SolidWorks and Inventor are two 3D computer-aided design (CAD) programs for machine parts design. Both have tools that go beyond simply modeling, including simulation, rendering, CAM, and more.

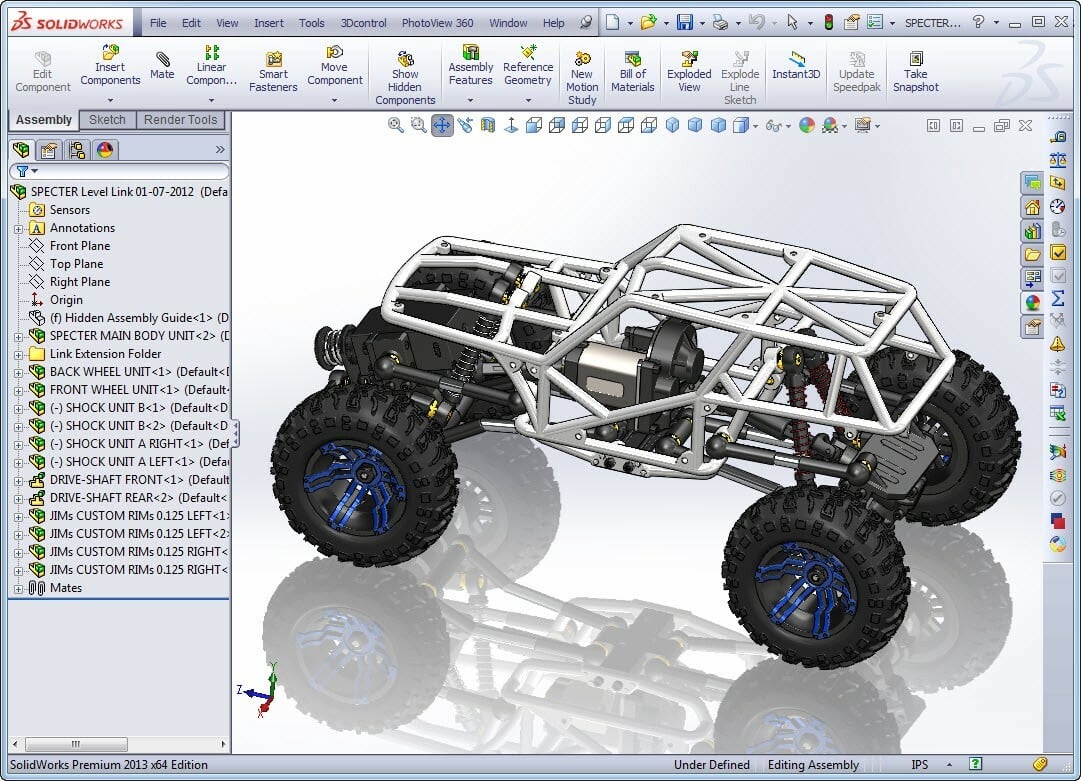

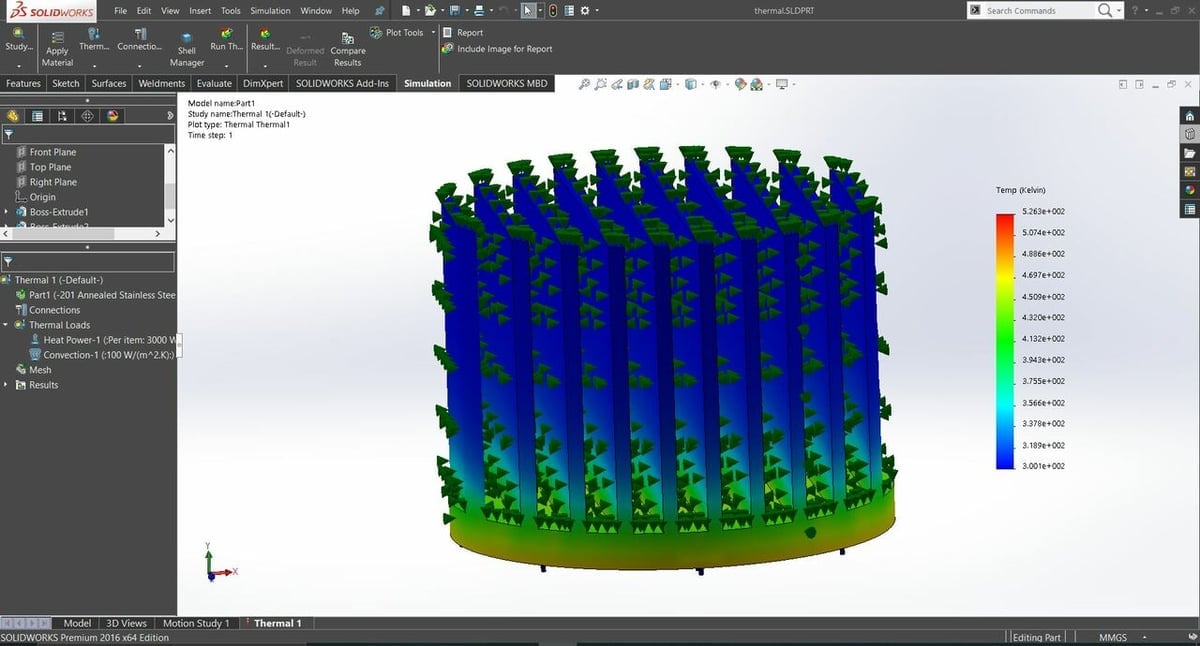

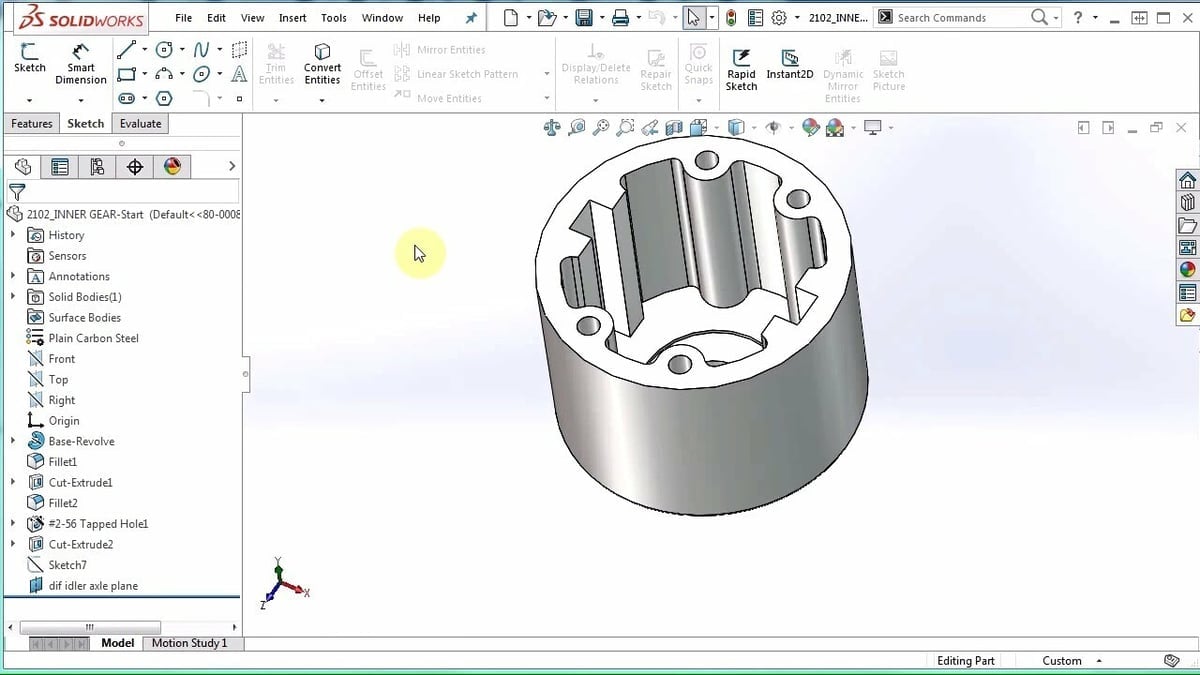

Developed by Dassault Systèmes, SolidWorks was first released in 1995, making it the first fully-capable 3D modeling program for Windows. SolidWorks can be used to, among other things, model parts and assemblies, draft manufacturing blueprints, as well as produce renders, generate simulations, and export models for 3D printing. Some features that set it apart from the rest are multi-solid part modeling and history-based modeling, which we’ll explain in more detail further down.

