If you want to 3D print engineering-grade objects, materials like PEEK, ULTEM or PEI come up sooner or later. They offer excellent mechanical strength, chemical resistance and also withstand high temperatures. Unfortunately, there aren’t many desktop machines that can reach the temperatures needed for printing these materials.

The Intamsys Funmat HT Enhanced checks off all these essential boxes – and does that for an exceptionally low price. The solidly built desktop machine was created by Intamsys – an abbreviation of INTelligent Additive Manufacturing SYStems – a 3D printer manufacturer based in Shanghai. And unlike most of its more established competitors, which have pricier machines starting from $20.000, the HT checks in at a relatively reasonable $6,000.

Don’t Miss: PEEK 3D Printing – The Ultimate Guide

This machine offers a lot of handy design features as well as essential tools that ensure printing with engineering-grade materials like PEEK, PEI, PPSU, and ULTEM. Here’s what we out.

Feature Check

Printing in PEEK is a persnickety business – and it’s a business that’s been largely dominated by established industrial 3D printing manufacturers like AON3D, Roboze, 3D Gence, and Stratasys. But companies like Intamsys are trying to change that by producing sturdily built printers boasting impressive specs, all for less money than their older, more well-known competitors.

Enhanced Version

There are two versions of the Funmat HT, the original, and the Funmat HT Enhanced. The latter sports automatic bed-leveling, an easily removable ceramic glass build plate which is held in place with magnets, and a software-improved bed motion system.

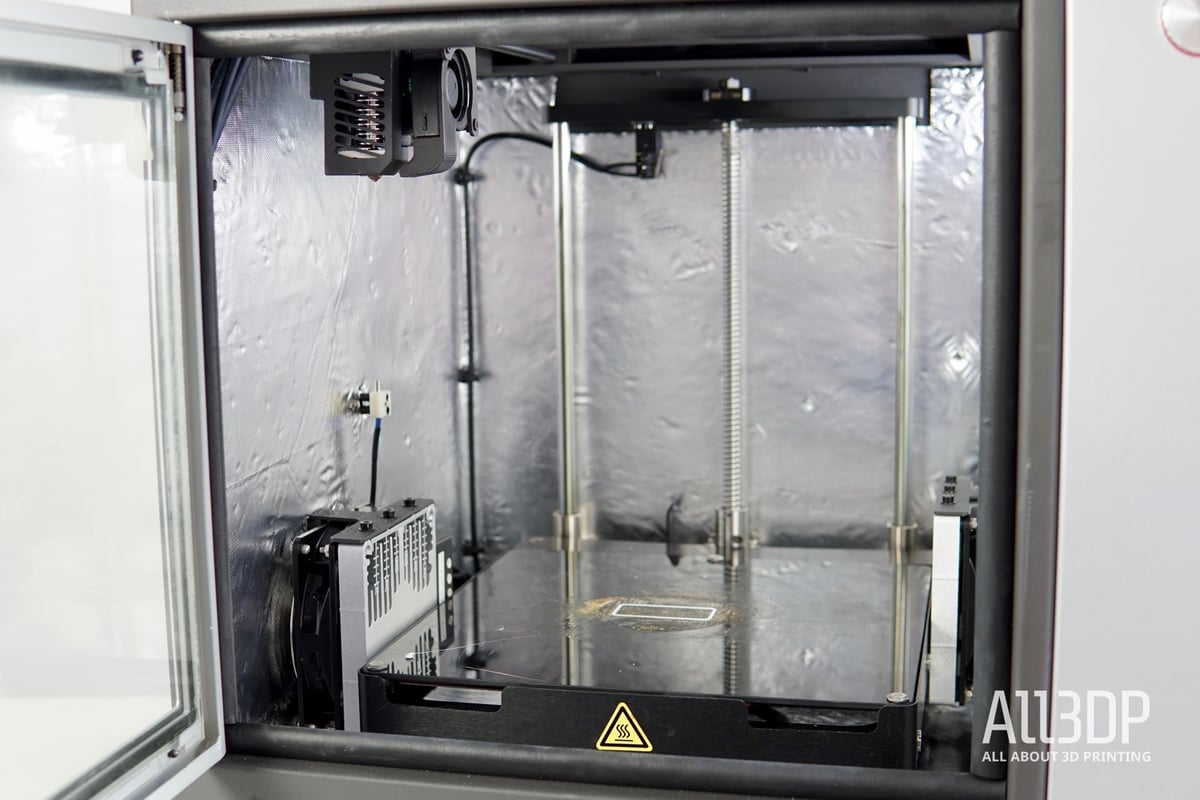

High-Temperature Environment

There’s a good reason the Intamsys Funmat HT weighs whopping 43 kilograms. Sporting a metal frame and being built like a tank, the machine is also insulated all over to ensure all the layers stick together and the print completes without a hitch.

