3D printing has been consistently making headlines over the past few years, usually for reasons unrelated to Benchys and filaments. While 3D printed houses are slowly becoming a reality for us commoners, the artistic and architectural industries have been regularly leveraging the many advantages of this technology.

In this article, we’ve selected 15 of the most incredible 3D printed structures that’ll certainly get you inspired. Keep in mind that these projects are explicitly not 3D printed houses or bridges, which we’ve covered in other articles. Indeed, the pavilions and structures we’ll look at are an exercise of public exploration and imagination.

Saltygloo

The Saltygloo is an experimental 3D printed structure made from salt harvested in the San Francisco Bay Area. The external design was based on Inuit igloos and the translucent properties of the salt allow light to flow inside the lightweight structure.

The 336 salt panels were made by additive manufacturing techniques similar to that of binder jetting, where the powder is selectively applied layer-by-layer and held together by a binding agent. In this case, it’s a special type of glue. While construction with natural salt materials is not an entirely new thing, 3D printing such structures had never been accomplished before this project.

- When: 2013

- Where: San Francisco, USA

- Who: Emerging Objects

Project EGG

Project EGG is one of the first original collaborative 3D printing construction projects. It was envisioned by designer Michiel van der Kley and it kicked off 2014’s Dutch Design Week. The structure consists of 4,760 unique building blocks that were individually 3D printed by the global 3D printing community.

Each building block was different and the STL files were distributed by Michiel to the 3D printing community. The participants then shipped their contribution to the Netherlands where the final structure was assembled. Once the exhibition had ended, project EGG toured around Europe for approximately 2 years.

- When: 2014

- Where: Eindhoven, The Netherlands

- Who: Michiel van der Kley

Vulcan Pavilion

Designed by Beijing’s Laboratory for Creative Design (LCD), this breathtaking pavilion is composed of over a thousand 3D printed components. It stood on a busy commercial and office complex that hosted the 2015 Beijing Design Week. The structure takes on the appearance of a mushroom cloud from a volcanic eruption – hence the name “Vulcan Pavilion”.

The project took 30 days and 20 large-scale 3D printers to produce, plus an additional 12 days to put it together. The entire structure was printed offsite and had to be divided into three modules for transporting to the final location.

- When: 2015

- Where: Beijing, China

- Who: Laboratory for Creative Design (LCD)

Bloom

Inspired by Thai flower patterns, this 3D printed concrete pavilion is one of the most stunning structures on UC Berkeley campus. Developed by Emerging Objects and personally headed by architecture professor Ronald Rael, the Bloom project was made of 840 custom-made 3D printed bricks made from an oxide-free Portland cement polymer material.

The different shades of brick create an external twirling flower design, while the openings allow light to seep into the structure. The 9-foot tall structure was materialized thanks to the PrintFARM facility at UC Berkeley College of Environmental Design and the Siam Cement Group in Thailand.

