Carbon fiber 3D printing gives you parts with the strength of metal, the weight of plastic, and high resistance to heat, chemicals, and corrosion. It makes bike frames lighter, propeller blades stronger, and industrial tools more durable.

In this guide, you’ll find the insights you need to make smart printer and material purchasing decisions for your industrial application, whether it’s production volume consumer products or large-scale factory aids.

Although carbon fiber has been a manufacturing material since the 1960s, as a 3D printing material, it’s relatively new. Mixed with other materials, including a wide range of high-performance plastics, carbon fiber enhances the characteristics of these base materials and broadens their applications. Today, 3D printed carbon fiber parts are used to stand in for metal parts in functional prototypes in aerospace and automotive industries. They’re used for the final production of a wide range of products and tools once made from steel. Below, we cover what you need to know about carbon fiber 3D printing technology and materials to make the best printer choice.

Not every printer can print with carbon fiber, and there’s more to look for than just a hot nozzle and a heated bed. New FDM carbon fiber 3D printers from a range of manufacturers, along with an ever-expanding menu of carbon fiber materials, are raising the profile of this versatile additive manufacturing option.

If you’re looking for a smaller desktop- or benchtop-size carbon fiber printer, check out our guide to those machines at the link below.

| 3D Printer | Technology | Build Volume (mm) | Min. Layer Height | Max. Extruder Temp. | Market Price | Print Speed |

|---|---|---|---|---|---|---|

| Delta WASP 4070 ZX | FDM Delta | 400 x 400 x 700 | 50 microns | 350 °C | $15,000 | |

| Fabbrix Elemento V2.1 | FDM | 1000 x 560 x 530 | 160 microns | 300 °C | $40,000 | 150 mm/s |

| MiniFactory Ultra 2 | FDM | 330 × 180 × 180 | 10 microns | 250 °C | $50,000 | 150 mm/s |

| Aon3D M2+ | FDM | 450 x 450 x 565 | 50 microns | 500 °C | $50,000 | 500 mm /s |

| Markforged X7 Gen 2 | FDM/CCF | 330 x 270 x 200 | 50 microns | - | $70,000 | |

| 3DGence Industry F350 | FDM | 340 x 340 x 350 | 50 microns | 500 °C | $75,000 | 400 mm/s |

| Markforged FX20 | FDM/CCF | 525 x 400 x 400 | 50 microns | - | ~$125,000 | |

| BigRep Pro | FDM | 1,020 x 970 x 985 | 300 microns | 300 °C | $170,000 | 600 mm/s |

| Stratasys Fortus 450mc | FDM | 406 x 355 x 406 | 127 microns | - | $185,000 | |

| Roboze Argo 350 | FDM | 350 x 300 x 300 | 10 microns | 450 °C | $195,000 | |

| Essentium HSE 280i HT | FDM | 695 x 495 x 600 | 50 microns | 550 °C | $200,000 | 500 mm/s |

| Titan Robotics Atlas-HS | FDM/CNC | 1067 x 1067 x 1118 | 150 microns | 400 °C | $90,000 | |

