Creality’s hot end is a workhorse in the 3D printing world. Its simple design lends itself to being incorporated into one of the most-sold 3D printers to date, the Ender 3, as well as its successors the Ender 3 Pro, Ender 3 V2, Ender 3 S1, and the Ender 3 Neo. By default, the Ender 3 printers come with a 0.4-mm brass nozzle, which fits in the heat block with an M6 thread.

The nozzle arrangement has the designation of an MK8 hot end from the RepRap 3D printer community. These printers use the MK8 due to its simplicity, effectiveness, and because it’s open source, so it has a large following amongst hobbyists.

In this article, we’ll look at size and material options for the nozzle on your Ender 3, but first, let’s take a look at the stock option that comes in the box.

The Stock Option

So, how good is the nozzle that’s included with your Creality 3D printer? Let’s take a closer look at the default material and size of the Ender 3 series’ stock nozzle.

Brass is Boss

In the world of FDM printing, the brass 0.4-mm nozzle is king, and the Ender 3 is no exception. What makes brass a good default material is that it’s cheap, easily formed, conducts heat well, and doesn’t tarnish or oxidize easily.

Naturally, brass also has its drawbacks, namely that it’s soft and doesn’t hold up well against the abrasive nature of more exotic filament types. Yet, given the price range of the Ender 3 series and that the majority of hobbyists print in standard filaments like PLA, ABS, and PETG, accessibility and low price have made this nozzle the perfect match.

Brass, however, isn’t the only nozzle material that’ll work with your Ender 3. Later, we’ll take a look at some alternative nozzle materials that have different material properties or specialty purposes.

Sized to Standard

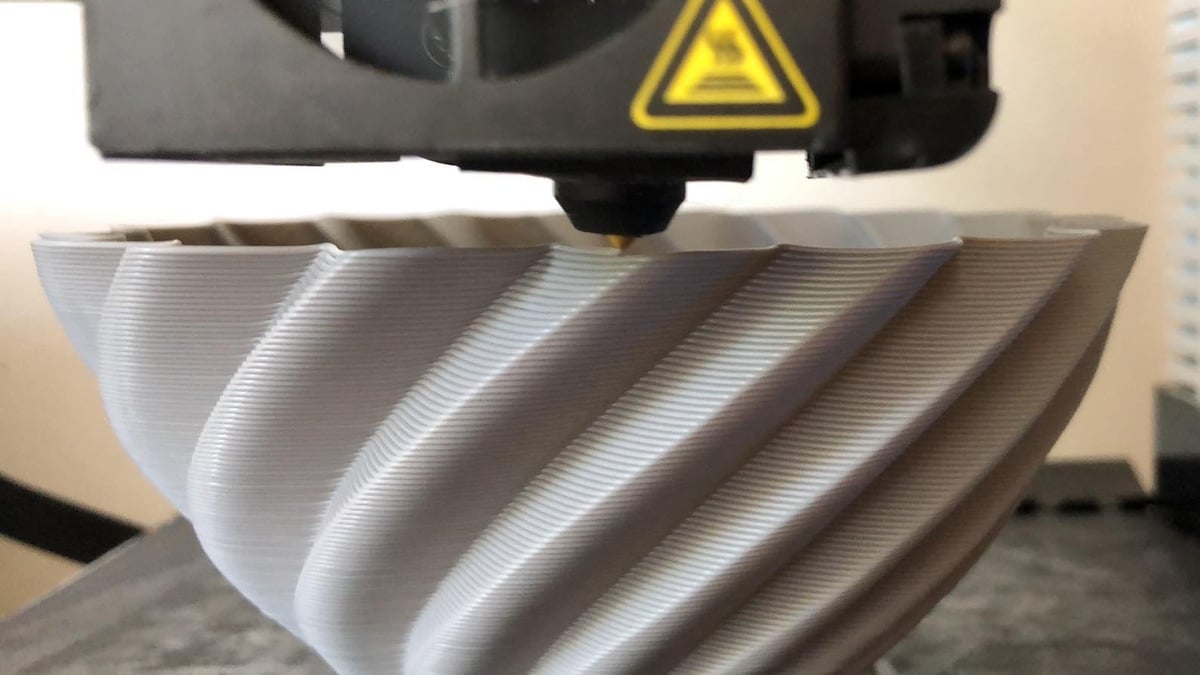

Considering the size of the Ender 3 printers, the 0.4-mm nozzle diameter is a good middle ground. This diameter is small enough to produce workable layer heights from as small as 0.12 mm to as large as 0.24 mm without trouble. Additionally, it’s large enough that most particulates will pass through smoothly, leading to fewer clogs.

However, the 0.4-mm nozzle is not ideal for every print design. What other size options exist for the Ender 3 series and when should you opt for a size change? Keep reading to find out what opportunities you have for larger and smaller nozzle diameters.

Does a Bigger Nozzle Print Faster?

