The Do-It-All Website

Slicers turn a 3D model file (STL, 3MF, OBJ, STEP, etc.) into a G-code script so that a 3D printer can create parts as expected. Without a slicer, if you tried printing a 3D model, your machine wouldn’t know what to do!

Usually, slicer programs are only available as offline programs that need to be downloaded and installed. However, in recent years, a few slicers have emerged that are usable on mobile devices or even web browsers. These slicers typically use the cloud for computing, so you can use them on lower-computing-power devices.

Kiri:Moto is one of these rising web-based slicers, so you just need a device with an internet browser to use it. Kiri:Moto runs on Grid.Space, an open-source cloud platform that allows you to slice models on the web. The program is free and offers much more than basic FDM slicing capabilities.

In this article, we’ll go over the Kiri:Moto slicer, discussing what it can do and a few of the program’s significant features. We’ll also touch on available support and how it compares with another popular slicer, Cura.

Happy slicing!

UI & Layout

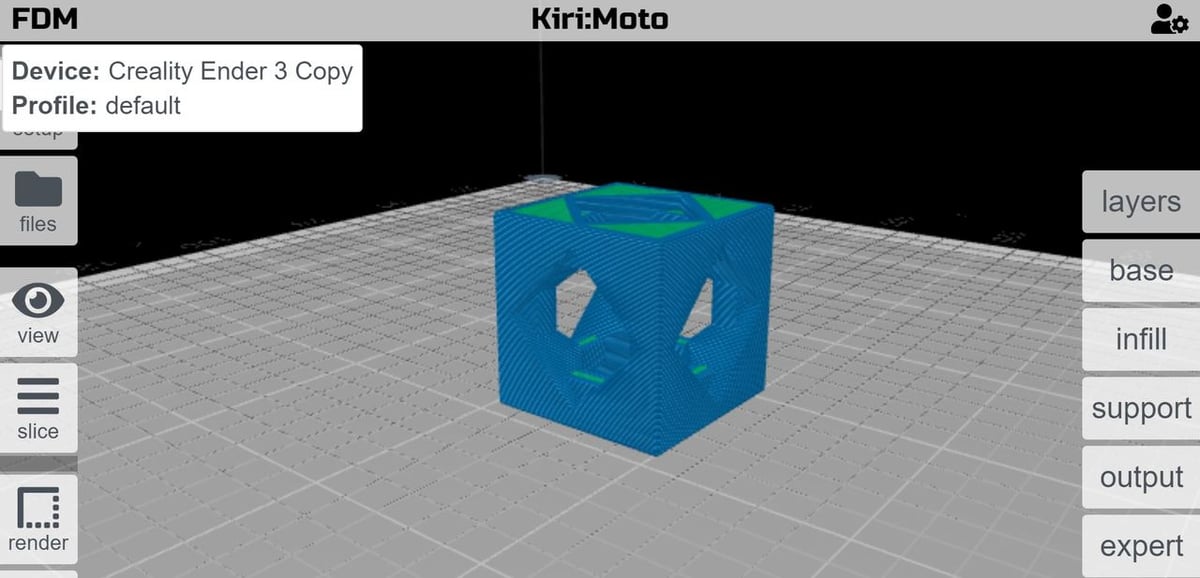

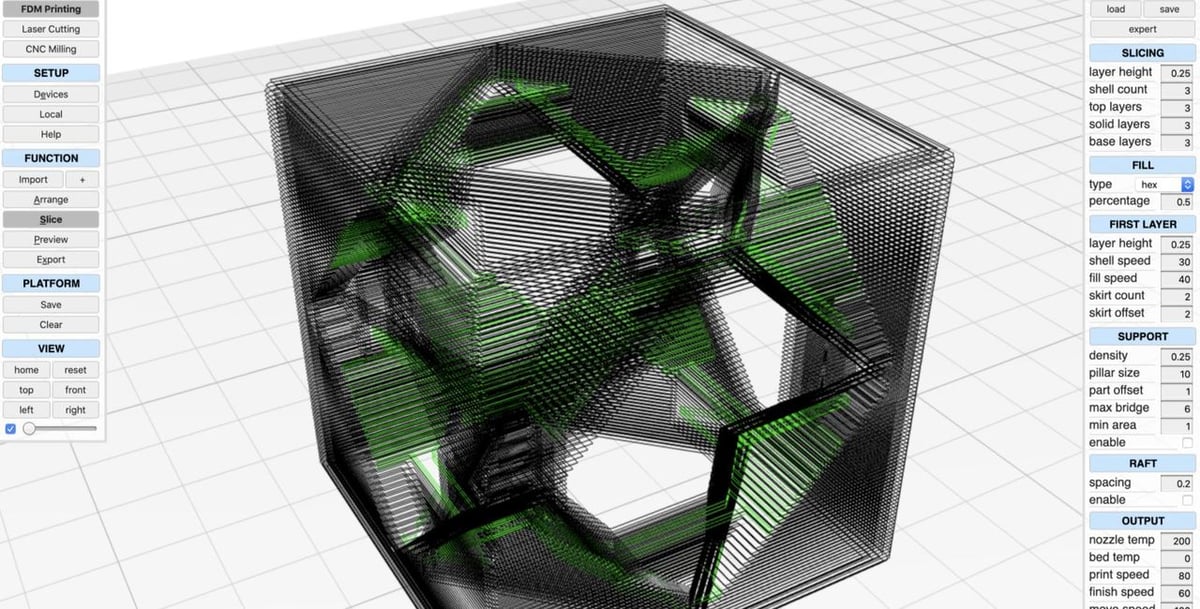

The user interface of Kiri:Moto is uncluttered and well-organized. All the tools and buttons are separated into categories with other relevant features. This contributes to its ease of use for new users because it’s basically self-explanatory.

Tools are divided into categories on the left and right side of the interface, with the more generic tools on the left and the more technology-specific features on the right. You can choose which type of printing or manufacturing that you want to use with the button (“FDM“, “SLA“, “CNC“, “LASER“) in the top-left corner.

Overall, Kiri:Moto has an exceptionally organized user interface that simplifies using the program so that most people, regardless of experience, can figure out what to do.

Different Technologies

As we’ve mentioned, Kiri:Moto brings a lot more to the table than 3D slicing through an internet browser. The program supports not only FDM 3D printer slicing but also SLA, CNC machining, and even laser engraving. Not many slicers, especially browser-based ones, support all of these manufacturing technologies in the same program.