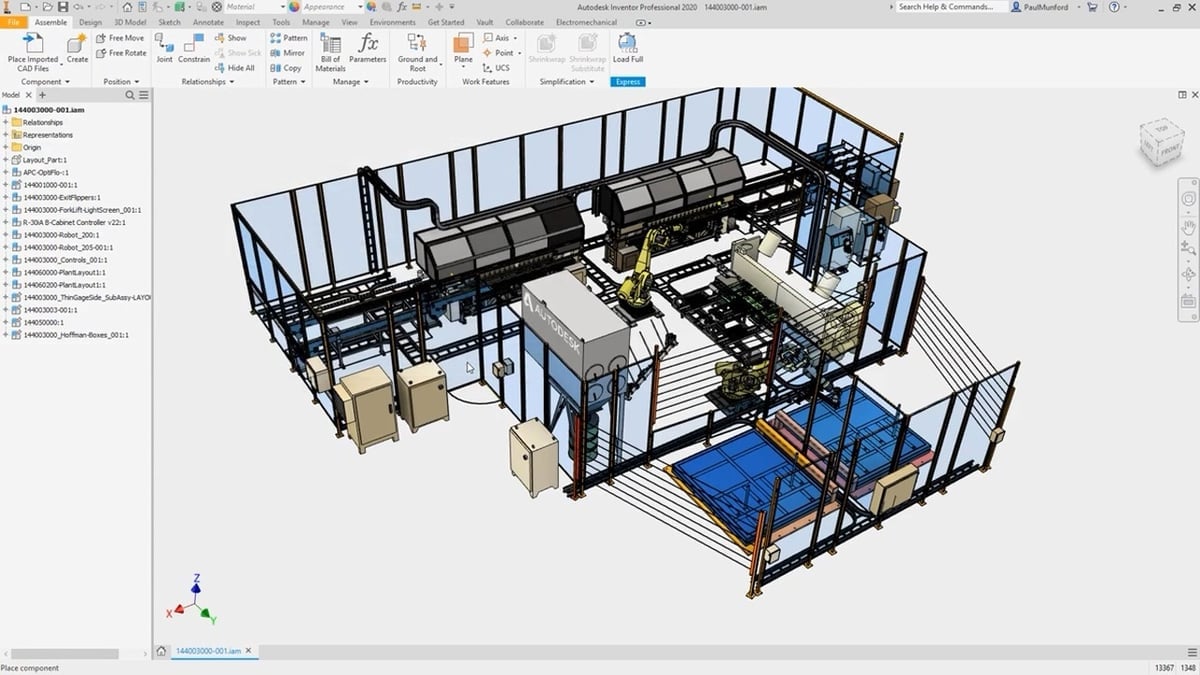

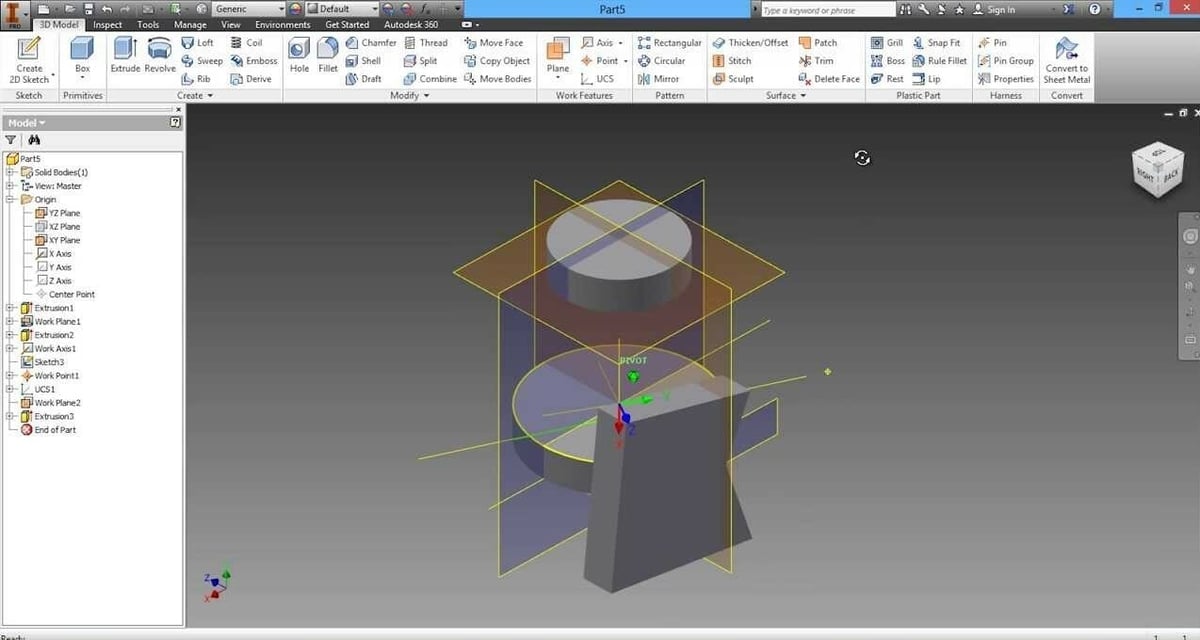

Inventor is from Autodesk, a software giant better known for its 2D modeling counterpart AutoCAD, and is one of the most popular Autodesk products. Inventor was released in 1999 as a direct competitor to SolidWorks and is similarly based on parametric modeling for machine parts. One of its main advantages over SolidWorks is being lighter in terms of processor requirements, making it more stable when working with large assemblies.

In this article, we’ll compare both CAD programs, paying specific attention to the differences that set them apart. Let’s dive in!

Prices & Licensing

SolidWorks and Inventor both offer free trials and various pricing options for different software versions. There are also special offers for qualifying students or educators.

SolidWorks

SolidWorks has three different plans:

- Basic: The standard SolidWorks license has a price of just under $4,000 for a perpetual license. This license is version-specific, so to update to a more recent version, you’ll need to buy a new one. An annual subscription costs around $1,300. When you renew your license, it updates to the most recent version. If you’re a student, you can get an educational version for about $100 annually.

- Professional: This version has all the features of its basic counterpart plus tools like SolidWorks PDM Standard, CircuitWorks for electrical CAD, the toolbox of standard parts, and Visualize for advanced rendering. This version costs $5,495 for the perpetual license or $1,495 for an annual subscription.

- Premium: Among other features, this version has linear stress analysis, piping and tubing design tools, and time-based motion analysis. It costs $7,995 for the perpetual license or $1,995 for an annual subscription.

Additionally, if you want to try it out before buying, SolidWorks allows you to try a limited, web-based version. It’s also worth mentioning that SolidWorks isn’t bought online but rather through authorized distributors.

Inventor

Inventor’s license is subscription-based, and there are three pricing options: $290 monthly, $2,300 annually, or $6,555 triennially.

