When plastic is sent to a recycling center, it gets washed, sorted, shredded, then melted into small pellets, which are then used as raw material for manufacturing new products. Each of these steps can be done at a single facility or split across multiple sites.

Whether it’s done at one or many locations, the sorting stage is extremely important to the recycling process. Contaminating one type of recycled plastic with another can seriously reduce the strength and longevity of the final material. As a result, plastic sorting plants use a variety of methods to separate the types of plastic from one another, all the way from simple hand sorting to high-tech IR detectors!

What role do PLA and PETG play in this matter? In this article, we’ll go over how recyclable 3D printing filaments are, the possibility of composting, tips for reducing plastic waste, and more!

What Types of Plastic Are Recyclable?

Plastic can be classified into two types: thermosets and thermoplastics.

Thermosets are materials that are molded, then cured into their final forms. They include materials such as silicone rubber and some polyurethanes. In 3D printing, the resins used in vat polymerization are thermosets. Typically, these are difficult to recycle (3D printed or not), so this article will focus on the other type of plastic.

Thermoplastics don’t have a curing step and can become pliable or workable after being heated above their melting temperatures. As a result, all FDM 3D printers use thermoplastic filament materials.

In theory, most types of thermoplastic can be melted down and recycled, with differing amounts of efficiency and material loss for each type. However, the types of plastics that are processed by recycling plants can vary around the world, or even between different neighborhoods within the same city!

For example, almost every recycling center processes PET and HDPE, which are the materials typically used to make plastic bottles and food containers. On the other hand, even though PVC recycling is growing in Europe, it’s much less common in North America.

Is 3D Printer Filament Recyclable?

The two classic types of 3D printer filament, ABS and PLA, aren’t recycled by most curbside municipal recycling programs. Under the ASTM International Resin Identifier Codes, both are classified as Type 7, or “Other”, which is not typically processed by municipal programs. So, unfortunately, you can’t just throw your failed prints into the recycling bin.

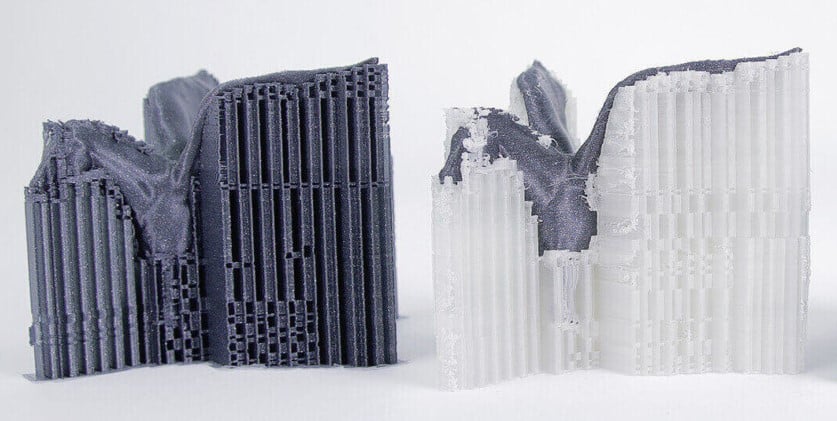

Even though PETG and PET are chemically very similar, PETG is also excluded from being recycled by most programs. In fact, PETG is a pesky contaminant during the recycling of PET because their chemical similarity makes them difficult to distinguish and separate. Combining PETG into the normal PET recycling stream will give the mixed material a lower melting point and out-of-spec thermal stability, which ultimately means the mixture will get tossed in the incineration pile.

Polypropylene (PP) filament isn’t commonly used for 3D printing, as its semi-crystalline nature causes it to warp significantly while cooling. For the brave few that do print with PP, it may be recycled in some municipalities. Contact your local recycling center to find out whether they accept it and how to mark it for identification.

Almost every other type of printer filament (including nylon and polycarbonate) is also classified as Type 7, so they aren’t usually processed by normal plastic recycling plants either.

Non-Municipal Recycling Centers

Even though most local recycling programs won’t turn your failed 3D prints into recycled plastic, there are many independent plastic recycling and processing companies that recycle the materials that aren’t processed by the local pickup service.

While most recycling services will be location-dependent, a US-based example is Terracycle, a recycler specializing in difficult-to-recycle materials. They offer a “Zero Waste Box” that one can fill up with printing scraps, then send it back to them for recycling.

You can also try calling local recycling companies to ask whether they process your plastic of choice. You might need to try multiple places because even if a company processes a plastic type used in 3D printing, many companies might hesitate to accept plastic waste from a non-verified source.

If, however, they’re willing to accept your waste materials, try accumulating big batches of waste plastic that you can periodically drop off. If you’re part of a Makerspace or FabLab, you can also make a big communal waste box for failed prints and take it over when it’s full. Just make sure to keep the different types of plastic separated, with the plastic types clearly marked!

