This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Big Things, Small Packages

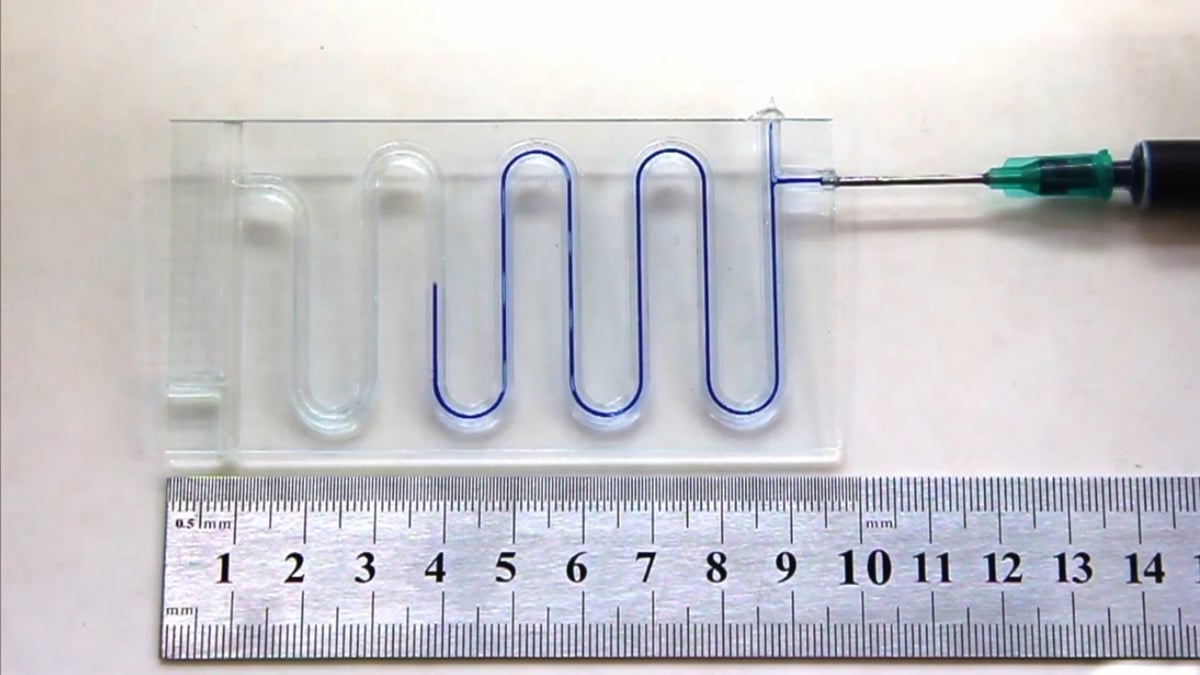

3D Printing Microfluidic Models – 5 Most Interesting Projects

One of the goals of low cost 3D printing is to be able to create medical and scientific devices from it. Diagnostically capable microfluidic models represent the first step into this exciting new world of 3D printing and biosensing capabilities.

Advertisement

Advertisement