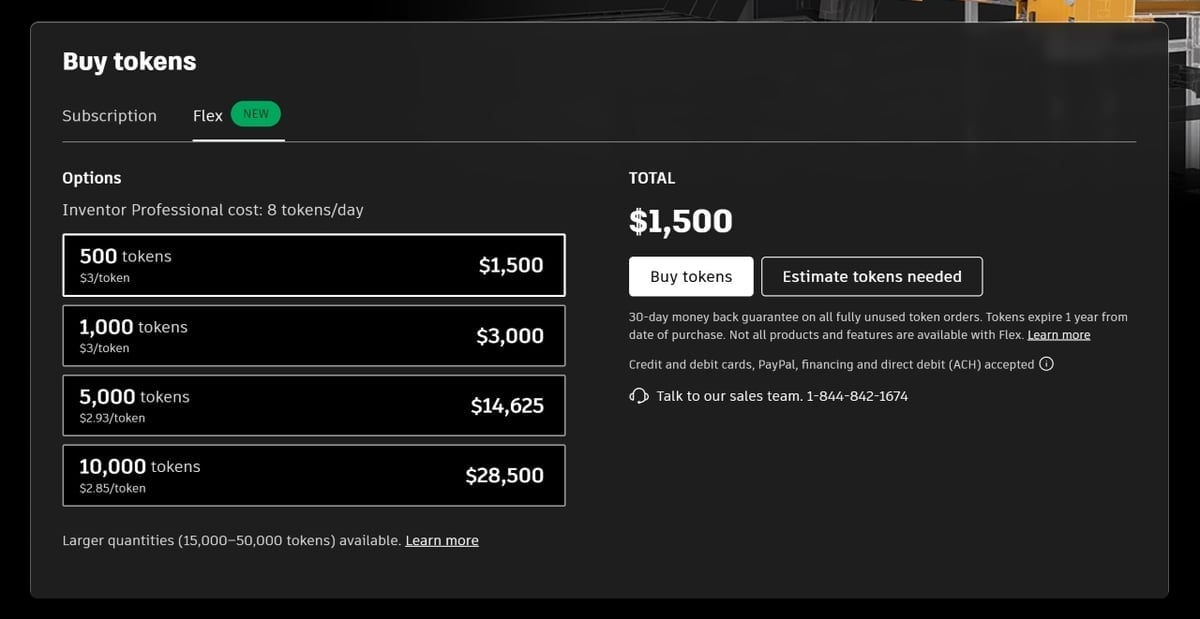

That said, there is a Flex option, which gives you a license for a limited period of time. It’s based on tokens, with 8 tokens being worth one day of use. Tokens are sold in the following packages:

- 500 tokens for $1,500

- 1,000 tokens for $3,000

- 5,000 tokens for $14,625

- 10,000 tokens for $28,500

It’s worth noting that the Flex license doesn’t include the complete set of features of the full license.

If you’re a student or educator, you can also acquire the full version of Inventor by going to the Autodesk student portal and proving your enrollment at an educational institution. An educational license lasts one year, after which you’ll have to once again prove you’re enrolled in the most current semester.

System Requirements

As they’re both professional-grade 3D modeling programs, SolidWorks and Inventor work with a heavy set of graphics and mathematical information, so no matter which program you choose, it’s recommended to have a pretty powerful machine. There are some powerful laptops nowadays, so using either of them on a laptop is possible and can be effective. However, using a touchpad won’t be enough; you’ll need a mouse with a scroll wheel to be able to comfortably and efficiently work in either of these programs.

SolidWorks

SolidWorks 2022 runs on 64-bit Windows 10 and 11. Older versions of SolidWorks may only work as far as Windows 10. If you have Windows 7, versions up to SolidWorks 2020 should still work on it. There’s no support for SolidWorks on MacOS or Linux.

To install SolidWorks, you’ll need at least 22 GB of free disk space. And to run it properly, at least 12 GB of RAM are necessary, although 16 GB would be better. Most of SolidWorks’ processes are carried out by the CPU, so strong graphics cards aren’t a hard must. Yet, features like RealView and ambient Occlusion will need a GPU.

To obtain SolidWorks, you don’t actually go to the Dassault Systèmes website. Instead, you have to contact an authorized reseller directly, who will send you the installation files and a key.

- OS: Windows 10 64-bit, Windows 11 64-bit

- Processor: 3.3 GHz or higher

- RAM: 12 GB minimum, 16 GB recommended

Inventor

The most recent version of Inventor, Inventor 2023, works on 64-bit Windows 10 and 11. Previous versions only run on 64-bit Windows 10. Inventor only runs on Windows; there are no MacOS- or Linux-supported versions.

To install Inventor, you’ll need at least 40 GB of free disk space. At least 16 GB of RAM is required, but 32 GB is recommended. The program will probably run with less, but it will also be more likely to crash.

In contrast to SolidWorks, the installation files for Inventor are downloaded from the Autodesk website, and during the installation, you’ll need to access your Autodesk account to confirm the license. As such, you’ll also need a stable internet connection during the installation process.

- OS: Windows 10 64-bit, Windows 11 64-bit

- Processor: 2.5 GHz or higher

- RAM: 16 GB minimum, 32 GB recommended

UI & Layout

SolidWorks and Inventor share a pretty similar layout, with the workspace occupying the center of the screen, a ribbon of main features on top, and the property manager to the left.

SolidWorks

SolidWorks is divided into three main environments:

- Part is the environment for modeling parts, as the name indicates.

- Assembly is used when you’re bringing parts together to make, for example, a complete system or machine.

- Drawing is for drafting blueprints for manufacturing, making user manuals guides, and so on.

These three environments are accessed through the splash page when you create a new document: You switch to one of them when you open the inherent file. For example, if you open a .sldprt file, you’ll be in the Part environment. An .sldasm file will open the Assembly environment, and an .slddrw file, the Drawing environment.

For each of these three environments, the layout remains the same, but the displayed features change. To access more features than those shown in the ribbon, known in SolidWorks as the “Command Manager”, you can go to the Insert menu, where you’ll find the complete list. It’s also possible to right-click the tabs of the Command Manager to enable more features to be displayed.

SolidWorks organizes open files in tabs. To switch between them, you have to use “Ctrl + Tab” or use the Windows toolbar to switch between windows, as SolidWorks keeps each open file in a unique window.

