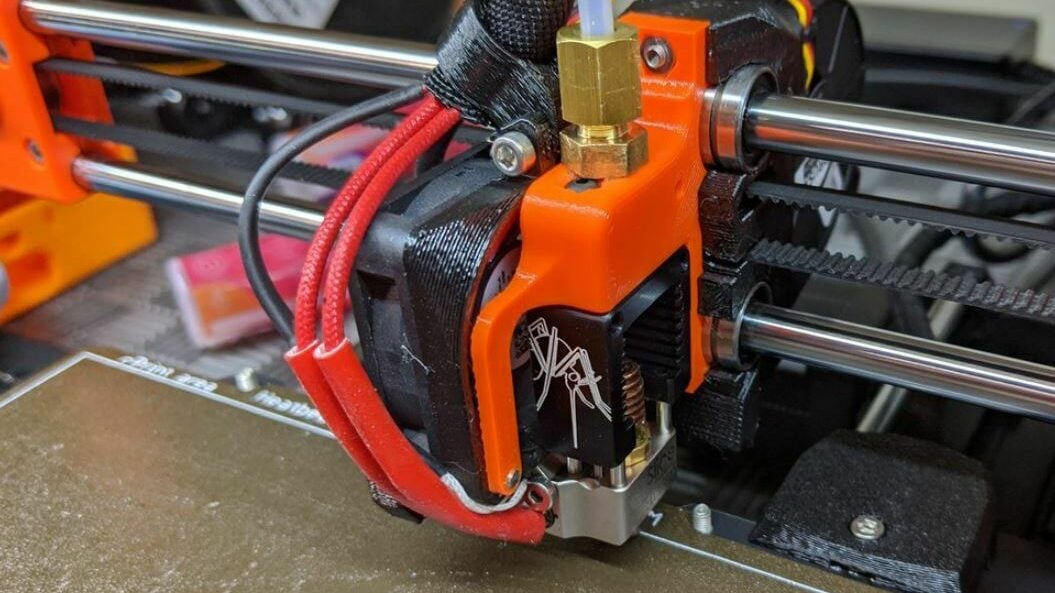

With its tried-and-true reliability, the E3D V6 has proven itself capable of producing high-quality prints across a vast range of materials. With thousands of users running this hot end (or one of its many clones) on hundreds of different machines, the E3D V6 family of components will likely work on yours, too.

Yes, you’ve read that right: the E3D V6 family. A major reason for the V6’s incredible popularity is its ever-expanding ecosystem of parts. From tiny, 0.15-mm nozzles to the hefty SuperVolcano, from standard brass nozzles to the nickel-plated, WS2-coated, tool-steel Nozzle X, E3D has an unrivaled range of parts for every user and use case. There’s something for every temperature range and material.

With plenty of customization options, the V6 is sure to have your needs covered!

