3D printing can be accomplished in various ways with various technologies. Some methods, such as fused deposition modeling (FDM) or wire arc additive manufacturing (WAAM), deposit layers of material, one on top of the other, starting with a layer on a print bed or corresponding surface. Others, such as selective laser sintering (SLS), harden powder into various shapes inside a heated build chamber.

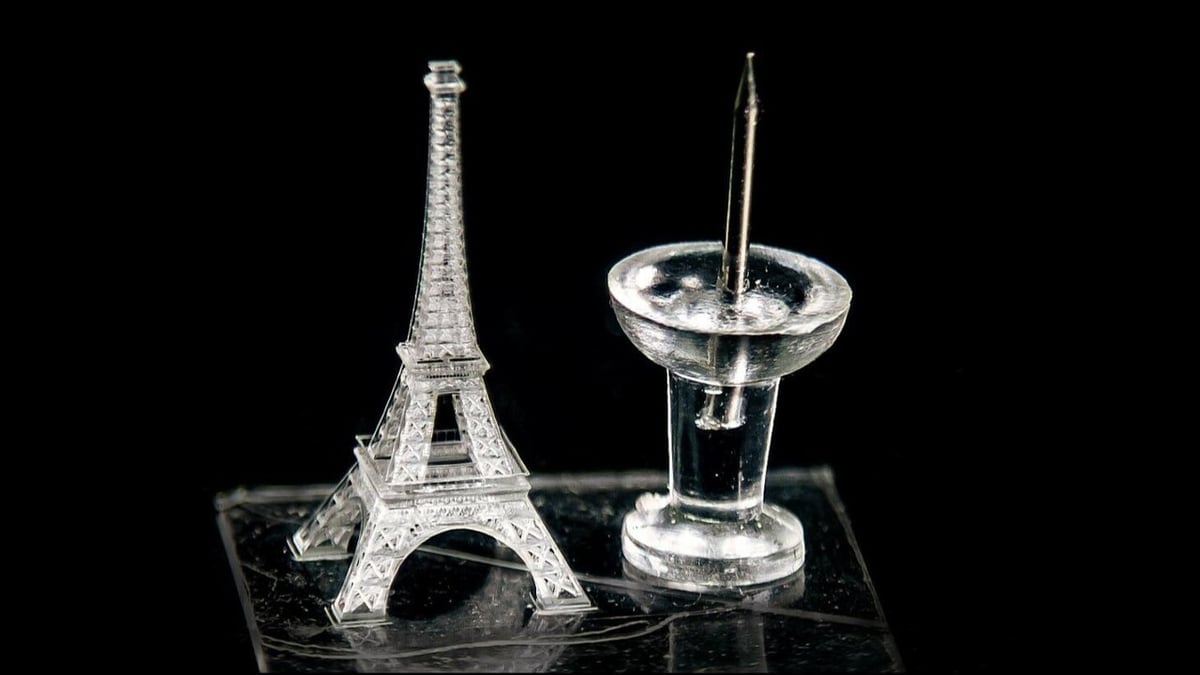

DLP, which stands for digital light processing, is one of these additive manufacturing technologies that can seemingly lift solid objects out of thin air, along with similar LCD and SLA 3D printing technologies. So how does it work, and why do people use it?

