Believe it or not, 3D printed cars are gaining ground as the different technologies advance.

Beyond the novelties of 3D printing, additive manufacturing has proven valuable to the automotive industry in a host of applications, from prototyping to production and even restoration!

Since cars consist of various materials, 3D printed parts are prevalent wherever plastic or metal are needed. For end-use components, automotive manufacturers primarily take advantage of fused deposition modeling (FDM) technology for plastic parts, whereas selective laser melting (SLM) printing is used to create metal parts. However, for prototyping purposes, any 3D printing method can be used.

In our list of the coolest cars with 3D printed parts, you’ll find that most of our picks rely on FDM and SLM technologies for mass-produced components, with other methods being used for one-time concepts or prototypes.

In the long run, additive manufacturing will more than likely continue aiding the innovation of cars both functionally and aesthetically.

Cupra Dark Rebel

Cupra, a Volkswagen Group member, is gaining attention for its commitment to sustainability and high-power vehicles that exude sleekness. This style is apparent in the Cupra Dark Rebel, which, thanks to its sleek exterior, might trick you into thinking it’s sculpted from a single piece of metal at first glance. This may just be the result of creative additive manufacturing.

The defining feature can be found in the main cabin – a central spine crafted with 3D metal printing technology. This printed piece not only gives lightweight structural integrity but also allows for an eye-catching asymmetrical shape. The central spine gracefully emerges from the base of the seats, extending forward to create a visually striking interior.

In a collaboration with HP, Cupra has also manufactured and tested various end-use parts, like new door mirrors, at Cupra Racing with Multi Jet Fusion technology.

- Designer: Cupra

- Technology: SLM

- Status: Functioning concept

- Printed Material: Metal, polymer-fiber composites

Czinger Vehicles 21C

Czinger Vehicles’ 21C, praised as one of Time Magazine’s Best Inventions of 2023, is at the forefront of automotive innovations. Imagine a design process using supercomputers and artificial intelligence to create the car’s frame where each part is precisely optimized, ensuring no material goes to waste.

Turning this digital design into a real structure involves 3D printing, with carbon fiber strategically employed for specific components, including vital structural elements. This reduces weight and optimizes functionality for improved performance. However, the 21C isn’t just about performance, it’s about redefining sustainability in the automotive industry.

The parts are carefully made so they can be taken apart and re-atomized, allowing them to be reprinted and reused. This is a step forward in being more conscientious about the planet.

- Designer: Czinger Vehicles and Divergent Technologies

- Technology: SLS, FDM

- Status: Functioning concept

- Printed Material: Metal, polymer-carbon fiber composite

Nio EP9 Concept

A concept vehicle is typically a car designed to demonstrate new automotive designs and technology for exhibitions.

While most concept cars aren’t meant for production, the EP9 is an exception, with a price tag of just under $3.5 million. Designed by Vital Auto for Chinese automotive manufacturer Nio, the EP9 is currently the fastest and most expensive electric vehicle (EV) in the world. It was designed and developed in just 18 months, thanks in part to 3D printing.

Using the Formlabs Fuse SLS printer for structural and mechanical parts, and the Form 3L SLA printer for complex, interior parts, Vital Auto was able to prototype much of the EP9 within their studio. By drastically reducing costs and time normally dedicated to outsourcing, in-house manufacturing allowed them to produce multiple design iterations within 24 hours.

The Vital Auto team views 3D printing as an “inseparable” part of their process.

- Designer: Vital Auto

- Technology: FDM, SLA (stereolithography), SLS (selective laser sintering)

- Status: Functioning concept

- Printed material: Plastic (variety)

BAC Mono R

The BAC Mono R, introduced at the Goodwood Festival of Speed in July 2019, stands as a testament to the fusion of British craftsmanship and cutting-edge technology in the world of supercars. In a strategic collaboration with DSM, BAC has elevated its manufacturing capabilities by seamlessly blending 3D printing into its production processes.

