As the name suggests, laser cutters use a thin and focused laser beam to melt, burn, or vaporize certain materials, creating the cut or etch you need for your custom designs, patterns, and shapes.

Since its invention in the early 1960s, laser cutting has found a home in industries such as electronics, medicine, aerospace, automotive, and semiconductors. One of the most common applications is for cutting metal – whether tungsten, steel, aluminum, brass, or nickel – because lasers deliver clean cuts and smooth finishes.

Lasers are also great for cutting wood, glass, paper, metal, plastic, and even some gemstones. To add to their versatility, no special tools are needed for producing more intricate designs.

Naturally, the specifics of what you can cut (and how efficiently) will depend on what kind of laser you’re using. In order to compare the main types of lasers, it would first be helpful to understand what’s going on under the hood. So, after that, we’ll take a look at other aspects of laser cutting, including the type of software you need, how to design for laser cutting, and what to consider if you’re looking to buy one of these bad boys for yourself. Let’s dive in!

How Laser Cutting Works

The process of laser cutting, namely the selective burning or melting away of material – including metals – makes it obvious that we are talking about some pretty powerful light. But how is this light different from the light coming off the screen you’re reading this article from? Well, the answer is right in the name: “Laser” is actually an abbreviation of “light amplification by stimulated emission of radiation”. Let’s break that down.

Without getting too detailed, the light we see is usually made up of a range of different wavelengths (which we interpret into colors), heading in all directions, and out of sync. Laser light is generated by the ability of certain materials to take one form of energy input and convert it into energy in the form of light with a corresponding wavelength. The same material will always emit the same wavelength, and smaller wavelengths have the highest energy. When we arrange for enough of a material to emit its wavelength at the same time, direct all the resulting waves in exactly the same direction, and filter out any out-of-sync waves, then we’ll end up with light strong enough to literally cut through metal. Pretty impressive.

And by directing this powerful light using instructions in the form of G-code, one can cut a custom design out of a wide range of materials at home, and even more in professional settings.

So now, let’s take a peek inside the machine so we can establish some important terminology that will help us later when we compare the different types of laser cutters.

Core Components

For our purposes, there are three main parts to a laser cutting tool that operates within a machine.

The Laser Resonator

A newly generated light source will often require assistance from a laser resonator, a component that refines the laser beam and amplifies its strength. The material responsible for this amplification, also called a gain medium, will vary between the different types of lasers. Highly reflective mirrors may also be involved in directing the laser beam.