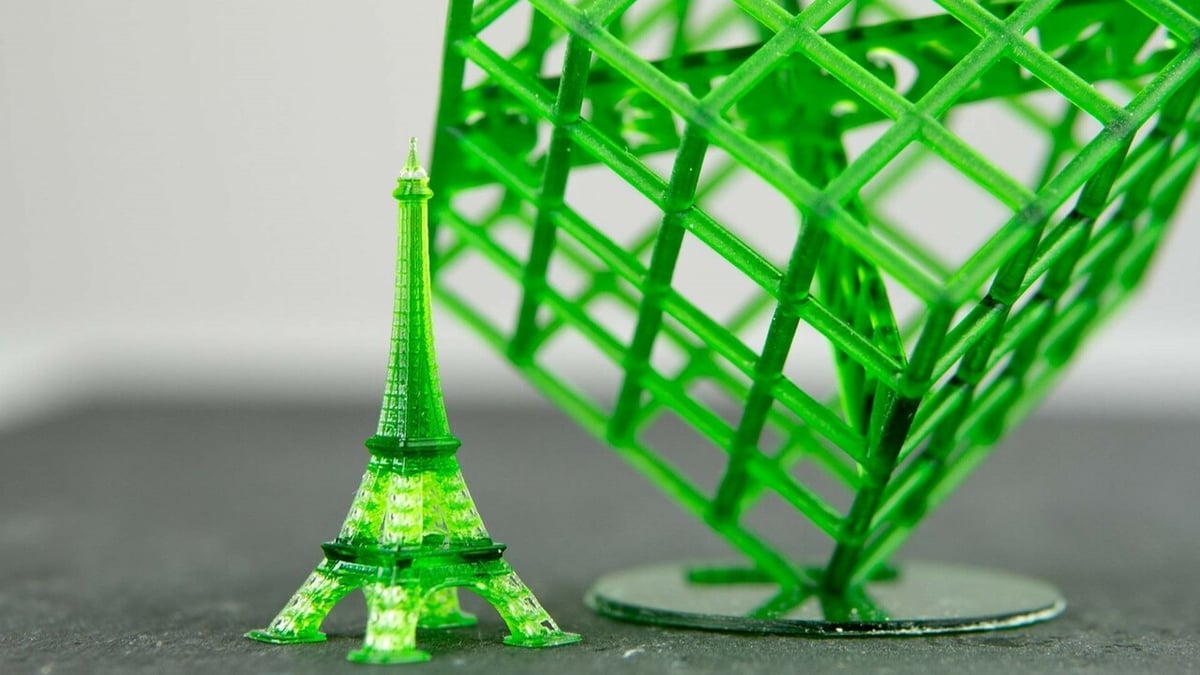

DLP is a type of vat polymerization. Vat polymerization 3D printing technologies use a (liquid) photopolymer resin that can cure (solidify) under a light source.

In this article, we’ll take you through what a DLP 3D printer is and, more importantly, how it fits into the world of 3D printing today.

How Does It Work?

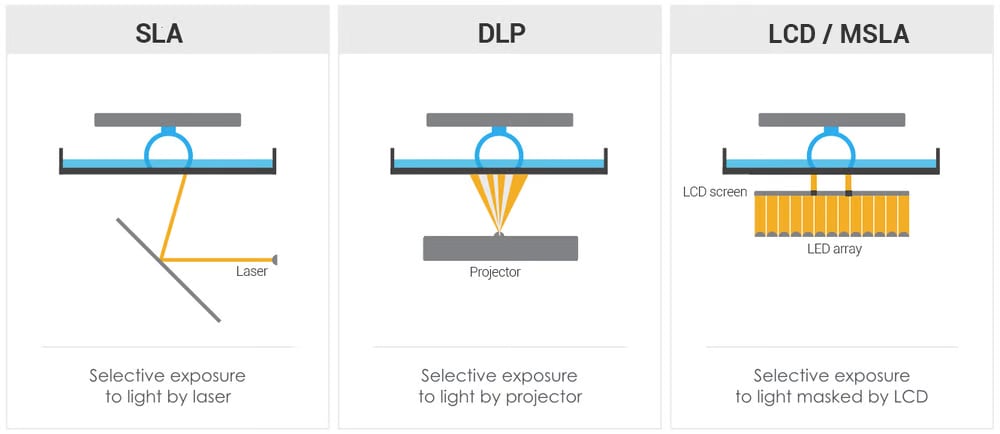

Vat polymerization 3D printing technologies use resin and a light source to produce parts. The main difference between the three vat polymerization technologies (DLP, SLA, and LCD or MSLA) is the type of light source that is used to cure the resin.

While SLA printers use lasers combined with galvanometers to cure resin, with a DLP 3D printer, the light source is an especially developed digital light projector screen. Thanks to this screen, DLP is generally considered to be faster than SLA when printing objects with small Z-axis heights. This is because, with SLA, the laser has to individually cure the resin in a “point to point” technique. On the other hand, a DLP projector screen flashes an image of a layer all at once! Thus all points of a layer can be cured simultaneously. In this way, the print speed is slightly increased in comparison to SLA since it takes less time to cure a single layer.

