Pick

- It can detect print failures

- Compact, but easy to handle

- Useful Wi-Fi & app experience

- Can't detect partial print failures

- Below average build height

Resin 3D printing is more affordable than ever. Sitting in the sweet spot between high resolution and large build volumes, medium-size machines are where the market is at these days. There’s more choice than ever, making it harder to pick out the good from the bang average (and the bad).

Now, when we talk about mid-size resin 3D printers, we’re thinking very specifically machines that offer build areas between 8 and 12 inches across the diagonal. The majority of these machines use LCDs as a key part of their resin-curing process, and we’re borrowing this common measurement to help us draw a line between the wide variety of machines available today.

We’ve gone hands-on with as many mid-size resin 3D printers as we can, including the latest releases, to bring you our recommendations. These are the best mid-sized resin 3D printers worth knowing about right now.

Desktop resin 3D printing is a messy process. And the larger the printer, the more resin involved, and the greater the potential for a toxic resin mess to clean up.

With this in mind, we place some weight in our consideration on the design of the printer – the measures it has in place to make handling it easier and less cumbersome. This could be easy-to-handle print plates and vats, large-volume vats, and enclosures that are easy to open and access. It’s nice when you don’t have to reach around the back of the printer to plug in the USB stick, too.

Of course, print volume and resolution each play a role, too. Newer LCDs with higher pixel counts mean that mid-size resin printers offer incredible print quality comparable to the smaller volume machines. Mid-size (and large-format) printers today let you print big without compromising on detail.

And not forgetting general usability. A large, user-friendly UI, connectivity options, and helpful support documentation to guide you through the process of updating, troubleshooting, and generally using the machine are also important.

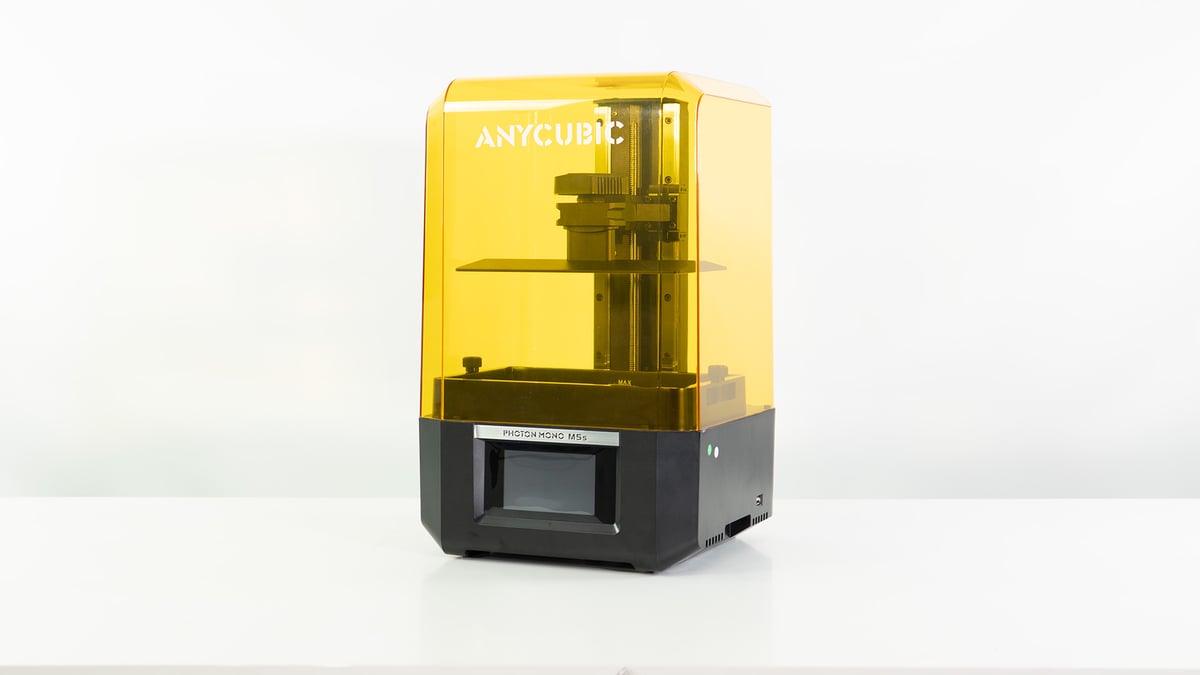

Anycubic’s shiny new Photon Mono M5s is a different breed of desktop resin printer that introduces print-boosting smarts – the likes of which we’ve only really seen in filament 3D printing over the last couple of years. Packing a print-plate gantry-mounted sensor, the M5s can detect peel force, resin level, and the vat bottom to effectively automate and augment your printing experience.