PLA Composting

One of the unique features of PLA is that it’s a biodegradable plastic, which means it can be broken down over time by microorganisms. This organic process could be a great way for us to deal with plastic waste without sending it to a landfill.

Industrial composting of PLA uses ideal conditions like high temperatures and high humidity to keep those munching microorganisms thriving, breaking down the plastic into smaller, harmless molecules such as carbon dioxide and water. The time frame in which this process takes place is heavily dependent on both environmental conditions and the material itself.

Unfortunately, compositing 3D printed parts is not (yet) an effective method for its disposal. While industrial composting facilities can effectively break down some PLA films in a matter of months, thick, bulky parts will not be able to be consumed within the standard turnover time. If you mix PLA into your food waste, it’ll probably end up getting removed from the compost and sent to a landfill anyway.

Home composting isn’t a great option either as it’s much more difficult to maintain the conditions required for PLA biodegradation, at least on any reasonable timescale. Moreover, additives in PLA filament like those used to create a silky appearance or give glow-in-the-dark properties can be harmful to microorganism communities and the environment.

For now, it’s best to keep this plastic out of the compost stream.

Re-Extruding Filament

A great feature of the thermoplastics that are used in 3D printing is their ability to be melted down and re-extruded without a significant loss of material.

Making and using a filament extruder at home is a little more advanced than using a 3D printer, but it’s definitely within the reach of a dedicated hobbyist. It also allows you to make your own filament, which cuts down on material costs – that is, if you don’t consider the cost of making your own extruder. However, you would be able to recycle more than just filament scraps. There are many projects out there that demonstrate how to turn plastic bottles into printable filaments!

Recycling waste plastic into usable filament requires two steps: shredding the plastic into small pieces, then melting and extruding it with a filament extruder. There are many solutions for the latter step, with hobby-grade plastic extruders like the Filabot available for sale, as well as designs for DIY filament extruders that you can build yourself.

Unfortunately, the plastic shredding step remains a bit difficult for the average hobbyist. Grinding up large pieces of plastic puts a lot of strain on the types of motors found in most commercial appliances. Thankfully, there are a growing number of services out there aimed at making filament recycling accessible to those who don’t want to build their own equipment.

One such company is Recycling Fabrik, a Europe-based start-up. Specializing in 3D printing materials, they take PLA and PETG recycling scraps sent to them by makers and turn them into a fresh spool of filament purchasable for around €20. They even offer a wide selection of colors!

Tips for Reducing Plastic Waste

Even though the suggestions above can help you cut down on waste plastic buildup, the easiest way to reduce your waste is to prevent it from happening in the first place! Failed prints and prototypes are an inevitable source of waste for any 3D printing hobbyist, but here are some quick tips for preventing waste buildup:

- Eliminate supports as much as possible. Printing with supports results in a lot of wasted plastic and a lot of time removing it from the part. Whenever possible, try to print your models without supports, or design minimalistic supports into the part itself. (If you use slicing software like Simplify3D, you can also trim the number of supports manually.)

- Print with a brim instead of a raft. Rafts are a good way to ensure that the part will stick to the build surface of your printer. However, like supports, they use a lot of material and require extra steps to be removed from the part. If you’re having bed adhesion problems, try adjusting your first layer height, or print with a brim instead of a raft. Brims also help parts adhere to the bed but use significantly less plastic than a raft.

- Don’t print too many parts at once. The chance of a print failing tends to increase when too many parts are being printed at once. If the printing of one component fails, its aftermath will probably carry over to the other components on the bed, possibly ruining them as well. Try to separate multi-component projects into multiple prints rather than a single large one. It will take more time, but it might be worth it in the end!

- Keep up with printer maintenance. We all know how many things can go wrong during a print. While it’s difficult to prevent all possible mishaps, keeping a regular schedule of maintenance checks and calibrations can help prevent issues from arising. Fewer printing issues mean fewer prints ending up in the trash!

- Consider a print monitoring system. Catching print failures as soon as they begin can mean fewer platters of unusable filament spaghetti. Thankfully, this doesn’t mean standing next to your printer during the entire 8-hour print. There are many tools out there you can use to keep an eye on how your print is going. If you have OctoPrint set up, consider adding a webcam for remote monitoring or the Obico plug-in that can automatically detect print failures.

- Opt for recycled filaments. While making your own recycled filament is quite the task, there are lots of companies out there that take care of the process for you! Professionally recycled plastic can give you similar results to that of brand-new plastic, all while reducing your consumption of raw materials! There’s a range of options out there from ReFuel, which sells a filament made from the combination of all their manufacturing scraps, to Reflow, which sources high-quality plastics to make PLA and PETG filaments that are practically new. Many 3D printing services, like Craftcloud by All3DP, offer recycled filament as a material option for making your parts!

License: The text of "PETG/PLA Recycling: How to Recycle 3D Printer Waste" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.