One Coin, Two Sides

If you have a special object and you want to reproduce it, would you 3D model it? Well, you shouldn’t. That’s exactly what 3D scanning and 3D printing are for, working “together” to help you create your replica!

But what does it mean to 3D scan an object? And what does it mean to 3D print one? Essentially, the two technologies are inverses of each other. With one, you can convert a real object into a virtual one. And with the other, you use a virtual object to produce a real one.

It would, of course, be great if there was a single machine that could both 3D scan and 3D print. But with the technology, we have now, all-in-one scanning and printing remains limited to the domain of 2D.

Here we present the processes of 3D scanning and 3D printing, their differences, and what you can accomplish if you use both of them.

3D Scanning

A 3D scanner is a device that collects physical data of an object or environment in order to create a digital model. This data can include volume, texture, and color.

There are two main types of 3D scanners: contact or non-contact.

Contact 3D scanning employs some kind of arm, like a robotic arm, equipped with a probe. With the object fixed in place, the probe touches its surface to collect information relating to position and distance. As the probe scans the object, it maps coordinates, which together eventually make up the 3D model.

This technology is mostly used in manufacturing and is slow compared to other techniques. It also requires physical contact with the target object, which can be damaging.

Non-contact 3D scanning involves collecting radiation originating from the target object and can employ active or passive techniques:

- Active scanners emit the radiation, typically light or a laser, and collect what is reflected by the object’s surface.

- Passive scanners collect ambient radiation that originates from another source and is reflected by the object’s surface.

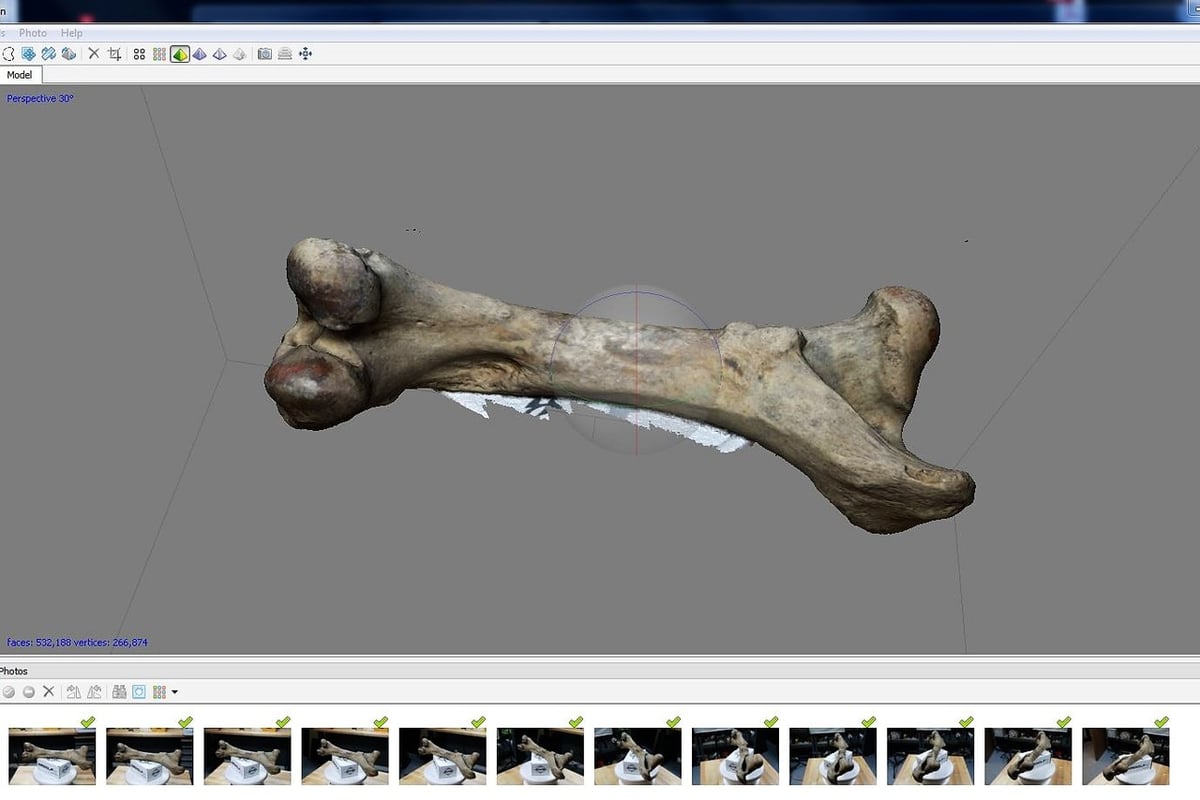

Regardless of the technique employed, non-contact scanners generate meshes of what they “see” based on the relative strengths of the radiation received.

3D Printing

A 3D printer is a device that produces a real three-dimensional object from a digital model.