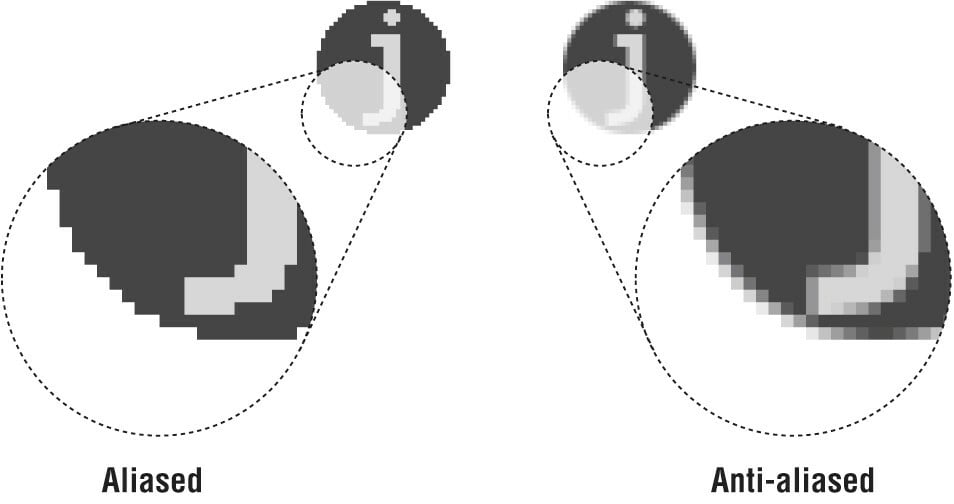

Since DLP is a digital technology, the 2D image that is projected is composed of pixels. When translated into three dimensions, they become voxels. This means that, compared to a smoothly-moving laser, a magnified cross-section of a DLP 3D print will be more pixelated than an SLA 3D print. This pixelation is similar to what causes inaccuracies in LCD 3D printers, which are closely related to DLP 3D printers but have a different means of (preventing) light exposure: the less-expensive LED screen.

At the heart of every DLP chipset is the digital micromirror device (DMD). A DMD contains hundreds of thousands or even millions of small micromirrors that direct the light from the light source and project the pattern onto the bottom of the resin tank.

The resolution of a printed part using a DLP 3D printer usually corresponds to the number of micromirrors inside a DMD device. This unique photocuring system is a significant part of why DLP is used, and what it is used for, in industry today.

Characteristics of DLP 3D Printing

The specific process of DLP 3D printing causes DLP printed parts to have specific, distinguishable qualities. Like all resin 3D printing technologies, UV light from the DLP printer’s light source cannot penetrate more than 100 microns (0.1 mm) into the resin tank. This means that layer heights on DLP 3D printers typically fall between 25 and 100 microns. This means that even a centimeter-tall print can have up to 400 layers.

Surface Finish

Unlike SLA 3D printers, DLP 3D prints have voxelated surfaces, or pixelated layer cross-sections. This is because, unlike a laser tracing a smooth surface into the resin, the projector projects the entire line at once using pixels from its screen at the bottom of the resin tank. Sometimes this can prevent 3D prints from having the same level of surface smoothness as SLA prints (as pixels, as a general rule of thumb, are about 50 x 50 microns on hobbyist LCD and DLP 3D printers). However, this means that DLP 3D printers can technically print thinner walls than their SLA counterpart, which has a comparatively much thicker laser (for example, the width of the Formlabs Form 3B’s laser is 85 microns).