High-Temperature Hotend

The all-metal hotend can heat up to a whopping 450°C, a crucial feature when it comes to printing engineering-grade materials like PEEK / ULTEM, carbon-filled filaments, PEKK, PEI, ABS, PC, Nylon, and TPU.

High-Temperature Bed

Curling and warping isn’t a problem thanks to a heated bed that gets nice and toasty at 160° C. The Funmat HT Enhanced comes with two glass beds that are magnetically held in place. Once the glass cools down, it’s much easier to remove prints.

Heated Filament Chamber

The Intamsys Funmat HT also offers a dedicated chamber for the filament, which is also fully insulated. It has two heaters, which keep the temperature at 90°C evenly and consistently throughout the enclosure.

Proper Tools

Besides a full high-quality set tools for FDM printing, Intamsys provides high-temperature gloves. The touchscreen is also pressure-sensitive, so you don’t have to remove them while working with the Intamsys Funmat HT.

Also Noteworthy

Additional features are:

- It also sports an in-chamber camera for monitoring your prints.

- The Intamsys Funmat HT Enhanced offers filament absence warning and will let you know when the filament is running low or has run out so you can replace it and carry on with your print.

- Backup power: An essential feature for any industrial-grade machine is a backup power tool so when the lights go down, your print doesn’t have to go with it. Intamsys says this printer will save your print before powering down and moving the extruder to a neutral position. When the power is back up, it will resume the print and carry on like nothing bad happened.

- The build chamber has three doors: One for the filament compartment, another one in the front for access to the build plate, and a last one in the roof. The latter can be opened if you wish to print with low-temperature materials.

Printing with PEEK

Polyetheretherketone, also known as PEEK, is considered to be one of the world’s highest-performing engineering thermoplastics. It offers exceptional chemical resistance and excellent mechanical properties at high temperatures. That‘s why its main applications include functional prototyping, metal-replacement, and even end-use parts. PEEK parts are often found in industries like aerospace, automotive, oil and gas, medical, dental and research. Plastic parts in your car are most likely made from PEEK.