When we talk about 3D printing, we’re usually referring to fused deposition modeling, but there are other types of 3D printing, as well, like SLA and SLS:

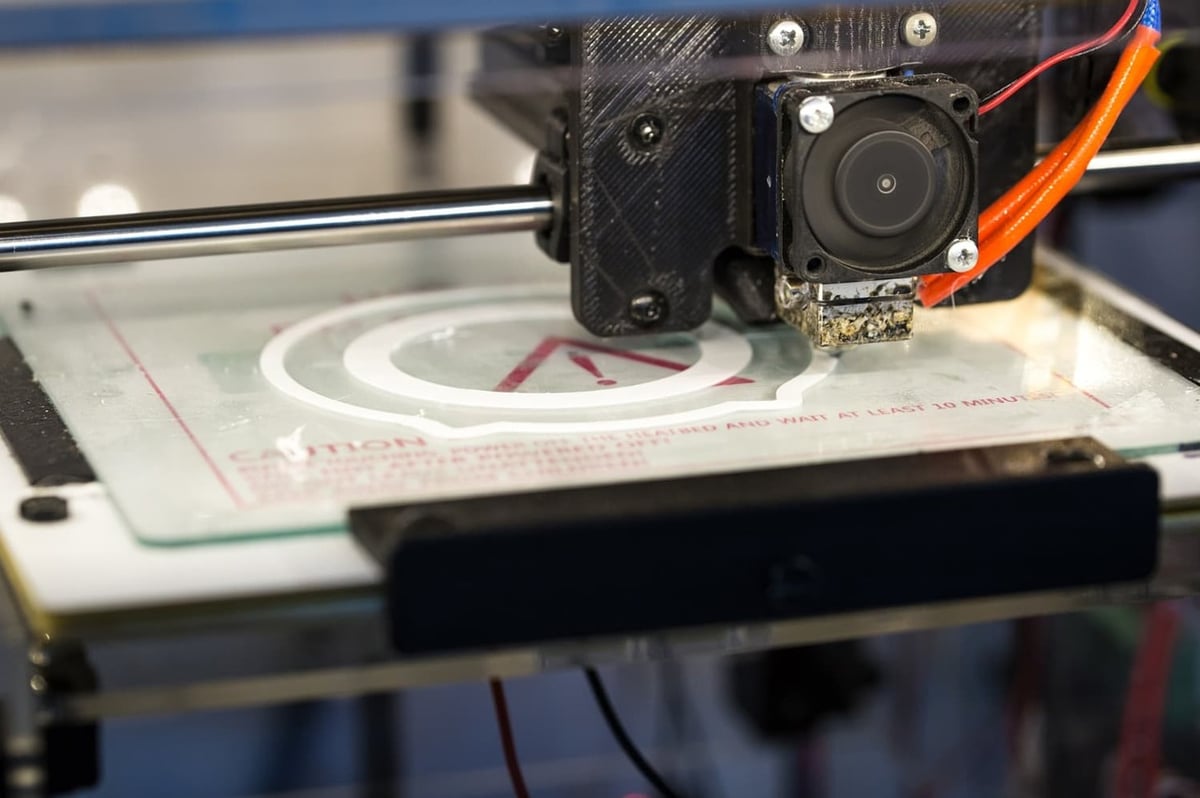

- Fused deposition modeling (FDM) melts thermoplastic filament with a heated nozzle and extrudes the molten material, which rapidly cools to produce an object.

- Stereolithography (SLA) uses UV light to transform liquid photopolymer plastic into a solid object.

- Selective laser sintering (SLS) uses a laser to selectively fuse powder.

With all three of these technologies, the object is produced layer by layer. This means that a special software tool, called a slicer, must first translate the original 3D model into commands that the 3D printer understands.

Types of Devices

Even within each type of 3D scanner and 3D printer, there is a wide variety of devices to choose from. Nevertheless, most can be generally categorized as either professional or consumer devices.

Professional

Professional or industrial devices produce high-quality results in exchange for costly components, which sometimes require a lot of space, power, and maintenance. This is especially true in the case of 3D printing.

Our article on the best 3D scanners includes a category on high-end 3D scanners. Typically, they are easy to use, produce highly accurate 3D models, and come with a full complement of devices and software.

To get a better idea of professional 3D printing, check out our article on industrial 3D printers. Here you’ll see the kind of machines mostly used by manufacturing companies or, at the very least, medium-sized businesses.

Consumer

In contrast to the professional end of the spectrum, consumer devices cater to hobbyists, self-employed professionals, and small businesses. Although many are still capable of producing decent results, their main advantage is that they are cheaper and easier to operate in homes or small workshops.

If quality really isn’t a necessity, the simplest 3D scanning solution is to use a 3D scanning app. Otherwise, a number of low-cost 3D scanners also exist on the market.

Consumer 3D printers come in all shapes, sizes, and prices. Because it’s generally cheaper, the most common technology among hobbyists is FDM, but a number of affordable SLA devices also exist. For now, SLS primarily belongs to the professional arena, due to the high power and cost requirements of the lasers.

The Scanning and Printing Process

If you’re interested in recreating an already existing object, here we provide the general process:

- Choose an object to 3D scan as well as a 3D scanning technique. Note that, depending on the size of your model, you may be limited in what you can use for scanning.

- 3D scan the object. You’ll probably need to reorient it to catch different perspectives. With a simple object, you may need at least three different positions. With a more complex object, you’ll likely need more than five. If you’re using photogrammetry, find out how many images are required by your software. Note that, the more scans or photos you have, the better your 3D model will be.

- Once you’re done scanning, execute the necessary operations required by the respective software. Each scan or photo will need to be cleaned (of supports, platforms, and background objects) and aligned. This is a very important step because all the views must be correctly aligned. If not, the final model will be distorted. Once properly aligned, all overlapping meshes will be fused into a single virtual object.

- Export the virtual object as an STL or OBJ file.

- Import your STL or OBJ file into the slicer appropriate for your 3D printer and prepare it for printing. Once you’ve set the necessary parameters, your slicer will generate the necessary g-code, i.e. the operations necessary to print the object one layer at a time.

- Send the g-code to your 3D printer and 3D print your replica.

Looking online, you’ll find plenty of examples that demonstrate just how practical it is to combine 3D scanning and 3D printing. In the field of medicine, for example, replacing body parts is made much simpler when the patient’s body can first be scanned. Fields like paleontology and archaeology also benefit greatly from producing replicas of bones and artifacts.