What Is It?

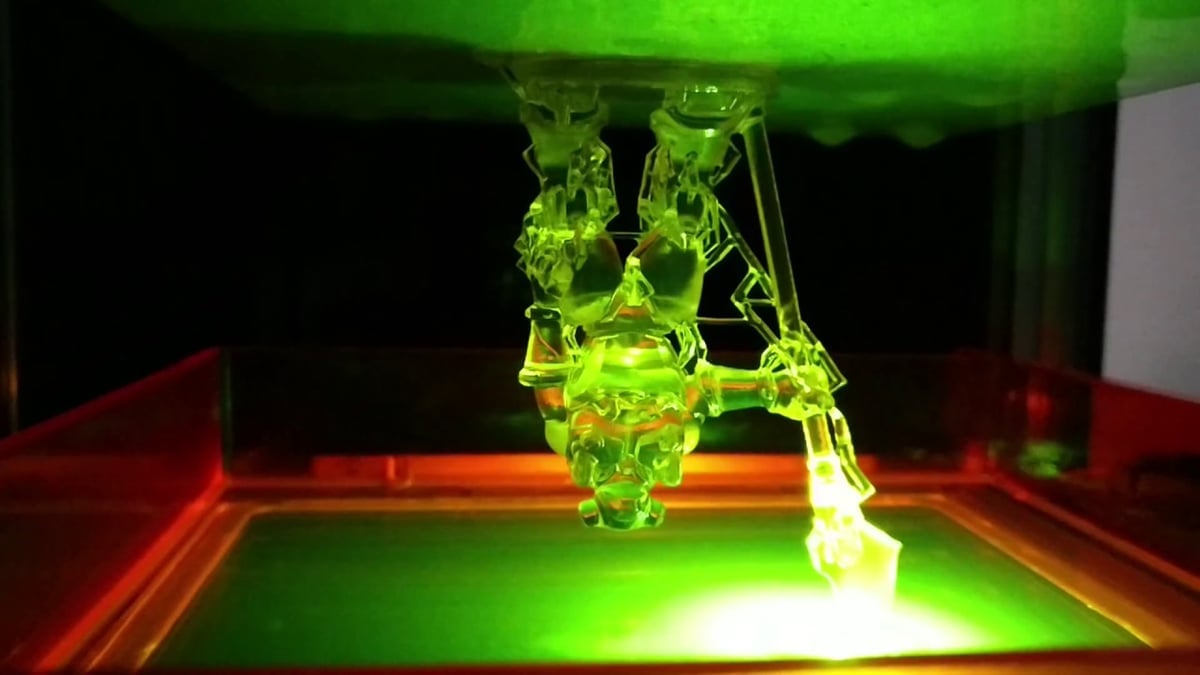

When you think of UV 3D printers, you probably think of the amazing videos in which an object is grown out of liquid inside the 3D printer. The liquid in question is a photosensitive resin that solidifies when exposed to light, therefore creating a layer of a part. However, the term “UV 3D printer” isn’t always correct, as some of these types of printers use different light sources to cure the resin. The proper term for resin 3D printers is as simple as that: resin 3D printers.

As you’d expect, there are multiple resin 3D printing technologies. The differences are found not just in the light sources, but also in how resin is stored and distributed during printing.

Resin-based 3D printing in which a liquid photopolymer resin is stored in a vat (as opposed to being jetted through a nozzle) is collectively known as vat polymerization. This includes technologies such as stereolithography (SLA), digital light processing (DLP), and LCD (similar to DLP; also called mSLA). The term “vat polymerization” was even officially defined by the International Organization of Standardization (ISO) with the goal of promoting greater efficiency in industry communication.

Outside of vat polymerization, there’s also material jetting, a unique technology that jets resin droplets onto the build plate while simultaneously curing them with UV light. Material jetting is one of the fastest and most accurate 3D printing technologies.

There’s quite a lot to wrap your head around, but don’t worry, we’ve got you covered! To give you the best possible overview of resin 3D printing, each of these technologies is further explained below.

Stereolithography (SLA)

Although many people might think FDM was the first 3D printing technology, that title actually belongs to SLA, a technology first patented almost 40 years ago.

SLA is a very precise 3D printing technology thanks to the combined nature of the laser and the resin. An SLA 3D printer consists of a vat (a resin tank), a build platform, an elevator, a light source, and a pair of galvanometers.