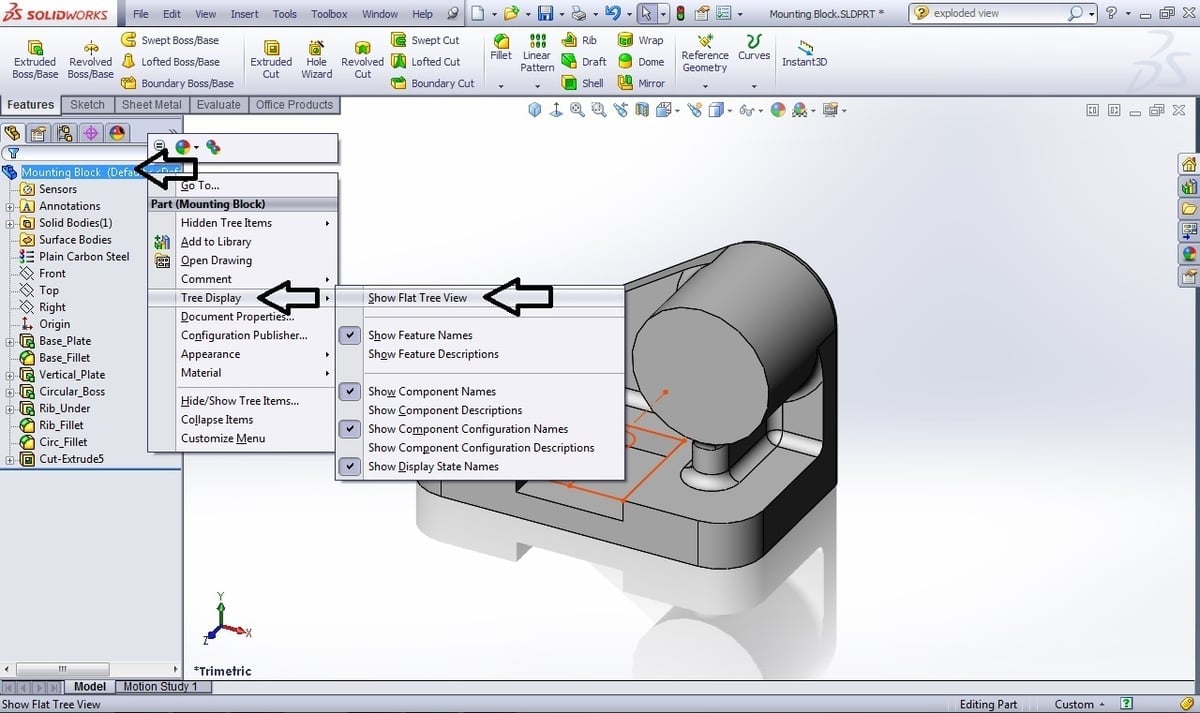

To the left of the workspace is the Feature Manager Design Tree, where you’ll find a history of all features applied to whatever you’re working on, be it a part, materials, equations, parts present in an assembly, solids present in a multi-body part, drawing views, and so on. The design tree is organized in tabs, and other tabs include Appearances and Configurations.

On top of the workspace, there’s a floating menu called the “Heads-up View Toolbox”, which contains options like views and display modes.

Inventor

Similar to SolidWorks, Inventor is divided into six environments inherent to an Inventor file type:

- Part is for traditional modeling.

- Sheet Metal Part allows one to model for sheet metal construction.

- Assembly is for bringing parts together into a complete machine.

- Weldment Assembly creates assemblies with weld-specific design features.

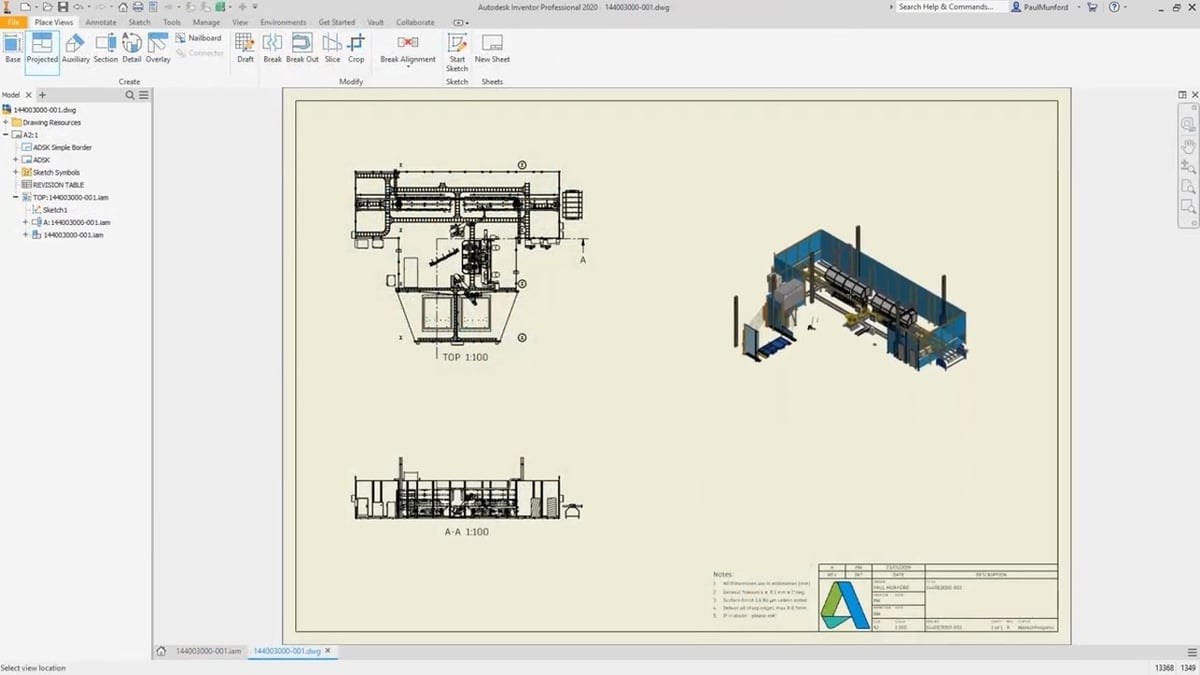

- Drawing is configured for laying out blueprints.