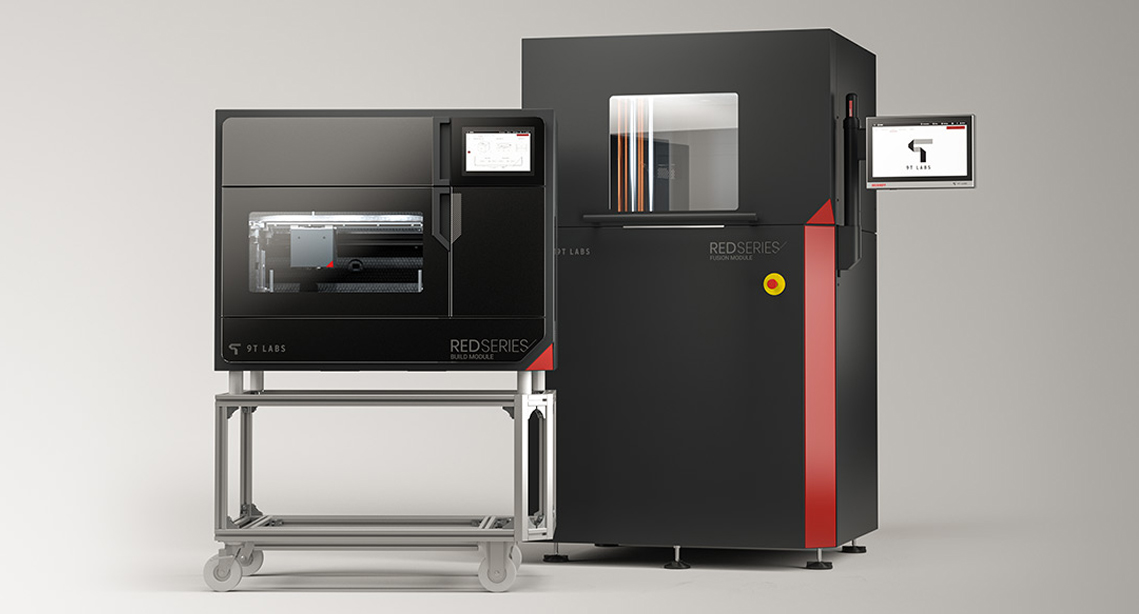

| 9T Labs Red Series | FDM/CCF | 350 x 270 x 250 | - | - | - |

The Case for Carbon Fiber

One great example of a carbon fiber end-use part is the Superstrata unibody all carbon fiber bike frame (pictured above) that has no seams, no welding, no bolts and is custom made to order by Arevo, which uses a proprietary continuous carbon fiber 3D printer. Carbon fiber is not new to the bicycle market, but 3D printing carbon fiber bike frames is faster, requires no tooling, and far less labor, Arevo says. With this manufacturing method, Superstrata can be more responsive to bicycle market trends and get new products to market faster.

Another popular use for carbon fiber is production line tools, jigs, and fixtures. Major automakers worldwide have moved to 3D printing carbon fiber production tools in-house for the speed and flexibility it offers, not to mention the much lower price compared to outsourcing machined stainless steel or aluminum tools.

Carbon fiber additive manufacturing is growing as a solution for companies that need low volumes of parts that would be too expensive to create via injection molding due to the high cost of the mold-making process or machine due to the labor involved in machining parts individually.

One recent example is the limited edition ProPilot Coulson watch from Swiss watchmaker Oris. Intending to only make 1,000 of these timepieces as a tribute to Coulson Aviation’s aerial firefighters, Oris selected a process that did not involve the same mold-making and fine machining required for its metal watch cases yet featured a durable, lightweight, and aesthetically pleasing material. The company used continuous carbon fiber 3D printing from printer maker 9T Labs.

Although the use of carbon fiber for end-use products is growing, such as bicycle helmets and drones, its use in functional prototyping still dominates.

If your final part needs strength and functionality, a carbon fiber prototype is ideal. In many cases, end users can install the carbon fiber prototype (think car parts, drone propellers, robot arms) and conduct a proof of concept under real-world conditions.

The advantages over tooling a prototype, especially a metal one, include iteration speed and lower cost. Fine-tuning your prototype over multiple 3D prints is ultimately far less expensive and time-consuming than tooling metal and enables you to innovate faster and get your product to market ahead of the competition.

Carbon Fiber Pros & Cons

PROS: Carbon Fiber

- Is a lightweight alternative to metal

- Creates parts that have industrial strength and stiffness

- Adds exceptional dimensional stability to polymers and helps avoid warping and shrinking

- Is used for both end-use parts and functional prototypes

- Creates parts that are resistant to corrosion, heat, oil, and grease

CONS: Carbon Fiber

- Is more expensive than most filaments without carbon fibers

- Is an extremely abrasive material that can wear down and clog some printer nozzles

- Makes your polymers more brittle

Know Your Carbon Fiber Printer Technology

There’s a growing range of better, smaller desktop carbon fiber 3D printers at work in machine shops, factories, and design firms around the world, so be sure to check out our guide to those. But here, we’ll explore the printers and technology among the top large-scale industrial carbon fiber 3D printers. The differences hinge on volume, speed, and features.

Which Carbon Fiber Method is Right for You?

