3D printing beginners often start with PLA because it’s an easy material to work with. While PLA can produce some excellent parts, there might come a time when you need materials with different properties for a specific project.

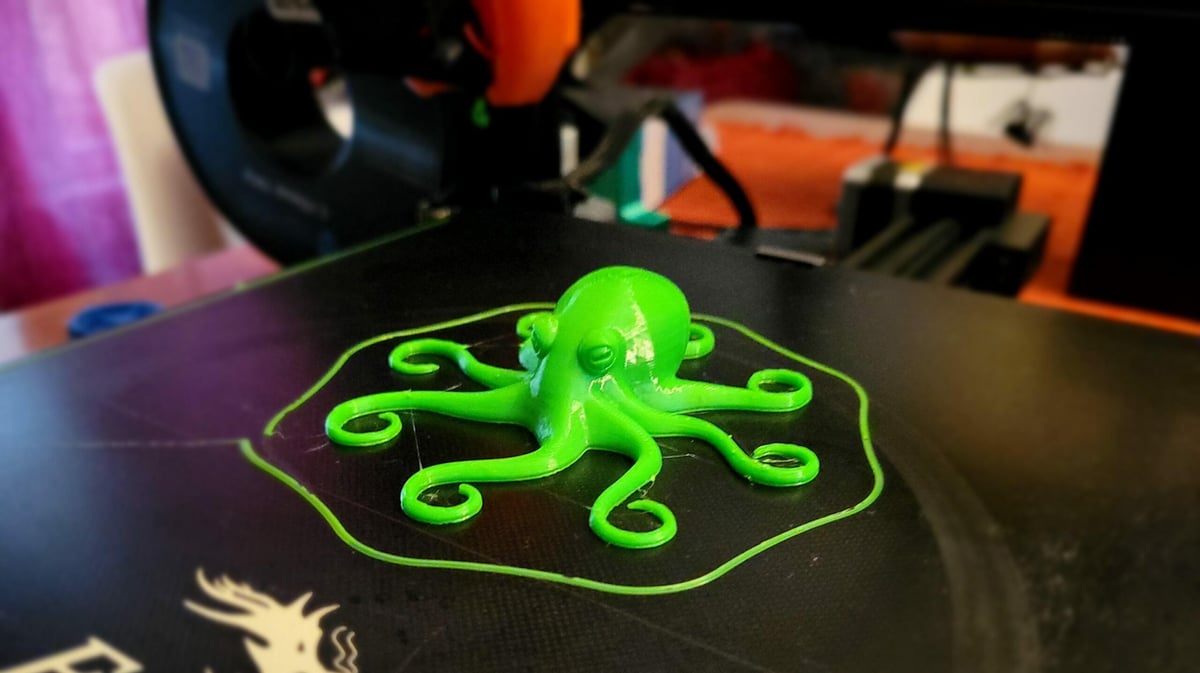

That’s where flexible filaments come in. TPU is an example of a flexible material you can use to create different types of models. From RC car tires to coasters, this material unlocks new possibilities when added to your arsenal.

In forums, you’ll often see complaints that the Ender 3, Pro, and V2 can’t print in TPU or flexible filament because of the way they’re built. The extruder, the Bowden system, and the hot end will likely be mentioned as insufficient in one way or another.

However, there are hardware modifications to address each of these issues as they relate to TPU. In this article, we’re going to cover all the options you have to get TPU printing smoothly on your Ender 3.