The star of the show, the Mono R, represents a paradigm shift in automotive design. Every panel of this sleek marvel is crafted with graphene-enhanced carbon fiber, setting a high standard for structural integrity. This infusion not only makes the car panels strong and lightweight but also enhances their mechanical and thermal performance.

Over 40 components of the BAC Mono R, ranging from meticulous elements like front and rear light surrounds to mirror arms, hatch hinges, and engine inlet components, bear the distinctive mark of 3D printing. In the words of Ian Briggs, co-founder and design director of BAC, 3D printing is not merely a rapid prototyping tool; it has become an indispensable manufacturing technique, playing a pivotal role in the creation of a high-performance masterpiece.

- Designer: BAC and DSM

- Technology: FDM, SLS, SLA, FFF (fused filament fabrication)

- Status: Functioning concept

- Printed Material: Metal, thermoplastics

Bugatti Bolide

Luxury car manufacturer Bugatti was one of the first high-end automotive companies to adopt 3D printing as a manufacturing method and continues to embrace it. Since 2018, they have utilized SLM technology to print lightweight, durable parts out of titanium, carbon, and even ceramic.

After perfecting the process, Bugatti decided to incorporate it into the design of the Bolide. From brake components to complex brackets, 3D printing is present in both the car’s interior and exterior.

- Manufacturer: Bugatti

- Technology: SLM

- Status: Functioning concept

- Printed material: Metal, ceramic

Lamborghini Diablo Eccentrica

Eccentrica Cars have undertaken a remarkable venture, breathing new life into the iconic Lamborghini Diablo to introduce the world to the Lamborghini Diablo Eccentrica. Unveiled at the prestigious Goodwood Festival of Speed in 2023, this restomod stands as a testament to the fusion of retro elegance with cutting-edge technology.

A restomod is more than just a restoration; it’s about taking a vehicle and giving it a technological and design upgrade to enhance its performance and looks. Only 19 versions of the Eccentrica Restomod have been produced, ensuring each one is unique. While you can contact them for configuration, customizations, or test drives, the restoration itself will cost ~$1,300,000, and the donor car (in this case, the Lamborghini Diablo, which on average costs ~$300,000) will be an additional expense.

Moving beyond mere unique aesthetics, this project delves into the realm of advanced manufacturing, incorporating 3D printing technology into the titanium bodywork. The utilization of this technology isn’t just for visual appeal; it contributes to the restomod’s lightweight, durable nature. Noteworthy 3D printed components are the cuboidal intakes and the width-spanning titanium vent.

- Designer: Eccentrica Cars

- Technology: SLS

- Status: Functioning concept

- Printed Material: Metal

XEV Yoyo

The XEV Yoyo, formerly known as the LSEV, is one of the few 3D printed cars that have successfully been released to the public.

A compact electric car designed for the urban environment, the Yoyo was developed by XEV in partnership with Polymaker, a filament manufacturer. Excluding parts like tires, windows, seats, and chassis, both the interior and exterior of the vehicle are 3D printed.

The Yoyo is a very lightweight car, coming in at only 450 kg (without the battery). Its battery system has a range that’s said to be 150 km (90 miles), with a top speed of 80 km/h (43 mph). The Yoyo utilizes a unique 3D printing production line that maximizes efficiency and customization options during manufacturing operations.

As of 2022, most Yoyos can be found on the streets of Turin, Italy. The city, which is also the home of XEV, signed an agreement with the startup to deploy 100 cars with an adjacent car-sharing service. You can also purchase your own with prices starting at just $14,000.

- Manufacturer: XEV and Polymaker

- Technology: FDM

- Status: In production

- Printed material: ABS

Audi Type C Replica

This 1:2 scale replica of the Audi 1936 Auto Union Type C is Audi’s (and the Volkswagen Group’s) first fully 3D printed vehicle, produced entirely in-house. It’s a fun way for the German automaker to demonstrate the potential of 3D printing metal parts.

All of the metal parts were produced using an SLS 3D printer and were later assembled to form the complete 3D printed car.

