3D printing has a waste problem. Accessible manufacturing and the ability to easily experiment with new designs drive innovation, but it also ramps up mistakes and creates a pile of useless objects. When discarded, these prints contribute to landfills that are already at a critical level.

It’s hard to get a handle on the exact statistics of how much waste 3D printing produces. This is especially true as the technology enters the homes of more and more hobbyists each year. But there are estimates out there.

Filamentive sent out a survey in early 2019 to find the amount of filament that is used and wasted by consumers. Accounting for the increase in the use of 3D printing over the past few years, Filamentive gave an estimate that in 2023, at least 379,000 kg of plastic waste was produced by FDM printers in the UK alone. This is worsened by the fact that most of these failed prints end up in landfills.

We already know that plastic is causing environmental issues, and these statistics prove that the widespread use of 3D printing is compounding the pre-existing problem. However, there are ways we can help counteract the effects of 3D printing waste, specifically that of the popular material PLA.

In this article, we’ll take a look at what PLA is, the state of recycling infrastructure, and some ways you can recycle PLA.

What is PLA?

There’s a lot of talk out there about PLA being derived from crops like corn, but also a lot of vagueness around what that means and its implications. To better understand this, we’ll have to start small.

PLA is a synthetic polymer, as are most plastics. Such materials start as small chemical units called monomers. These small units are bonded together in a process called polymerization, forming long chains of the units called a polymer.

Monomers for PLA come from lactic acid, a chemical that can be formed through the fermentation of plant sugars, including corn starch, but can also come from petrochemical origins. The lactic acid undergoes a reaction to convert it into a suitable monomer, which can then be polymerized into its final form. At this point, the final PLA is far from resembling any plant-based origins and is indistinguishable from PLA with petrochemical origins.

Zooming out to look at PLA properties, it notably belongs to a group of materials known as thermoplastics. This means that when heated, the interactions between individual polymer chains loosen, but can reform once cooled, unlike thermoset resins. These properties make PLA a practical material for FDM 3D printing, in addition to other favorable properties like rigidity, low shrinkage, and a relatively low melting temperature.

The same thermal properties that make PLA so ideal for 3D printing also mean that PLA can be melted down and reused without significant reduction in strength. However, just because it can be done, doesn’t mean it’s easy…

The State of PLA Recycling

The short answer is that you can definitely recycle PLA filament, but not in the same way you can recycle your milk jugs, food containers, and other types of everyday plastic. PLA has a different melting point than plastics we’re already recycling, so it can’t go into the same bundle with the rest.

Recyclable plastics fit into multiple categories, as per the Resin Identification Code. These categories are on a numbered scale of one to seven, which also correlates with how recyclable the plastic is, with PET being “1” and the most readily recyclable plastic. You can find a resin identification code symbol on many plastic consumer items.

PLA is included in the “other” category, which also includes materials such as acrylic, nylon, or polycarbonate. Being the seventh category, “other” plastics are deemed the least recyclable and are, unfortunately, rarely accepted by recycling plants, even though PLA is the most used bioplastic. Therefore, PLA is currently best disposed of with regular garbage because throwing PLA parts in the recycling bin is only a contaminant to recyclers.

It’s also worth noting that PLA is more sensitive to thermal degradation compared to other recyclable materials. This means that with heating, the polymer chains can break and result in worsening mechanical properties. Especially when using DIY methods of recycling, which can rarely achieve the temperature control that industrial systems are capable of, the degradation of properties in recycled PLA may be more noticeable.

What About Composting?

You may be wondering why composting has not been mentioned as a disposal method for PLA. After all, PLA is often touted as an eco-friendly filament due to its plant-based origins. However, just because something can be made from a plant-based chemical, does not mean it can be disposed of back into the environment.

While PLA is in fact compostable, it takes very specific conditions, like those of industrial composting, for it to fully break down. These conditions include high temperatures, lots of moisture, and ideally digestive enzymes. Moreover, 3D printed parts contain dyes and other additives that may be harmful when released into the environment.

All that is to say that if PLA ends up in a compositing facility, it will be diverted to the landfill anyway. And PLA parts certainly won’t be going anywhere if you bury them in your backyard.