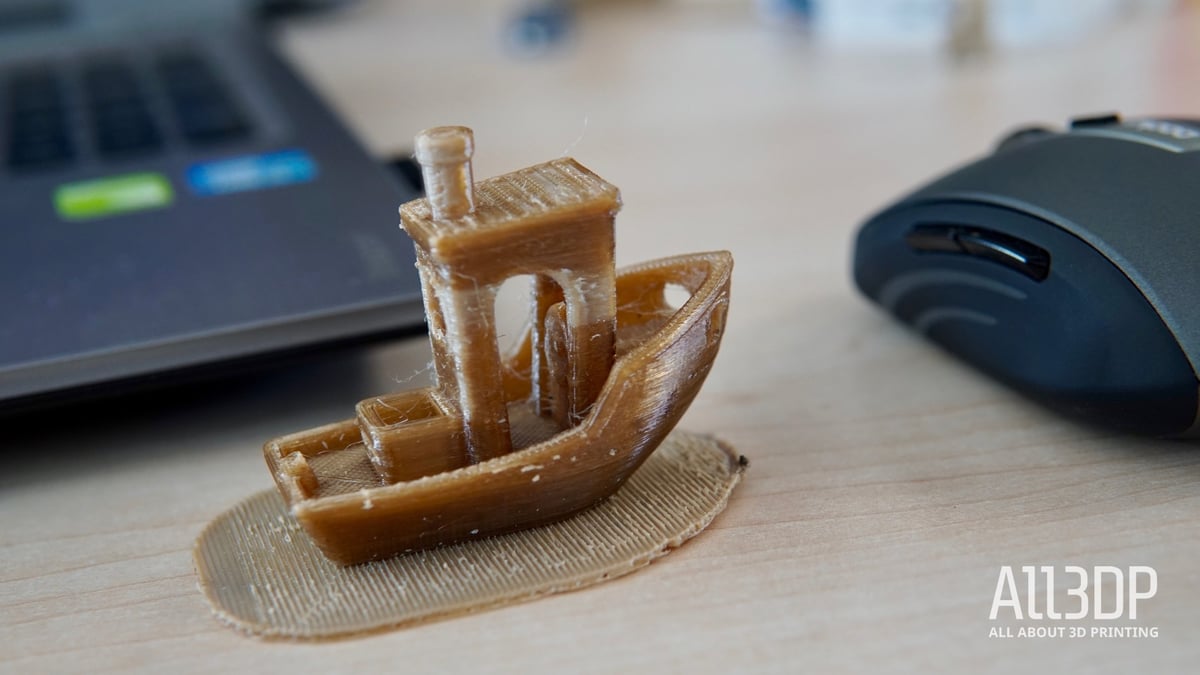

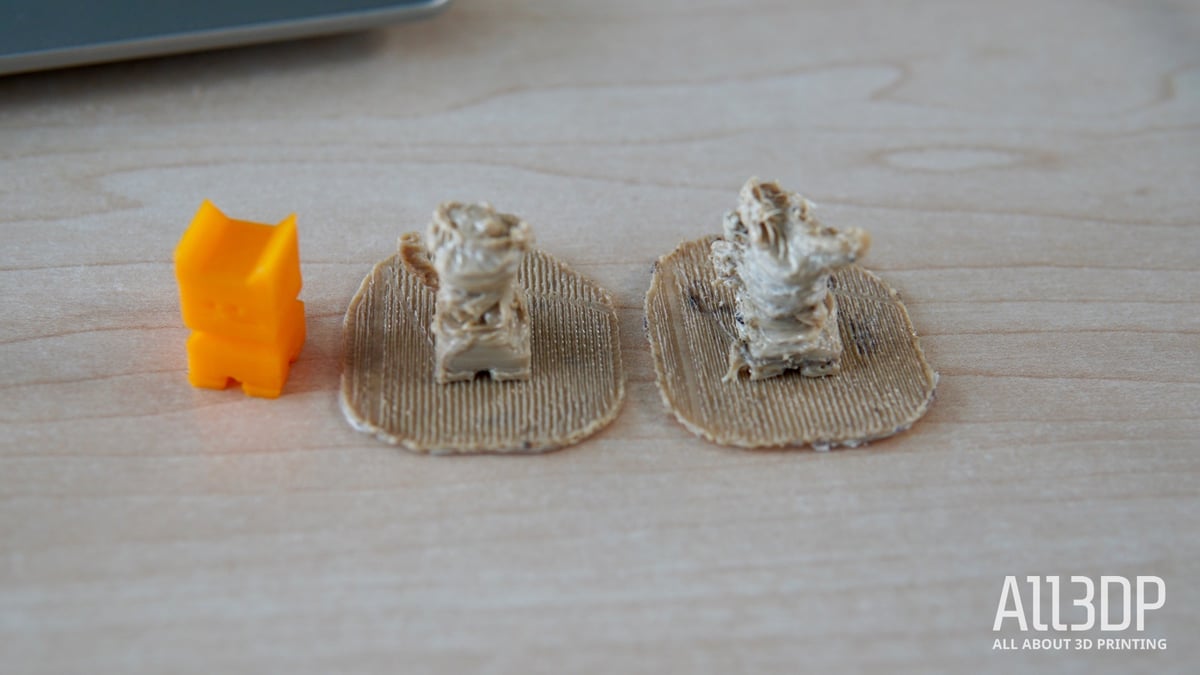

There are some drawbacks, though. PEEK is notoriously difficult to print, as the All3DP testers soon found out. With the Intamsys HT being the first printer capable of printing industrial-grade PEEK parts in our offices, our efforts weren’t crowned with presentable parts right from the start. We’re giving you a short tour of our successes and fails so that you might not fall into the traps we encountered.

As a first test, we chose small calibration cats – at least that was the intention. We printed too fast with a speed of 50 mm/s, so the material wasn’t able to cool down quick enough and created mainly blobs.

After several attempts and altered temperature settings, we also found out that consistent chamber temperature crucial to produce more than hardened PEEK blobs. First of all, heating the chamber to 90 °C for at least an hour will give you better results. Secondly, the PEEK spool itself must also be heated to at least 90°C. Otherwise, your prints will most likely fail – a costly experience, as a half-kilogram spool will set you back at least $400.