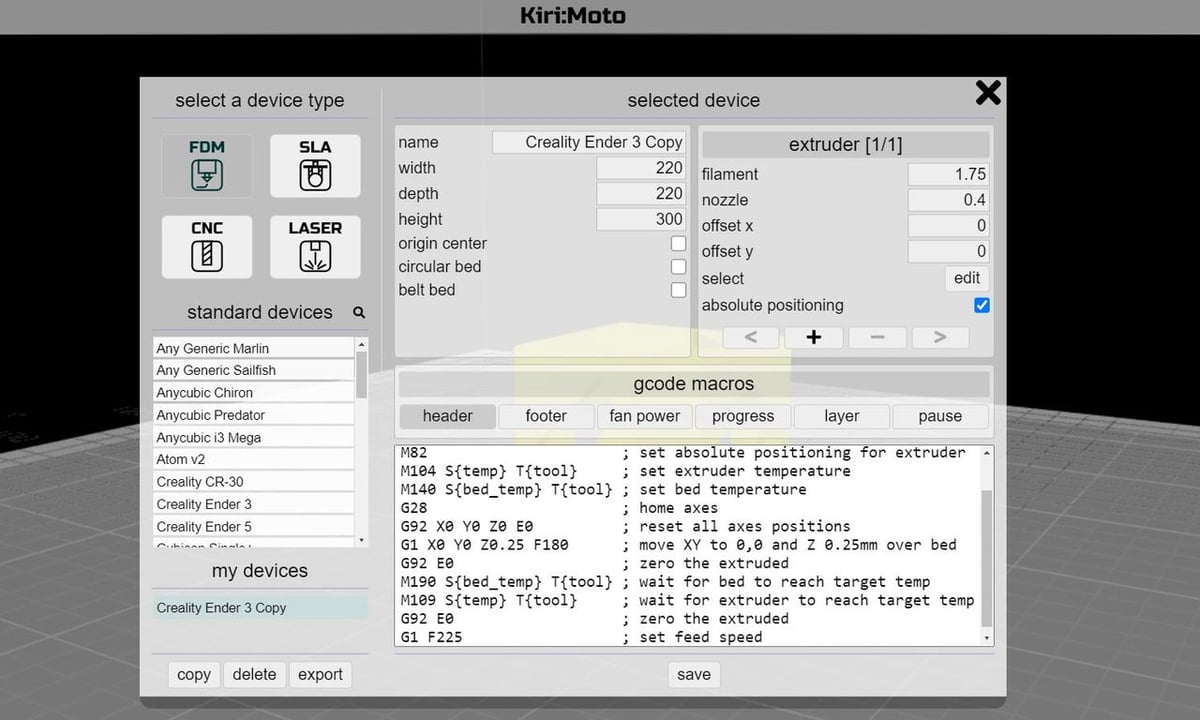

For each of these methods, Kiri:Moto has a different set of tools on their right-hand side toolbar specific to the selected manufacturing technology. It also supports a few machines, including popular ones like the Ender 3 (FDM), Anycubic Photon (SLA), Genmitsu 3018 (CNC), and Glowforge (laser engraver).

For each of these compatible machines, Kiri:Moto has pre-set dimensions, speeds, start and end G-code, and other product-specific settings. And if you’re using a custom-built or unlisted machine, you can adjust their generic profiles so that the slicer is compatible with your machine.

Features & Functions

Kiri:Moto has many features and functions that make it a versatile program. Let’s take a look at a few places it stands out!