In testing, we didn’t find it to be flawless, but that this system pulls off even half of what it does makes the M5s our preferred choice over all the other desktop 3D printers we’ve experienced of late, even at its slight premium of $515. Not to mention, this is all in a compact frame, to boot – the Photon Mono M5s is barely any larger than the likes of the Phrozen Sonic Mini 8K S and Photon Mono 2; both machines we consider to be small 3D printers.

The M5s is ready to run right out of the box, running a short list of self-checks before letting you rattle off prints at its heightened prints speeds, made possible by an alternate vat film material that releases prints easily, less viscous resin that works better for fast printing, and, we’ll admit, some shenanigans with thick layer heights. It’s important to note that you can print quickly with the Photon Mono M5s and “standard” resins, but it’s more that blistering print speeds are achieved with specific “fast” materials and with a compromise in Z-axis quality.

With that said, the M5s packs a 12K 10.1-inch masking LCD that puts extremely small pixels at its disposal for super-fine print resolution. It’s as fine as you can get.

The usability of the M5s is higher than that of similar systems, too. Anycubic has gotten the Wi-Fi connectivity of the printer to sing, with a seamless link between the company’s software and hardware. You can also keep tabs on things using the company’s surprisingly slick mobile app, which gives you diagnostics of the printer, guides, tips, and a community aspect with models you can pipe to the printer at the click of a button.

It’s a quick and compact printer with layers of features that other printers fail to pull off – one for prioritizing convenience.

Elegoo’s resin 3D printers have always offered a degree of quality and completeness that others lack. This continues with the Elegoo Saturn 3.

And, at $399, the Saturn 3 costs much less than the Saturn 2 did at launch, making it an immediate budget pick for us.

If you prioritize the potential resolution of your prints, the Saturn 3 packs a 10.1 12K LCD, bringing its pixel size down to 19×24 microns; the same as the Anycubic Photon Mono M5s. And, being a marginal design update on the Saturn 2, it maintains the ergonomic and user-friendliness we value the series for including single-handed print plate removal, a solid thin-walled resin vat, and two-point ball-socket print plate leveling.

Other improvements include a 9H hardness layer of protection over the LCD, a fetching laser-etched print plate that looks pretty extra (in addition to providing a texture for prints to adhere to), and a USB-powered removable air filter.

All the Saturn 3 asks of you during set up is to level the print plate, a matter of loosening and tightening two chunky machine screws. Otherwise, there’s very little to the Saturn 3. For lack of other words, it just works. You prepare your model and slice it in your slicer of choice (there are machine definitions available for all major slicers), export the file to a USB stick, insert the stick in the machine, and hit print. No frills, just prints.

For the time being, too, the Saturn 3 includes a lifetime license of Voxeldance Tango: a premium slicer that’s gradually gaining traction as an alternative to freemium options like ChiTuBox and Lychee. We can’t speak to its efficacy or the experience it offers compared to those slicers – it didn’t adequately support the high-resolution display we tried to use it on – but a year’s unlimited access to it typically costs an eyewatering $720.

Little-known company UniFormation makes possibly the most user-friendly desktop resin 3D printer going. Period. From the print plate’s friction lock that you can operate with one hand to the resin vat sliding securely into place as opposed to fiddly thumbscrews found on every other budget resin 3D printer – the experience of using the Uniformation GKtwo is frictionless. It shouldn’t be understated how valuable this is given photopolymer resin’s utter nastiness and that you should minimize your contact with it.

Priced at approximately $899, the GKtwo costs a significant premium over our two other picks. However, its feature set is led by the knock-out punch of an actively heated resin vat. Programmable to heat to one of three toasty temperatures, this feature alone virtually guarantees print success, provided you did an adequate job leveling the print plate. Too cold a temperature contributes hugely to print failure, so such a system that helps you to save money and time is wild to see at this price point.

Following this, a suite of features is available here that most printers lack (certainly not all in one machine), including a hinged lid, which is tidier than the bucket lids prolific in budget resin 3D printing. You also get a large, responsive touchscreen UI that feels more modern than most others. You’ve got quick USB access from the printer’s front-facing port, too, plus the power button is front and center for easy power cycling.