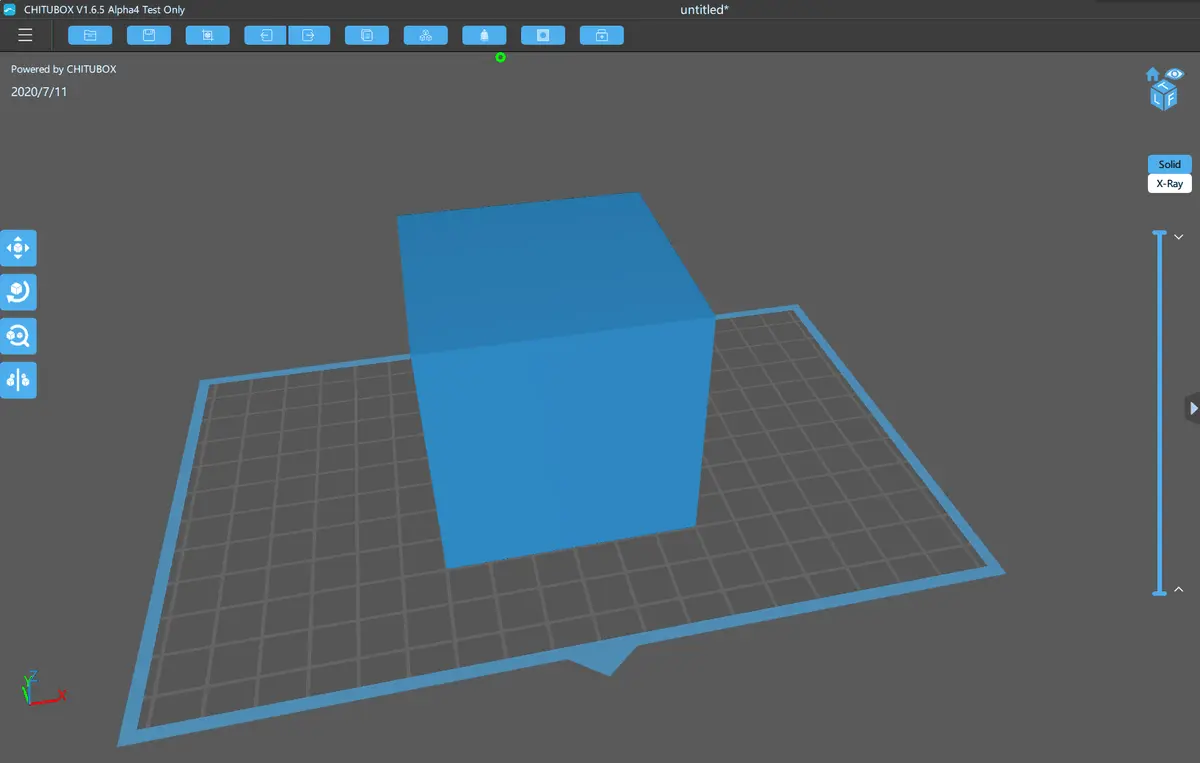

Because of the pixelation problem, DLP print preparation programs such as ChiTuBox or Lychee, as well as many proprietary slicers, have a feature called “anti-aliasing” that smooths out jagged micro-edges by partially curing the resin immediately outside of the object boundary. This fix is used for both LCD and DLP 3D printers. Specifically with DLP 3D printers, however, there is another fix. As DLP 3D printers use a projector, the pixels curing the resin are themselves scalable. This means that, up to a point, smooth lines are achievable by scaling the resolution of the DLP 3D print.

Printing Material

DLP 3D printers use liquid 3D printing resin, which is more expensive per unit volume than typical FDM 3D printer filaments such as PLA or PETG. Fortunately, since LCD 3D printing became more affordable for hobbyist 3D printers following the release of the Anycubic Photon, resin prices have been trending downwards.

Regardless, the price of resin means that many print preparation programs for DLP 3D printers have hollowing features, wherein large objects are shelled by the slicer, with drainage holes added to release resin from internal areas, in order to save resin costs for objects that don’t need to be completely solid.

It’s important to note that every DLP 3D printer emits light at a certain wavelength (usually between 385 and 410 nanometers), and most resins have a range of light wavelengths that will activate or harden the resin. It’s crucial for successful printing to make sure that the DLP 3D printer is able to harden the resin that you will be using to 3D print. Otherwise, the resin will either not harden consistently or won’t harden at all.

DLP As a Technology

Given the absence of DLP 3D printers in the homes of many hobbyists, who favor more budget-friendly LCD 3D printers, it might seem to some that DLP is an obsolete or unused 3D printing technology. While it is true that one might be hard-pressed to find a DLP 3D printer in someone’s home, DLP 3D printing has an important place in businesses that do high-precision, high-volume resin printing.

Dentists, jewelers, and medical modelers use the technology to create high-detail, small parts for various applications. Additionally, it serves as a base for other technologies, such as Carbon3D’s CLIP 3D printing technology.

Interestingly, though, the world might soon see a rise in DLP machinery usage by hobbyist 3D printers. 3D printer producer Anycubic released the Photon Ultra, designed to be a more affordable DLP 3D printer. While it hasn’t quite reached LCD status in terms of it being the technology that’s chosen by hobbyists, it might just be a matter of time.

DLP 3D Printers Today

Today, DLP 3D printers are sometimes sidelined for affordable LCD 3D printers in vat polymerization applications, although it’s still used to make high-detail parts for specific industries such as jewelry making, dentistry, and prototyping facilities.

This shift in technologies, as well as the subtlety of the difference between DLP and LCD 3D printing, has led to many LCD 3D printers being marketed as DLP 3D printers, as both technologies use a light source to harden an entire layer of resin at once.

If you’re on the fence about what technology may fit your needs best, check out the best resin printers – maybe one of these will be just right for your setup.

License: The text of "What Is a DLP 3D Printer? – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.