Unfortunately, warping can happen to the best of us during the fused deposition modeling (FDM) 3D printing process. Whenever some part of your 3D print starts to curl upwards, you’ve got a case of warping on your hands.

This problem occurs when the extruded filament cools too quickly on the build plate and shrinks. This, in turn, creates tension within the model. When it becomes too much, lower layers start to drag or lift up at the corners, creating a warp.

Luckily, there are several ways you can keep your prints warp-free. Let’s take a look at some possible solutions!

Why Does It Occur?

Filaments used in FDM 3D printing are usually thermoplastics, materials that can melt (turning to liquid), cool (turning to solid), and still keep their properties. In 3D printing, we heat the filament beyond its melting point and extrude it onto the build plate.

Thermoplastics expand while heating and shrink when they cool down and return to a solid. This transformation creates movement in extruded plastics, which is the root of 3D print warping: colder layers pulling on hotter layers as they contract. When the earlier layers of a printed object are cooling, and therefore shrinking, faster than the new melted layers can keep up with, the object will be forced to let go of its grip on the build surface and curl away.

To make matters worse, the problem can (literally) pop up after a good portion of the print job is already finished, ruining an otherwise perfect print!

If we could keep the entire 3D printed model at the exact same temperature at all times, not even a tiny corner of the model would try to warp. However, this is pretty much impossible. We can try our best to keep the 3D printed model’s temperature as even as possible and to convince the model to hold on to the build surface like its life depends on it!

Below, we’ve covered three methods to help combat warping and save your prints.

Rare Case: Print Bed Warping

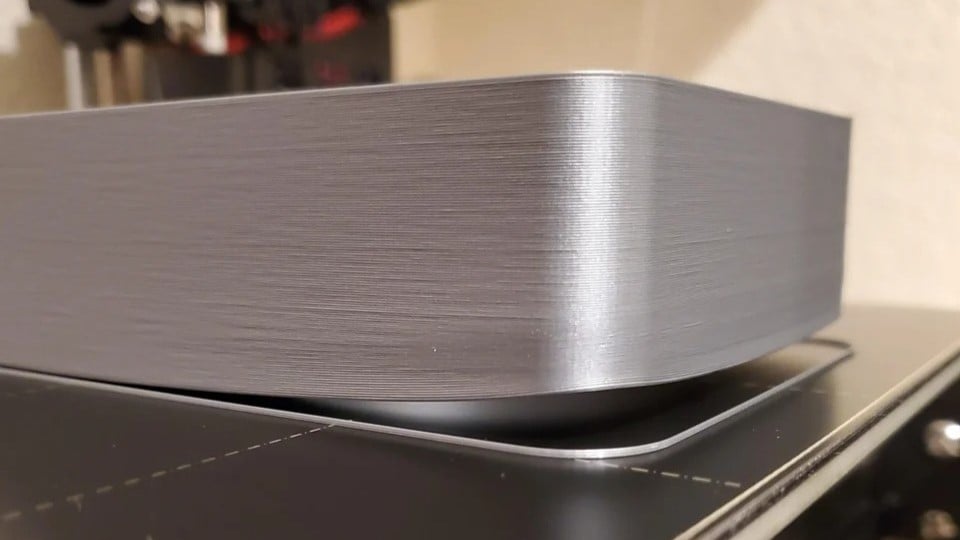

Some hobbyists have reported the print bed warping along with the print. This problem primarily occurs with larger prints (with broad first layers) on spring steel surfaces. The large print accumulates higher warping forces than smaller objects, and the flexible build plate – while sticking well to the print – bends along with it! If you experience this problem (or are worried you might) and can’t apply the following solutions to mitigate it, consider switching to a glass build plate.

Regulate the Temperature

Temperature, not just of the filament but also of the bed and the surrounding air, is perhaps the most important factor in preventing warping. Here are some tips on maintaining optimal temperature conditions:

- Use a heated bed: This helps even out the temperature in the model. A heated build plate also helps with bed adhesion. Usually, the filament manufacturer recommends ideal bed temperatures for each filament. If you’re still experiencing warping after heating the bed, consider printing the first layer hotter and then dropping the temperature for subsequent layers to help with adhesion.