In general, we found that PEEK is great for any functional parts, but it isn’t a good material to print detailed objects. It is also crucial to keep the nozzle clean after the print is finished – once hardened, the crystallized PEEK be hard to remove from the nozzle.

Lastly, we printed a Raspberry Pi case to check the dimensional accuracy – the case is known to be a tight fit for the computer. As you can see in the image above, the results were decent. Yet, we encountered improper crystallization (check the brown discoloration). This results from insufficient temperature control throughout the print. We started to experiment by increasing the temperature and cooling each print, but then we burned through the spool of PEEK without getting a 100 percent perfect result.

Benchmarking

The next step was putting the Intamsys through All3DP benchmarking process. We printed two torture tests on a new, freshly unboxed and unaltered machine, using PLA filament and averaged slicer settings for the ranges specified for the material.

If you want to dive deeper, here’s how we are conducting these tests.

Benchmarking Object 1: Benchy

We used white eSun PLA+ filament. To prepare the G-code, we used Intamsys’ Intamsuite slicer (which won’t win any prizes for usability, but does the trick), adapting the existing profiles for the material. The temperature was set to 215 °C and the bed to 60 °C. We got decent results on the first try, so we measured the physical dimensions of the print (jump to the detailed results here).

The Benchy overall turned out dimensionally accurate, giving the Intamsys Funmat HT Enhanced top marks of 15 out of 15 points.