The Cutting Head

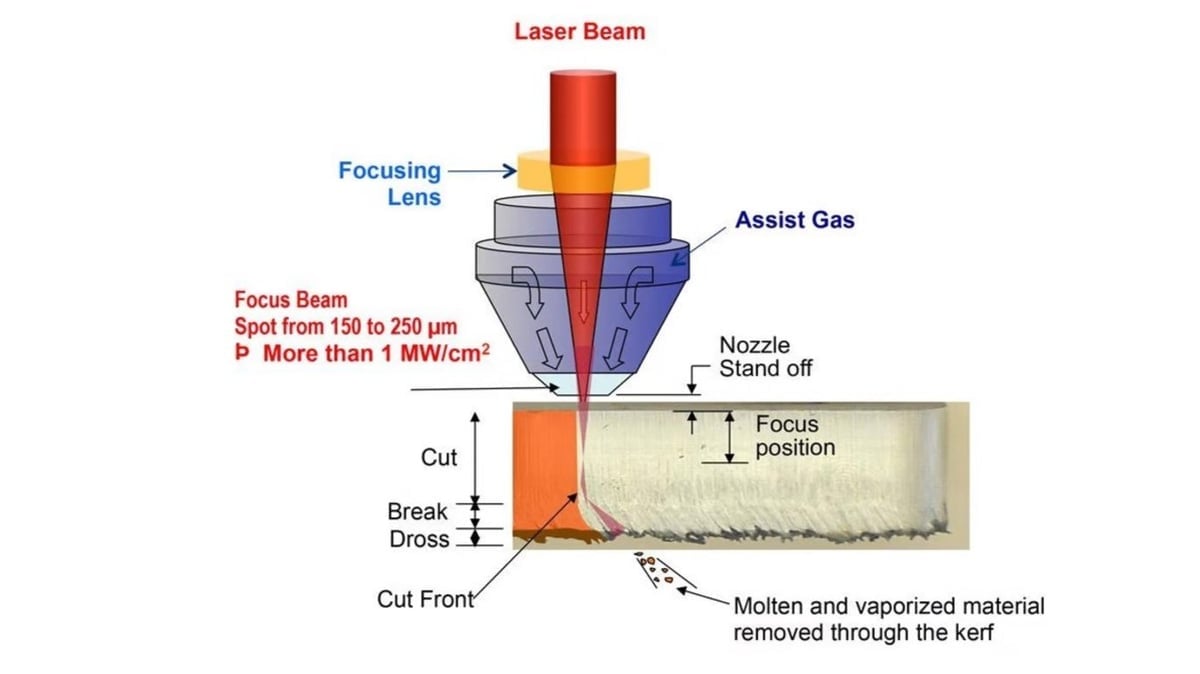

After the laser light gains enough strength by bouncing around in the resonator, it arrives at the cutting head. Here, the light passes through a curved mirror or lens to be focused into a thin, concentrated beam able to cut or raster. The focal point of the lens needs to be on the surface of the material being cut. At all times during cutting, an accurate distance is maintained between the plate and the cutting head in order to maintain the focal point and thus a high-quality cut.

The Beam

The beam itself, for most at-home machines, is typically between 0.1 and 0.3 mm in diameter and has an optical power output between 5 to 50 kW, but professional machines that can cut through metal slabs can (and need to) go even higher. For use on reflective materials like aluminum and copper alloys, the power needs are much greater to compensate for losses due to reflectance.

In addition to these three components, some laser cutters will also employ pressurized gas to aid the process. Let’s check out how!

Three Major Varieties of Laser Cutting

Depending on the material you’re cutting, blowing pressurized gas into the kerf (the slit in the material made by cutting) can aid in efficiency. Three of the most common approaches to this are the following:

- Reactive cutting: Also called flame cutting, oxygen is blown into the kerf at high pressure. This will readily oxidize heated metal, making it significantly weaker. This reaction also provides more heat and improves the energy efficiency of the laser. However, you may sacrifice the quality of the cut as the fresh edges of your material may oxidize as well.

- Melt and blow: Also called fusion cutting, an inert gas (typically nitrogen) blows molten material out of the kerf, significantly reducing the power that is required. The material is first heated up until it reaches its melting point, then the gas blows it out. This is best for thicker metal materials.

- Remote rutting: At a larger working distance (or distance from the material), a high-intensity laser beam partially evaporates (ablates) the material, enabling thin sheets to be cut without the need for an assist gas.

Now that we have the basics covered, let’s take a look at the different types of laser cutters and how they work!

Types of Laser Cutters

As we’ve seen, the main components of a laser cutter all lead to one consistent element, which is the laser beam itself. There are, however, a few different ways that the beam can be generated, so let’s have a look at what they are.

CO2

A CO2 laser is generated by sending an electrical current through a glass tube filled with CO2 and other gases like nitrogen and helium. As the electricity flowing through the tube aggravates the gases, it causes them to produce light. The light bounces around some cleverly placed mirrors at the end of the airtight glass tube before being focused by a lens and exiting the device, hitting the surface of the material you’re working with.

CO2 lasers emit a 10.6-mm wavelength, which is enough energy to pierce through a quarter-inch slab of solid wood in one pass. These lasers can give a smooth finish when used to cut thicker materials. CO2 lasers are the most common types of laser cutters because they’re efficient, inexpensive, and can cut and raster several materials. Budget- and beginner-friendly devices are also called K40 laser cutters, named for their typical 40-watt specs.

That said, CO2 lasers have upsides and downsides. Positives include a smooth cutting finish and a relatively quick straight-line speed (compared to other forms of laser), but they’re also pretty sensitive machines. With their combination of mirrors and glass tubing, they’re quite fragile and need perfect alignment to function at their best. This results in more expensive upkeep and servicing costs in terms of both time and money. Still, this is balanced by their initial affordability.