- Presentation is for visualizing the model.

As Inventor has an Environment tab in the ribbon, you also have the option to open environments while working on certain file types. The ribbon is otherwise pretty similar to SolidWorks and contains 2D sketching, 3D operations, and inspection.

The program displays open files in tabs at the bottom of the screen. Switching between them is easier and helps you take up fewer resources, as they’re tabs in one program instead of many open windows.

To the left of the workspace, Inventor has a box called the “Browser”, where you can see parts, objects, views, and other elements in the workspace. Note that there aren’t any additional menus for material or appearance like there are in SolidWorks. Instead, you find those in the Quick Access toolbar at the top of the window.

In contrast to SolidWorks’ display modes in the Heads-Up View Toolbox, Inventor has Graphics Presets. These display modes allow you to view your model as realistic, shaded with edges, or simplified.

Features & Functions

On the whole, both programs share many of the same features: sketching, creating bosses and bases, parametric modeling, motion simulation, and more. After all, they’re both examples of 3D parametric modeling software. The difference between the programs is in the details: how they execute actions, which inspection options the offer, and what workflow aids are available, among other features that will be covered in detail below.

SolidWorks

Mouse Gestures

SolidWorks allows you to customize right-click mouse movements to increase efficiency while working. For example, if you use the Mates tool a lot, instead of searching for it every time, you can enable it every time you right-click and slide to the left.

History-based modeling

SolidWorks’ history-based modeling is a great part of what makes it so powerful. If you extrude a cut, for example, the operation will show in the Feature Manager Design Tree. Then, if necessary, you can go back to a time before you extruded that cut, add more features, and go forwards again, re-enabling the cut. This is useful during the conception stages of a project when you need to be able to go back and add details without having to undo your process.

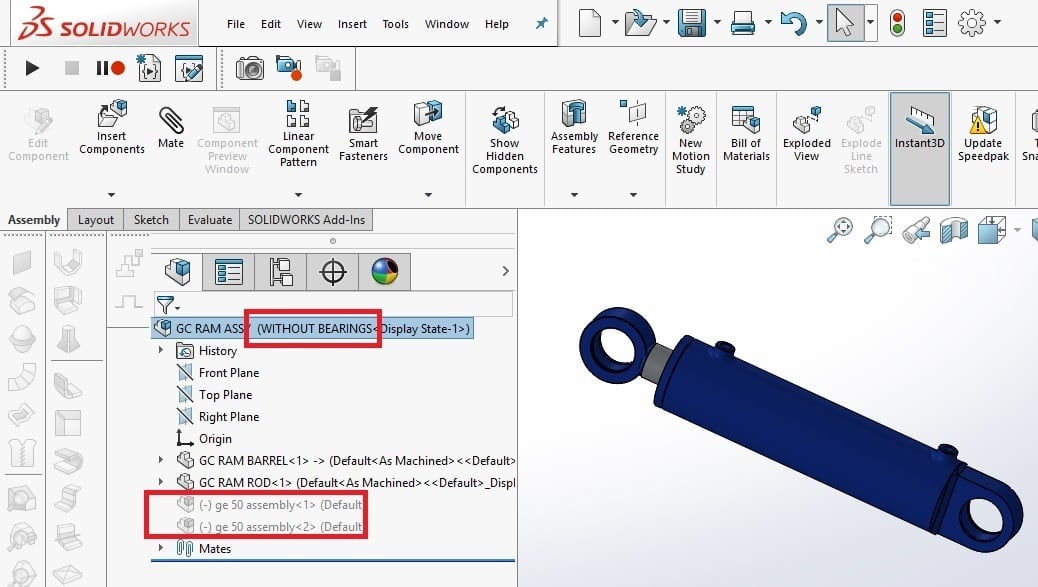

Multi-solid Modeling

Usually, it’s expected that, if you want to create two parts that interact together, you need to model each part separately and then unite them in an assembly. But let’s say that those two parts will never have any relative movement between them and that they have common geometries – perforations, for example. In that case, it’s so much easier to simply model them together but as separate solids.

It’s possible to do this using SolidWorks. When applying features to a part, you can choose whether the features will affect only one of the solids. Moreover, you can have more than two solids in one part file.

Configurations

A very important and powerful element of SolidWorks is Configurations, which is found in one of the Feature Manager Design Tree’s tabs. As the name implies, the feature allows for different configurations of the same part or assembly.

For example, if you want to have a bar with drill holes and another without drill holes, instead of creating two parts, you create two configurations inside the same part. Since SolidWorks is history-based, it allows you to suppress operations. So, you can suppress the drill operation in one of the configurations.

The program allows you to create these configurations inside the same model by using equations for parametric modeling or by suppressing features in a given configuration. Just keep in mind that this can make designs incredibly heavy; the program may lag or become bug-prone.

Advanced Toolsets

In addition to these basic features, SolidWorks has specialized toolsets for sheet metal, structural design, simulation, rendering, plastic injection molding, and animation.

Tool Box

The Tool Box is a library of standard parts, mainly filled with nuts, bolts, screws, and bearings. These can accommodate the metric or imperial systems, DIN, or other manufacturer standards.

