Back in 2009, when the 3D printing community was primarily confined to the then-infantile RepRap project, a trio of makers came together to start a company called MakerBot. With an open-source philosophy and eye-catching branding, MakerBot first emerged onto the scene with the Cupcake CNC, a wooden-framed desktop 3D printer that looks antique compared to what is currently on the market.

Since its founding, MakerBot has been on a roller coaster ride with plenty of ups, downs, and unexpected loops. In 2013, the company was acquired by the 3D printing titan Stratasys, marking a new chapter in the MakerBot story. This acquisition was followed with some unfortunate hardships for MakerBot, including a few rounds of major layoffs and a hardware-related issue with the extruder system that caused the Fifth-Generation MakerBot Replicator Desktop 3D printer to flounder.

In recent years, MakerBot has strived to rehabilitate its identity, becoming heavily invested in the educational market and maintaining its status as the leading 3D printer manufacturer in North America. As we approach the ten-year anniversary of MakerBot, it’s only fitting that the 3D printing pioneer reinvents itself once again – this time with a performance 3D printer that is sure to shake-up the professional market.

Led by Nadav Goshen, who came on board as CEO in 2017, the company has been quietly developing the MakerBot Method, a desktop 3D printer that is chock-full of what MakerBot is calling “Industrial DNA.” Today, the manufacturer has revealed its new machine, and it’s unlike any product that has ever sported the iconic MakerBot logo.

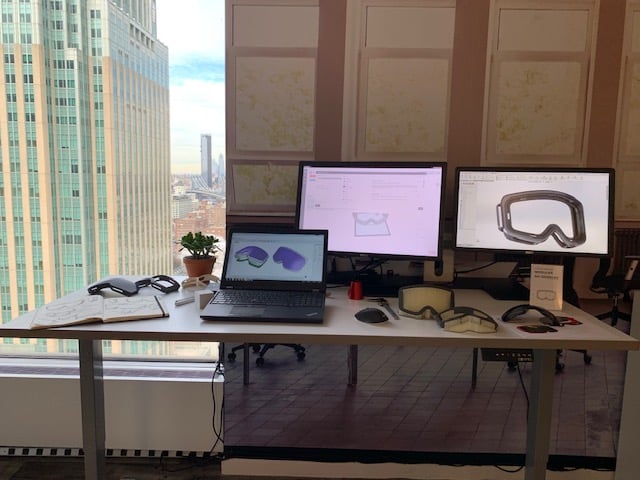

MakerBot recently invited All3DP for a sneak preview of its new MakerBot Method 3D printer at the company headquarters in Brooklyn, New York. We received a first-hand look at this new performance-minded machine, which the 3D printer manufacturer has designed to offer professional 3D printing quality within the guise of a desktop 3D printer.

Needless to say, we were extremely impressed with what MakerBot managed to accomplish with its latest machine. Priced at $6,499, the MakerBot Method aims to provide individual designers and engineers with a compact 3D printer that boasts a variety of industrial features.

Here’s what we know about the MakerBot Method 3D printer so far.

MakerBot Method 3D Printer Fuses Industrial Performance with Desktop Accessibility

When we arrived at the MakerBot office to get acquainted with the new 3D printer, the tour started with a brief look at the history of MakerBot products. After strolling past the various generations of 3D printers, we were greeted by the MakerBot Method. One look at this sleek, desktop-sized 3D printer and it was instantly clear – the MakerBot team has been cooking up something special.

Leveraging the industrial expertise and know-how of Stratasys, MakerBot has managed to pack an avalanche of industrial features into an accessible machine. Dubbed as a performance 3D printer, the MakerBot Method is intended to bridge the gap between industrial and desktop 3D printing, providing designers and engineers with professional quality prints at a significantly lower cost.

“When we looked in the professional segment, we discovered that there is a real gap in the current technologies of desktop systems. And if we want to provide the same quality of product to that segment, we need to build from zero, a new platform. And that platform is the MakerBot Method that you just saw. So, the understanding is that professional engineers and designers need a professional tool,” Nadav Goshen, CEO of MakerBot, told All3DP during the visit.

There’s a ton of unique features to delve into, but the most impressive aspect of the MakerBot Method is the unprecedented print quality that it offers. This machine is engineered to control every factor of the 3D printing process, delivering repeatability and high precision.

The manufacturer claims that the new 3D printer produces consistent parts with ± 0.2 mm dimensional accuracy, as well as vertical layer uniformity and cylindricity. This sort of precision is typically reserved for industrial 3D printers, but the MakerBot Method accomplishes this within the desktop format at a relatively low price of $6,499.