The build platform sits above the vat and is fixed to the elevator, which is used to raise and lower the build platform during printing. Beneath it all, under the transparent bottom of the vat are the galvanometers. These are a set of movable mirrors used to point the laser beam. Galvanometers directs where the laser beam to the bottom of the vat according to a precise set of coordinates.

The light source used in most SLA 3D printers is a solid-state laser. When the laser beam hits the resin tank, guided by the galvanometers, it cures the resin at that specific point. When the laser has finished curing a layer, the build platform is elevated by the height of one layer, and the process is repeated until the part is complete.

Types of SLA Printers

There are two types of SLA 3D printers. and they’re differentiated by the direction of the movement of the build platform and where the light source is placed.

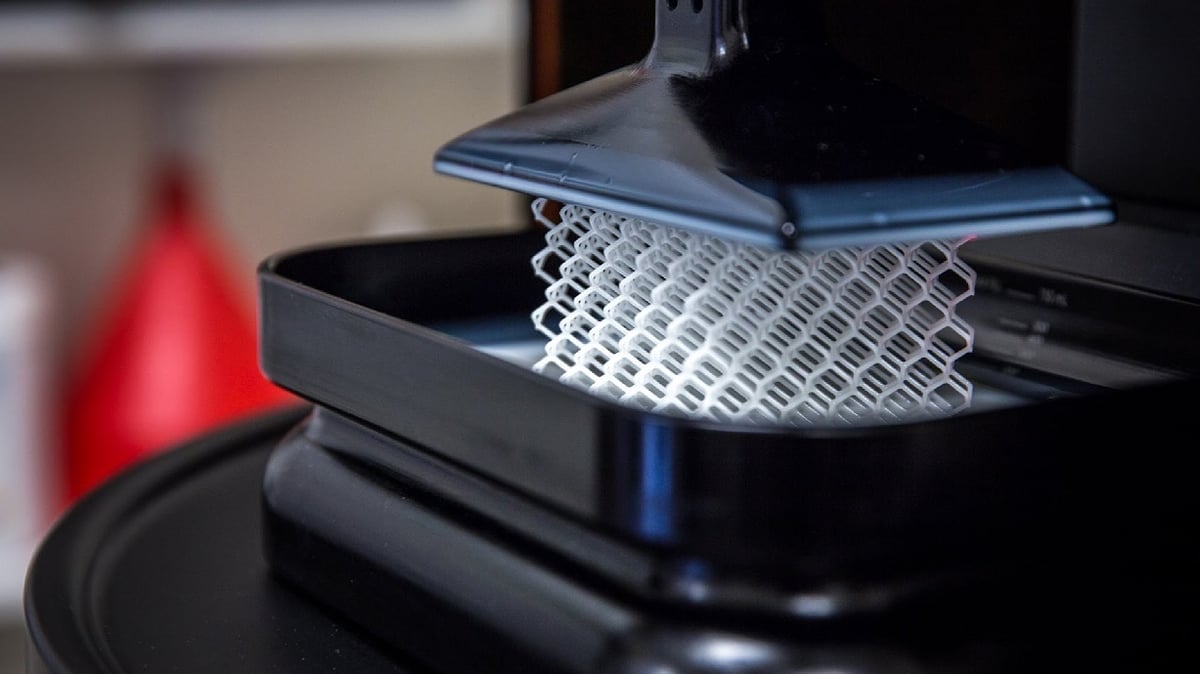

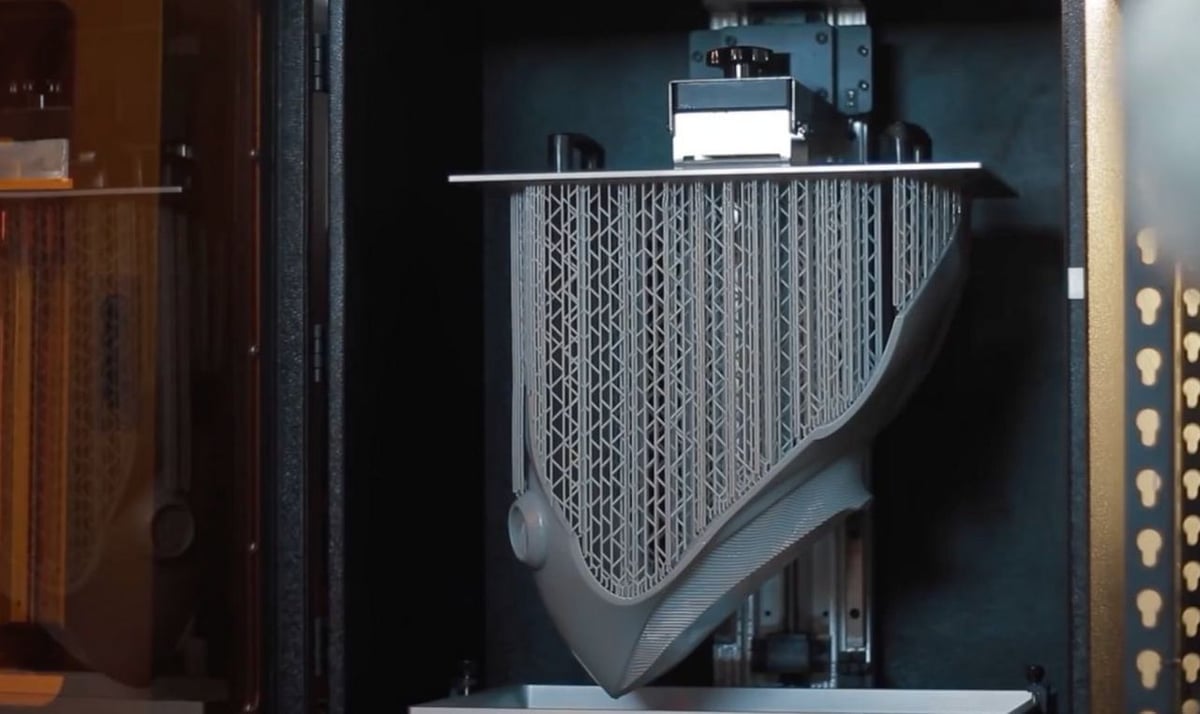

The majority of SLA 3D printers are inverted (or bottom-up), meaning that the light source is positioned under the resin tank. When looking at a timelapse video of a bottom-up SLA 3D printer in operation, it looks like the part is being pulled out of the resin tank. Popular examples of this type of printer include Formlabs’s Form 3 and the Peopoly Moai.

The other type is the so-called top-down SLA 3D printer. Here, the light source is positioned above the resin tank and build platform. When starting a 3D print on a top-down SLA 3D printer, there’s a single layer of resin on the build platform. Once the light source cures that layer, the build platform moves down into the vat, meaning the final part will be completely submerged in resin.

- Light source: UV laser

- Pros: smooth surfaces, high and constant precision

- Cons: build speed decreases as the print area grows, risk of warping with bigger flat surfaces

- Price: $1,000+ (with the majority falling around the $2,000 mark)

- Popular examples: Formlabs Form 3, Peopoly Moai

Digital Light Processing (DLP)

DLP is a technology similar to SLA, but instead of a laser, DLP uses a digital projector screen as a light source.