When it comes to carbon fiber printers, there are three distinct kinds: carbon fiber-infused polymer filament, continuous carbon fiber, and composite fiber coextrusion, plus unique and up-and-coming technologies.

Carbon-Fiber-Infused Filament

First, and most common among desktop printers are the fused deposition modeling (FDM) printers that use carbon fiber-infused filament (among other kinds of filament) to lay down layer after layer of material. Almost any type of polymer filament can be infused with chopped carbon fiber bits, but nylon is the most common. Note, when you’re shopping for carbon fiber filament, be sure to find “chopped” carbon fiber-infused material and not “filled” carbon fiber, which is essentially carbon fiber powder and doesn’t add strength to your base polymer. To make it more confusing, there are even different grades of carbon fiber, so be sure to check out the material’s technical data sheet to see if it meets your requirements.

You might be thinking; How strong is chopped-up carbon fiber? Actually, the heat used to make the filament pliable and extrudable also aligns the embedded carbon fibers in the print direction, which gives the final print its strength and stiffness. A wide range of FDM printers can get hot enough to print with carbon fiber-infused filament but require a special nozzle because of the abrasive quality of the material.

Carbon fiber-infused filament can contain 15% or more carbon fibers. Some printers are “open material,” so they’ll print with a wide variety of third-party filaments, while others are limited to proprietary materials, which isn’t necessarily a drawback since you may experience better consistency with materials specially tuned to a specific printer.

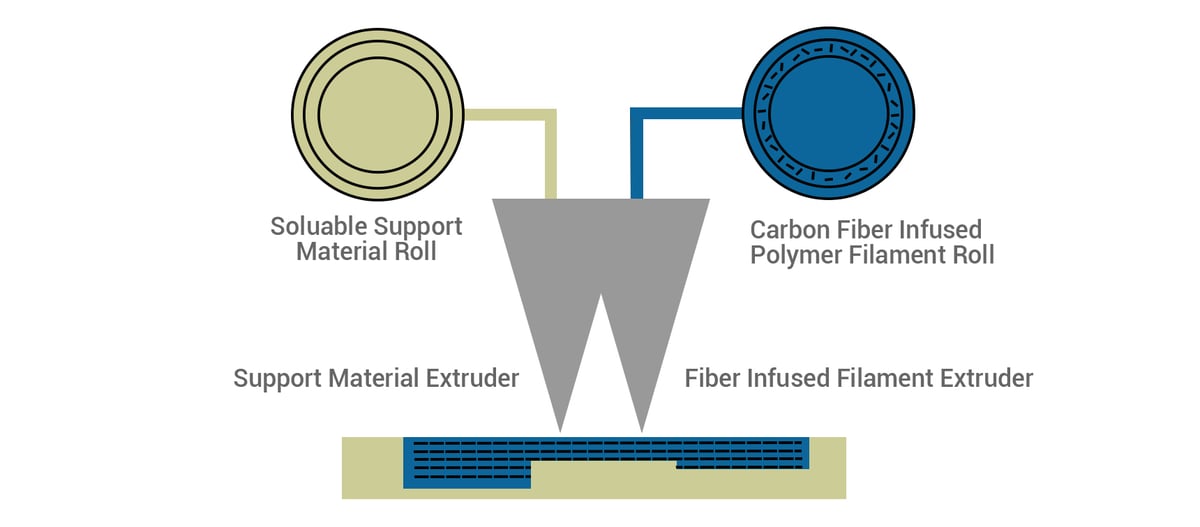

Continuous Carbon Fiber (CCF)

The second method of carbon fiber printing uses dual extruding nozzles; one lays down a layer of continuous carbon fiber (in a polymer coating, so it’s malleable), not chopped fibers, while the other lays down a layer of another material, such as nylon. This method using continuous carbon fiber strands creates parts that are stronger than using chopped fibers and provides a more consistent load distribution. This method is also ideal for parts that don’t require carbon fiber throughout but, instead, reinforcement in specific areas – just on the outer wall or inner lattice structure, for example.