- When: 2015

- Where: UC Berkeley Campus, USA

- Who: Emerging Objects

Rise Pavilion

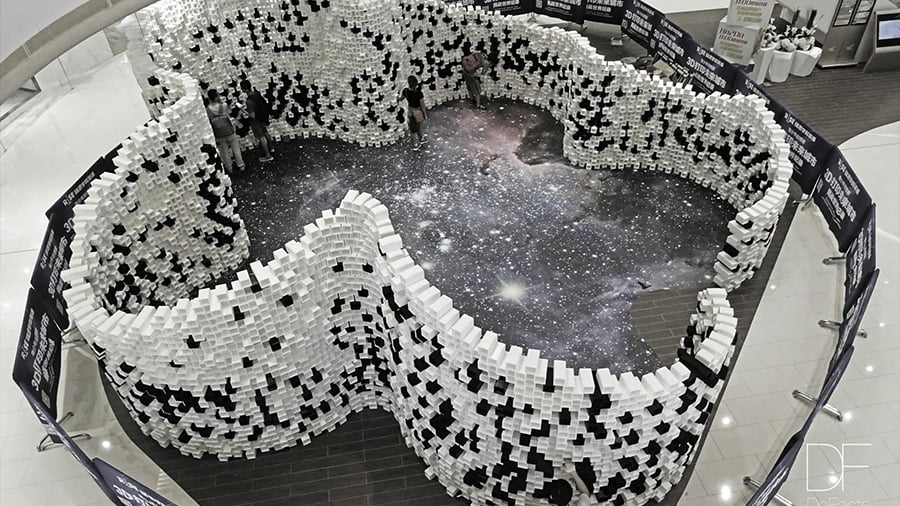

This huge pavilion was the result of a project developed by DeFacto for Rise Education’s Young Creator Cup. It consists of 5,370 separate 3D printed pieces, called poly-blocks. These were produced on 70 3D printers and took 45 days to complete. After the competition, the poly-blocks were distributed and repurposed as vases, planters, lampshades, and so on.

The Rise Pavilion weighed 1.87 tons and stood over 11 feet high, but only took approximately 24 consecutive hours to be built. It was the largest 3D printed structure at that time according to Guinness World Records, a record now held by Dubai’s municipality office building.

- When: 2016

- Where: Beijing, China

- Who: DeFacto

Daedalus Pavilion

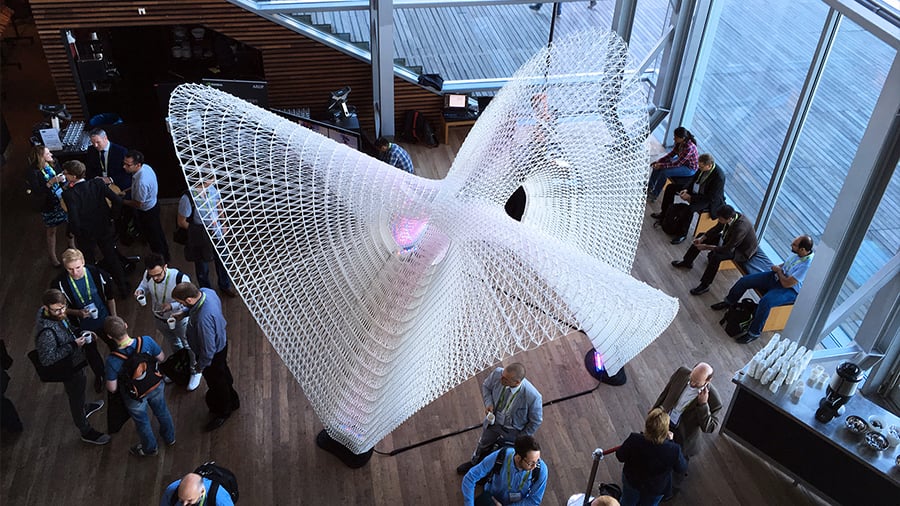

The Daedalus Pavilion is a 3D printed installation designed for NVIDIA’s GPU Technology Conference in 2016. It was envisioned and constructed by AI Build, a British company that uses AI, advanced robotics, and additive manufacturing to create large-scale 3D prints.

The 5 x 5-meter structure is made out of 48 separate pieces that were 3D printed using an adapted standard industrial robot. Around 160 kg of biodegradable plastic was used in the Daedalus and all the material was provided by a local Dutch manufacturer. The intricate patterns on the pavilion’s lightweight structure make for a stunning look.

- When: 2016

- Where: Amsterdam, The Netherlands

- Who: AI Build

Kooky Cubby

The Kooky Cubby was designed for the Cubby House Challenge by Kids Under Cover, a non-profit organization. Cubby houses are small playhouses, allowing kids to exercise their creativity with role-playing and imagination. Architects from FMSA Architecture also exercised their creativity to come up with this small structure using the design freedom offered by 3D printing techniques.