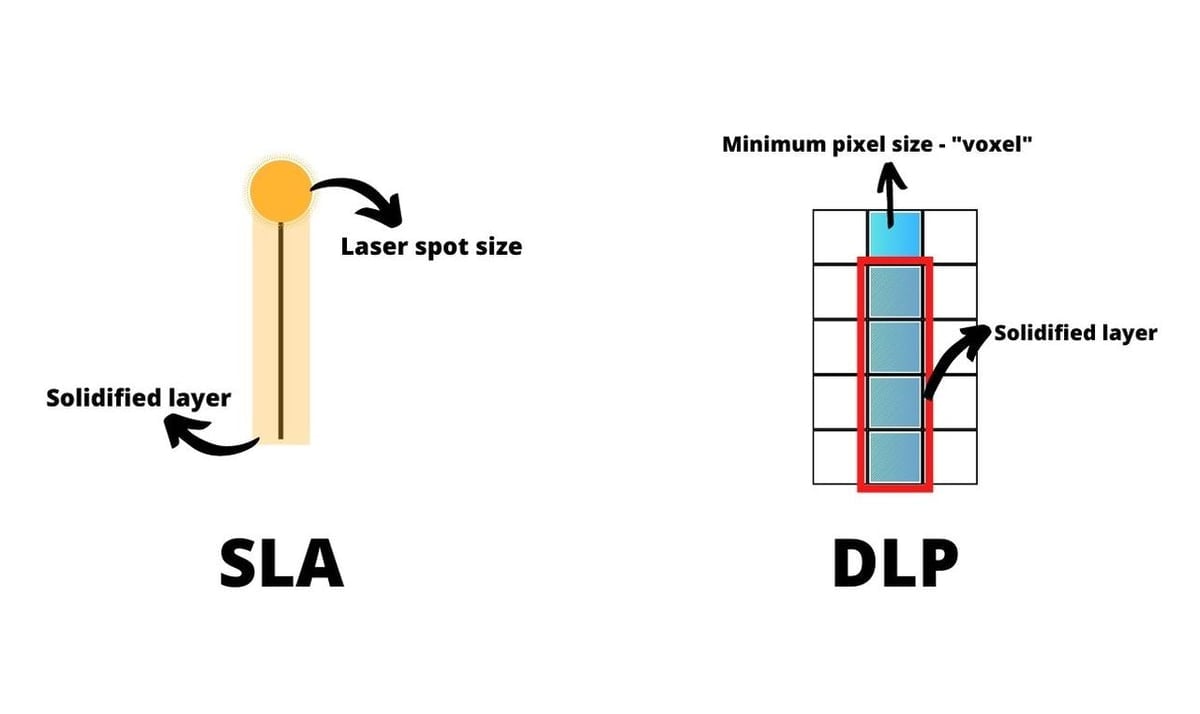

Whereas in SLA, a laser cures only a single point at a time, a DLP printer’s screen projects the image of an entire layer all at once. As a result, DLP printers generally print slightly faster than SLA printers.

The device used for controlling where light is projected in DLP 3D printers is called a digital micromirror device (DMD). A DMD contains hundreds of thousands or even millions of small micromirrors that direct the light and create the pattern of a layer, thereby solidifying the whole layer at once. The DMD is at the heart of every DLP chipset.

Because a digital screen is the starting point of each layer made with DLP, the image of a layer is made out of pixels. Once the layer is made upon its image, it’s composed of voxels, tiny rectangular prisms visible in all three axes.

Once a single layer has been formed, the build platform moves up the height of a single layer, and a new image of a new layer is projected. The part continues to grow this way until completion.

- Light source: digital light projector screen

- Pros: smooth surfaces, faster print times when compared to SLA

- Cons: build quality decreases as the print area grows, curved surfaces might have a bit of a “boxy” look

- Price: $3,000+

- Popular examples: Flashforge Hunter, Wanhao Duplicator 7

LCD/mSLA

It’s easy to distinguish SLA from DLP, but the confusion starts when trying to differentiate DLP from LCD. LCD, sometimes also referred to as mSLA (masked SLA), is very similar to DLP, but there is one subtle difference in the nature of the two technologies.

With DLP, a DMD is required to direct the light of the projector onto the bottom of the vat. With LCD, there’s no need for such an additional device since the UV light is coming from an array of LEDs that shine through an LCD screen. The screen acts as a mask (the reason for the name “masked SLA”), revealing only the specific pixels for the desired layer.

Thanks to the invention of this technology, resin 3D printing was finally made more accessible to the public, as the components of LCD 3D printers are generally slightly cheaper.

You could say that LCD 3D printing is something of a double-edged sword. The positive side is that the prices are generally lower, but the lifespan of an LCD screen is much shorter than it is for a DLP chipset, meaning more frequent maintenance will be required.

- Light source: digital light projector screen

- Pros: smooth surfaces, faster print times when compared to SLA, less pixel distortion than with DLP

- Cons: build quality decreases as the print area grows, LCD screens have a relatively short life cycle (500 hours)