- Manufacturer: Audi

- Technology: SLS

- Status: Functioning replica

- Printed Material: Metal

David Bowie Tribute Car

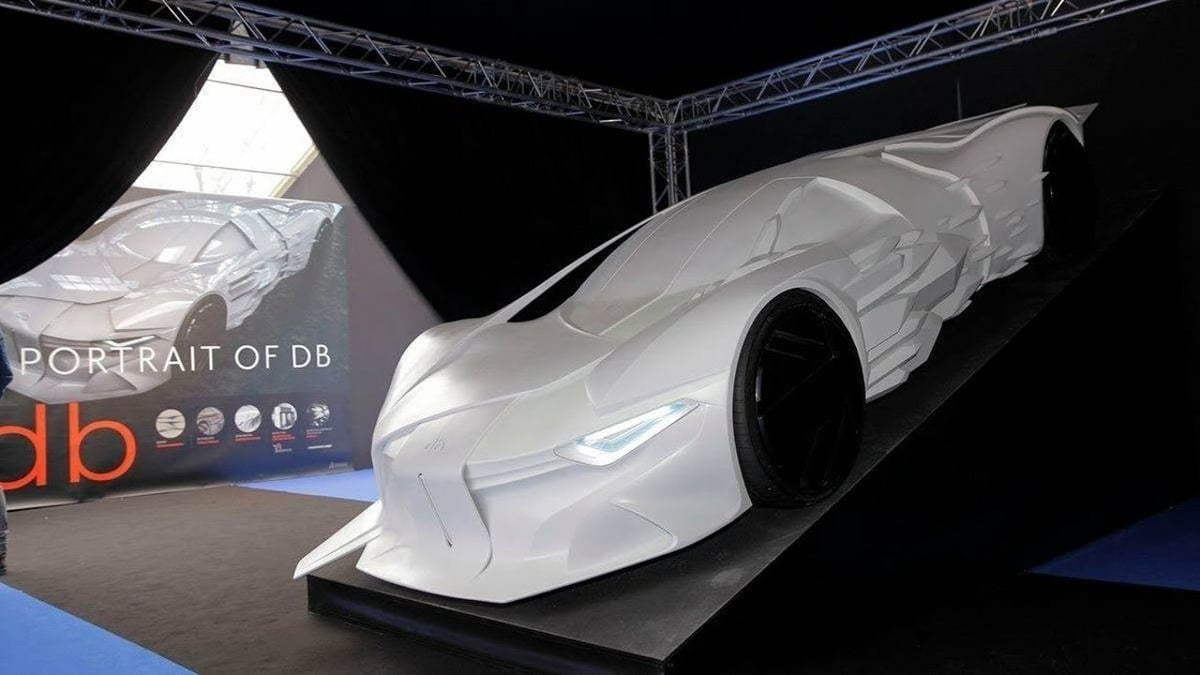

Massivit 3D, an Israel-based 3D printing company, made headlines in 2019 for introducing the first full-scale and fully 3D printed concept car at the Festival Automobile International. However, the car itself is better known as a tribute to the late David Bowie.

Created by automotive designer Takumi Yamamoto and prototyped by Massivit, this collaboration fully leveraged large-format 3D printing to create bold geometry and forms that captured the essence of the music icon. While not a fully drivable car, the David Bowie Tribute Car is a 1:1 scale prototype that serves as an aesthetically inspiring piece of art.

- Manufacturer: Massivit 3D Printing

- Technology: FDM

- Status: Functional concept

- Printed material: Dimengel thermoset plastic

Alfa Romeo C41

Alfa Romeo, synonymous with high-performance luxury cars, brings its high-performance gears to the Formula 1 racetrack. In collaboration with Sauber, they have been steering towards cost-effectiveness and sustainability.

The journey began in 2017 when Sauber’s Metal 3D Printing Competence Center partnered with Additive Industries, marking the start of a three-year collaboration focused on the efficiency of 3D printing. In the same year, Alfa Romeo announced its title sponsorship for Sauber, and shortly after the center brought in five 3D Systems ProX 800 SLA 3D printers to enhance their capabilities.