- Materials: Wood (solid and plywood), cardboard and paper, leather, acrylic, some plastics and rubbers, some metals

- Difficulty: Intermediate

- Cost: $2,000-$5,000

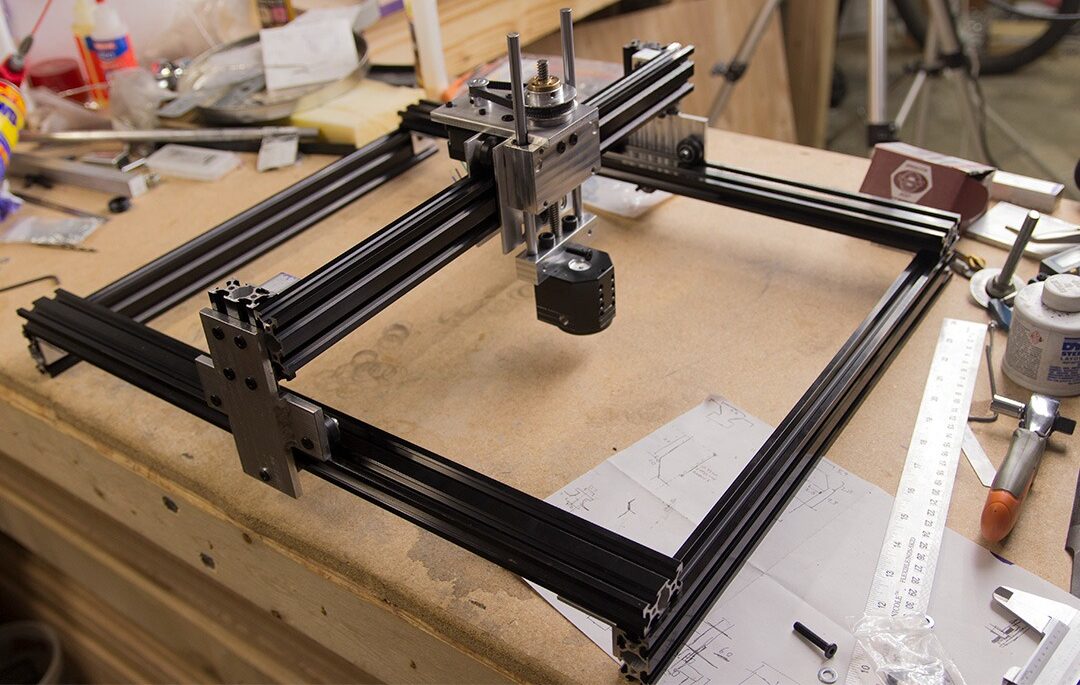

Diode

Diode laser cutters generate beams from crystals like Nd:YVO (neodymium-doped yttrium ortho-vanadate) and Nd:YAG (neodymium-doped yttrium aluminum garnet), but there’s no need to get caught up in the crystal structure. Essentially, diode lasers use those special semiconductor diodes, sort of like the diodes in LEDs, to generate highly directional light with a wavelength on the visible light spectrum between 550 nm to 950 nm. A gain material may not be needed, but a focusing lens is a must.

You may notice that there are two colors of laser used for cutting: red and blue. This difference indicates that the lasers aren’t the same wavelength, and are best suited for different use cases. The blue laser has a shorter wavelength, so it can create deeper cuts and reduce blurring to give a more accurate finish on shiny surfaces. The red laser is more prone to reflecting back to the detector on shiny surfaces and therefore miscalculating the distance, leading to inaccurate cuts. The red laser is therefore better suited to non-reflective surfaces.

While diode lasers are far more limited than other laser technologies in terms of raw power, they’re quite affordable, making them extremely popular engraving and cutting machines among makers. If you’re not picky about working with softer materials, you can save quite a bit by opting for this technology.

- Materials: Wood (solid and plywood), cardboard and paper, leather, acrylic

- Difficulty: Beginner

- Cost: $500-$1,500

Fiber

In a fiber laser, the laser itself is generated by feeding an initial light source through an optical fiber that is doped with rare-earth elements (such as erbium, ytterbium, or neodymium). The laser light, within the optical fiber, travels through the laser resonator where it gets filtered and amplified. The guidance by the optical fiber allows for extremely efficient filtering and amplification of wavelengths that make this cutting method quite powerful, and in fact, too aggressive for soft materials like wood and plastic.

