Just What Is 3D Printing?

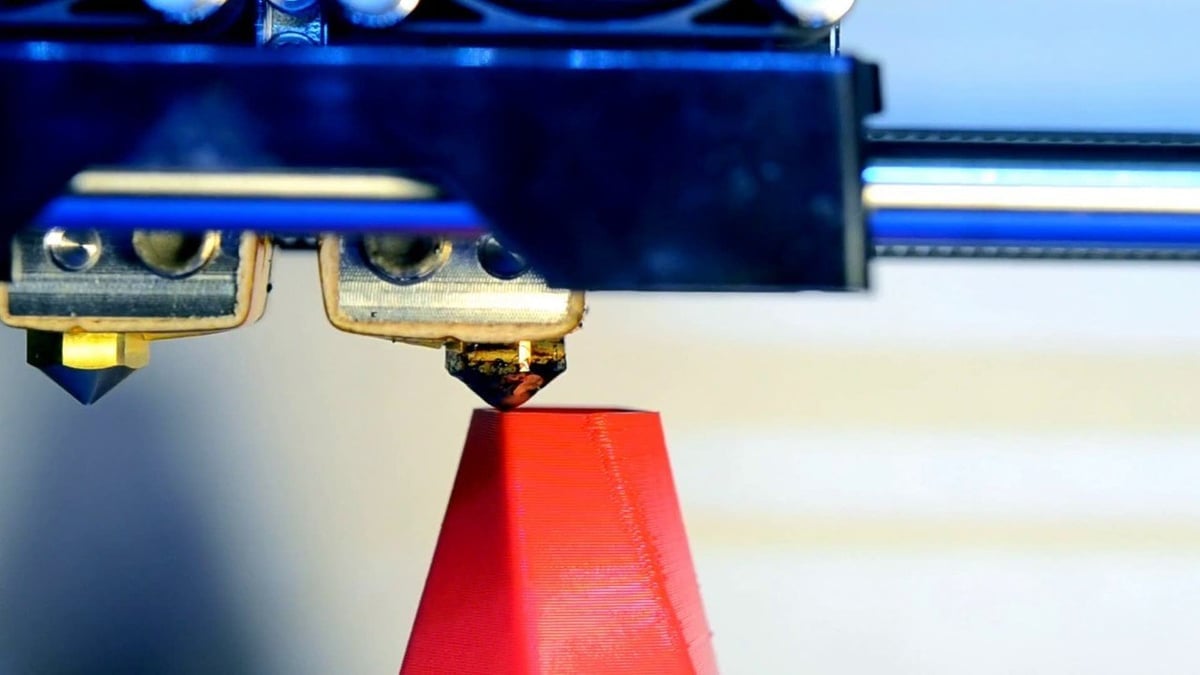

Additive manufacturing now defines a large branch of industrial (and hobby) systems for creating new parts and products. More commonly referred to as 3D printing, most systems in this category are characterized by their layer-by-layer method of building a part.

There are notably some differences between individual systems, with 10 types of 3D printing existing today. However, the main differences between these and more typical industrial processes can be broken into categories:

- Speed defines how fast a given part can be manufactured from design to finish.

- Cost is the average amount of funding needed to create a single part.

- Quality is a realistic measure of how perfect and precise a part can be made.

- Consistency is how similar “identical” parts are between separate manufacturing runs.

- Flexibility defines how easily a design can be customized or modified during manufacture.

- Accessibility is a rough measure of how easily a person or business can obtain the means to create a part or product.

- Sustainability is a rough measure of the amount of waste generated by the manufacture of a single part and the ease with which the part can be recycled compared to other processes.

Speed

One of the biggest advantages of 3D printing is summed up in two words: Rapid Prototyping.

Rapid prototyping is essentially the ability to design, manufacture, and test a customized part in as little time as possible, and then be able to easily modify the design without adversely impacting the speed of the manufacturing process.