- Filament diameter: 1.75 mm, 3 mm

- Supported 3D printers: Fits on most FDM printers

- Price: $50-$100, depending on the model and kit

Phaetus APUS

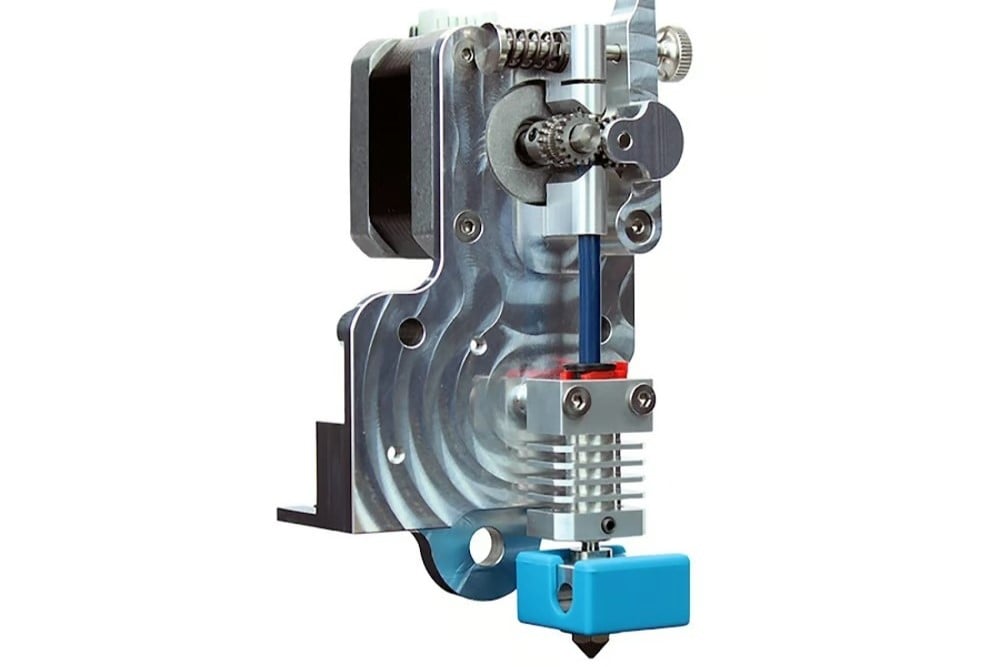

The Phaetus APUS extruder is a unique, low-profile extruder that earns a spot on this list because of its compact frame and compatibility with a high-quality hot end, the Phaetus Rapido. This extruder has a small profile because it uses a smaller motor than the NEMA 17 in standard extruders (such as the MakerBot MK 8). It opts for a smaller stepper motor with a 63:1 gear reduction. This gear reduction is highlighted in the design, with the larger driven gear protruding out of the extruder’s frame.

The Rapido hot end is impressive for its nozzle compatibility and design. Instead of typical cartridge heater blocks, this innovative, spindle-shaped hot end uses a ceramic tube heater that surrounds the nozzle to evenly heat the filament. Coupled with the fact that the nozzle can switch between two modes, high flow and ultra-high flow, this extruder setup is particularly useful for makers.

- Filament diameter: 1.75 mm

- Supported 3D printers: Fits on most FDM printers, but is optimized for the Voron

- Price: ∼$80, plus ~$100 for the hot end

Slice Engineering Mosquito

The Slice Engineering Mosquito is a relatively new product that brings a radical, but quite successful, take on the traditional hot end design. Instead of consisting of a heatsink connected to a heater block via a thin, metal heat “break”, it builds everything off of a sturdy metal frame.

This offers several benefits: For thermal performance, the large, aluminum heatsink used by most other hot ends can be replaced by a more efficient copper one, as the sink no longer has to sustain any mechanical load. This means that heat creep is effectively eliminated.

Since the heater block is connected directly to the frame via four stiff rods, setup is a breeze, with no oddly-shaped mounts to worry about. One-handed nozzle changes are also possible, with no heat break to potentially damage. Speaking of nozzles, the Mosquito is compatible with E3D’s entire range of products, and Slice Engineering also produces their own Vanadium nozzles.

The Mosquito hot end proves that plug-and-play ease of use doesn’t have to come at the cost of quality. If you’re looking for a no-fuss hot end that can deliver top-of-the-line performance and willing to pay accordingly, the Mosquito may be right for you.

- Filament diameter: 1.75 mm

- Supported 3D printers: Fits on most FDM printers

- Price: ~$150

E3D RapidChange Revo

Nozzles are a pain to change. They require specific tools in specific sizes, and switching extruders almost certainly means purchasing a new hex wrench or two to deal with the updated nozzle dimensions. Even worse is dealing with jammed filament, where the nozzle has to be heated before it can even be unscrewed. E3D’s RapidChange REVO hot end does away with all of these problems by offering hot- and hand-switchable hot ends.

By including five snap-in-place nozzles with color-coded silicone tabs around the heat block, this nozzle allows makers to pull out a hot end and replace it with one of a similar or different diameter (demarcated by the color of the nozzle). In this manner, nozzle switching becomes a breeze, and a 3D printer can be quickly converted from printing low-fidelity draft parts to printing finely-tuned, finished pieces.

E3D’s extruder system itself is proprietary, but fortunately for the maker community, their cold end is completely open source. This means that if you’re purchasing the extruder for a 3D printer with an obsolete or non-standard mounting system (such as the Anet A8), E3D allows and even encourages you to design your own mounting system for their extruder.

