Shedding Light on Things

The term “3D printing with light” can be applied to a number of methods used in 3D printing. In fact, some sites out there are touting light 3D printing as if it were some new and revolutionary technology. It may be revolutionary, but the technology is not new, despite the latest advancements.

While it may be true that the technology involved is more suited to professional applications, it has a number of advantages. 3D printing with light can be much faster and more precise than with many other 3D printing technologies, with some light-based 3D printing systems capable of producing prints with a resolution measured in microns, rather than millimeters. The ability to print with UV-cured resins has also opened the possibility of introducing reinforcing material such as carbon fiber to make lighter, stronger parts.

Today, we’re going enlighten you on SLA, DLP, SLS, and material jetting, all of which are 3D printing technologies that use light.

Stereolithography (SLA)

Technically, DLP can be considered a form of stereolithography, but generally when you hear the terms “SLA” or “stereolithography” the SLA 3D printing technology we’re talking about uses lasers, and differs from DLP (and FDM) functionally in that it takes longer and can be more accurate. This is because it uses galvanometers to rapidly aim the light of a laser beam to cure a UV-sensitive resin one point at a time on each layer. This allows it to produce very high resolution prints, at the expense of taking a bit longer than DLP, which typically cures an entire layer at once.

Another advantage of using this technology to 3D print with light is that you can use resins with various interesting properties. One group of researchers managed to make antibacterial teeth by introducing an antibacterial agent into the resin used to print them.

Atypical SLA designs have been explored as well. One team demonstrated the ability to harden liquid resin with one wavelength of light while preventing the hardening of the resin by superimposing light of a different wavelength. This allowed them to print objects much faster than existing SLA 3D printers.

Digital Light Projection (DLP)

DLP technology can be used to 3D print with light by using a projector with digital light processing technology to polymerize a vat of UV-sensitive resin. As such, both DLP and SLA printers can be classified as vat polymerization 3D printers. Because a DLP projector projects and cures an entire layer of resin at once, it’s considered faster than SLA. Depending on how advanced the digital light processor is, the resolution of the print can vary, but it’s still typically much higher than that of FDM printers.

Atypical DLP printer designs have also been explored, designs that are much faster than conventional ones. Using “tomographic reconstruction”, researchers have created “volumetric additive manufacturing” with a DLP projector. Another team has developed a method using holograms to cure light-sensitive resin to create an entire object in as little as five seconds.

Selective Laser Sintering (SLS)