Generic Tools

Besides the technology-specific tools like layer height for 3D printing and clearance for CNC machines, Kiri:Moto has many generic tools applicable to all manufacturing methods. These include some basics like importing models, scaling, and rotating. Of course, you can also drag objects across the digital build plate to move them.

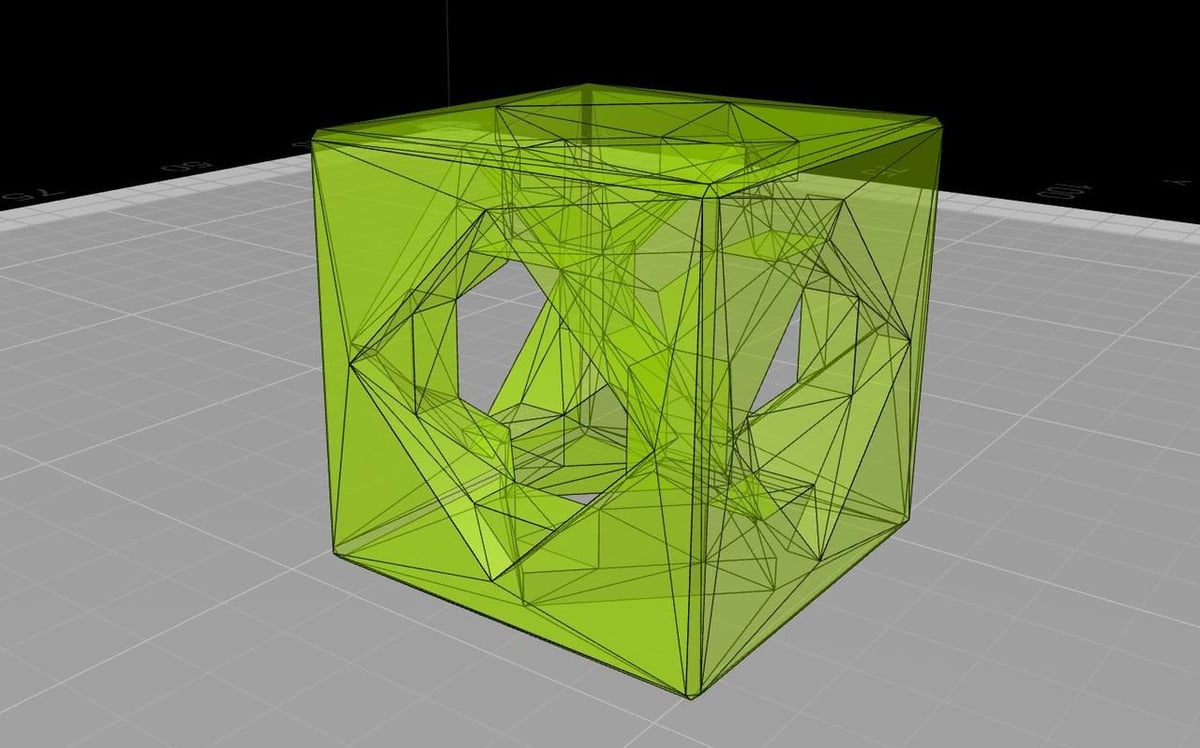

Besides these basics slicer necessities, Kiri:Moto has other features less standard for slicers, such as their render tool, which allows you to choose how you see your model. With this tool, you can choose from viewing an imported 3D model as a solid rendering, a wire, and a ghost (very translucent). Kiri:Moto also contains tools so you can view the G-code pathway and adjust which layer you are viewing.