Further ergonomic innovations include a print plate that lets resin run off effectively. There’s also a chunky air filter embedded in the case of the machine to help deodorize the air inside the print chamber. We wouldn’t rely on this alone for safety – always print in a ventilated space.

Underpinning print performance is a 10.3-inch 8K LCD, giving resolution not entirely up to par with the Photon Mono M5s and Saturn 3, but honestly, few would be able to tell the difference.

For how great the GKtwo is, there are a couple of quick gripes to mention. For one, the print plate is too heavy, making wielding it a little tricky. (That said, an ultrasonic cleaning station is available that accepts the plate perfectly and makes cleanup ultra-efficient – sold separately.) Secondly, you can’t alter print parameters after a print has started – a feature we’re seeing more often that lets you fine-tune a print without repeatedly slicing your model.

Editor’s note: A previous version of this article criticized UniFormation about the apparent lack of open-source licensing of PrusaSlicer for its own slicer, provided with the GKtwo. It turns out there is a GitHub repo with the source code from back in 2021, albeit with no direct link from the software or company site to suggest attribution.

We considered many resin 3D printers before arriving at our top picks above. Here’s a whistlestop tour of the other printers we’ve used and have been thinking about lately.

The Nova3D Whale 3 SE is a mid-size resin printer worth noticing, with 8K resolution across its 10-inch LCD. Wi-Fi connectivity (that we failed to get to work – unfortunately) and build quality that’s a little rough around the edges shouldn’t detract from the high print quality and reliability we’ve seen from it. At $599, it’s competitively priced against our top pick, the Anycubic Photon Mono M5s, but not nearly as user-friendly in our experience.

We also got to grips with the Creality Halot-Mage Pro, a printer we were pretty excited about until we actually went hands-on with it. There are a lot of good ideas at play – the automatic resin pump alone would be a dream if the implementation weren’t cheaply done and didn’t get in the way of using the printer. You have to fight to mount the resin vat with the pump properly positioned, and even then, with it being spring-loaded to return to its upright position, you risk flicking resin onto yourself. Other issues that require deeper troubleshooting put paid to our time testing it. We’ll persist with it to see if it’s worth a recommendation when operating as it should, but for now, it’s a pass from us. A year of ChiTuBox Pro is included in the box, which is a mighty proposition considering the Halot-Mage Pro’s already low price tag of $399.

Elegoo’s deluxe Saturn 3 Ultra has also occupied a spot in our print lab. It seems that, with a new Linux-based OS, Elegoo has some kinks to iron out with this new heavy-duty variant of the Saturn series before it’ll match up to the standard of it-just-works we’ve come to expect of the lineup. It has some advantages over its sibling printers, including a hefty ball screw driving the print plate motion (promising greater accuracy and repeatability over the leadscrews used in most printers). Wi-Fi connectivity, ACF release film for speedy printing, and, again, a super value-add in a lifetime Voxeldance Tango license up the appeal of the Saturn 3 Ultra, but we suspect it’s a price jump ($100 over the Saturn 3) only superusers will really benefit from.

Below, you’ll find a changelog mentioning things that have changed, so you can see our past recommendations and how the machines, and our opinions, have changed. The moment we test a printer that deserves to be known, it goes on this list.

Update –July 19, 2023: A flurry of new releases has stormed into our recommendations for the best mid-size resin 3D printer. Goodbye, Elegoo Saturn 2, Saturn S, and Phrozen Sonic Mighty 8K. Hello, Anycubic Photon Mono M5s, Elegoo Saturn 3, and Uniformation GKtwo. Also, our thoughts on more printers we’ve tested but not gonged on this go around can be found in the “Other Machines” section – check it out.

Update – May 2, 2023: No changes to our lineup, although we’ve gone hands-on with a small handful of new machines, which are now included in our “Other Machines” section. We didn’t feel any of them were good enough to unseat our current recommendations, all of which are a little cheaper than they were at the time of our last update.

Update – November 24, 2022: We’ve gone about and updated the pricing and some of the runner-ups mentioned in our “Other Machines” section. None of them merit a change in our top picks, though. They still are the best medium-sized resin 3D printers currently out there, period.

Update – July 16, 2022: Previously, we’d lump medium-sized resin 3D printers alongside large-format resin 3D printers in one guide. But with the widening gulf between these mid and large-format machines, we thought it high time we split them into two different guides. This new article focuses solely on what we consider to be the mid-sized resin 3D printer. You can find our large-format picks over in our guide to the best large-format resin 3D printers.