Before 3D printing existed as a mainstream manufacturing process, a prototype would take weeks to manufacture. Every time a change was made, it would be another few weeks until the modified design could be manufactured. Add in shipping times, and it could easily take a year to fully develop a product from start to finish.

Enter modern 3D printing: Businesses now have the ability to design a part, manufacture it in-house on a professional 3D printer, and then test it, all in the space of a few days (and sometimes even less). This means that the time needed to effectively prototype a part from start to finish has been decimated to almost nothing!

Let’s not forget about the little guys, either. Due to the advent of desktop 3D printers, makers, hobbyists, and enthusiasts alike can now create almost anything. They can be as creative as they please without the need for warehouses full of machinery. They are also free of the huge lead times associated with outsourcing complex manufacturing jobs. For these users of 3D printing, rapid prototyping takes a whole new meaning: they are free of the constraints of minimum orders, can customize anything and everything they create with ease, and are able to share or sell their unique designs to others who also have a 3D printer, right from their home or workshop.

This is not to say there are not limitations of 3D printing when it comes to speed. By nature, the layer-by layer process has a fixed time per part, meaning that a single component will always take the exact same amount of time to create as the last. With systems like injection molding, after the initial investment of time needed to create the proper tools and molds, the system can be automated and the part rapidly mass-manufactured. This significantly decreases the amount of time needed per part.

So, for small production runs and prototyping, 3D printing is one of the best options as far as speed is concerned. However, for producing a finished product on a mass-manufacturing scale, traditional manufacturing systems still outpace 3D printing by a long run.

Cost

This is where things become somewhat interesting. As discussed in the previous section, 3D printing takes a lot less time to manufacture a single unique component or prototype. However, traditional methods of manufacture are able to expedite the mass production of a finished part.

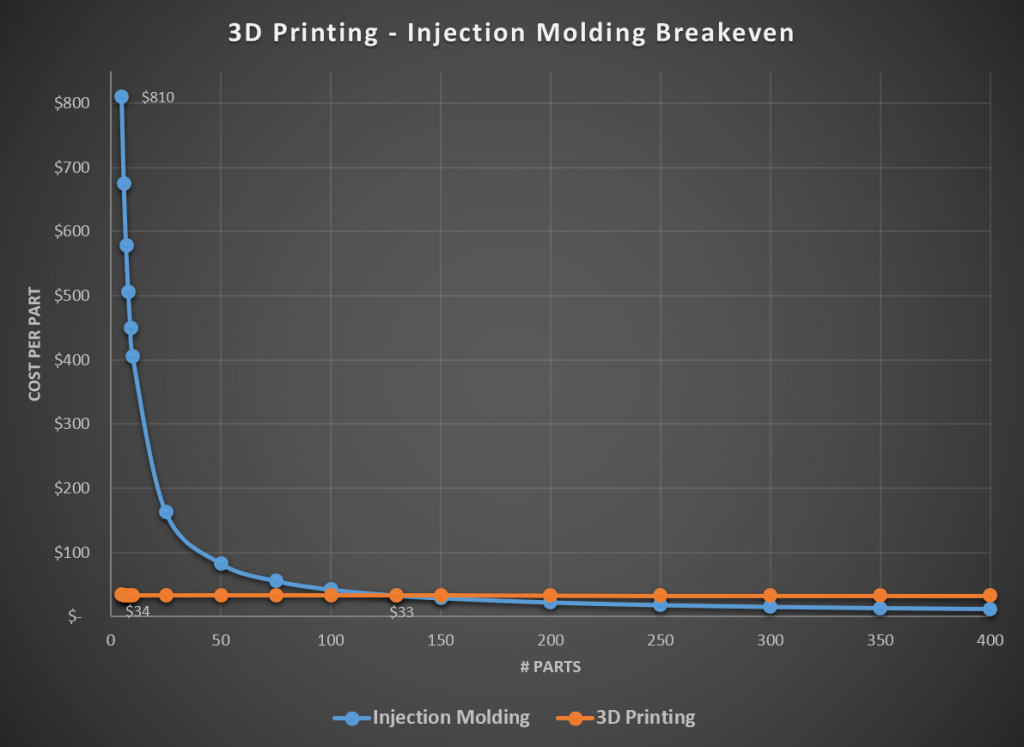

Is the same true when looking at the balance of costs? For very small runs, 3D printing is cheaper, as there will be only one or two machines needed (depending on the system) to manufacture a part out of a given material. There is also far less waste material as the part is being built from the ground up, not carved from the top down as in some processes, and requires no additional tooling. As such, the cost per part from a 3D printer is fixed for any given part.