On an industrial level, they’re often deployed to cut thin sheets of metal for production components. In desktop form, they’re fairly rare and very expensive machines. Though somewhat similar in concept to diode lasers, fiber lasers require less maintenance as they have fewer moving parts. They’re also far more electrically efficient than CO2 lasers, meaning that they cost less to run in terms of power. Thus, they offer a more economical and longer-lasting alternative to other laser cutters in professional and heavy-use scenarios.

Unfortunately, the price of the technology itself tends to make fiber lasers very difficult to obtain, meaning fiber lasers are few and far between in All3DP’s buyer’s guides.

- Materials: Metals, some plastics

- Difficulty: Professional

- Cost: $15,000-$20,000

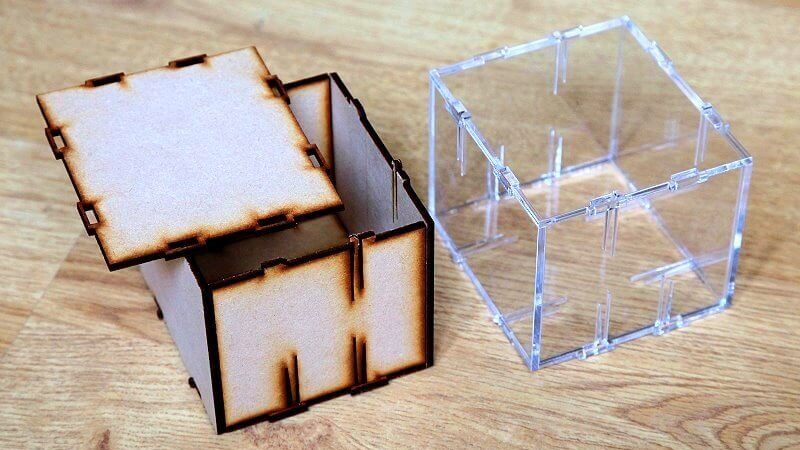

Materials

Laser cutters can be used with multiple materials. Most commonly, you’ll find them being used with wood, leather, metals, paper and cardboard, acrylic, and even glass. Some of these materials are easier to work with than others, and each will require its own approach and methods to achieve the best results. It’s important to research what material you want to cut before buying your machine, as well as the appropriate methods for cutting, as some machines won’t work with all materials.

If you’re looking to work with wood or acrylics, CO2 laser cutters are likely the way to go. This type of laser cutter will give you the most flexibility when it comes to material selection. Depending on your machine, you may be able to use a CO2 laser cutter on plastics and certain metals like aluminum. Some CO2 laser engravers can also be used to cut thin materials like cardboard.

Diode laser cutters have a particularly difficult time cutting reflective and clear materials. Because of this, you may also have a more difficult time cutting metals, although it’s possible with the right preparation. On the other hand, if you’re mostly sticking to wood and paper-based projects, a diode laser is a safe, low-maintenance, and budget-friendly option.

If your needs are primarily cutting metal slabs of thick plastics, then it may be time to consider a fiber laser. As mentioned, fiber laser is so powerful that it’s not recommended for softer materials.

Software

Laser cutting software comes in two different flavors: design and control. Design software is the tool by which you create a design that you want to laser cut. Control software handles the machine and the commands it needs to get on with the job.

With some machines, the software will be provided for you. This is the case with Full Spectrum Laser, which provides a piece of browser-based control software called RetinaEngrave v3.0 with its machine. This software was developed by the company itself, so it ought to work pretty flawlessly with its own machines.

Some machines will require you to source (and pay for) your own laser software. You do have the option of using free ones, but many users believe that paying for quality software is crucial in obtaining good results from your laser cutter. It’s a cost to factor into your purchasing budget.

Let’s check out the most popular choices for laser cutting software!