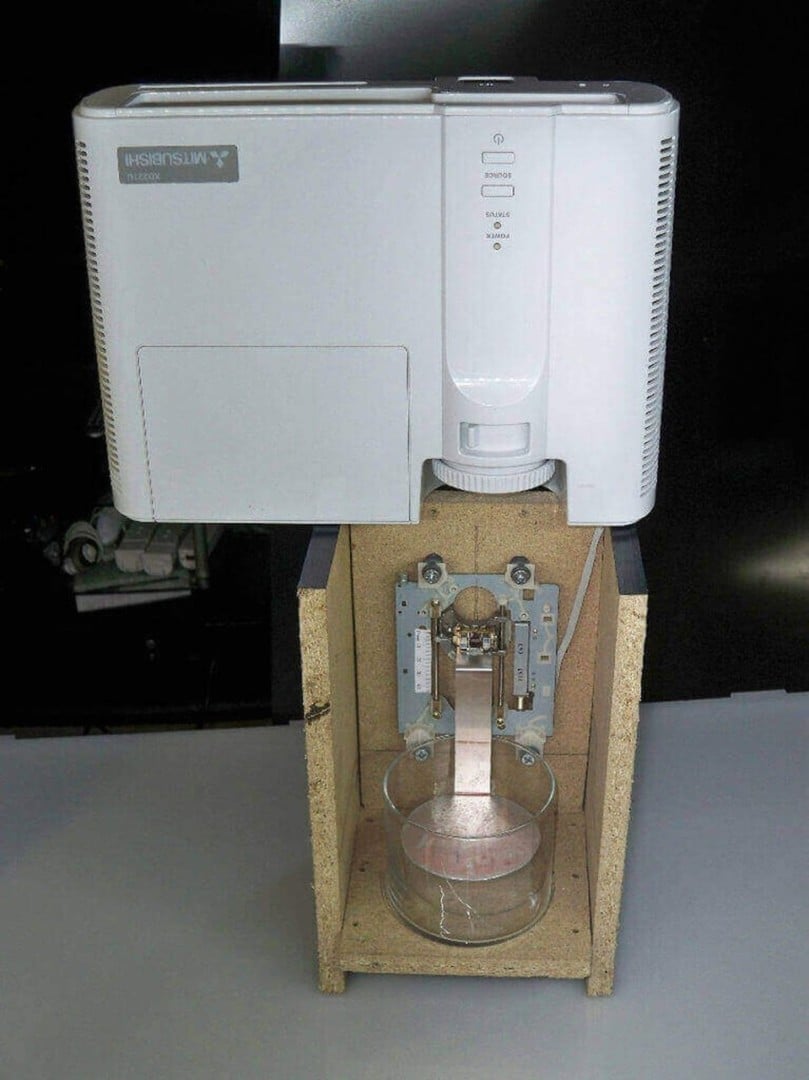

Selective Laser Sintering (SLS), also known as “powder bed fusion” involves using a laser to sinter/fuse particles together layer by layer with a high-powered laser beam, until a model is produced. Once a layer is finished, another layer of powder is applied as the build plate is lowered into the powdered material to be selectively sintered with the laser beam. Although this can cost more than some other methods, it’s capable of producing fully functional parts out of thermoplastics such as nylon and metals. Don’t let the cost deter you, however, the image above is of instant tea fused by a DIY SLS 3D printer you can build yourself!

Direct Metal Laser Sintering (DMLS) technology directly sinters or fuses metal powder specifically to produce a strong, detailed, and functional metal product. DMLS and SLM can require structural supports to prevent warping, unlike other powder bed fusion and SLS technologies. One main disadvantage is that direct metal laser sintering can also produce porous parts, which may necessitate post-processing.

Selective Laser Melting (SLM)

Selective laser melting technically differs from SLS in that it melts metal powder rather than fusing it. It is however, functionally the same in the way that the process works. This technology works best with pure metals, whereas SLS can be used to fuse metal alloys successfully as well as nylon and other plastics. SLM products often require post-processing to sand off imperfections and remnants of support material. In addition to the rough surface finish and post-processing requirements, SLM can also be rather expensive. Despite these drawbacks, SLM can produce fully functional parts and prototypes.

Material Jetting

Material jetting uses photopolymer resins cured by light drop by drop with UV light. The advantage of this method is that a high resolution can be achieved while also being very fast. This technology works very similar to an inkjet printer with print heads accompanied by a UV curing light which cures resin as it’s deposited, one droplet at a time. An added advantage is that this technology allows for multiple materials or colors to be used, much like in an inkjet printer. Unfortunately, the strength of parts can be limited, and the price can be cost-prohibitive.

In Closing

Light can be used in various ways to create a 3D printed object. It can be used to fuse metal or plastic particles, as well as cure resins to produce products that are highly detailed. Extraordinary results can be achieved with today’s technology, but it’s always improving. As DLP projectors become better and cheaper, for example, DLP resin printing will become more feasible and effective.

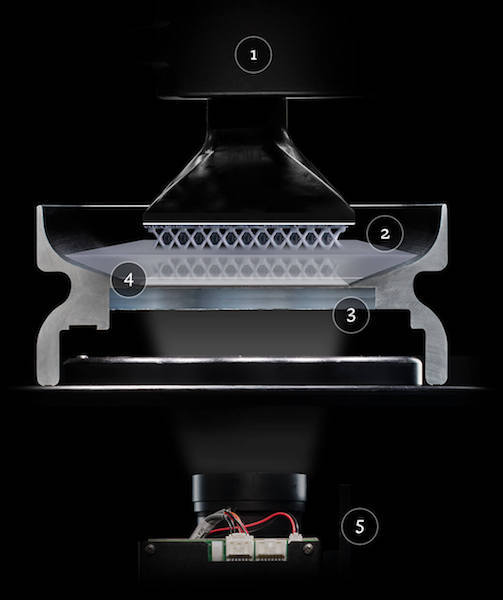

Companies are already developing innovative technologies to achieve faster prints, such as Carbon3D which has developed an oxygen-permeable window to prevent resin from curing improperly. As resin manufacturers formulate advanced resins, products with interesting properties can, and likely will, be developed for years to come. With printers getting better and cheaper, and not to mention affordable and DIY systems, you can even start printing with resin or other materials relatively inexpensively. If you can’t manage that, then there’s always 3D printing services that can help you, if you need a part 3D printed with light.

Feature image source: Tangible Engineering USA Corporation / Kickstarter