If you guessed that an unbroken continuous carbon fiber makes for stronger parts than chopped fiber, you’re right. However, chopped carbon fiber filament shouldn’t be dismissed and is the more economical option. For the best of both worlds, you can use a chopped carbon fiber filament and a continuous carbon fiber strand together, although that may be overkill for most applications.

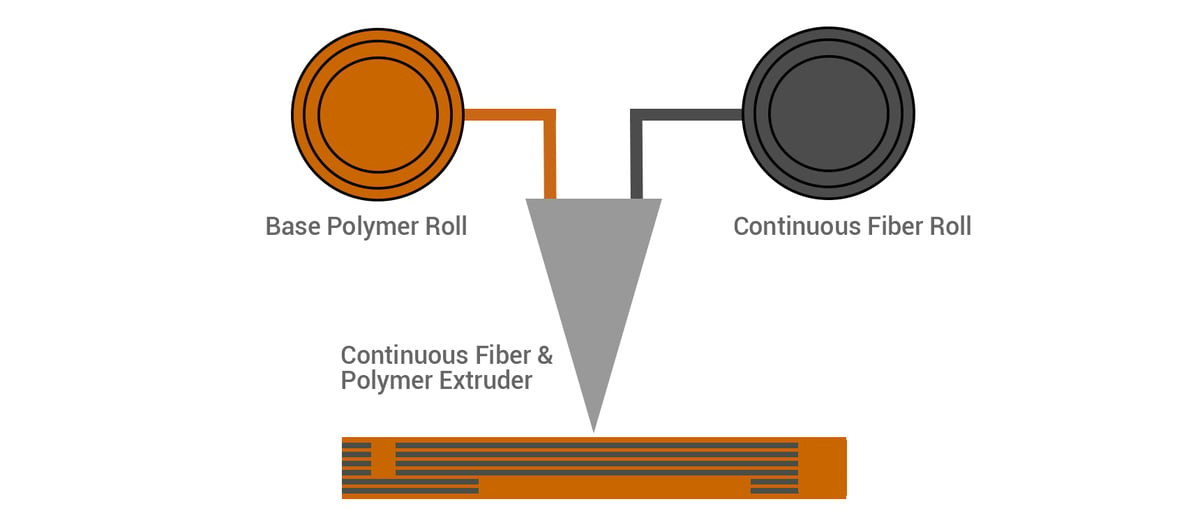

Continuous Fiber Coextrusion (CFC)

Another less common version of this approach is continuous fiber coextrusion, where a plastic material and a continuous fiber are merged inside a single extruder. The one company on our list taking this approach, Anisoprint (which has a printer set to launch in 2023) says merging these two in the extruder while printing ensures a better impregnation of fibers within the polymer. This option still gives you the opportunity to use the continuous fiber only where you want it.

Carbon Fiber Selective Laser Sintering (SLS)

Another type of carbon fiber 3D printing is called selective laser sintering (SLS), which uses a powder material, usually, nylon, which can be mixed with carbon fibers. A laser sinters the powder into the desired shape layer by layer. None of the 3D printers capable of printing with nylon carbon fiber powder are featured in this guide since we’re focusing on FDM printers, but you can find the top machines in our guide to the top SLS 3D printers.

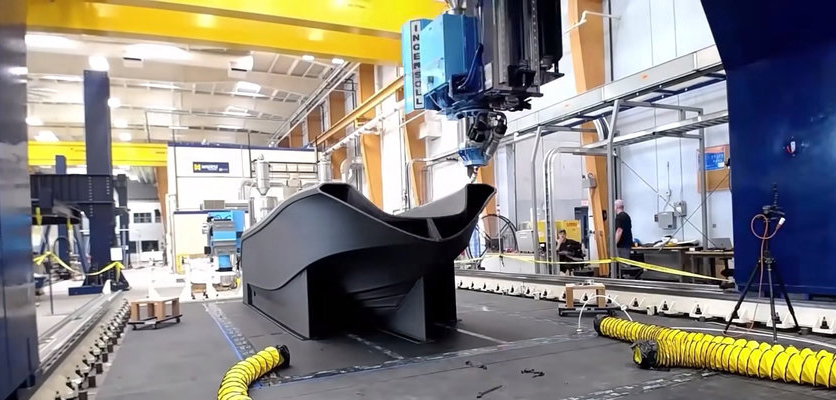

Other carbon fiber 3D printing technologies involve laminating sheets of carbon fiber, curing photopolymer resin-coated carbon fiber, or using a robotic arm 3D printer with nylon carbon fiber pellet materials.