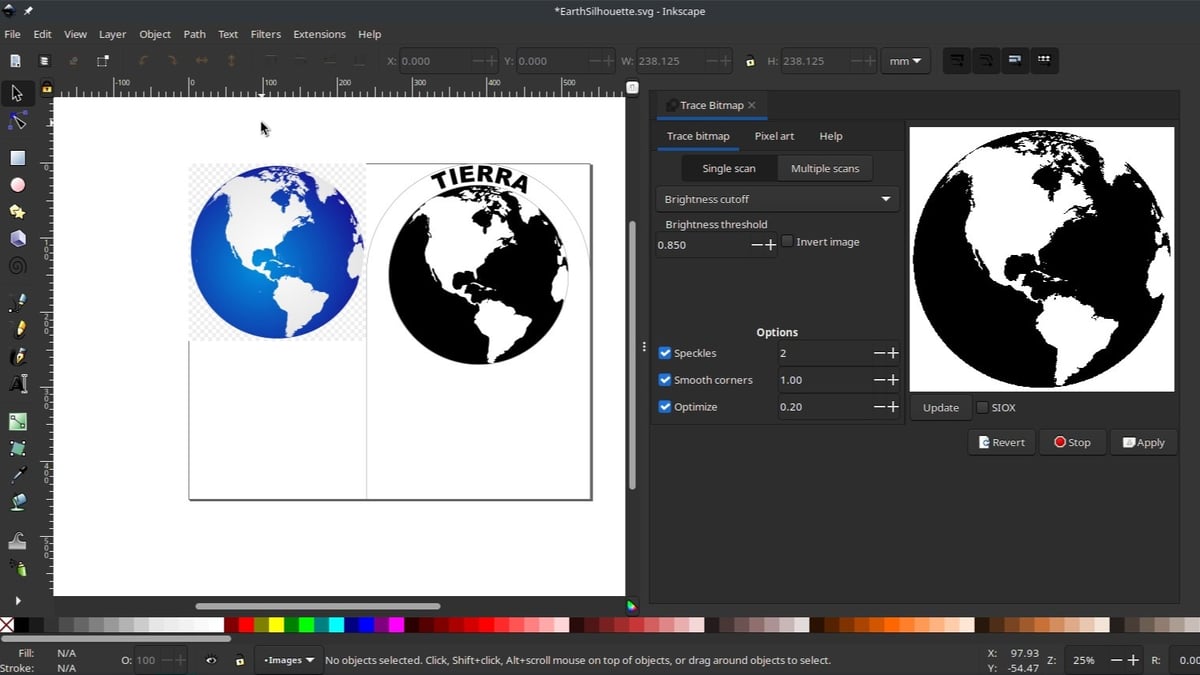

Inkscape

Inkscape is free, professional-grade design software. It’s been developed by a large team of people and is open source. This powerful vector graphics editor can be used to create all kinds of designs and images and has a superb reputation among community members who use it. A number of user-created extensions add to its abilities, and it’s available for Windows, Linux, and Mac.

With an extension, like the Inkscape Laser Tool Plug-In by JTech Photonics, Inkscape can be used to create files for laser cutting by exporting a 2D G-code file.

Affinity Designer

To round off the design software, Affinity Designer is for Mac and Windows, as well as being optimized to run on iPad, according to its maker. Marketed as a “stripped back, pro-end workhorse,” Affinity Designer is a perfectly viable alternative to the likes of Adobe Illustrator that feature separate workspaces for vector and raster files.