However, a traditional process being used to mass manufacture a part will use less energy over less time to create a large number of parts. After the upfront cost of creating the required tools, the cost of a part is often not much higher than that of the material used to create it. At some point, this combined with the speed of a traditional manufacturing process will counterbalance the initial investment in machinery and become less costly than maintaining a 3D printing system to produce the same part.

The point at which the cost of running and maintaining a 3D printer intersects that of maintaining and using its industrialized competition will vary depending on the parts being created. This point is called a “breakeven”, after which a traditional method becomes cheaper per unit part than 3D printing. In an analysis done by Xometry, this breakeven point could be found within the first 150 units manufactured, when comparing SLS 3D printing services with injection molding for a simple test part.

Quality

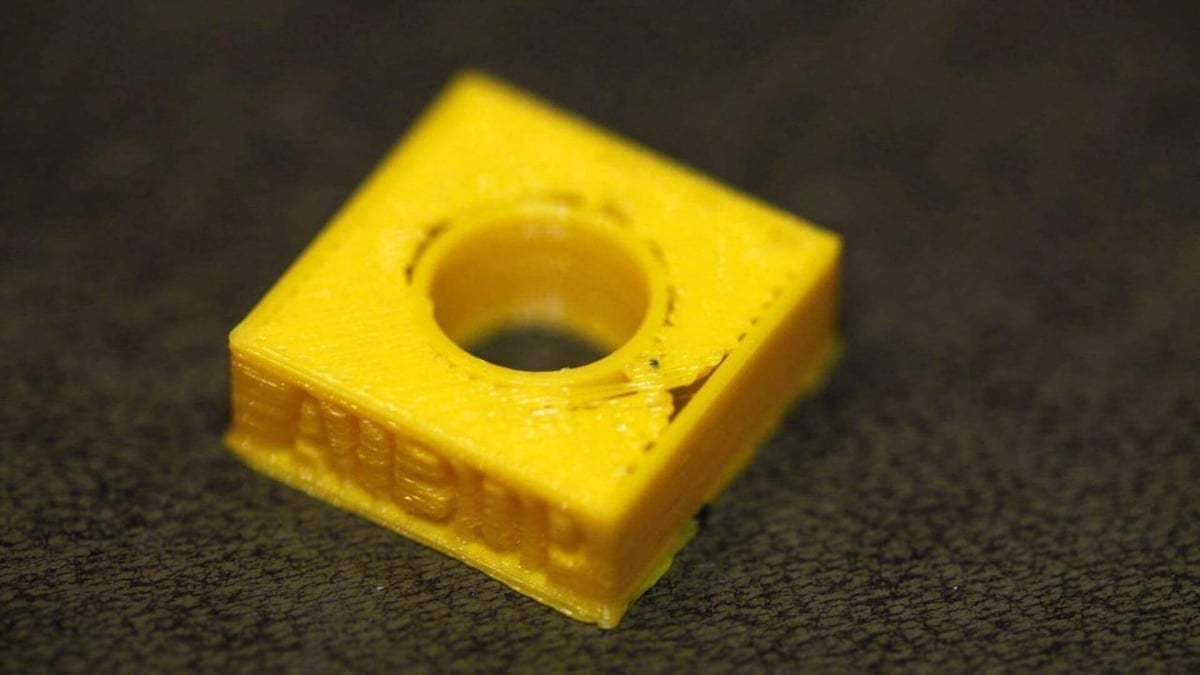

Likely the largest limitation of 3D printing is the final part quality. Due to the way each successive layer is deposited on top of the last in typical 3D printing methods, an inherent weakness is literally built into the design. There are of course ways to design around this weakness, for example keeping certain features parallel to the print bed, but this can be problematic for those attempting to create extremely high-quality parts for industrial uses.