If there’s one thing that testing a lot of 3D printers has taught us, it’s that maintaining a broad benchmarking scheme for 3D printers is impractical for getting a sense of what a 3D printer is like to use and live with. Holding a sub-$200 self-assembled printer for hobbyists to the standard of a $6,000 production machine designed to handle engineering-grade materials won’t tell you that the former is a breeze to set up and the latter a tangled web of firmware updates, buggy systems, and unreliable performance.

We want our reviews and buyer’s guides to cut straight to the chase. What is it like to use a printer? What are the defining features like? What didn’t we like? And, more importantly, is it worth the money? We don’t want to get bogged down benchmarking numbers out of context or hung up on issues affected by more variables than we can control.

Our buyer’s guides and reviews take the intended end user of a 3D printer into consideration. We imagine what they’re likely to do with it and focus the testing on challenging this. If we have a large-volume printer, for example, we’ll be printing – surprise, surprise – large prints, making use of the entire bed, and checking the performance at the limits of Z-height.

Other points of consideration for what makes the best 3D printer include ease of use, supporting software, and repair options. If something goes wrong, how easy is it to fix the machine? Does the documentation or customer service provide adequate information?

We strive to answer all these questions and more in our quest to find the best 3D printer for you.

Trust is important to All3DP, so our product testing policy is strict. When sourcing test units from a manufacturer, we do so under a zero guarantees policy. We make no guarantee of coverage in exchange for the printer, and the first time a manufacturer sees what we think is when we publish the content.

If a manufacturer doesn’t reclaim the unit after testing is complete, it is donated to a local cause or goes into deep storage for responsible disposal later. We occasionally buy machines for testing, too. In such cases, machines purchased by All3DP either remain in the office for team usage or are donated or disposed of in the manner described above.

Manufacturers or benefactors donating units for review do not influence the outcome or content of the reviews we produce. To the best of our ability, we will investigate abnormal issues with the manufacturer to glean better context or get insight into their awareness of the problem. But we make no excuses for poor design or bad QA.

One method we monetize our content at no additional cost to the reader is through affiliate product links. If you click on a shopping link featured in our buyer’s guides and reviews, we may receive a small commission from the store if make a purchase. This is at no additional cost to you. For more meaty content policy details, we cover it all in the advertising and commercial activities section of our terms of use.

For most readers, our top recommended 3D printers are your best bet in a given category.

But, facing the fact that there is no one-size-fits-all solution to home 3D printing, we’re here to help. Here are some pointers to orient you in this terminologically dense but wonderful world. (A word on terminology, we have a handy glossary of terms to know at to bottom of this article.)

Many 3D printers pitched for “beginners” or children go to such lengths to baby the user that they quickly become claustrophobic experiences. You will encounter more limitations than possibilities as your experience grows. If you aren’t satisfied with a “beginner” 3D printer’s features, we’d recommend a budget pick instead. You’ll save a little money, and the opportunity to learn by doing is far greater. And if something goes wrong, there are giant tribes online for each printer that have already asked and answered every question under the sun.

While the general quality of budget 3D printers has dramatically improved in recent years, quality control is often lacking. While manufacturers with large user bases are adapting to meet the demands of their newfound fans, including better customer support, there are usually better wells of knowledge to be found in the owners themselves, who contribute to the vast forum knowledge bases for some 3D printers.

We have zero obligation to manufacturers to sugarcoat what we find, and the first time they read it is when you do too. That’s why you can trust our reviews. We don’t pander to anyone, and our experience with the printer is what you read on the page.

If you can’t find any information about a printer you’d like to know more about, let us know at editors@all3dp.com.

A 3D printer for the home is rarely ever a one-and-done investment. Besides the continual purchase of materials, maintenance costs on perishable printer parts can stack up – think nozzles on an FDM printer or FEP film on an MSLA machine. Of course, parts can wear down or break, too, meaning sourcing replacement parts is a sensible consideration if you plan to print long-term. Printers with roots in the RepRap movement and open-source designs will be easiest to source parts for, with off-the-shelf components part and parcel of the design ethos behind them. Enclosed-design printers aimed at beginners may offer the gentlest introduction to printing, but your options to source spare parts will often be limited to the manufacturer. That’s if you can even get to and diagnose the problem.