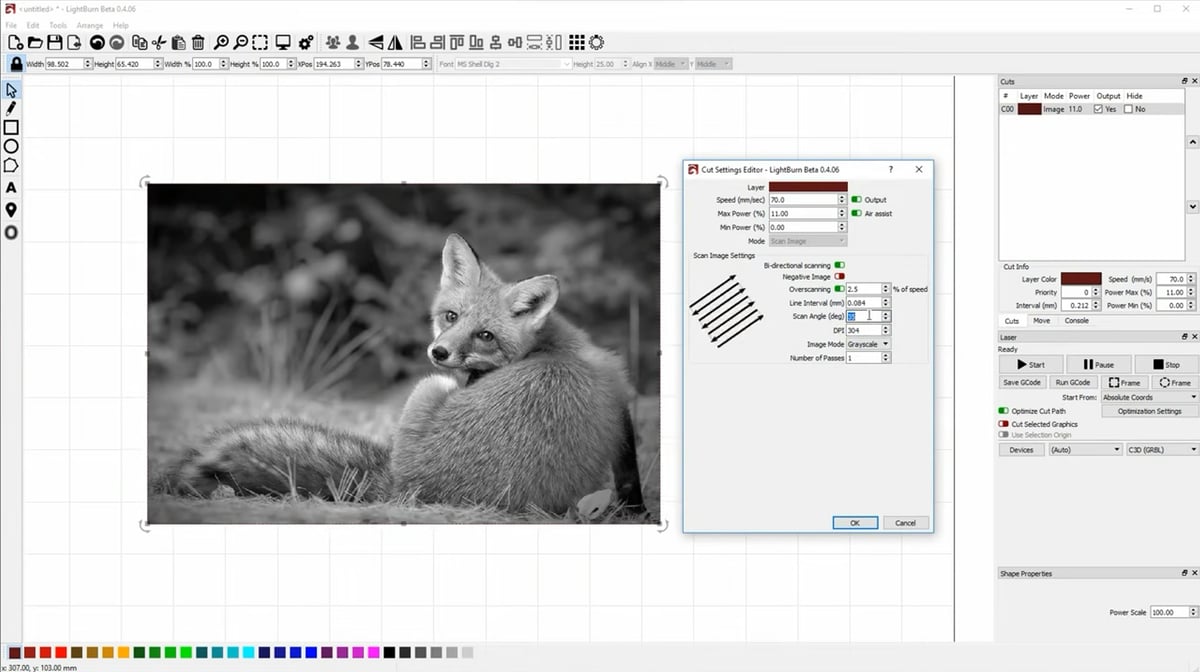

LightBurn

In terms of control software, LightBurn has a great reputation among the maker community and is often the first port of call for those upgrading from free software. Costing around $60, it isn’t a huge expense for the benefits that it brings: namely the number of options and flexibility with regard to laser settings, as well as design and layout. You can create and edit designs in this software, then go straight into adjusting the laser cutting settings. LightBurn is, for many, a must-have when it comes to laser cutting or engraving, but there are several other options out there.

LaserGRBL

As a free alternative to LightBurn, LaserGRBL makes a great control option for those looking for a no-frills software or beginner hobbyists. It includes all the basic operations and machine control that one would need to get started with laser cutting, but lacks many design options that LightBurn has, so you may opt for another program to create the design. Pleanty of makers in the community rely on LaserGRBL for their cutting machines, so it may be worth giving it a shot before you invest in something more expensive.

Applications

Laser cutters are famed for their precision and ability to assist in a wide variety of tasks. Away from the workshops of hobbyists, lasers are used in all kinds of industries, from medical to automotive.

One example of industrial laser cutters is in the automotive sector, where laser cutting is used from the initial design stage right through to the final production line. In the design process, a laser cutter is used to create precision working models of the final vehicle and to produce prototypes of intricate parts and circuitry. Once the vehicle has been designed and reaches production, laser cutters again come into play, but this time in conjunction with robotic systems which move both the laser and the part to perform precision cutting.