If you’re interested in printing something the size of the 3D printed carbon-fiber boat pictured below, you’ll need a robotic arm 3D printer. These are covered in our separate guide on that technology.

Delta WASP 4070 ZX

Launched in April 2022, the Delta WASP 4070 ZX is a large format double-extruder 3D printer designed to print technical materials, such as carbon fiber-reinforced nylons.

The “ZX” replaces WASP’s popular Industrial X carbon fiber printer. WASP says the ZX features new motor drivers that make the printer much quieter and more precise, combined with new, more powerful stepper motors that give it greater solidity. The mechanics have also been renewed with the introduction of the new carbon arms, which halve the weight, and the new laminated safety glass doors to guarantee greater thermal stability within the print volume.

The actively heated chamber (up to 70 °C) is designed for technical thermoplastics while maintaining a relatively low temperature on the mechanics.

Another notable feature is the printer’s remote camera control enabling you to monitor and manage printing via mobile phone, tablet or computer. Other extras include a vacuum-controlled build plate for easy removal and a HEPA filter.

Fabbrix Elemento V2.1

With a large 1,000 x 560 x 530 mm print volume, a heated build plate to 100 °C, and a nozzle temp up to 300 °C, this dual-extruder industrial machine features an open-materials system and is capable of printing with nylon carbon fiber, PET, nylon glass fiber, BVOH, and more. Fabbrix also manufactures a wide range of filament for the printer.

Large, but built for workshop environments, the Elemento v2.1 features an air purification system fitted with a HEPA filter. It also has automatic print bed leveling and extruder lifting systems, and comes with four different nozzle sizes.

Fabbrix is the division of Crea3D, the large 3D printer and materials reseller.

MiniFactory Ultra 2

The latest version of miniFactory’s high-temperature FDM 3D printer, launched in November 2022, has some impressive performance enhancements that engineers will appreciate.

The new machine’s quality control software, called Aarni, is intended to give users a sense that the 3D printing processes going on in the build chamber are being monitored and recorded so that errors can be detected on the spot and successful prints are repeatable. Although most industrial FDM 3D printers today have onboard cameras for live monitoring, Aarni goes a step further and records the material history of the part, any operator information, snaps of each layer, and a full process history, all detailed in a “manufacturing report.”

The Ultra 2 is an update to the company’s flagship Ultra but “two times faster”, the company says. How is it twice as fast, you may wonder. The company will only reveal that “improved technical solutions together with software optimizations” are behind the new 120 mm/s print speed for amorphous high-performance polymers. The company uses a servo motor-driven system that is more accurate and repeatable than a belt system but a bit slower, they say.

The MiniFacyory Ultra 2 is a carbon fiber specialist with 15 carbon fiber materials on its menu, including carbon fiber HIPS, carbon fiber PEEK, carbon fiber Ultem, and carbon fiber PEKK. Plus, the Ultra 2 is an open material system that can handle a range of thermoplastics and features automatic calibration, automatic and integrated post-processing (annealing), plus an exchangeable carbon filter.

It takes the Ultra less than 30 minutes to heat and stabilize the printing chamber at 220 °C. The machine’s heated filament chamber also monitors the moisture and kicks on the heated drier when needed.

Aon3D M2+

The large-volume Aon M2+ is an industrial 3D printer built by Aon3D and designed for a range of applications, including tooling, jigs and fixtures, end-use parts, and rapid prototyping.

Specializing in high-performance thermoplastics, the M2+ prints carbon fiber PEEK and carbon fiber PAEK in its open-material environment. The M2+ features a higher-temp extruders (up to 500 ºC) with water-cooled hot ends to handle these composite materials and a range of configurable process parameters so you can dial in to suit your exact application.

There’s an actively heated build chamber (to 135 ºC) with temperature control for consistent part properties, the company says, and a bed system that uses a heated vacuum build plate to enable faster cycle times and configurable adhesion properties via build sheet choices.