FDM Slicer

FDM 3D model slicing is likely one of the most used capabilities of Kiri:Moto, as FDM 3D printing is more popular than any other manufacturing technologies recognized on the program. Kiri:Moto’s FDM slicer isn’t the best out there, but it isn’t too shabby given that it’s a browser-based, four-in-one technology G-code generator.

There’s a moderate amount of categories to organize the settings to keep the user interface and layout clean. There are seven categories, each with a few settings, totaling over 50 adjustable features. Some of these settings include common ones like layer height, infill density, temperatures, and speeds, while others – such as “anti-backlash” and a “bubbles” infill patterns – are rarer.

By clicking the button in the top-right of the interface, you can change a few FDM-specific settings such as the start and end G-code scripts. You can also give your printer a name, define its dimensions, and more!

Kiri:Moto also has an SLA slicer, but most of the settings for SLA are shared with FDM. Still, the SLA slicer has fewer adjustable settings than the FDM slicer.

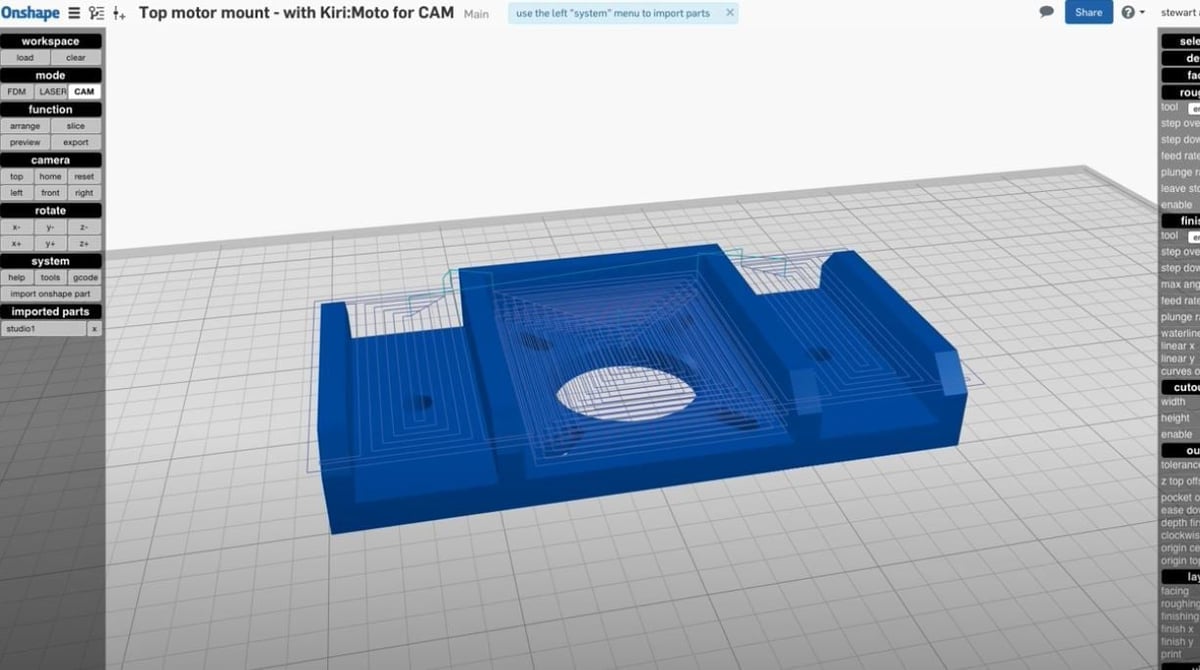

CNC CAM tools

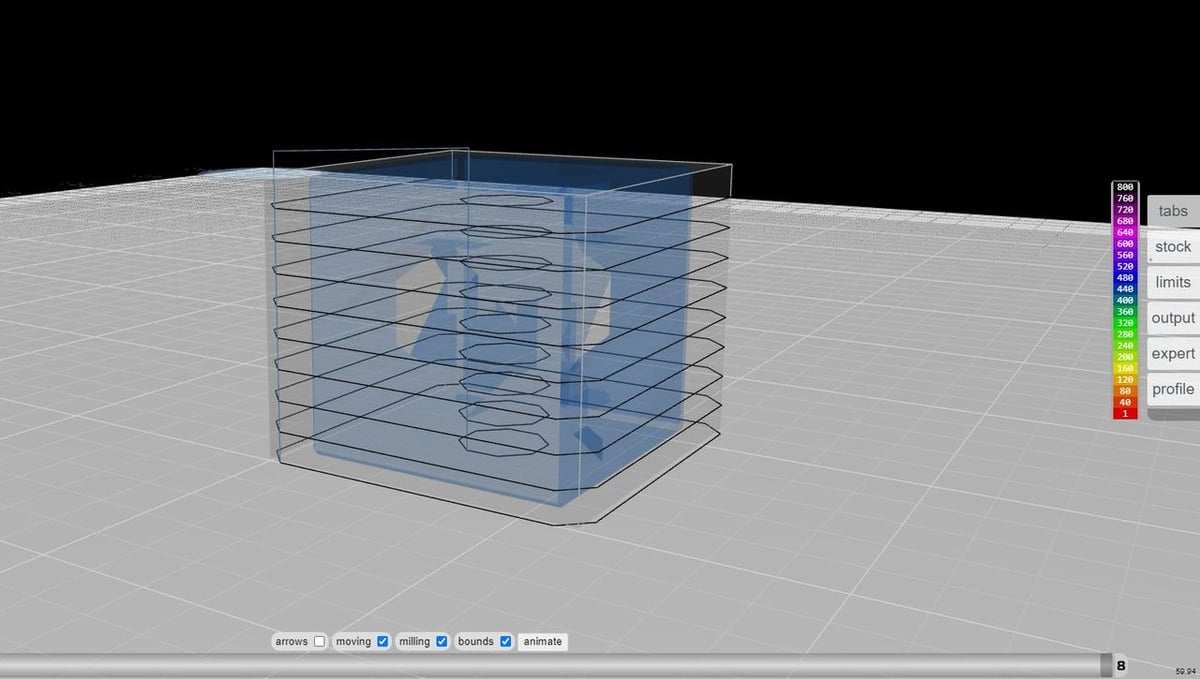

A CNC computer-aided manufacturing (CAM) program is a G-code generator, like a 3D slicer, but for CNC machines instead of 3D printers. Like a 3D printer slicer, a G-code generator produces G-code for machining a model based on set parameters and settings. The Kiri:Moto CNC machining G-code generator is well-equipped to handle most 3-axis CNC machining jobs.

For CNC machining, you can change the settings for your cuts, such as offsets or clearances, on the right-hand side toolbar. Besides the right-hand side toolbar for the CNC settings, you can add different machining tasks, such as drilling, tracing, outlining, contouring, and more. You can then turn the model and tasks into a G-code script, which you can view using the generic tools we’ve mentioned previously.