Ways to Recycle & Reuse

While recycling PLA through your preexisting waste stream is currently not available, you can still find a new life for your PLA scraps. There are some specialty recyclers out there equipped to recycle PLA, or you can melt it down yourself and extrude it into a new filament. Not only do options such as these contribute towards a greener planet, they can be financially beneficial, too.

Recycling Services

The easiest way to take care of PLA filament that you don’t want anymore is to give it to recycling centers that know how to handle it properly. Local centers exist in many large cities, but be sure to check if they accept 3D printed scraps. If you need to outsource your recycling, several services let you box up your PLA and send it to them.

Among such services is the Recycling Fabrik, a German-based company that allows people to mail in 3D printing scraps so that they can be turned into fresh filament. So far, the company accepts PETG and PLA. As a bonus, the scraps can be mailed in for free, though there is a minimum acceptable weight of 2 kg for Germany and 15 kg for the rest of Europe. In exchange for the covered shipping costs, Recycling Fabrik requires users to purchase one of their products, although at a discounted price.

Creating Your Own Filament

If you expect to have large quantities of PLA scraps that you’d like to recycle, you could consider taking the recycling into your own hands. With consumer machines, like those from Precious Plastic or Filabot, you can grind up your PLA scraps and extrude them as usable filaments. These complete systems even come with equipment to wound the recycled filament into a spool, ready to be printed again. Although these machines will cost a pretty penny, there’s unlimited saving on filament to be gained as well.

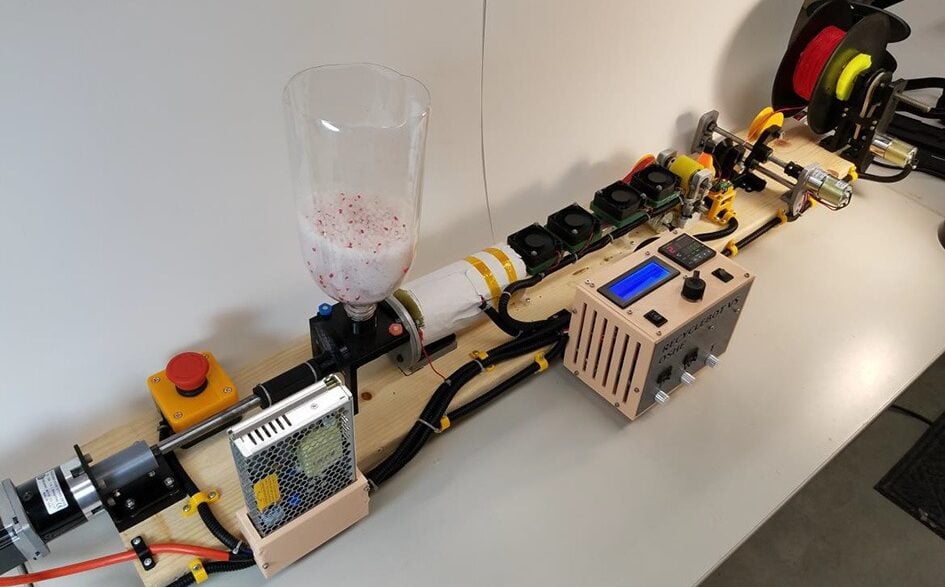

To cut down on the price, there are also DIY recyclers you can build yourself, like the Recyclebot. These are great for 3D printing enthusiasts who like to tinker and experiment with challenging but rewarding projects. With the right machines and practice, you can turn your mistakes into new materials.

Melt & Mold

For those looking to recycle PLA in a cheaper, less labor-intensive way, melting down scraps in a mold can give it a new form and look that even 3D printing cannot achieve.

For this process to work, a high temperature (~200 °C) must be reached so that the PLA liquifies, rather than just softens. Therefore, the mold must be able to withstand such temperatures without losing its shape, making silicone an ideal material.

Once the mold is made, pieces of failed 3D prints can be chopped up into small pieces and placed in the mold. Then, the whole assembly must be placed in an oven that can achieve the required temperatures. Once all of the plastic has been melted, the part is allowed to cool and the mold is removed and can be reused. The final product will generally have unique patterns due to the nature of recycled plastic, making it perfect for display.

This method of reusing scraps is experimental so don’t be afraid to experiment with an efficient technique. Uncle Jessy has a great informative video on this approach on YouTube.

License: The text of "Is PLA Recyclable? – Simply Answered" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.