Dual extruders would be assumed in any industrial FDM but the M2+’s independent dual extruders is somewhat of a novelty.

Aon3D has partnered with TÜV SÜD to certify the Aon M2+ to applicable CSA, UL, and CE standards.

Markforged X7 Gen 2

Straddling the divide between benchtop and fully industrial carbon fiber printer is the X7 from Massachusetts-based 3D printer manufacturer, Markforged. This industrial-grade 3D printing platform with a relatively small footprint features continuous carbon fiber and Kevlar reinforced materials for producing high-performance parts.

The X7 includes a strengthened dual nozzle system and a laser inspection process that scans parts mid-print to check the dimensional accuracy. Other features include a 330 x 270 x 200 mm build volume and a layer height of 50 microns.

Using the dual material system, the Markforged X7 is able to produce composite parts where the first nozzle builds the plastic matrix of the model while the second nozzle winds carbon fiber throughout the part. The X7 is a good option if space at your business is at a premium and you need a compact machine.

3DGence Industry F350

3DGence’s the Industry F350 is a dual extruder FDM 3D printer designed for industrial applications using high-performance thermoplastics, such as PEEK, PC, PA6, and PA-carbon fiber.

The F350 features a maximum nozzle temperature of 500 °C, a build volume of 340 x 340 x 350 mm, and a heated build chamber up to 140°C. The F350 offers users the choice between three interchangeable printheads with varying maximum hot end temperatures.

3DGence says the F350 is ideal as an end-use production machine with print speeds of up to 400 mm/s. All 3DGence printers come with the company’s cloud services that include running and queueing prints, remote monitoring of the printer and prints status, file sharing, live camera feed, and collection of the statistics.

The PA-CF filament recommended with the F350 contains about 20% carbon fiber.

Markforged FX20

The new FX20 is by far Markforged’s most ambitious industrial-grade 3D printer. It’s bigger, faster, and the company says “more sophisticated” than the rest of the Markforged family. Setting it apart is its ability to print with high-temperature Ultem 9085, a flame-retardant high-performance thermoplastic used to create tools and end-use parts in aerospace, automotive, and heavy industry. And not just Ultem, but carbon fiber reinforced Ultem.

Ultem has a lower impact strength relative to other high-performance plastics, such as PEEK and PEI, but is generally less expensive, so reinforcing this material with continuous fibers should solve the strength issue while remaining affordable. An extra large spool of Markforged’s Ultem 9085 filament is about $1,400 (still less than the same amount of PEEK).

The FX20 can print with the full line of Markforged materials.

Markforged says the FX20 is the most precise machine the company has ever produced and it’s massive compared to its little brother, the X7 featured above. Its turbo mode builds parts faster than any other Markforged machine, although the company doesn’t disclose an exact print speed.

The FX20 features a 7-inch touchscreen from which users can control every aspect of the printer. Automated calibration and leveling reduce operator input, while a wide variety of sensors give live feedback on machine performance. A material bay contains two active XL spools and can store two more with precise moisture control.

The FX20 runs on the Eiger software.

BigRep Pro

BigRep’s large-format industrial BigRep Pro is specifically tailored for industrial users, and the manufacturer says it can effortlessly produce full-scale parts from functional prototypes to tooling, patterns, molds, and end-use parts.

The machine comes with BigRep’s Advanced Capability Extruder (ACE) with a maximum temperature of 300 °C, enabling printing with both BigRep’s HI-Temp PA12 CF and third-party carbon fiber filaments. The PRO’s environmentally sealed filament chamber with a two-spool capacity ensures that all materials, including engineering-grade and water-soluble, remain dry in a consistent temperature and humidity-controlled environment.

BigRep Pro has an upgraded MXT Controls System that unifies the performance of all internal components. It also employs proprietary algorithms to improve G-code print files and enables Jumpstart, BigRep’s software-hardware solution for faster and easier printing.

The company also still offers the Studio G2 printer, featured on this list year. It’s still a capable industrial-scale printer with a slightly smaller chamber and a lower price tag.