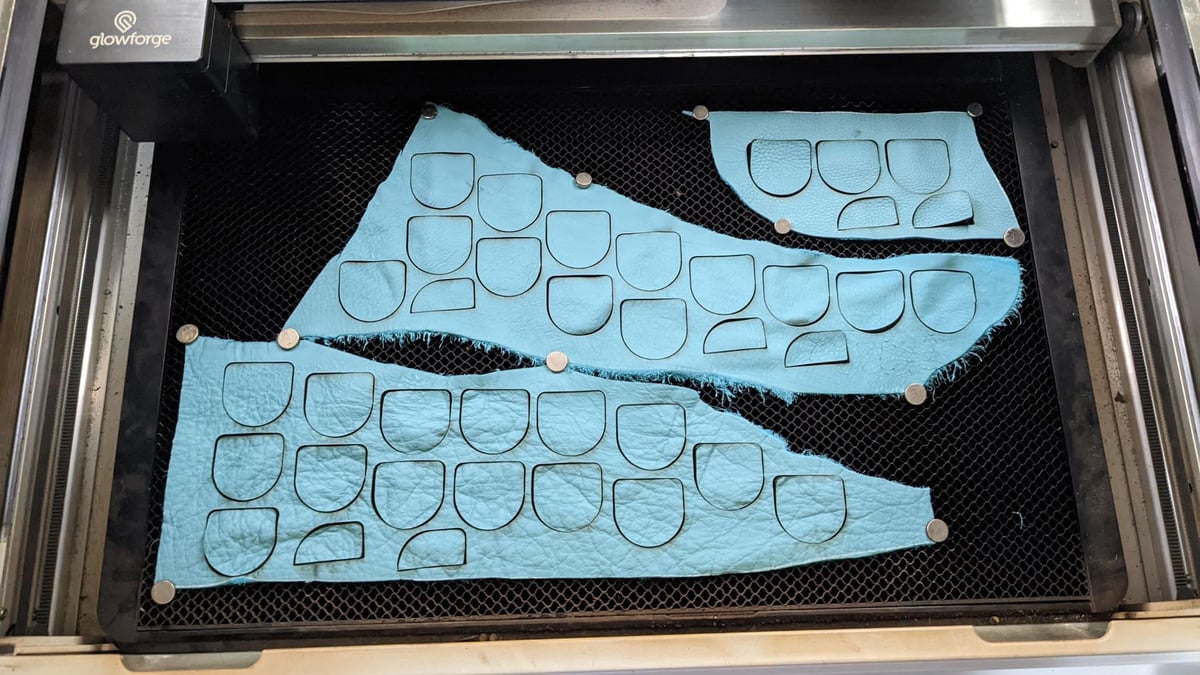

Back in the workshop, laser cutters are often used to cut (and engrave) wood, leather, cardboard, and more for crafted goods like wallets, jewelry, lighting fixtures, and signage. Projects can range from small decorative items to whole pieces of furniture. It’s not uncommon for hobbyists to utilize machines like this to produce items with added personalization or logos. These are then often found for sale on popular online sites like Etsy or at craft fairs.

Designing for Laser Cutting

While the designer’s imagination is theoretically the only limitation to what can be created, here are some general guidelines when designing for laser cutting:

- Know your machine: The design must meet the technical requirements of your machine control. Trying to convert a file may lead to a loss of detail. Also, familiarize yourself with the minimum and maximum material dimensions.

- Check the material thickness: Details cannot be smaller than the material thickness. If you want to make a hole, for instance, its diameter should at least be larger than the thickness of the material. As a rule of thumb, let the distance between cuts be 2x the material thickness.

- The law of physics always applies: When you cut out a piece of metal, it’s going to fall off unless there’s a connecting piece in the design.

- Show restraint: Your design will fall apart or become fragile when you have many lines intersecting at the same point.

- Closely examine the details: Zoom into the detail of your design and ensure intersections meet where needed.

- Watch out for bend reliefs: Improper bend reliefs won’t give you a good cut straight off the laser.

- Save material by nesting: When you have multiple components to cut, having an optimal arrangement by nesting the designs can help you save time and material. There are some great software out there to do the heavy lifting for you.

If you’re looking for some design inspiration, there are plenty of files designed for laser cutting to be found in online repositories in addition to sites like Instructables. Luckily for you, we have compiled a list of our favorites.

Buying a Laser Cutter

No matter what kind of laser cutter you’re going for, there are several things to keep in mind before you head to the checkout. While we can’t tell you exactly what will and won’t work for your projects, here are some key considerations when shopping for a laser cutter:

- Support: Several vendors stock cheap laser cutters, but are they reliable enough to provide you with the necessary support when your machine breaks down? How easy is it to find replacement parts?

- Size: The bed size puts a limit on the size of the material you can work with. A bigger bed will let you cut multiple pieces at once, while a smaller bed will only allow you to work on one material at a time.

- Power: The more wattage, the more powerful your machine is. And remember, more power means you will cut faster and more reliably. It also means you’ll have higher operational costs.

- Compatible materials: You can’t just pick any material and start blasting it with a laser. The composition of the material should guide you when selecting the right laser cutter. Also, note that some materials catch fire while others produce toxic fumes.

License: The text of "What Is a Laser Cutter? – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.