For some systems, another downside of the layering is the inevitable layer lines produced in and on a part, which can significantly detract from the visual appeal of a product. Again, there are ways to finish 3D printed parts to make these layers invisible, but this requires extra time and effort compared to products manufactured by other means.

The easiest ways around these problems is to print using laser-based systems at extremely high resolutions. However, this means the parts will take a lot longer to manufacture (remember the fixed time per part characteristic of 3D printing) and depending on the material, may still need additional treatment to reach full strength. Additionally, such laser-based systems are fairly expensive to acquire and run, making them more suitable to already industrialized companies and large businesses.

Consistency

While it could be considered an extension of part quality, we have decided that consistency ought to be considered its own topic, as it does not necessarily equate to quality.

In a traditional manufacturing process, for example injection molding, there is a percentage of any given batch of parts which may be somewhat defective or inconsistent in quality compared to the rest of the parts. Due to huge advances in industrial manufacturing technology, these make up only a very small percentage of the total number of parts produced per unit time.

With 3D printing, the process is a bit more complex. Due to the parts being printed in succession, each individual print can be monitored and errors caught in real time, reducing the overall number of failed parts and wasted materials. However, small inconsistencies can occur print to print due small changes in the material quality and surroundings. In order for a batch of parts to be completely consistent, the machines must be kept very well tuned and in a controlled environment.

Flexibility

Another advantage of 3D printing is the ability of any given printer to create just about anything that can fit within its build volume.

In any other manufacturing process (aside from milling), each new part or change in part design requires a new tool, mold, die, or jig to be manufactured in order for said new part to be created. With 3D printing, the design can be fed into a slicer software, any needed supports added, and then printed with little to no change whatsoever in the physical machinery or equipment.

Another celebrated advantage of 3D printing is the ability to create “impossible” geometries that could not previously be manufactured either as a single part, or at all. Such things include:

- hollow cavities within solid parts

- parts within parts

- print-in-place mechanisms

Even things that any 3D printing enthusiast would take as a given, like hollow infill patterns, are generally too complex for traditional methods of manufacturing and as such are exclusive to 3D printing. This is also true for the ability to include multiple materials into a single object, which allows a plethora of different colors, textures and mechanical properties to be mixed and matched.

Another of the many advantages of 3D printing is the ability for any user, even those with limited CAD experience, to edit designs to their liking, creating unique and completely custom new parts. For companies, this means that there is now the option to let each customer customize a product to their personal taste, a growing trend in modern markets. It also means that a given design can be manufactured in a large range of different materials.

Accessibility

As we saw during our look at Consistency, the accessibility of 3D printing systems varies based on the quality and capability of the system.