Stratasys Fortus 450mc

Stratasys’ Fortus 450mc is the company’s industrial workhorse for carbon fiber printing, especially for tools and end-use parts that demand high strength and stiffness. The company says. the 450mc has a 93% print success rate for consistent, repeatable results.

Designed for efficiency, the Fortus 450mc is compatible with the Stratasys CAD-to-print GrabCAD Print software and features a touchscreen interface that requires little to no training to navigate, the company says. It also includes easy-to-replace build sheets and loading options. The Fortus 450mc uses Stratasys ProtectAM technology to provide various secure connectivity solutions, including STIG compliance, that satisfies U.S. government DOD requirements.

Even though the printer has a menu of more than 12 materials, its proprietary material platform was a turn-off to some, which may be behind the new OpenAM materials license announced in 2022. By paying a bit more, customers can now use third-party materials on the 450mc.

When it comes to carbon fiber, Stratasys’ proprietary FDM Nylon 12CF material has a 35% chopped carbon fiber filling by weight. If the 450mc isn’t big enough for your need, Stratasys also offers a much larger Fortus 900mc.

Roboze Argo 350

The Argo 350 from Roboze features a high-temperature build enclosure and nozzles to handle a wide range of technical polymers, such as carbon PEEK and carbon PA. The hot build chamber is designed to reduce the thermal shock of the material it is extruding out of its super-heated nozzles and to cool it down more slowly in order to reduce mechanical stress, the company says.

By eliminating the rubber belts typically used in the sector and introducing a patented movement system with gears, Roboze says its precision and accuracy align with the typical kinematics of industrial machine tools.

The 350 features a filament dryer, auto-leveling build plate, and a beltless printing system that the company says increases accuracy and reduces print time. It’s a single-extruder solution that uses chopped carbon fiber materials in a carbon nylon or carbon PEEK. The company’s Carbon PA Pro has 15% carbon fibers by volume, the Carbon Peek has 20%.

Argo 350 is equipped with remote control, to allow printing and status monitoring functions.

If you need more volume, Roboze offers the Argo 500 and the Argo 1000. Intended to replace metal parts in extreme end-user applications, like aerospace, the Argo 1000 machine bumps up the chamber size to 1,000 x 1,000 x 1,000 mm.

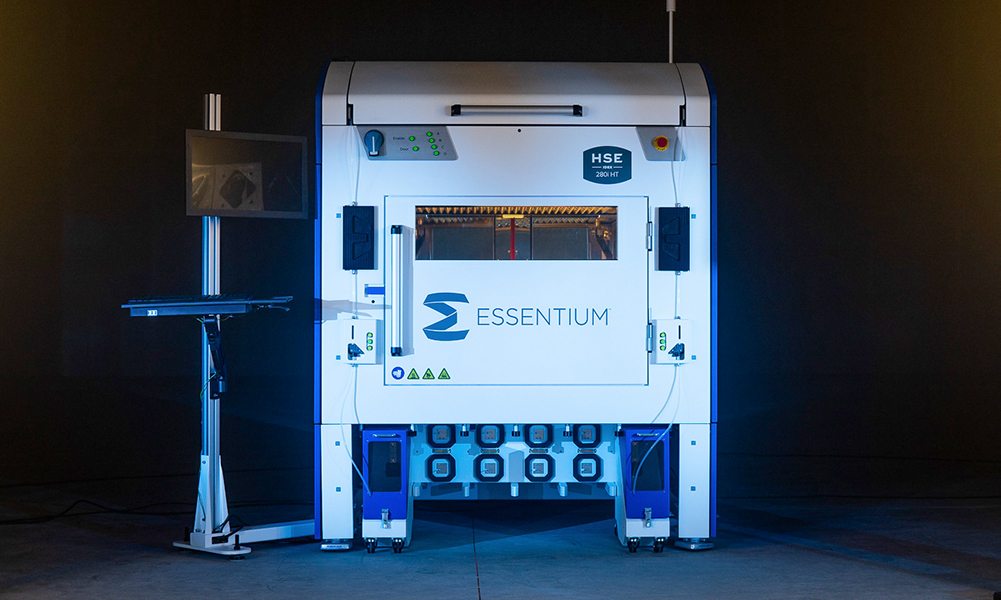

Essentium HSE 280i HT

Boasting some innovative features not seen on most other industrial-grade, high-temperature FDM 3D printers, the HSE (High Speed Extrusion) 280i HT from Essentium is aimed at high-volume factory customers. Take, for example, the heated build chamber that heats the part, not the entire chamber, with inferred energy that’s more tuneable and accurate, plus uses less overall energy, the company says.