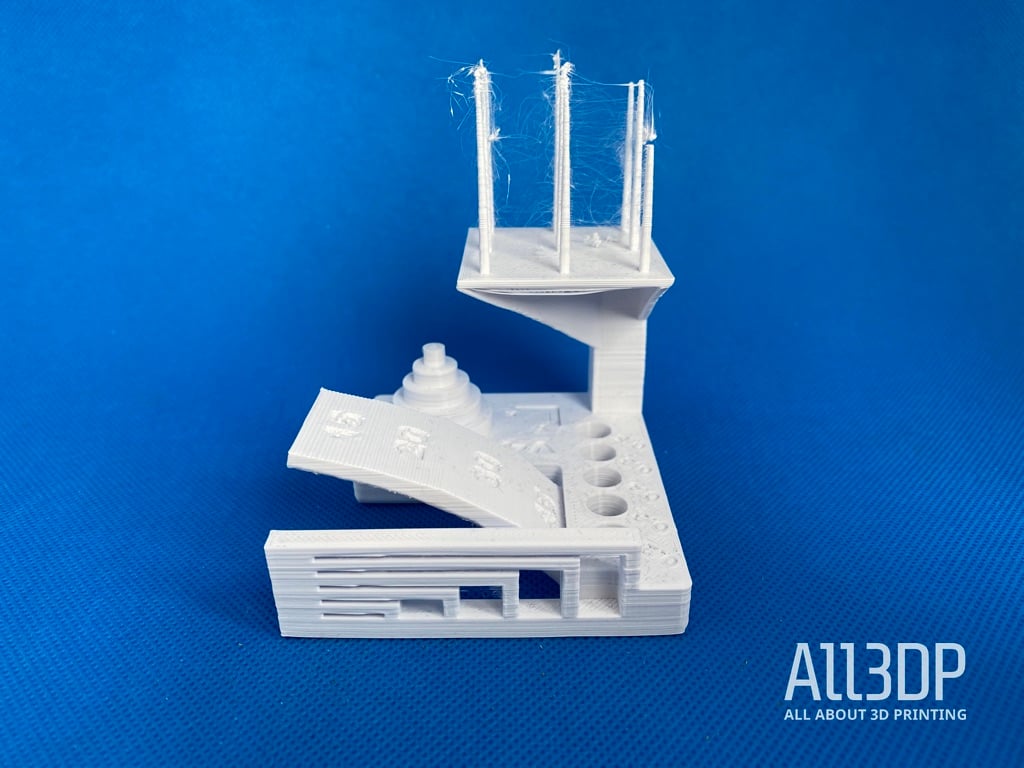

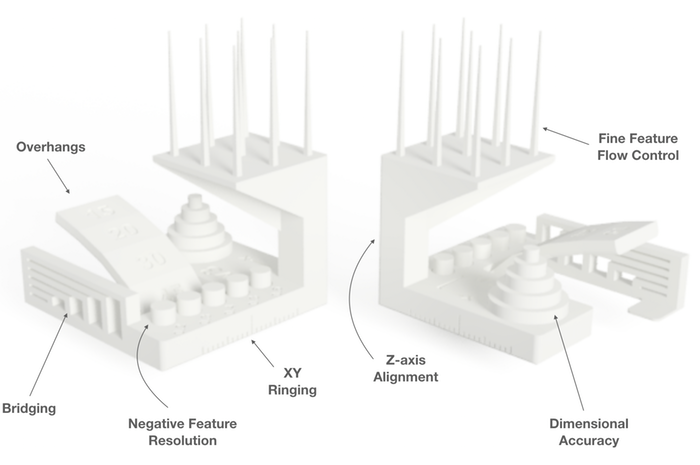

Benchmarking Object 2: Kickstarter-Autodesk Test

The Kickstarter-Autodesk test model looks at an FDM printer’s precision. We used the same white eSun PLA+ filament and the same temperature settings (215 / 60).

With a score of 19 out of 30 points, the Intamsys sits alongside the Kodak Portrait and the Raise 3D Pro 2 Plus: Mediocre, not outstanding.

Verdict

The Intamsys HT Enhanced ticks all the right boxes for printing with pro materials.

Print results were mostly good. We managed to print decent objects with the Intamsys Funmat HT Enhanced, even if we didn’t have prior experience with PEEK. We found the material extremely difficult to work with, resulting in a much higher failure rate than expected. If you’re new to the game, be prepared to burn through several spools until you’ve found your perfect settings.

The Intamsys HT Enhanced struggled with basic day-to-day materials and prints – although that’s not its key feature and more of a side aspect.

If you’re running a lab or a workshop, this specialist’s machine surely is an interesting choice. However, it does lack some of the fancier workflow features like print queuing and WiFi connectivity.

If you want to know more about PEEK alternatives that also can be printed on this machine, here’s more information:

Don’t miss: Intamsys Funmat HT Enhanced

Technical Specifications

Here’s a rundown of the Funmat HT’s technical specifications:

General specifications

- Technology: FDM

- Year: 2017

- Assembly: Assembled

- Mechanical arrangement: Cartesian XY-head

- Manufacturer: Intamsys

3D PRINTING PROPERTIES

- Build volume: 260 x 260 x 260 mm

- Feeder system: Bowden

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 450 °C

- Max heated bed temperature: 160 °C

- Frame: Metal

- Bed Leveling: Automatic

- Connectivity: SD card, USB

- Print recovery: Yes

- Filament sensor: Yes

- Camera: Yes

MATERIALS

- Filament diameter: 1.75 mm

- Third-party filaments: Yes

- Materials: PEEK, Carbon Fiber-filled metal, PLA, ASA, PETG, etc.

SOFTWARE REQUIREMENTS

- Recommended slicer: Intamsuite, Cura

- Operating systems: Windows, Mac, Linux

- File types: STL, OBJ

DIMENSIONS AND WEIGHT

- Box dimensions: 635 x 737 x 889 mm

- Outer dimensions: 538 x 498 x 650 mm

- Weight: 43 kg (95 lb)

Where to Buy

You can purchase the Funmat HT from these retailers:

Benchmarking Results

Here you find the detailed results of our initial testing. Our benchmarking procedure can be found below.

Benchy

- Overall length (60 mm ±1 % tolerance): 59.43 mm, 1 point given

- Overall width (31 mm ±1 % tolerance): 30.91 mm, 1 point given

- Bridge Roof length (23 mm ±1 % tolerance): 22.97 mm, 1 point given

- Chimney roundness inner diameter (3 mm ±10 %): 2.79 mm, 1 points given

- Chimney roundness outer diameter (7 mm ± 5 % tolerance): 6.89 mm, 1 point given

- Vertical overall-height (48 mm ±1 % tolerance): 47.95 mm, 1 point given

- Box depth (9 mm ± 5 % tolerance): 9.03 mm, 1 points given

- Box inner length (7 mm ± 5 % tolerance): 7.05 mm, 1 point given

- Box outer length (10.81 ± 5 % tolerance): 10.70 mm, 1 point given

- Box outer width (12 mm ± 5 % tolerance): 11.84 mm, 1 point given

- Box inner width: (8 mm ± 5 % tolerance): 8.10 mm, 1 point given

- Hawsepipe inner diameter left (4 mm ±10 % tolerance): 3.70 mm, 1 point given

- Hawsepipe inner diameter right (4 mm ±10 % tolerance): 3.81 mm, 1 point given

- Bridge front window width (10.5 mm ±5 % tolerance): 10.55 mm, 1 point given

- Rear window inner diameter (9 mm ±5 % tolerance): 8.95 mm, 1 point given

Overall, the Portrait scored 15 out of 15 points.