In the setup tab of the CNC G-code generator, you can change the settings for the tools used on your CNC machine. Here, you can adjust the tool end size, give it a name, select what type of end it is, adjust the length, and more.

Laser Engraver CAM tools

Laser engraving is sort of like CNC machining because it’s subtractive manufacturing, but instead of spindles, it uses high-power lasers. Kiri:Moto offers a fair amount of laser engraving CAM tools to turn a 3D model into an engraving file for a laser engraving machine to read and perform.

These settings are split up into organized categories, making the interface less cluttered. Some of these settings include offset, height, spacing, cut depth, cut passes, laser power, and speed. Once sliced, you can adjust which height you’re looking at in the preview mode.

Community Support

Kiri:Moto has been out for a few years now, but it’s a bit lacking in community support, as there aren’t that many forums, videos, guides, or other support groups. This may be because Kiri:Moto still isn’t fully developed, and there’s room for growth and improvement.

While there aren’t many, you can check out some of the YouTube videos about how to use the slicer, as well as some forum posts about the program. There’s also a subreddit for Kiri:Moto, but it has almost no followers, so getting help from there may be difficult.

On the bright side, though, Kiri:Moto is integrated into both Thingiverse and Onshape as a plug-in. The integration is meant to consolidate the number of programs it takes to go from a 3D model to G-code script. This has helped spread the popularity of Kiri:Moto, as both platforms have large followings.

