Going Up

3D printers, sometimes known incorrectly as “3D printing machines”, are additive manufacturing machines that specialize in making custom parts with accuracy.

As the name suggests, 3D printers add material, layer-by-layer, to form a 3D object. Virtually any geometry can be 3D printed, including some that cannot be made with other traditional processes.

Thirty years ago, 3D printers were large, expensive, and used primarily for prototyping and modeling industrial parts. Over the last decade, costs have dropped dramatically to the point where most hobbyists or machine shops can afford an entire rack of these little wonders. Machining and molding operations that were once limited to high-end CNC mills and complicated injection molding systems can now be done on everyone’s desktop. Not only has the technology improved, but costs have also dropped, as well.

Printing materials have evolved too: You can now print with dozens of plastic variations, metal, and even carbon fiber composites. From synthetic steak to turbine blades, 3D printing has become the technology that does it all.

How It Works

The three most popular forms of 3D printing are fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). SLS is primarily an industrial process, while FDM and SLA cover the gamut from high-end industrial manufacturing to simple desktop units.

3D printers are classified as “additive” for a reason. Unlike CNC mills, which have to remove material using rotary cutters, additive processes build up objects one layer at a time. Specialized software “slices” a 3D model into layers as thin as .05 mm for fused printers, and as thin as .01 mm for SLA processes. These layers are then deposited by the print process, slowly building up a 3D object.

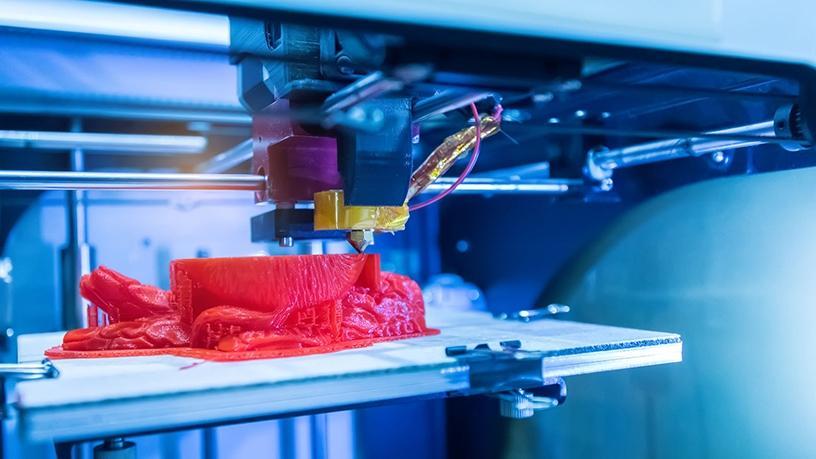

FDM – Flexible & Affordable

If you’re looking to try 3D printing, you can’t go wrong with a fused deposition modeling (FDM) printer. FDM was the first technology to properly reach the hobbyist level, and it’s been continuously improved for the past decade. Perfectly good printers can be had for under $200, while larger print volumes and tighter tolerances drive prices up to several thousand dollars. Our guide can help you choose the right FDM printer for your needs.

Keep in mind that, although the ‘F’ in FDM stands for “fused”, the only requirement for FDM 3D printing “ink” is that it sticks to itself. Heated nozzles are used to print plastic and other materials that can be melted for printing, but if you’re printing food, living cells, or other non-fusable materials, the nozzle stays cool.

The range of FDM materials is quite extensive, ranging from simple plastics (PLA, ABS, PET, and nylon) to more esoteric materials, like carbon fiber, wood fiber, as well as metallic and conductive materials. Turn off the heaters in the print head and plate, and FDM printers can be used to print batter, ceramic paste, chocolate, and various other materials.

FDM printers are nearly unlimited in capacity. Besides the mundane, folks have printed cars, human organs, and even an entire house. On the other hand, if tiny details are what you need, look to the oldest 3D printing process…

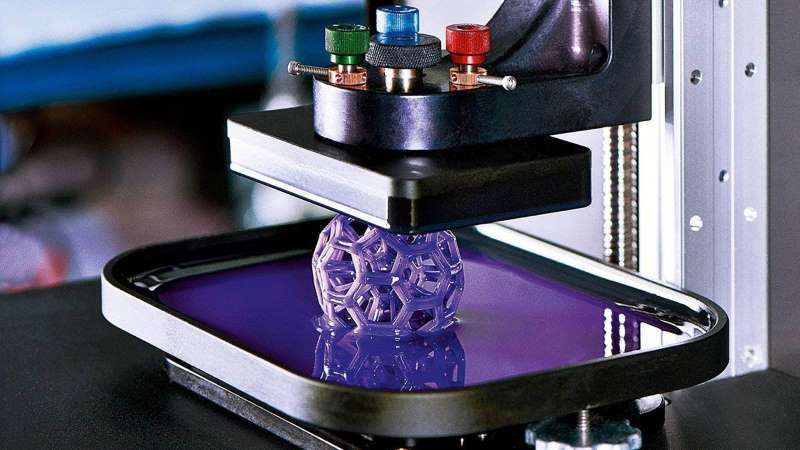

SLA – First & Finest

Stereolithography (or SLA) was the first additive manufacturing technology to leave the laboratory, but until recently, it was too expensive for non-industrial users. That’s because SLA uses ultraviolet light to harden a light-sensitive liquid resin.

Like an FDM printer, SLA prints its objects from the bottom up. But unlike FDM, which prints objects from the plate upwards, SLA most often prints from the plate downwards. This difference and many more make FDM and SLA rather different processes. Recent advances in SLA resin and masking technology have made these units as cheap as FDM printers, with prices starting around $200.

SLA is capable of much finer detail, limited only to the resolution of the laser (or projector or LED screen, if you’re interested in DLP or LCD). Downsides include the cost of the resin, a messy manufacturing process, and materials that are often toxic. SLA objects also require cleaning and further hardening under a UV light source, whereas FDM objects are usable right off the printer.

SLS – Industrial Powerhouse

Looking to build a gas turbine? Then selective laser sintering (SLS) may be the 3D printing technology for you.

SLS often steps in where conventional machining processes fail. If a part requires hidden cavities or contours that cannot be created by a cutter on a spindle, SLS may be the only way to create the part. Besides, SLS is often faster than conventional machining and is being used more and more for small production runs of high-value parts. The only constraint is the strength of the sintered material compared to its solid counterpart.

While quite a bit more expensive than FDM printers, prices for these SLS machines, like most 3D printing tools, are dropping. You can also check out our guide on the latest SLS printers from entry-level to semi-pro.

Many of the hobbyist-level SLS printers actually use powdered plastic as a feedstock. Metal SLS processes still operate mainly in the industrial realm, where the technology is typically referred to as selective laser melting (SLM) or direct metal laser sintering (DMLS).

Dive In!

3D printers are quickly becoming the rechargeable drill of the 21st century: Every household needs one. Break a knob on the stove? Print one up in ABS on your FDM printer. Captivated by the detail on the miniature figures from the hobby shop but scared off by the prices? Build as many as you want on your SLA printer.

And because 3D printing is becoming more and more accessible, there’s never been a better time to start printing. Then again, some of these processes are quite complex and could require technical expertise.

If you just need parts made without the fuss, you’ll want to use a professional 3D printing service. In that case, Craftcloud by All3DP, might be for you. Upload your parts and get a quote from top services worldwide, instantly!

(Lead image source: MachineDesign)