Kickstarter Autodesk Test

- Dimensional Accuracy: 4 of 5 points (24.91 / 25, 24.94 / 20, 19.99 / 15.1, 15.02 / 10.08, 10.08 / 5.03, 5.03)

- Fine Flow Control: 2.5 of 5 points (spires were printed with intense stringing)

- Fine Negative Features: 5 of 5 points (all pins were removable)

- Overhangs: 2 points (surface quality got worse at the 10° overhang)

- Bridging: 0 points (all bridges were touching the surface beneath it)

- XY Resonance: 2.5 points

- Z-axis alignment: 2.5 points (not visible)

Overall, the printer scored 18.5 out of 30 points in this test.

How We Benchmark

For the benchmarking element of our review, we use the following guidelines:

Unbox the printer: We unbox the printer and assemble it according to the manufacturer’s instructions. Deficiencies and errors are noted and build around according to the consensus online for the printer.

Filament: We use white eSun PLA+ filament. Temperature settings are 215 °C for the nozzle and 60 °C for the bed.

Printing: We print two test models — Benchy and the Kickstarter x Autodesk FDM 3D Printer Assessment — using the manufacturer-provided/recommended slicer and settings. If the printer ships without a dedicated slicer and profile, we generate a generic Cura profile using the essential information of the printer.

After the first print, we inspect the object for easily fixable problems (i.e., a loose belt or a poorly leveled print bed) and then print again. If the printer can’t provide a decent result after three attempts, we stop. Printers that fail to produce a test object receive zero points for the respective test object.

1. Benchy

The Benchy 3D printer torture test is one of the world’s most popular prints. It helps to measure the dimensional accuracy capabilities of your printer and helps highlight other visible print nastiness.

We measure our best Benchy print using digital calipers, scoring 15 criteria against their target value. A total of 15 points are available.

- Overall length: 60 mm

- Overall width: 31 mm

- Bridge Roof length: 23 mm

- Chimney roundness inner diameter: 3 mm

- Chimney roundness outer diameter: 7 mm

- Vertical overall-height: 48 mm

- Box depth: 9 mm

- Box inner length: 7 mm

- Box outer length: 10.81

- Box outer width: 12 mm

- Box inner width: 9 mm

- Hawsepipe inner diameter left: 4 mm

- Hawsepipe inner diameter right: 4 mm

- Bridge front window width: 10.5 mm

- Rear window inner diameter: 9 mm

To accommodate the difficulty and inaccuracies when measuring small features, we have implemented a sliding scale of tolerance in our scoring. The smaller the feature, the greater our allowance for deviation:

- 60 mm to 23 mm: 1 percent tolerance allowed

- 23 mm to 7 mm: 5 percent tolerance allowed

- 7 mm to 0 mm: 10 percent tolerance allowed

Finally, we do a visual inspection and note any flaws and problems we encounter.

2. Kickstarter x Autodesk FDM 3D Printer Assessment

The Kickstarter x Autodesk print exposes an FDM printer’s precision via six distinct tests in one object.

By pushing a printer’s hardware and software the system to the point of failure, the print reliably visible imperfections that can be used to assess the performance of the slicer, the extruder, and the motion system together.

Here’s what’s getting measured.

- Dimensional Accuracy

- Fine Flow Control

- Fine Negative Features

- Overhangs

- Bridging

- XY Resonance

- Z-axis alignment

The tolerances and measurements are very detailed. You can find the exact measuring procedure on Github. The highest possible score is 30, indicating a very well-calibrated system.

It’s worth noting that these benchmarking tests are not a definitive measure of a printer’s worth. More an indication of a printer’s state out of the box with no-tinkering, it’s only after a full evaluation and in-depth review that we fully judge a 3D printer.

License: The text of "Intamsys Funmat HT Enhanced Review" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.