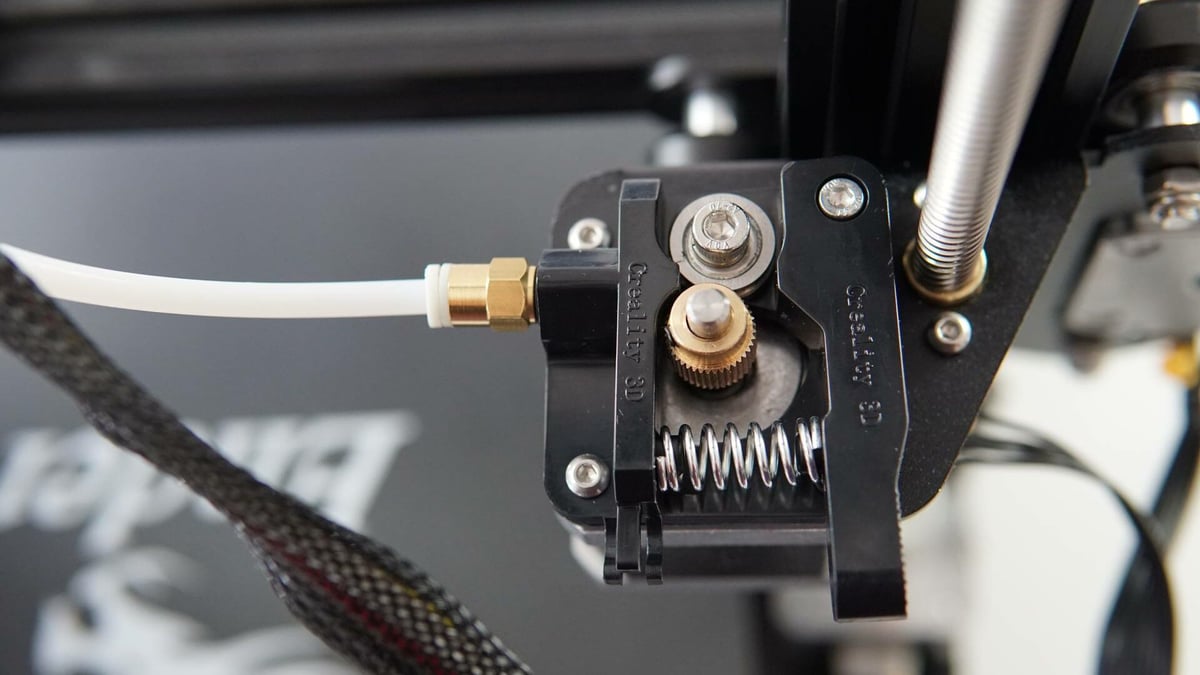

The Extruder Assembly

The Cold End

Discussions around the Ender 3’s extruder will generally point out the likelihood of the filament bending in the cold portion, after it passes the toothed gear. This is a bigger problem with flexible filament because… it bends, and the motion of the extruder motor won’t be transferred properly.

All-Metal

An upgraded all-metal extruder can help with the potential bending of the filament in the extruder, but if you’re on a smaller budget, this extruder upgrade from Thingiverse user joshvv addresses the issue. Some makers have even recommended using a straw to keep the filament straight – the key is to avoid bending of any kind.

Direct Extruder

Another highly recommended extruder upgrade is a direct extrusion system. Eliminating the Bowden tube entirely allows your Ender 3 to be much more precise while using flexible filaments, and indeed while printing in general. The shorter filament path and increased traction give a much better chance of success while printing with flexibles.

The Hot End

As stated earlier, an upgraded all-metal hot end can make printing with TPU easier since it eliminates the PTFE tube that could cause issues with flexible filament. In addition, these types of hot ends can reach higher temperatures, which gives you access to a whole range of other materials.

The Bowden Tube

The Bowden tube can sometimes be at fault for allowing the filament to bend too much, causing a problem. Upgrade kits often include a fresh Bowden tube, but you can also opt for a higher-quality tube, which should result in easier movement of the filament to the hot end.

Slicer Settings

TPU prints with a hotter nozzle temperature than PLA, usually somewhere around 220-230 °C, while many users print PLA at or around 200 °C. You’ll probably also find that you need to turn up the temperature of your heated bed and may need to use tape or hairspray for bed adhesion, even if your PLA sticks to your bed with no aid.

As far as cooling goes, keeping the fan off for the initial layers will help with bed adhesion. After that, you can keep the cooling fan at a low setting but increase it when printing models with bridging.

In addition, reduce your speed to at most 30 mm/s. If your extruder clogs or gives you messy, stringy prints, you may need to adjust your retraction to as low as zero. You’ll also need to adjust the nozzle distance from the bed, as TPU doesn’t require as much “squish” as PLA.

As with all slicer settings, the key to success is experimentation. Different brands of TPU may require different settings, but good prints are just one experiment away!

License: The text of "Ender 3 (V2/Pro) & TPU: How to Print Flexible Filaments" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.