The thrill of a new hobby will only sustain you so far. Being the desktopification of an otherwise complicated manufacturing process, expect to encounter, sooner or later, problems with a home 3D printer – even the occasional show-stopping issue. Having an end goal in mind for your printing gives you purpose and a reason to learn the solutions to the problems. Printing simply because it looks cool will result in a small mountain of useless doodads and, eventually, disinterest at the hands of cost, frustration, and the buildup of useless plastic trash.

Most home 3D printers are single extrusion fused deposition modeling machines, meaning a single printable material extruded through a single nozzle. Versatile enough for many applications through material compatibility, they’re safe machines to start with. But if you know you need to print objects with challenging geometries or semi-enclosed volumes, a dual extrusion printer would make your printing far easier. Likewise, single objects that need to have different material properties will only be achievable with dual extrusion. A resin printer will be the way to go for high-detail miniatures. Understand the technologies to find a printer that best suits your needs.

While the size of FDM 3D printers can vary greatly, the spillover is small. You’ll get some emissions from the filament melting, cloying the air, making it inadvisable to spend prolonged periods nearby. Generally speaking, the cleanup is minor and relatively easy to contain, depending on the models you print.

Resin 3D printing, however, is dramatically different and has unique demands that should make you think twice before investing. To varying degrees, the resin is smelly and toxic to you and the environment. It requires dedicated cleanup stations and personal protective equipment. You typically need 95 %+ isopropanol to clean prints and dissolve uncured resin from surfaces.

All printers should be operated in well-ventilated spaces, but this applies doubly to resin 3D printers.

While many excellent 3D printers have gotten their big break on Kickstarter, there’s the unavoidable issue that the platform is not a store. You are not buying a printer when you commit money to a campaign on Kickstarter; you are backing a vision. It’s putting money into the pot to help a company or person trying to achieve something.

You get nothing in return if a project is grossly mishandled and the money disappears. Often what you do get is the beta version of the product. You are paying for early access and all the wrinkles across all stages of the product that come with it.

We’re seeing more big-name companies turning to Kickstarter than ever to launch their products – it’s a safe way for them to gauge demand and drum up some interest against the pressure of a ticking countdown. Despite many companies being capable of outright launching products, they go cap-in-hand to enthusiasts with the promise of shiny new tech. Don’t be that user unless you absolutely must be the first to use a product and have money you can afford to lose.

We don’t think it’s worth the risk, but in the interest of cool new tech, report on new campaigns with our news coverage. You will never see a Kickstarter 3D printer in our buyer’s guides unless it has completed its campaign and the printer is widely available at retail, with all the protections that come with buying from a store.

But where’s the UltiMaker? Or Formlabs? What about Raise3D? Desktop Metal?

In the past, we’d list the best professional 3D printers alongside what we consider consumer or hobby-oriented machines (the printers we mainly focus on). An apples and oranges comparison, we know.

With this in mind, we created All3DP Pro, a wing of our content exclusively covering the professional applications of 3D printing and additive manufacturing solutions. Here’s a selection of articles covering the best 3D printers for professional use to get you started.

Choosing the best 3D printer is tricky, not least because the terminology surrounding 3D printing is dense. Here are some need-to-know terms, their explanations, and useful links to help you on your way to 3D printing mastery.

FDM: Fused deposition modeling, otherwise known as FDM, is a 3D printing process that extrudes heated thermoplastic material through a moving nozzle to build an object layer by layer. FDM is a trademarked term, which led to the RepRap open-source movement to coin the alternative phrase “fused filament fabrication” (FFF), but the two are interchangeable.

Filament: Filament is the base material used to 3D print objects via FDM. The filament is typically a solid thermoplastic fed to a print head, heated to its melting point, and extruded through a small nozzle. Filament is commonly available in spools of either 1.75 mm, 2.85 mm, or 3 mm diameter widths – dimensions that dictate the printers that can use them.

G-Code: G-code is the machine language used to instruct computerized tools such as 3D printers. Giving coordinates and instructions for tool heads and other non-movement functions, it is almost exclusively generated by slicing software. It comprises a library of commands to control specific actions like motion, speed, rotation, depth, and other related switches and sensors used in a machine’s operation. You can get to grips with G-code in no time with our guide to G-code commands.

Heated bed: This is a build plate that is heated so that the few layers of extruded plastic are prevented from cooling too quickly and then warping. A heated bed is essential for working with ABS or PETG materials but not so much with PLA.

Hot end: This is the cluster of components that heat and melt the plastic for deposition through the nozzle.