The organically shaped walls of the Kooky Cubby were made out of translucent PLA and create small texturized passageways within the structure. FMSA architects also claim this project addresses other technical considerations like UV stability and weather resistance, not to mention the biodegradability of materials like PLA.

- When: 2017

- Where: Melbourne, Australia

- Who: FMSA Architecture and RMIT University

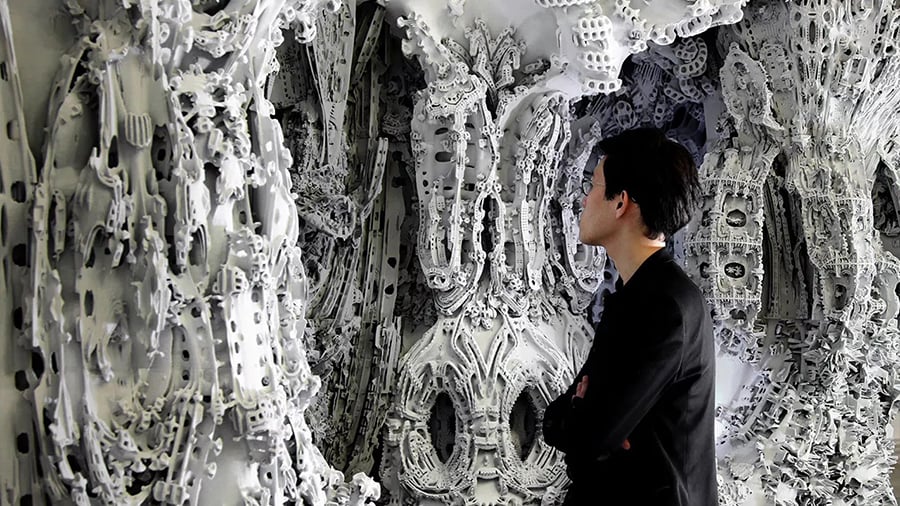

Digital Grotesque II

Back in 2013, architects Michael Hansmeyer and Benjamin Dillenburger unveiled the world’s first fully 3D printed room. The entire room was constructed with a unique type of 3D printed sandstone. The intricately designed room was inspired by the natural process of cell division. Named Digital Grotesque, the complex project contained over 80 million surfaces, some of which were glazed and gilded.

Fast-forward to 2017, yet another intricate structure was commissioned by the Centre Pompidou from Hansmeyer and Dillenburger. This time it was a full-scale grotto that was 3D printed from the same sandstone material of the previous structure. The design process was 100% digital, being developed by algorithms and took over 2 years. The results are incredible!

- When: 2017

- Where: Paris, France

- Who: Michael Hansmeyer and Benjamin Dillenburger

Trabeculae Pavilion

Nature-inspired designs seem to be a recurring theme in 3D printed structures. The Trabeculae Pavilion takes its name from the porous inner structure found in human bones. This naturally lightweight tissue is load responsive as it gets its properties from mechanical stimulation.

The Trabeculae Pavilion is no different, being designed by computer algorithms to emulate this aspect through “continuous variations in sizing, topology, orientation, and section in order to maximize material efficiency” according to ACTLAB, the group responsible for the project. The arched structure was fabricated in polymer by delta 3D printers at the Politecnico di Milano and took over 4,352 hours of continuous production.

- When: 2018

- Where: Milan, Italy

- Who: ACTLAB

One City Pavilion

Once the largest 3D printed structure of all, the One City Pavilion still amazes with its sheer size and intricate design. The 21-feet-tall metal structure was commissioned by Dallas-based company Cambridge and is a permanent outdoor feature in Nashville.

Although it seems to be made out of steel framing, this pavilion is actually 3D printed in carbon-fiber-reinforced ABS, with an ultraviolet protective metallic paint finish. It is claimed that it can withstand 12 in (30 cm) of snow and wind up to 90 mph (145 km/h), which is backed up by the fact that the One City Pavilion has stayed standing outside since 2018.