- Price: $150+

- Popular examples: Anycubic Photon S, Zortrax Inkspire, Peopoly Phenom

Material Jetting

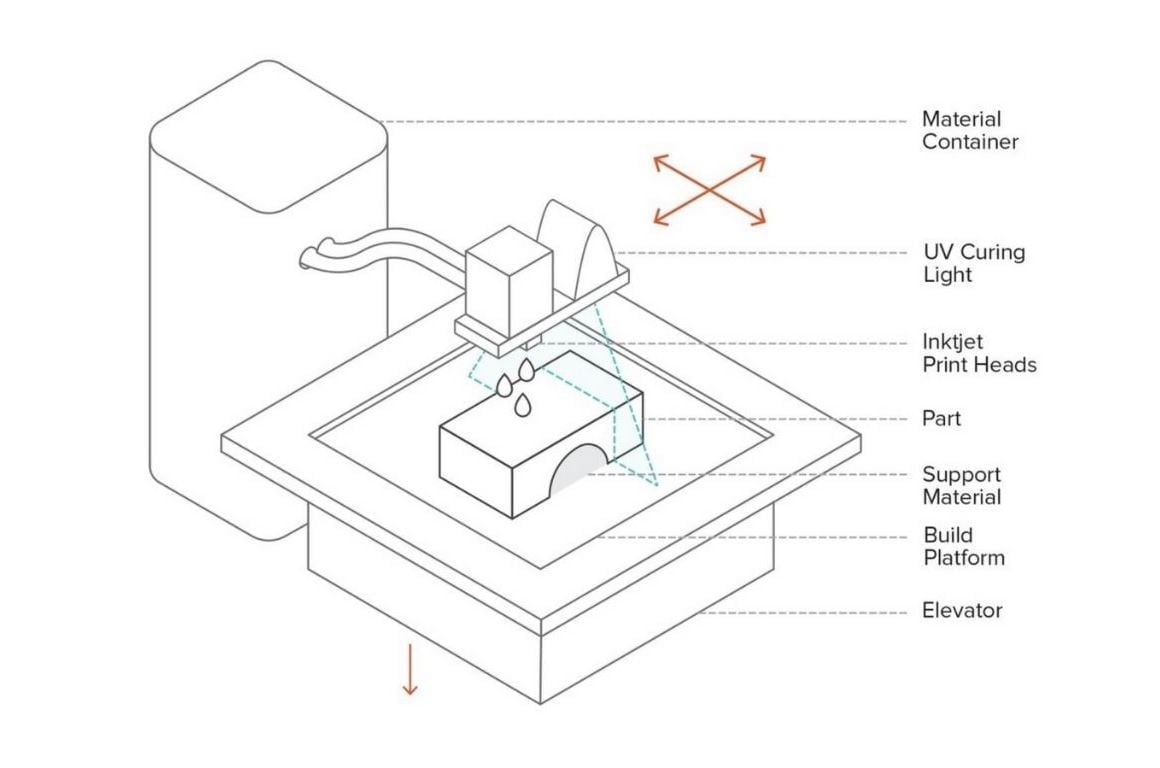

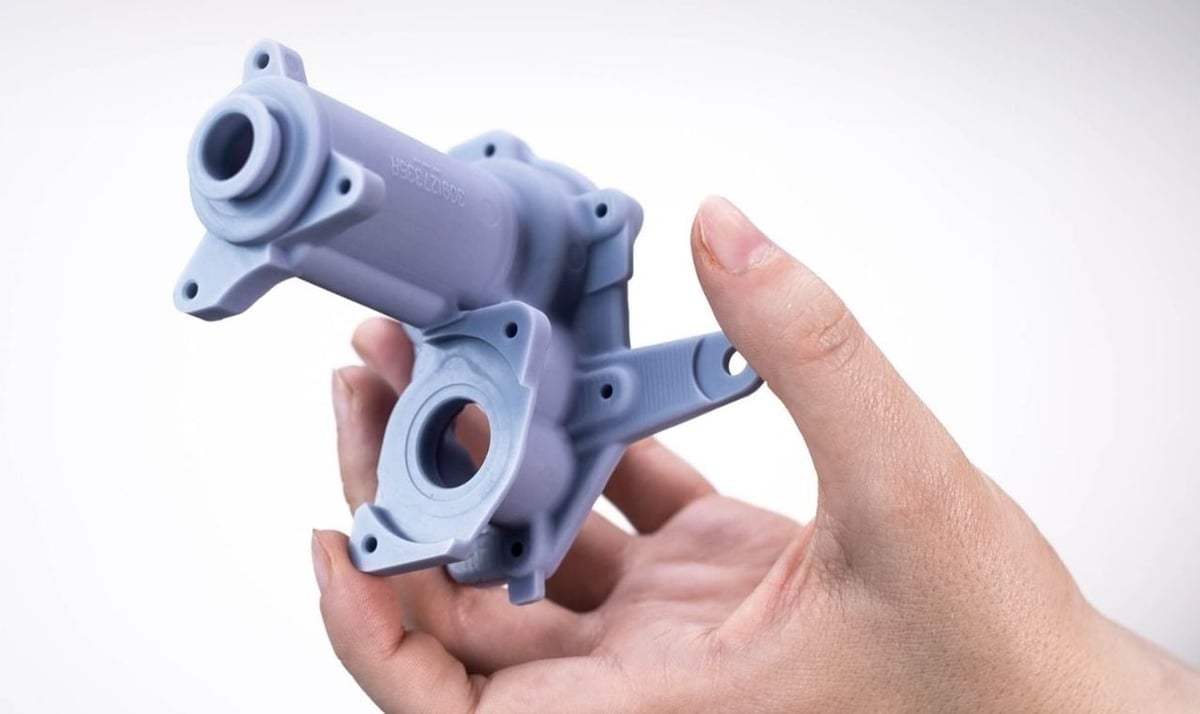

Material jetting is a unique resin 3D printing technology that works somewhat like an office inkjet printer. It’s also considered to be among the fastest and most precise 3D printing technologies available.

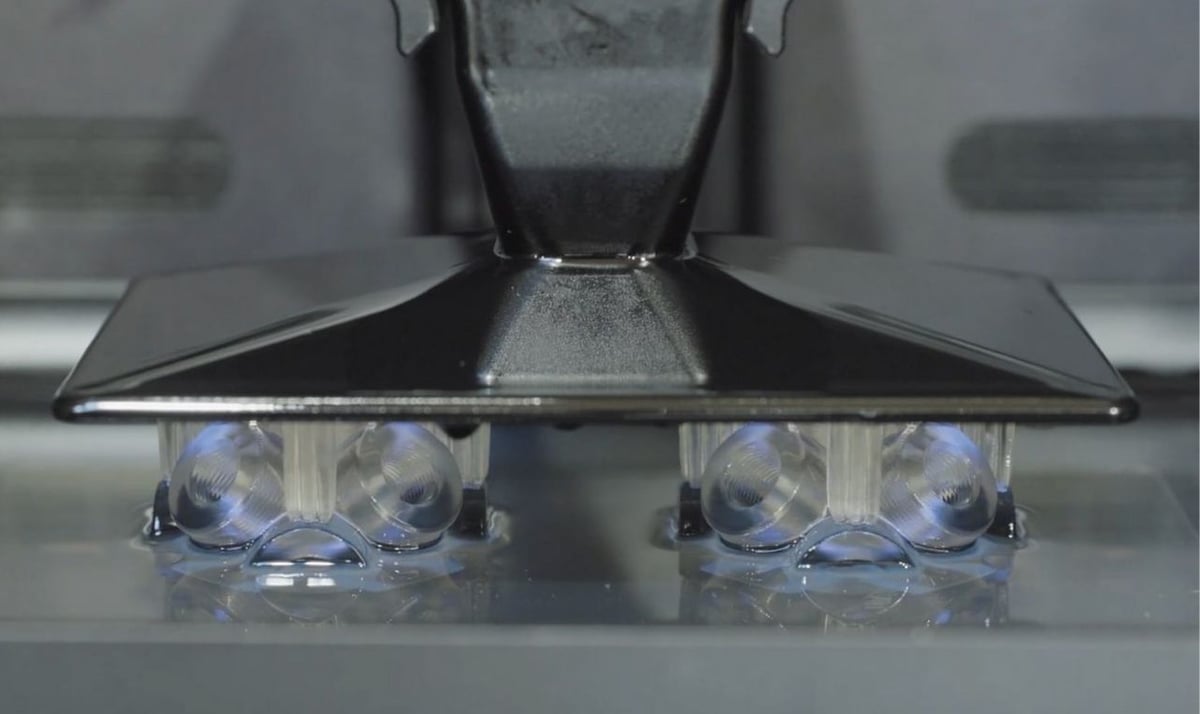

Why is it similar to an inkjet 2D printer? Because material jetting 3D printers have a printhead out of which thousands of tiny resin droplets are sprayed onto the build platform, then cured with the UV light. When one layer is complete, the build platform lowers itself the height of one layer, and the process is repeated until completion.

The nature of material jetting technology enables great dimensional accuracy, but speed is also a fascinating factor. Resin droplets are jetted from multiple print heads that sweep back and forth above the build platform. This is called line-wise deposition, and it ensures multiple parts can be built without affecting the build speed.

- Light source: UV lamp

- Pros: speed, dimensional accuracy, choice between matte and glossy surfaces

- Cons: expensive equipment and material, material waste when printing matte, low strength of parts

- Price: industrial pricing is in the range of hundreds of thousands of dollars

- Popular examples: Stratasys Objet500 Connex3

Lead image source: Forbes

License: The text of "What Is a UV 3D Printer? – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.