While the 0.4-mm nozzle diameter is the reasonable middle ground, there are other options. Why go larger? Available nozzle sizes are 0.5 mm, 0.6 mm, 0.8 mm, and 1.0 mm, but how do these affect your print?

If you’re printing something large that doesn’t require fine detail, consider whether you could benefit from a 0.6-mm or 0.8-mm nozzle upgrade.

Larger Nozzle Sizes

Pros

- Faster print speeds: Since 3D printers draw an object layer by layer, having a larger nozzle allows for a more substantial layer height. This increased height gives you a faster print time, as it takes fewer passes to complete the part.

- Stronger parts: One of the contributors to weaker parts in 3D printing versus, for example, injection molding is the creation of the layers during the printing process. When using a larger nozzle, there are fewer layers, and each is larger and more consistent. On top of that, the larger layer strands have greater surface areas with which to adhere to one another.

Cons

- Hot end demands: With a larger diameter nozzle, more plastic can be pushed out. However, the downside here is the amount of heat required to keep the plastic melted up to the nozzle’s heat break. If the hot end isn’t up to the task of heating the larger mass of plastic (especially when using the 1.0-mm nozzle), one solution is to maintain a slower print speed. Another solution is to upgrade your hot end to something like E3D’s Volcano hot end whose design allows for a larger melt zone and an increased volumetric flow rate.

- Visible layers: One of the major arguments against large-nozzle 3D printing: “Yeah, but I can see layers all over that.” A larger nozzle is only going to accentuate those layer lines.

Does a Smaller Nozzle Mean Higher Quality?

So we know that large nozzle sizes are ideal for quickly printing large models. but why go smaller? The Ender 3 printers can support smaller nozzle sizes of 0.2 mm, 0.25 mm, or 0.3 mm.

If you’re looking to print small parts that could benefit from high accuracy, perhaps a smaller nozzle could be what you need.

Smaller Nozzle Sizes

Pros

- Subtle layers: When specifying a printer’s layer height, you typically work at around 50% of the nozzle diameter. If you’re looking at making something that’s small and requires fine detail, a 0.2-mm nozzle can easily handle 0.08-mm layer heights.

- Fine detail: Nozzle diameter affects not only layer height, but also X and Y resolution. With a finer nozzle, it’s possible to capture smaller surface details that would otherwise be smoothed out or removed by slicing software working with a larger nozzle.

Cons

- Clogged nozzles: With a much narrower opening, a 0.2-mm nozzle has a higher likelihood of jamming with the smallest impurity or speck of dust than a larger nozzle does. A good filament wipe sponge with mineral spirits can help with this.

- Slow print speeds: A small layer height can lead to massive print times. Trying to make something with a 0.08-mm layer height can take at least three times as long as with a layer height of 0.24 mm. And that’s not including infill or other non-linear considerations.

Alternative Materials

The material that makes up your Ender 3 nozzle also makes a huge difference. The extrusion nozzle might need to be more durable than the standard brass when printing abrasive filament materials like carbon fiber or metal-filled PLA.

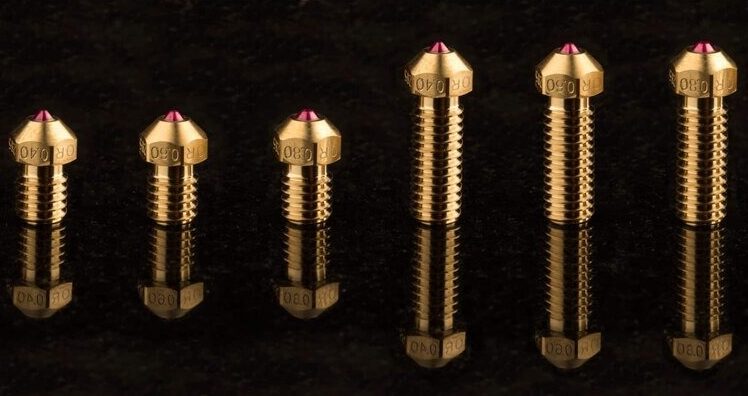

Here’s a list of some materials used for nozzles that you can use to upgrade your Ender 3 if you’re considering abrasive filament, ordered from least to most wear-resistant:

- Brass offers standard wear resistance with excellent heat transfer.

- Stainless steel has better wear resistance and is food-safe.

- Hardened steel has great wear resistance but lower heat transfer. Nozzles in this material may come in several varieties, like blackened or nickel plated.

- Copper with sapphire ruby provides the best wear resistance. Olsson produces a standard ruby nozzle as well as one particularly suited for high temperatures.

- Coated nozzles, such as the “polyphobic” coating of E3D’s Nozzle X also offer high wear resistance suitable for use with the most abrasive filaments, although a E3D V6 hot end upgrade is necessary.

With so many nozzles available, there’s sure to be one that matches your need and application. We hope you’ve enjoyed our survey of different nozzle sizes for the Ender 3 series and their effect on your prints. As always, happy printing!

License: The text of "Ender 3 (V2/Pro/S1/Neo) Nozzle Size: All Supported Sizes" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.