A nozzle clog on an FDM 3D printer is an annoying, inevitable pain for most owners out there. The nozzle can be partially or totally blocked, preventing smooth extrusion and leading to print (or even machine) failures. If you’re experiencing under extrusion or the filament curling as it’s extruded, a partial nozzle clog may be at fault.

To fix the issue, people use various techniques including a nozzle cleaning needle or cold pulls. The wrong thing to do is to heat the nozzle under a flame, as this can cause irreversible damage.

Another way to unclog your nozzle, or prevent a clogged nozzle from happening in the first place, is to use a cleaning filament. But with all these techniques being rather inexpensive, where does a dedicated “cleaning filament” fit in?

In this article, we’ll discuss when it’s appropriate to use cleaning filament, guide you step by step on how to remove clogs and clean your nozzle using cleaning filament, and lastly, we’ll give a few examples of cleaning filaments available in the market so you can get rid of clogs for good!

What is Cleaning Filament?

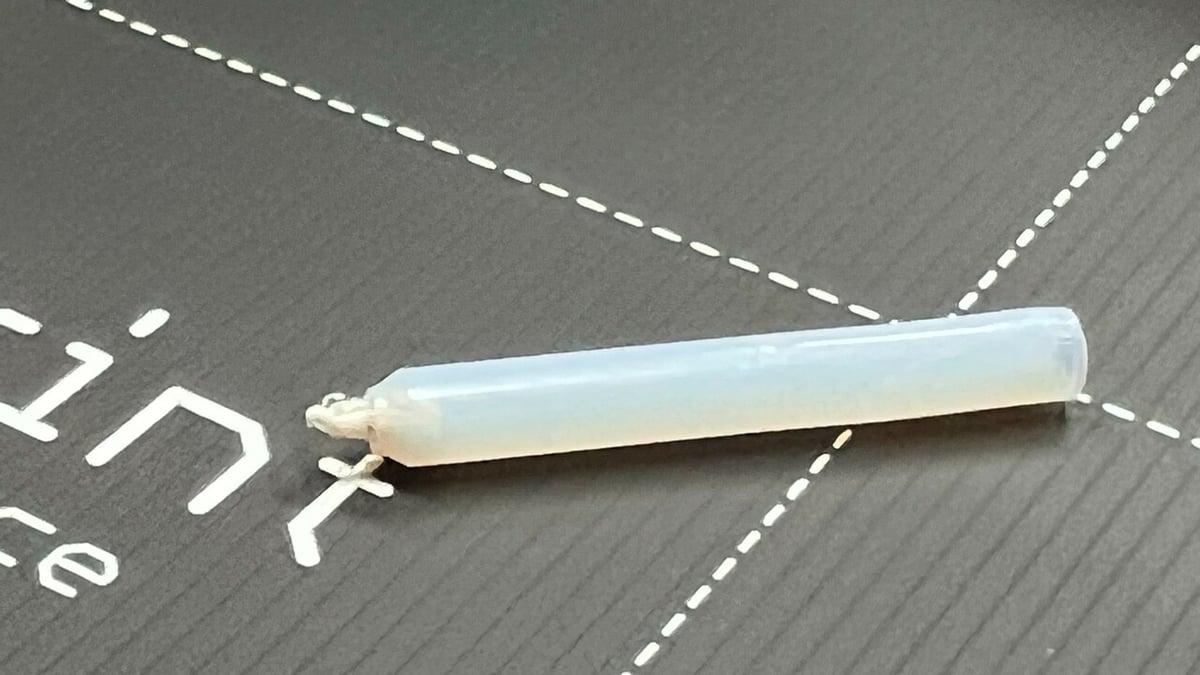

Cleaning filament is a specially designed thermoplastic material blend designed to remove residue and debris from your 3D printer’s nozzle. Usually sold in short sticks or coils, this stuff is only for unclogging the nozzle, not to print objects with it.

At first sight, these filaments may just seem like overpriced repackaging of the nylon filaments commonly used for other nozzle-cleaning methods. Don’t be fooled. The same type of material is used to clean out industrial injection molding equipment by pushing out stuck particles and carbonized plastic without damaging your nozzle.

In many cases, cleaning filaments can be more thorough and efficient in their cleaning than traditional hot and cold pulls.

What’s It Made Of?

The composition of cleaning filaments can vary from brand to brand. Here are the common elements:

- Base material: A thermoplastic compatible with a wide range of 3D printing materials. Nylon, HDPE (high-density polyethylene), or PC (polycarbonate) are commonly used as base materials.

- Cleaning additives: These include abrasive or hygroscopic (moisture-absorbing) substances that help remove residue within the nozzle.

- Expanding agents: While not always included, some cleaning filaments contain chemicals that slightly expand at high temperatures, which helps force out stuck material.

When to Use Cleaning Filament?

How often you should use cleaning filament depends on how much you 3D print and the cleanliness of your filament, among various other factors. For example, if a spool of filament is left in the open and accumulates dust, those particles may create buildup in your nozzle.

So, how can you know when it’s time to use cleaning filament? Here are some general guidelines to keep in mind:

- Regular maintenance: It’s hard to see when accumulation in the nozzle starts, so to avoid unexpected print defects, regular cleaning is a must. A good rule of thumb is to perform a cleaning routine every 20-50 hours of print time.