All-in-all, community support for Kiri:Moto is relatively weak, but hopefully, it’ll grow if more people see the benefits of an all-in-one, web-based, cloud-powered slicing program.

Kiri:Moto vs. Cura

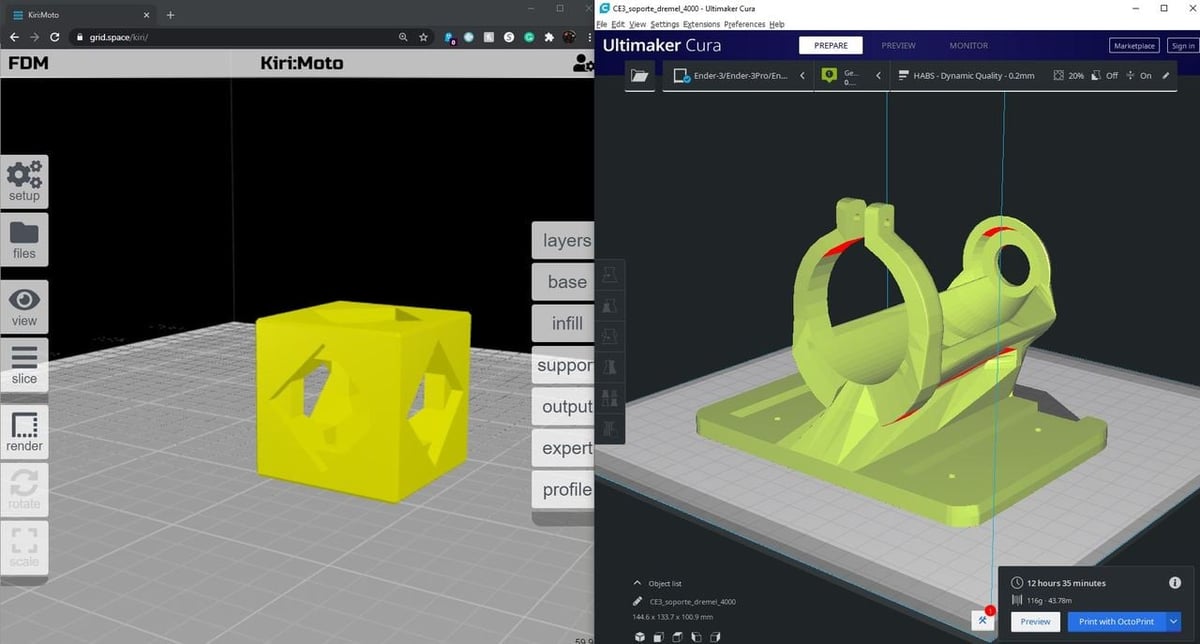

Kiri:Moto, as we’ve explained, is a pretty powerful slicer with many capabilities and uses. But how does it compared to other 3D printing slicers? In this section, we’ll try to answer that question using Cura, the popular open-source 3D printing slicer, as an example.

To start, the way to access each slicer is different because to use Cura, you have to download the Cura application, which can only run on devices like laptops and PCs. On the other hand, Kiri:Moto is exclusively accessible on a web browser like Chrome, Safari, and Firefox. Since almost all devices now have an internet browser, Kiri:Moto is probably the better option for on-the-go makers or people who don’t want to use their larger devices.

Cura is packed with adjustable settings, allowing you to change over 200 settings to fine-tune your printer’s performance and attention to detail. Kiri:Moto has nowhere near the number of settings as Cura, meaning it can be harder to fine-tune the quality of prints. At the same time, it’s less overwhelming for beginners.

Cura is just for FDM 3D printers and, unless you have a specially modified form of Cura, it won’t work with CNC machines, SLA printers, or laser engravers. In contrast, Kiri:Moto works with non-FDM machines, making the program very versatile. While the settings available on Kiri:Moto might be lacking, the program makes up for it by providing settings for more than just FDM 3D printing.

Kiri:Moto is also integrated into many Thingiverse models as a plug-in app, enabling you to slice models right from the Thingiverse model repository. While Cura isn’t a plug-in on Thingiverse, Cura offers their own set of plug-ins made by the open-source community. These plug-ins can help enhance Cura’s capabilities by performing tasks such as automatically orienting your part to reduce supports or adding OctoPrint to your Cura interface.

Lead image source: GridSpace via YouTube

License: The text of "Kiri:Moto (Web-Based Slicer): All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.