- Filament diameter: 1.75 mm

- Supported 3D printers: Fits on most FDM printers, and (in a particular configuration) as a drop-in replacement for the E3D Hemera

- Price: ∼$90 (single nozzle), ~$145 (all nozzle)

DyzEnd Pro

The DyzEnd Pro is a small-footprint, high-temperature hot end, great for professional and consumer use, and it’s one of DyzeDesign most popular products.

Because the DyzEnd Pro is an all-metal hot end and doesn’t use a PTFE tube liner in the heat break, it can reach up to 500 °C (if you use a 60-W heating cartridge). This high maximum nozzle temperature will allow you to print even the most advanced FDM 3D printing materials, from PLA to PMMA, even at high speeds.

Besides the temperature capabilities, the DyzEnd Pro has other great characteristics, such as a Tungsten Carbide nozzle, which the manufacturer states is very wear-resistant. The throat on this hot end is coated in ceramic material, which provides a smoother filament path through the assembly. Lastly, like many hot end products, the DyzEnd Pro also includes a fan, which fits over the small heat break to cool down the assembly and prevent heat creep.

- Filament size: 1.75 mm

- Supported 3D printers: Fits on most FDM printers

- Price: ~$130

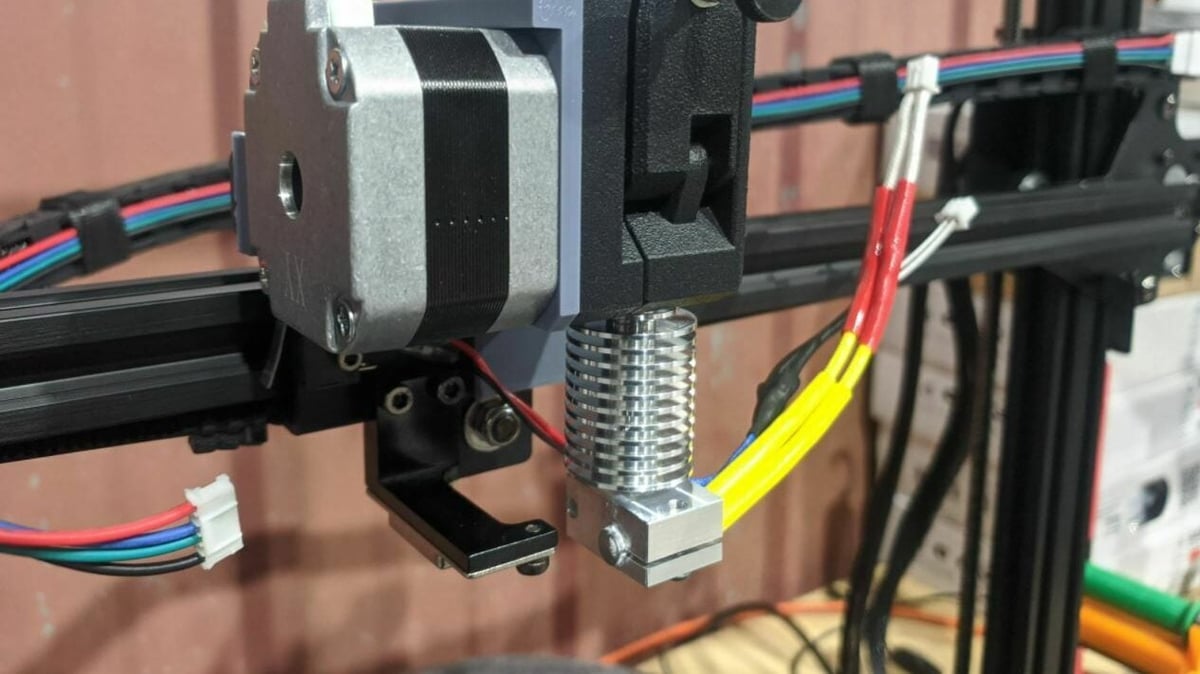

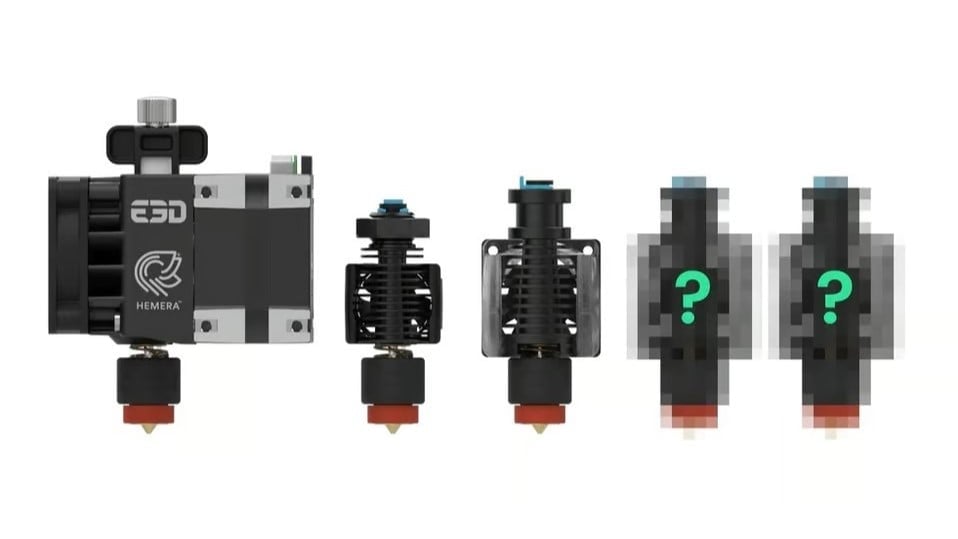

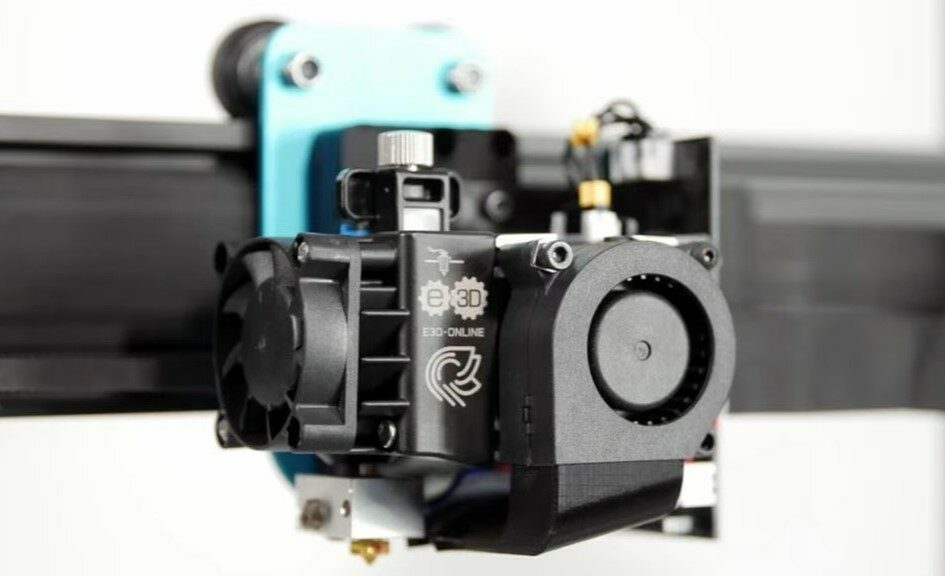

E3D Hemera

Like the Titan Aero that came before it, E3D’s Hemera is designed to be an all-in-one solution for 3D printer extrusion, combining the extruder and hot end into one compact design.

At the core of the Hemera are custom-made motor faceplates that are themselves part of the extruder design, making for an extremely compact build. Not only does this compactness reduce wobble while printing, but it also enables a short filament path: The filament goes almost directly from the Hemera’s dual-drive feeder gears into the attached hot end. This works wonders for extruder precision and reliability, especially when printing flexible filaments, which can be notoriously difficult to handle.

On the outside, the Hemera sports a new heatsink, which screws directly onto the motor faceplate. This heatsink directs air away from the print bed, preventing unwanted air from interfering with your prints.