Extruder: Used by some to describe the entire system of parts that pushes and melts filament, extruder can also refer specifically to the motor and accompanying gears that grip the filament, feeding it to the hot end. How the extruder is arranged can affect the printer and its capabilities. There are two common arrangements: Bowden and direct. It’s a messy subject with overlapping terms and technical explanations; our guide to 3D printer extruders gives you all the knowledge to make sense of it.

Bowden: A style of extruder that sees the extruder motor positioned away from the hot end – typically the structural frame of the printer or on one end of the X-axis gantry. So-called for the Bowden cable and its action of allowing a wire to move freely within tightly constraining tubing, the Bowden extruder feeds filament through a PTFE tube directly into the hot end.

Direct Extruder: The other commonly seen extruder type, a direct extruder sees the extruder motor and associated feeding mechanism mounted directly to the hot end, with barely any distance between the feed and the melt zone of the hot end.

Dual Extrusion: Some 3D printers carry two extruders/hot ends, allowing them to incorporate multiple colors or materials into the same print job. While the obvious appeal comes from the possibility for decorative two-tone prints, the real benefit of dual extrusion systems is combining different materials, such as dissolvable support material, to enable the printing of otherwise impossible geometries. It’s a deep topic worth exploring more in our guide to all you need to know about dual extrusion.

PLA: Polylactic Acid, otherwise known as PLA, is a thermoplastic commonly used as a material for printing with FDM 3D printers. It’s easy to work with and is available in many colors and finishes. PLA is somewhat brittle – don’t expect to print strong items with it – but it remains popular for decorative printing thanks to its low cost. You can learn more about PLA in our guide dedicated to the topic.

SLA: Stereolithography is a 3D printing technology that falls under the broader process of vat photopolymerization. The term is often (incorrectly) used to describe all methods of vat polymerization – really, it’s a particular technology that uses a directed laser beam to trace layers into a vat of liquid photopolymer resin. Alongside SLA, other technologies are considered vat polymerization.

Resin: The material used in desktop SLA, DLP, and LCD (MSLA) 3D printers. A blend of chemicals that includes a photoinitiator, resin solidifies under ultraviolet light. Highly toxic and difficult to clean up after a spill, care, attention, and personal protective equipment are musts when working with resin. It is an unpleasant material, and wastage must be disposed of in accordance with local laws. Despite all the warnings, it’s the only way to go for intricate detail.

LCD 3D Printer: A common term for resin 3D printers that use an LCD as a layer mask over UV light. The de facto standard in inexpensive resin 3D printers, the technology is cheap and widely used. The LCD panels are consumable, though, with monochrome LCDs typically having lifespans in the low 1,000s of hours.

MSLA: Mask stereolithography (MSLA) is a term coined by Structo but popularized by Prusa Research. It refers to, basically, the LCD 3D printer as described above.

Micron: One-thousandth of a millimeter. This unit of measurement is commonly used in 3D printing as a value to indicate accuracy, resolution, or surface finish.

Slicer: 3D printing works by building an object layer by layer. A slicer is a program that divides a 3D model into flat layers and generates the machine code for the printer to trace out said layers. The output of a slicer for FDM 3D printers is typically G-code, which gives instructions and coordinates for the printer to execute. Our deep dive explaining what exactly a slicer is gives good foundational knowledge. Many popular slicers are free and open source. Others are proprietary and machine-specific. It’s an essential tool for successful 3D printing.

STL: STL is the most popular file format for 3D printing. Developed by 3D Systems in the ’80s, the STL file type only contains the surface geometry of a 3D object. Despite industry efforts to move onto more efficient and data-rich formats such as 3mf, STL endures and is the most commonly found 3D model file type on popular 3D model file repositories. We explain in more detail in our guide to what exactly STL is.

Open Source: The term given to a product, typically software, but also applicable to hardware that is freely open for others to modify and redistribute according to their needs. In 3D printing, this is often in the spirit that individuals are free to modify, improve, and share changes to the source material for others to test, iterate, and reciprocate. Open source licenses govern the fair and correct usage of open source works, giving terms and conditions that ensure the freedom of access to the creation and any derivatives.

RepRap: A project started in 2005 by Dr. Adrian Bowyer, a mechanical engineering lecturer at the University of Bath. Created to develop a replicating rapid prototype, a low-cost machine capable of printing replacement parts for itself or other new machines. The vast majority of desktop 3D printers stem from the work laid down by the RepRap project. We have a fascinating alternative RepRap Wiki page on the topic if you want to dig deeper.

License: The text of "The Best Mid-Sized Resin 3D Printers of 2023" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.