- Partial clogs: If you notice extrusion inconsistencies but some filament is still able to pass through, you may be facing a partial clog that cleaning filament can help with. However, if the nozzle is completely blocked, then cleaning filament will not work, and you’ll have to turn to one of the other nozzle cleaning methods.

- Switching filament material or color: Whenever you transition from one filament type to another, especially when moving from a higher temperature filament (ABS or PETG) to a lower temperature one (PLA), cleaning filament ensures that no leftover residue from the previous filament contaminates your new print.

Cleaning Filament vs Cold Pull

Cleaning filament is used to remove residue and partial clogs from the 3D printer’s nozzle while cold pulling, also known as atomic pull or cold end cleaning, is used to clean a completely clogged nozzle and remove residual filament and debris from the inside of the hot end assembly.

Cold pulling involves loading a normal filament, heating the nozzle to printing temperature, and then quickly cooling it down to solidify the filament and create a plug. Once cooled, the filament is pulled out quickly, hopefully taking any debris or stuck material with it.

On the other hand, cleaning filament is not like regular filament – it’s specially formulated to remove debris and partial clogs. Cleaning filament is mainly used for routine maintenance and prevention of nozzle clogs or clearing partial clogs.

Let’s see how it works!

How to Use Cleaning Filament

Before using cleaning filament, remember that it only works with partial clogs since it needs to pass through the nozzle to remove debris. If it’s a significant partial clog, we’d recommend using a nozzle cleaning needle to break up stubborn chunks before using cleaning filament.

- If you have a Bowden system, remove the Bowden tube that may be attached to your printer’s print head.

- Heat the nozzle to the manufacturer’s recommended temperature (it may be slightly higher than your typical printing temperature).

- Manually feed the cleaning filament, applying extra pressure if necessary to remove the clog (on Bowden systems) or set the printer to extrude automatically (on direct-drive systems).

- You should see the cleaning filament coming out of the nozzle, bringing along old filament and other particles. Continue extruding until the cleaning filament is free of char and debris.

- Once the cleaning extrusion is complete, load a normal printing filament and adjust the printing temperature appropriately.

- Extrude the normal filament and check if it’s coming out properly from the nozzle. If you still have funky extrusion, it may be time to replace the nozzle or evaluate for other issues.

Once cleaned, you can start printing!

Example Filaments

If you’ve read this far, you may have decided a cleaning filament is right for you and are wondering about what options there are on the market. Luckily, there are several great cleaning filaments to choose from!

MatterHackers

One of the most popular cleaning filaments in the market, MatterHackers uses high-temperature nylon, along with added abrasives, for effective cleaning of nozzle residue and minor clogs.

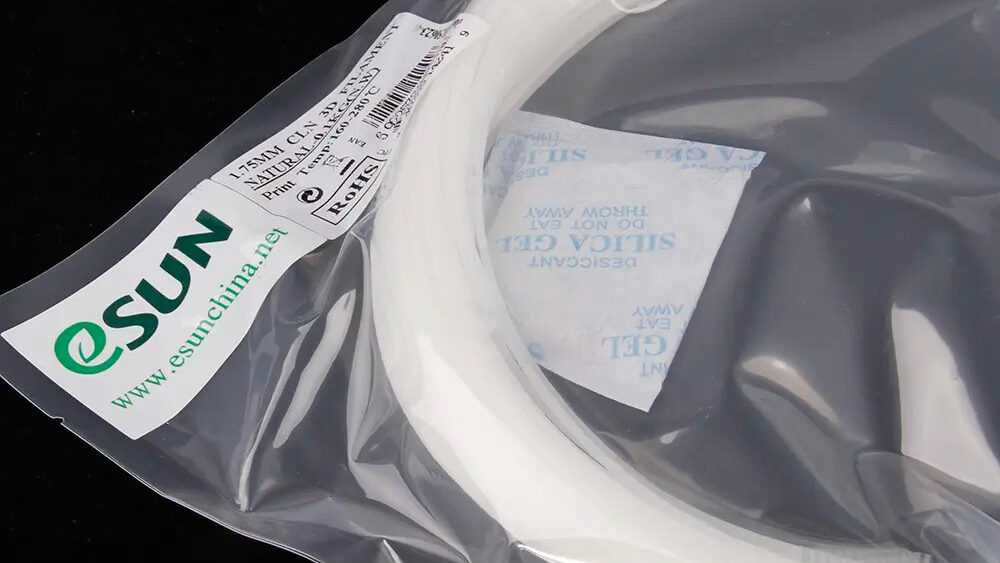

eSun

This cleaning filament is a powerful blend of PETG and PEEK polymers that offers exceptional heat resistance to clear stubborn clogs. It’s ideal for 3D printers that frequently use high-temperature filaments like ABS or PETG.

Inland

As a budget-friendly option, Inland’s cleaning filament is mainly nylon-based with cleaning additives. It’s great for regular maintenance cleaning, but it might not be the strongest choice against stubborn clogs.

License: The text of "3D Printer Cleaning Filament: How to Use It" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.