Inventor

Scripting

In contrast to SolidWorks, Inventor places a lot more value and emphasis on scripting to automate and parameterize design. For example, if you want to create a set of standard parts used in your company but not have to open them as files every time, you can model them by programming the parameters (which are programmed functions) instead of visually modeling them.

After modeling a part in this way, you can save it as a plug-in so that you later need only provide the diameter and length, for example; the other factors are calculated for you. In other words, thanks to scripting, you don’t need to model each individual part. If they’re similar, just do it once, then automate the rest.

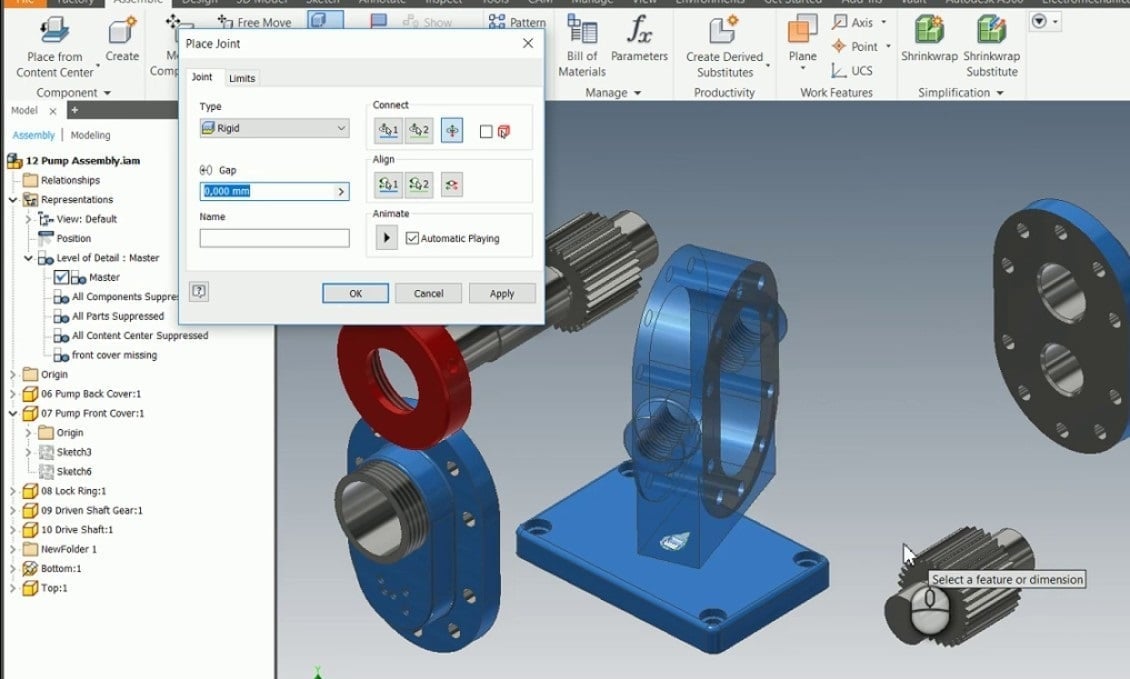

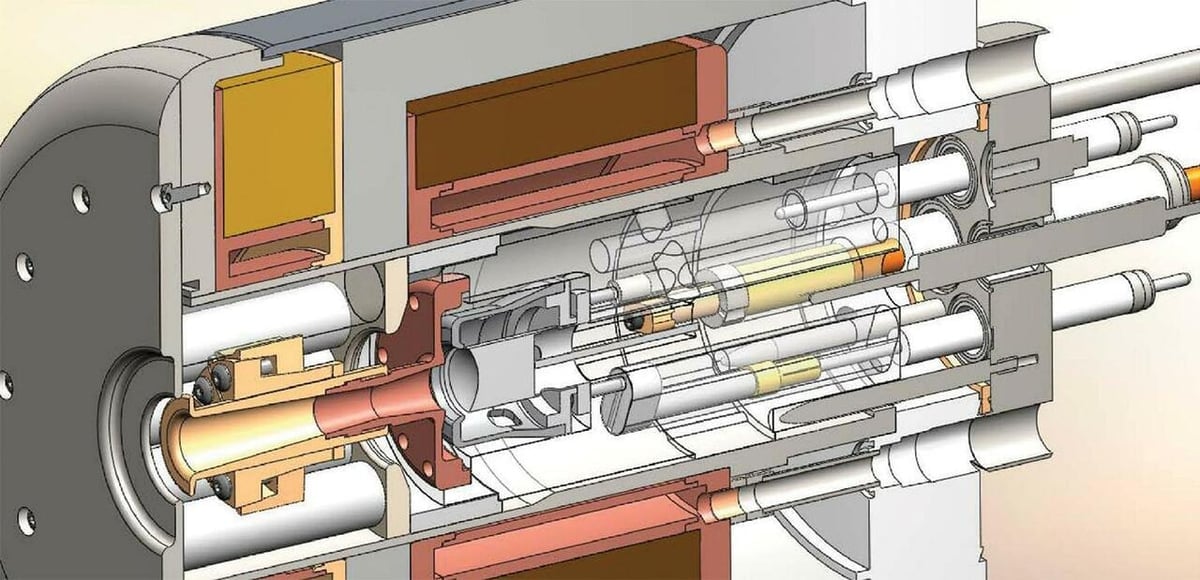

Assemblies

While SolidWorks works with mates when building assemblies, Inventor uses constraints, joints, and parameters to achieve assemblies. This is important because, again, if you want to simulate stress later, you have to define joints and such. Thanks to the assembly building process in Inventor, these are already set.