- When: 2018

- Where: Nashville, USA

- Who: Branch Technology

SUTD Time Capsule

To mark its tenth anniversary, The Singapore University of Technology and Design (SUTD) commissioned a special structure to celebrate its most significant innovations and milestones. The Time Capsule was presented in 2019 and represents the cyclical motion of time and nature. As of now, the structure is sealed with other artifacts and messages to be opened again in 2039.

According to SUTD, the surface of the Time Capsule is covered by 3,582 unique panels that were 3D printed with biopolymers. It was designed by AirLab architects Carlos Banon and Felix Raspall and secured them a Singapore Good Design award in 2020.

- When: 2019

- Where: Singapore

- Who: Architectural Intelligence Research Lab

Deciduous

This almost alien-looking pavilion was commissioned by the Dubai International Financial Center to celebrate the recent “Art Nights” event. The structure, called Deciduous, is made from three different materials: plywood for the flooring, 3D printed concrete for the base, and also 3D printed PETG for the standing columns.

According to the Middle East Architecture Network (MEAN), the architecture office responsible for the project, all the plastic used in the columns is sourced from over 30,000 recycled water bottles. Deciduous was fabricated off-site in several parts that were then assembled together in its final standing place. MEAN has documented the entire process, which can be seen in the video below.

- When: 2019

- Where: Dubai, UAE

- Who: MEAN

AirMesh

Yet another project by AirLab in Singapore, the AirMesh combines traditional metallic framing with 3D printed joints to create an ultra-lightweight structure for outdoor use. The design process was aided by digital optimization tools to come up with the most mechanically efficient structure.

The 54 uniquely designed nodes were 3D printed in a steel and bronze alloy, which were later joined to the 216 bars by simple screws. In fact, the final assembly took a crew of five people only a couple of days. The AirMesh pavilion weighs around 700 kg and can support more than 16 times its own weight.

- When: 2019

- Where: Singapore

- Who: Architectural Intelligence Research Lab

Rocket Launcher

This is a different one. Rather than a conceptual structure, this concrete shelter constructed by the US Marine Corps is a tough beast. It is made out of high impact-resistance material with special radiation blocking. This shelter was designed specifically for holding in an M142 HIMARS rocket launcher, protecting against harsh weather and enemy fire.

Four arches were built separately by ICON’s Vulcan concrete 3D printer and later assembled together. The printing process took only 36 hours to be completed and could be replicated virtually anywhere. With this successful demonstration, the US Department of Defense plans to accelerate the development of 3D printed structures.

Hemo Gorge

Beginning as an idea in 2015 by the New Zealand Māori Arts and Crafts Institute, the world’s largest 3D sculpture was just installed in New Zealand (three years later than planned). The design inspiration is from an indigenous folk tale of the power of the geothermic activity in the area.

Originally intended to be constructed out of stainless steel, fears of its weight led to the idea of using 3D printing. A local firm was commissioned to print the sculpture and it took reportedly took 16,500 hours (almost 2 years). At 12 meters high, this incredible helix-shaped piece had to be split into two pieces and flown in by helicopter to its new home in the center of a traffic roundabout.

- When: 2020

- Where: Rotorua, New Zealand

- Who: Stacy Gordine and Kilwell Fibretube

Sandy Darak Pavilion

This modern pavilion is intended to hold small gatherings from Darak’s village local community and tourists. The seafront surrounded by sand dunes makes for the perfect place for this structure that is currently under construction. The project is lead by AArchitects and was inspired by the natural curvatures from the same sand dunes that surround the village.

The 10-meter high pavilion is being 3D printed in a natural material mixture that includes sand and clay. The overall design takes into account the local traditional architecture and also the harsh environment of high temperatures. The final construction is planned to happen on-site by a large-scale 3D printer and should be completed in 2021.

- When: 2021 (under construction)

- Where: Chabahar, Iran

- Who: AArchitects

Lead image source: AI Build

License: The text of "3D Printed Structures: Most Important Projects" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.