One of the most used slicers in the 3D printing world is surely PrusaSlicer. Originally developed by Prusa Research for its own printers, the software has gained popularity over the years, thanks its open source nature and its large variety of printer profiles.

PrusaSlicer is appreciated for its long list of customizable parameters, and new features are constantly being added to improve its functionality. Released at the end of 2022, organic supports are among its newest and most appreciated features. This new type of support structure was implemented to be an alternative to the 2D grid-based approach of the existing grid and snug supports, and it has been constantly improved since its initial release.

To promote the use of organic supports, the company organized a Printables contest. Makers from all over the world unleashed their creativity to find ways to use organic supports for functional and aesthetic purposes. The results were stunning! So, let’s check out how you can use these special supports, too!

What Is It

Supports serve as a base for the parts of our prints that feature steep overhangs. Although PrusaSlicer’s grid and snug supports work, they can leave marks on prints. Sometimes, they’re even impossible to remove. Here’s where organic suppports come into play.

They’re very different from the classic type of supports. While grid and snug supports use a 2D grid-based approach, organic supports prefer smooth and natural shapes, as the name suggests. They’re generated to develop away from the body of the print and only get close to support the print’s overhangs. As a result, organic supports leave almost no marks on the print’s surface.

Classic supports have always cost time and material. In contrast, organic supports allow for faster printing and less filament waste, all while mantaining contact area with the overhang.

The Cons

Since the feature is new, some work still has to be done to refine it. One of the most common problems is the relative weakness of organic supports. They’re hollow, and even though that means the 3D printer extrudes less material, it can cause some problems. Some users report that the supports don’t stick to the build plate. In some cases, the supports break during the print. But don’t worry, keep on reading to discover some tips and tricks to optimize them!

Use

Organic supports have been a revolution for printing miniatures, sculpures, and intricate models. It’s difficult to find a design that wouldn’t benefit from them. So, what are you waiting for? Let’s give them a try!

Activating organic supports is really simple:

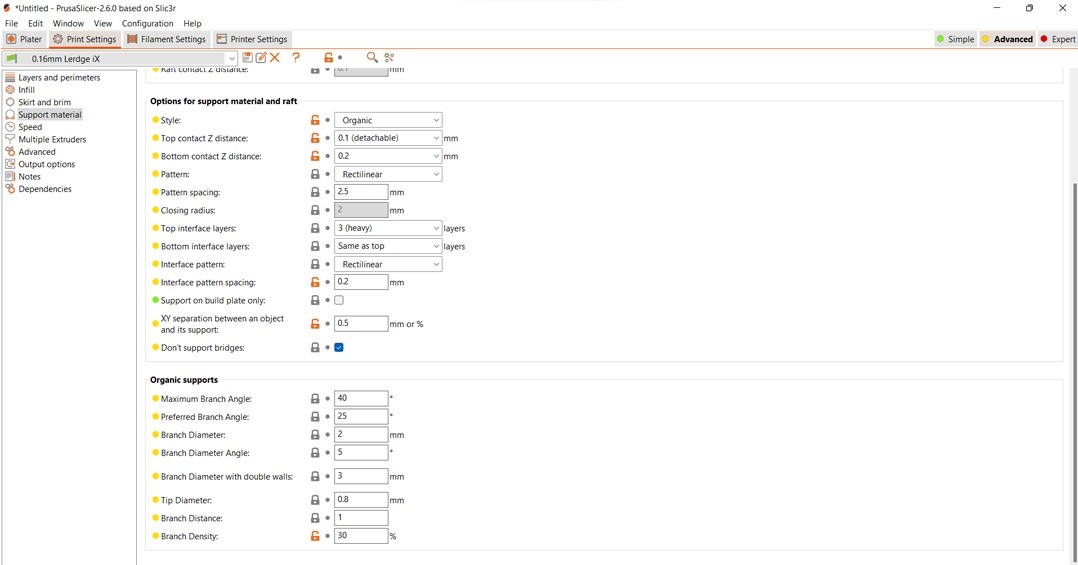

- Open PrusaSlicer (version 2.6 or later).

- Go to the “Print Settings” tab and click “Support material”.

- Select either “Advanced” or “Expert” mode on the top right side of the screen. You should then see a section labeled “Option for support material and raft” with a long list of options.

- Select “Organic” from the “Style” drop-down menu.

Settings

There’s a long list of settings for organic supports, so let’s check out the most important settings:

- Maximum Branch Angle controls the maximum angle of the branches to prevent them from touching the body of the model before it’s necessary to do so. A lower angle makes the supports more stable, while a higher one allows the supports to reach further to grab an overhang.

- Branch Diameter defines the diameter of the thinnest branches of the supports. The more you increase it, the sturdier they become, but of course, print time and material are also added. For the majority of the models, the default value of 2 is perfect. However, if you have a particularly heavy part of the model to support, you should increase this number to prevent the branches from breaking during printing.

- Branch Diameter with double walls defines the diameter over which the branches will print with double walls. Although you can save time by setting this to 0 (no double walls), the default value of 3 can be very useful for heavier models.

- Branch Distance represents the distance between branches when they connect to the model. A smaller value will better support overhangs but also make the supports harder to remove. This value will also depend on the specific filament you’re using; some filament types may be able to support larger values than others. So, you’ll have to experiment a little bit with this setting.

Tips & Tricks

As we have said before, the most noteworthy disadvantage of organic supports is their weakness. This can lead to some printing problems that will challenge your patience.

In addition to ensuring you have a level print bed and properly dialed in Z offset, the following tips should help:

- Supports break during printing: Since organic supports are hollow, it’s normal to experience this problem. The key to overcoming this issue is to increase the “Branch Diameter” and to define a lower value for “Branch Diameter with Double Walls”. This will make the supports sturdier.

- Supports don’t stick to the build plate: A good solution in such cases is to increase the contact area with the build plate by activating a raft and tweaking its XY expansion setting.

- Supports stick too well to the print: The golden rule here is to play around with the “Branch Distance”. You can gradually increase it to find the right value.

License: The text of "PrusaSlicer: Organic Support – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.