- Use an enclosed print chamber: This helps maintain a constant ambient temperature throughout the printing process. If your printer doesn’t have an enclosure, check out how to build your own.

- Control room temperature: This is especially important if you don’t want to opt for an enclosed print chamber. Do this by keeping windows and doors closed. (Just remember that you still need air to breathe!) Prevent any cold air from suddenly touching the 3D print.

- Adjust the cooling: This can be tricky, as you still need to cool the filament for better bridging, less stringing, and to ensure the melted plastic retains an accurate geometry. Turning off or lowering the speed of the cooling fans directed at the 3D print, at least for the first few layers, may help to even out temperatures enough to keep your model flat on the build plate.

Use Adhesives

Improving the adhesion of your bottom layer on the print bed can often be enough to prevent the corners from lifting. This solution usually involves coating the bed in a layer of something sticky before starting the print.

With any adhesive, it’s best to do a test print of a small part to make sure it’s not working too well. You don’t want it to be so stuck that you damage the part (or even your bed) when you remove it!

- Use hair spray: This helps establish a good grip for most filament types. You can also use a specially-formulated 3D printing bed spray like 3DLac.

- Use a PVA glue stick: A plain old glue stick is another popular option. There are also specific bed adhesion products, like Magigoo. This glue should help PLA and other filaments stick to the build plate. Whatever you choose, you should only need a thin, even layer on your build plate.

Change Your Slicer Settings

Finally, some slicer settings can assist in preventing warping and holding the print in place on the bed:

- Print more slowly: You would be surprised how often slower print speeds can help solve the most stubborn printing problems, like warping and curling. Remember to lower the nozzle temperature accordingly.

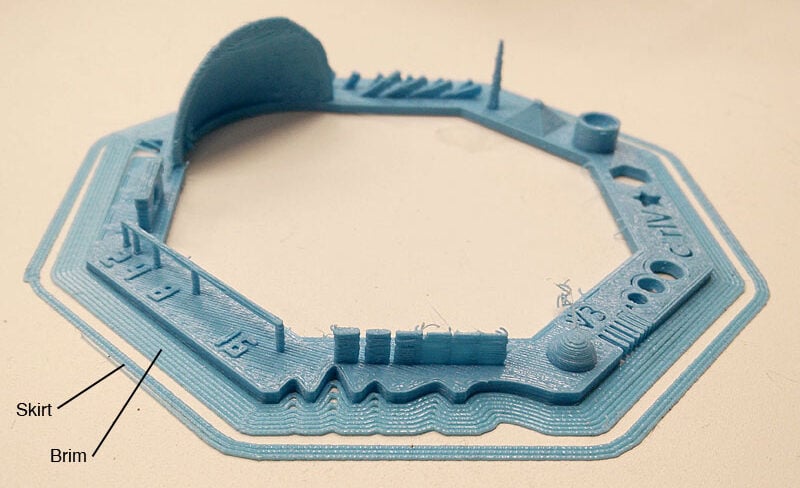

- Create a brim or skirt in your slicer: A skirt is a perimeter offset from the edge of the part, while a brim is one or a few extra layers of outlines attached to the edge of the base. This gives your model a wider base, enhancing the grip on the build surface.

- Add a raft: A raft is a structure that makes the base of your 3D printed model larger, similar to a brim. However, it also continues underneath the entire base of the part. This creates a better grip on the build surface but should be easier to pry off the model.

- Add mouse ears: Mouse ears are small discs, a couple of layers high, that you print under your model to enhance bed adhesion on corners. Place the discs on the build plate in your slicer so that they barely touch each corner of the model. It will be a piece of cake to remove them from your model when your print job is done. You can download some ready-made mouse ears from tugeagon on Thingiverse or use CAD software to draw your own.

License: The text of "3D Print Warping: PLA, PETG, ABS – 3 Easy Fixes" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.