More impressive, though, is the dual independent extruders that are actually independent on both the Y and X axes. This enables the printer to simultaneously create two different parts, such as two sides of a mold, in its massive well-sized chamber (695 x 495 x 600 mm).

The extruders can reach a maximum nozzle temperature of 550°C and the print speed is around 500 mm/s — more than 15 times faster than average, claims Essentium. The company offers five carbon-fiber-filled materials, including a 20% carbon fiber-reinforced polypropylene filament to complement the printer’s open ecosystem of materials.

There’s no proprietary software to learn since Essentium partners with Materialise and Simplify3D.

Titan Robotics Atlas-HS

Manufacturers needing a little bit of everything can find just that in the Atlas-HS from Titan Robotics, a 3D Systems company. The Atlas-HS’ hybrid additive and subtractive technology enables it to 3D print with both pellets and filament, while also including a three-axis milling system on the same gantry.

The pellet printing system can reduce material costs and increase deposition rates. It also supports hundreds of pellet materials, including carbon fiber-reinforced ones. In addition, the CNC-controlled milling unit shortens production times for end-use parts that require milling to achieve tighter tolerances.

Thanks to different tool head configurations, the Atlas-HS can print with two pellet extruders or a pellet and filament extruder simultaneously.

9T Labs Red Series

Unique on our list is the Red Series Additive Fusion Solution from start-up 9T labs. It is not solely a 3D printer but a hybrid continuous-fiber-reinforced solution consisting of two units; the 3D printer and the compression molder. Let’s explain.

By combining 3D printing with compression molding, which provides better surface finishes, the hybrid system offers the best of both additive and conventional manufacturing, the company says. This is especially handy for high-production volumes of continuous carbon-fiber end-use parts instead of unique tools or parts.

The Red Series consists of a build module and a fusion module (compact compression press providing preform consolidation and final part forming). The build module can be a stand-alone continuous carbon fiber, glass fiber, or basalt, 3D printer coupled with PEEK, PPS, nylon 12 or bio-based nylon. It features a dual extruder 400 °C nozzles, and heated material storage at 100 °C to avoid moisture intake.

The company says the print head has two deposition “feet”. The first one is for neat or chopped-fiber filament and the second one extrudes a unidirectional continuous fiber tape of 60% continuous fiber and 40% polymer. The tape and the filament must be with the same thermoplastic material if used in the same part.

The hardware is supported by 9T Labs’ Fibrify design software that takes your CAD files and optimizes the continuous fiber layups then syncs with your simulation tool of choice to verify structural performance.

Since the thermoplastic can be reprocessed, scrap material and parts can be recycled, and multiple 3D printed subassemblies can be “welded” together during the fusion step.

9T is collaborating with specialty polymer maker Solvay to develop a continuous fiber-reinforced PEEK, continuous fiber-reinforced bio-based high-performance polyamides, and continuous fiber-reinforced polyphenylene sulfide (CF/PPS) for use in 9T Labs platform. This material offering completes a portfolio already including continuous-fiber reinforced PEKK and PA11 from Arkema, and continuous-fiber reinforced PA12 from Evonik.

Carbon Fiber 3D Print Services

You can still get high-quality, carbon fiber 3D printed parts without investing in your own industrial carbon fiber 3D printer.

3D printing services experienced with carbon fiber materials can print your part from your CAD file or help you design the specific part you need. They can also further explain the benefits of printing in carbon fiber above other materials. Take a look at these companies below, many of which offer a free quote, to find the service that’s right for you or visit our guide to the Top Additive Manufacturing Service Companies.

Lead image source: Most of the carbon fiber 3D printed parts in the opening image are made by the printing service Weerg in Italy.

License: The text of "The Best Industrial Carbon Fiber 3D Printers" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.