All of these collaboration has recently been extended, underlining a long-term commitment to integrating 3D printing in Formula 1. This also mirrors a broader trend towards additive manufacturing in Formula 1. Teams like McLaren and Alpine, along with collaborations like Jabil with Renault F1 in 2019, highlight the industry’s pursuit of cutting-edge technologies for heightened efficiency and performance.

The 2021 Alfa Romeo C41 race car showcased 304 3D printed components, achieving a 90% cost reduction compared to traditional manufacturing. In a strategic move for 2022, Sauber Technologies embarked on a three-year collaboration with EOS, a prominent industrial 3D printer manufacturer.

- Manufacturer: Sauber and Alfa Romeo

- Technology: SLS, SLA, FDM

- Status: Functioning concept

- Printed material: Metal (titanium, stainless steel, etc.), plastic

Ruston-Hornsby Restoration

The Ruston-Hornsby car was a low-volume production vehicle produced between 1919 and 1924. Due to its scarcity, finding spare parts would be close to impossible unless you can manufacture them on your own. Luckily, Siemens UK had the adequate technology to take on this challenge.

Siemens used SLM technology to reproduce two essential components: the hood ornament and steering housing. Despite the Ruston & Hornsby company being a subsidiary of Siemens, the lack of surviving design drawings and various broken parts repeatedly delayed this restoration effort. Finally, in 2016, the company was able to use a combination of 3D scanners, computer-aided design (CAD), and newly acquired SLM printers to accurately recreate the parts. In an interview with Siemens engineers, it was revealed that the steering housing model was also improved through the addition of honeycomb cutouts to maintain the part’s light weight while retaining strength.

- Manufacturer: Siemens UK Material Solutions

- Technology: SLM

- Status: Fully restored

- Printed material: Metal (stainless steel)

Lamborghini Aventador

Last on our list is arguably the most affordable 3D-printed luxury car, although it might take you at least four years to build and several more years to make the final touches! It all started after 12-year-old Xander Backus got to drive a virtual Lamborghini Aventador in a video game. When he asked his father if they could build one from scratch, the father-son pair took on the challenge to make their own.

Most notably, the exterior panels of the Aventador were 3D printed with FDM and later laminated with three layers of carbon fiber on both sides to increase structural integrity and heat tolerance. The elder Backus chose to document their ongoing journey on YouTube, quickly going viral among the automotive and 3D printing communities.

As a result, they even caught the attention of Lamborghini, who provided them with real Lamborghini parts, including the pricey front headlights (~$5,000 each) and the steering wheel. In addition, the automaker even surprised them with the opportunity to drive a real Aventador for a holiday commercial.

While Aventador’s paint job is nearly finished, the duo continues to make improvements to the mechanical and electrical systems. They also take the car to exhibitions, including the 2023 RNR car show, where it looks quite similar to a real Lamborghini from a distance!

- Designer: Sterling and Xander Backus

- Technology: FDM

- Status: Functioning concept

- Printed Material: PLA, ABS, ASA, and PETG

Divergent 3D Blade

The Blade is a high-performance, 700-horsepower car designed to be manufactured out of carbon fiber tubes and 3D printed aluminum rods! The two components are implemented into the chassis in order to deliver high strength and low weight.

The company behind the Blade is Divergent3D, and one of its goals is to come up with various approaches through which cars, as we know them today, could be more lightweight and cost-effective to produce. According to Kevin Czinger, the founder and CEO of Divergent3D, the company uses topology optimization software to create the most effective geometry for their designs.

In 2017, the Blade was featured in an episode of Jay Leno’s Garage, where Czinger explained the vehicle’s design process before Leno took it for a test drive.

- Manufacturer: Divergent3D

- Technology: SLM

- Status: Functioning concept

- Printed Material: Metal (aluminum)

License: The text of "The Coolest 3D Printed Cars of 2023" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.