Simulating the movement of assembly components can be previewed directly in Inventor’s Assembly environment, and it’s much more comprehensive than SolidWorks’ simulations – which use a different environment set, Animation.

Simulation

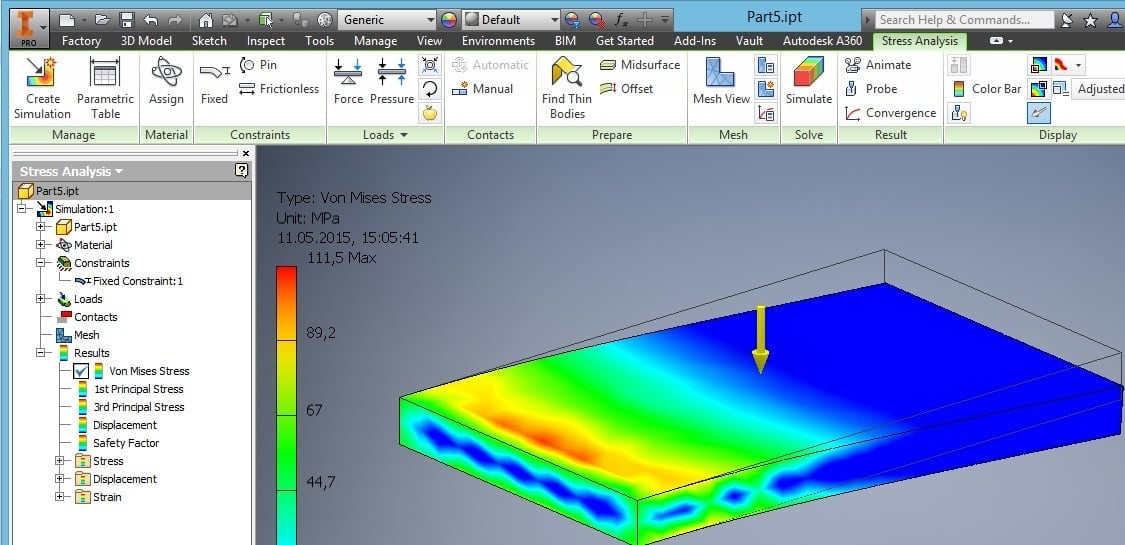

Because of how Inventor was conceived and the fact that it relies so much on scripting, it’s more instinctual to work with simulations. For example, it automatically converts constraints into mechanical joints when working in simulation. It even allows you to do explicit simulations, meaning it can work with accelerations (including gravity) as well as contact friction, which is an important point of analysis in any joint’s simulation.

Collaborative Work

Inventor’s Shared View Collaboration allows you to share a view with other people. The view is purely visual: It only shows you the model, which doesn’t move or have parameters or anything. Still, this allows others to see the model, which can be useful to check the progress of a design and showcase ideas to clients. Shared views last 30 days.

Advanced Environments

Inside each of the six basic environments, others are found to access specific and more advanced functionalities. These include Dynamic Simulation, Stress Analysis, Frame Analysis, Movement Studio, BIM Exchange, Cable and Harness, Tube and Pipe, and Weldment.

Content Center Library

This is Inventor’s version of SolidWorks’ Tool Box (i.e. a standard parts library). It mainly consists of bolts and screws.

Use Cases & Applications

Both tools are great options for industrial-scale work. SolidWorks is preferred when conceiving large-scale objects, such as in industrial plants, where there are many versions of the same component, making it more practical to work with the program’s configurations feature. Additionally, SolidWorks can open files in large assembly mode, which optimizes the review of such projects.

In contrast, Inventor is especially preferred when working on collaborative projects, as teams can review a project almost step by step and store projects in Autodesk’s cloud. Further, virtual simulations are accurate enough when translated to real life.

SolidWorks

SolidWorks was used in the design of the first solar-powered hybrid airship by Solar Ship Inc. National Superconducting Cyclotron Laboratory (NSCL), a world leader in nuclear development and research, uses SolidWorks for the mechanical parts of their designs. Finally, Aldebaran Robotics, which is very well-known for their humanoid robots, prefer SolidWorks for all the mechanical design of their robots.

Inventor

Inventor has been used by companies like Garant-Filter, who use Inventor to design their manufacturing line for energy-efficient ventilation systems. Another example is NOV Fiberglass Systems. They mention they’ve switched to Inventor along with Power Mill, and processes that used to take them three to five days now take them about 20 minutes. Finally, the company Rokion, which produces heavy-duty electric vehicles for mining streamlines, uses Inventor and Vault for their design process.

Company & Community Support

SolidWorks

- SolidWorks doesn’t have many official learning pages, but they do have an official YouTube page, where they show step-by-step models, patch notes on new versions, lesser-known features, and additional educational resources.

- SolidWorks also has an unofficial Subreddit, where the community connects.

Inventor

- Inventor has an official forum by Autodesk and a Knowledge Network page, where you can get beginner resources. There’s also Autodesk University, an official community of Autodesk educators, which contains written and video tutorials.

- There’s also the unofficial Autodesk Inventor Reddit community, where users of the program ask questions, share creations, and report issues.

Final Thoughts

Regardless of which program you go for, both options are professional-grade CAD tools used in industry. The difference tends to come down to the specific set of features you want. For example, if automating the design process is a priority, Inventor is usually preferred. However, if you want to conceive a new machine from scratch, SolidWorks’ design workflow is more convenient.

Naturally, the deciding factor could be whichever option your current or future employer uses. If possible, a good career strategy can be to check which one is preferred by companies for whom you aspire to work and to start learning that one.

License: The text of "SolidWorks vs Inventor: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.