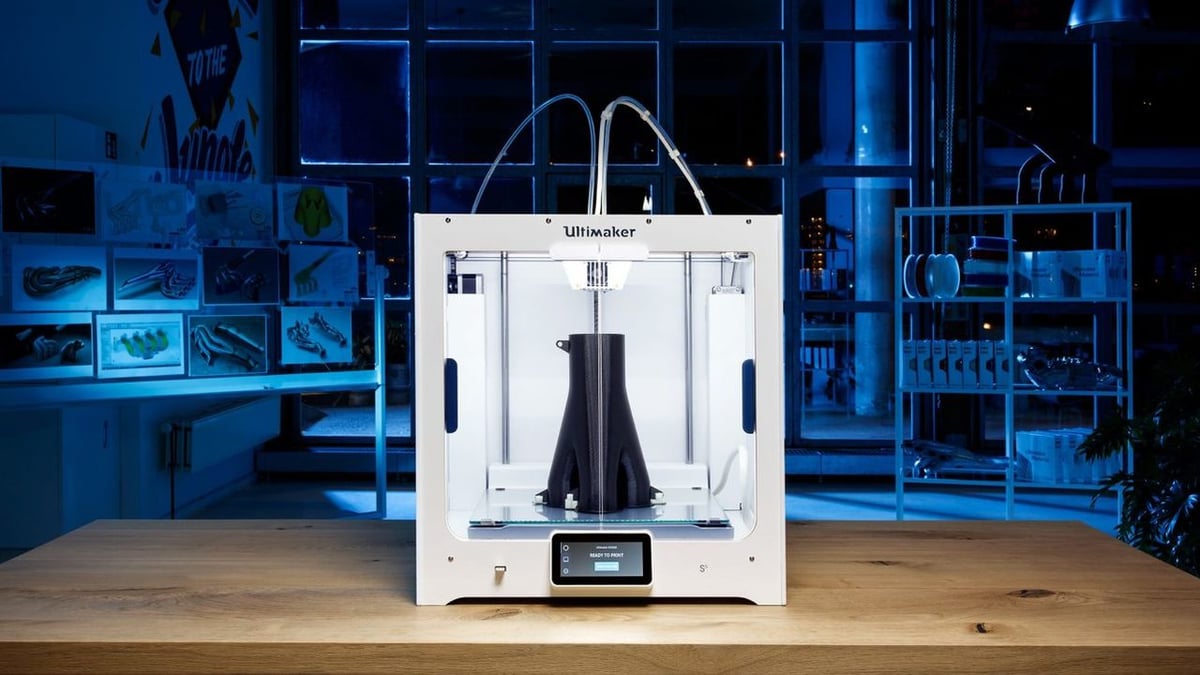

While an FDM 3D printer can be purchased for as little as $100, these machines are mostly targeted at individual consumers and hobbyists. Machines and systems targeted at professional users will start at around $1,000 and go up from there. Industrial end machines can easily cost as much or more than a brand new car.

While it sounds like this should be a part of the Cost section, what we are really looking at is how easily a person, professional, or company could acquire a full 3D printing setup. For comparison, a full injection molding setup can cost around $50,000 or more, and that doesn’t account for the installation price, or the additional tooling needed to create the molds themselves.

So, while still not cheap, 3D printing systems can be much more easily obtained and used by a much wider range of people than more traditional manufacturing setups. Additionally, 3D printing is almost completely automated by default, and requires little to no additional personnel to run, supervise, and maintain the machine. This makes 3D printing much more accessible than other manufacturing systems by a long run.

Sustainability

The aforementioned ease of access has another implication as well. Assuming a person or business has obtained a 3D printer, fewer parts need outsourcing for manufacture. This means there is less of an environmental impact created by shipping things across the globe, in addition to not requiring the operation and maintenance of an external factory.

Additionally, as mentioned in the Costs section, 3D printing creates a lot less waste material for a single part. Combined with the generally recyclable nature of the materials used for 3D printing, it becomes clear that 3D printing has a large advantage in immediate sustainability.

However, similar to factories, 3D printers still need energy to run and materials to build with. As seen in the Speed section, there comes a point at which 3D printing is outpaced by its industrial counterparts. What this means is that over time, the power needed to run a printer, and the need to refine or recycle materials into a printable format, will offset the immediate sustainability of a 3D printer.

Simply put, until renewable energy sources and “greener” material processing become more commonplace, a traditional method of manufacturing can still be more sustainable in the long run when mass manufacturing a set number of products.

Conclusion

To sum it all up, the main advantages of 3D printing are embodied in the Speed, Flexibility and Cost factors. As we’ve stated many times throughout this article, for small production runs, prototyping, and hobbyists, a 3D printer is a vastly better method of manufacture than other industrial systems.

However, if you’re looking to start mass-manufacturing a product, industrial systems start becoming a much better choice. This could explain why many companies have yet to consider 3D printing as a viable manufacturing system for modern products.

Feature image source: Shapeways