The Hemera is easily customizable to suit any budget and need. Though it was intended for direct extrusion purposes, the attached hot end can be unscrewed and replaced with a Bowden fitting if desired. Mounting the Hemera is also simple, as the custom motor faceplates feature flat sides and built-in mounting holes for direct attachment to your printer.

- Filament diameter: 1.75 mm

- Supported 3D printers: Fits on most FDM printers

- Price: $120-$150

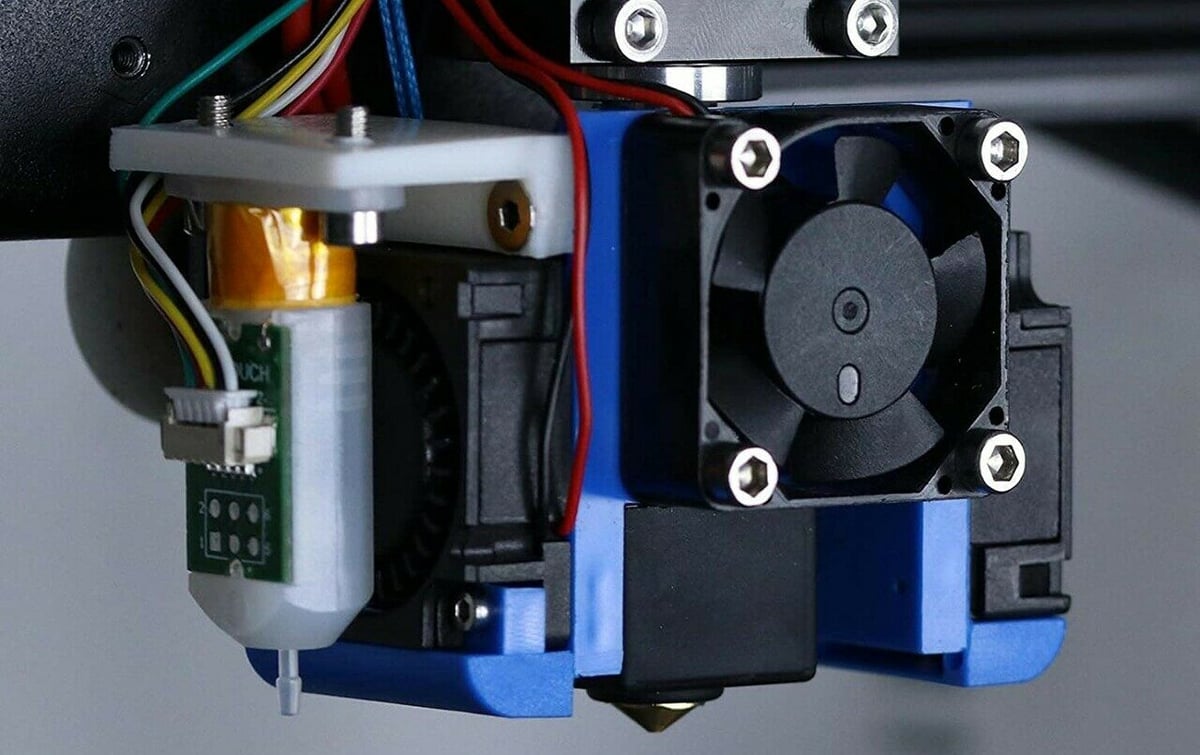

Haldis

Looking for a highly-configurable, adaptable extruder to replace a CR-10 or Ender 3 hot end? The Haldis is a budget extruder that’s highly customizable. This hot end can be configured with auto-leveling, two cooling fans, a heat block sock, and a series of different mounts for compatibility with many different FDM 3D printers.

An important aspect of the Haldis is that it’s compatible with E3D V6 nozzles and not MakerBot’s Mk 8 nozzles, which have different thread types. This shouldn’t be a problem, though, as both types of nozzles are widely available for purchase at similar prices.

There are multiple filament drive systems available for this extruder, such as the Frog Extruder for direct extrusion and a Bowden option.

- Filament diameter: 1.75 mm

- Supported 3D printers: Fits on most FDM printers, including the CR-10, Ender 3, and more

- Price: ∼$25 (Bowden extrusion), ~$120 (direct extrusion)

License: The text of "The Best 3D Printer Extruder Hot Ends of 2023" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.