It has a dual extrusion system that allows users to print with PVA material, thus granting them more design freedom and the ability to create complex geometries. But don’t be fooled, this isn’t your average dual extrusion 3D printing system. The MakerBot method is equipped with Dual Performance Extruders that allows for high-speed printing without sacrificing print quality.

These two extruders include a dual-drive gear system that grips the material securely, using a 19:1 gear ratio that grants three times the push force of a standard desktop FDM machine. The most fascinating part of the extruder system is definitely the lengthened thermal core, which is up to 50-percent longer than a typical hotend.

With this extended hotend, the MakerBot Method offers incredibly fast extrusion rates, while also maintaining smooth extrusion despite the high-speed movements and acceleration. In fact, if you look at the specs, you’ll discover that the Method provides a consistent feed of material into the hotend to produce 1± 0.2 mm or ± 0.002 mm per mm of travel, making it around two times faster than other desktop 3D printers.

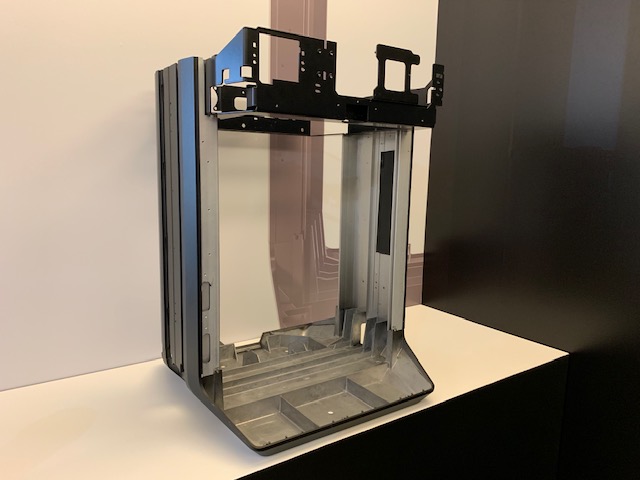

So, how is this machine able to withstand these turbo-charged print speeds? With an Ultra-Rigid Metal Frame, of course! The all-metal frame is designed to run the full length of the MakerBot Method, effectively offsetting any flexing or potential instability. By maintaining stability, the printer is able to operate at high speeds and still produce highly consistent and accurate prints.

Another industrial-grade feature integrated into the MakerBot Method is a circulating heated chamber that controls the temperature at every layer of the print. The manufacturer states that this “full active heat immersion” persists throughout the entire printing process, helping parts to cool at a controlled rate. This heated chamber provides higher dimensional accuracy, better layer adhesion, and improved part strength.

Inside of this build chamber is a Spring Steel Build Plate that is perfectly flat and pops right out of the printer, allowing users to quickly setup their next print. Near the top of the MakerBot Method is a 5″ touchscreen that functions as if it were a smartphone. This highly intuitive UI showcases status updates for print jobs and easy navigation through extensive settings.

Although the MakerBot Method is compatible with third-party materials, it’s definitely optimized for MakerBot-branded filaments. The printer is designed to hold these spools in a compartment underneath the build chamber, keeping the material sealed and free from moisture absorption.

These so-called “Dry-Sealed Material Bays” are equipped with built-in sensors that monitor the humidity and alerts users when the surrounding environment changes. This feature comes in handy when using water-soluble PVA, as it’s highly susceptible to moisture.

Each MakerBot-branded filament is mounted onto a Smart Spool, which utilizes an RFID chip to share information with the user, such as filament type, color, and how much material is remaining on the spool. This spool holder also has desiccant inside of the base, ensuring that the moisture levels inside of the chamber are always low. Finally, the Method also contains a built-in camera that connects with MakerBot Print and the MakerBot Mobile app, allowing users to monitor their print jobs from virtually anywhere.

According to MakerBot, the team has spent over 220,000 hours conducting tests on the system reliability, subsystem, and print quality. Thus, they feel confident that their latest system will deliver industrial-grade performance with the accessibility and affordability of a desktop 3D printer.

Outside of the MakerBot Method, the manufacturer has been working to enhance its entire 3D printing workflow. The new and improved MakerBot Print Software is now compatible with 25 of the most popular CAD programs, streamlining the process in between design and slicing. Groups can also collaborate and share projects together with the native Cloud Management platform.

All in all, the MakerBot Method was developed to allow designers and engineers to streamline the product development process, optimizing the workflow between design and prototyping. Moreover, it essentially functions as a plug-and-play 3D printer, automating everything from setup to maintenance.

While we chatted with the MakerBot team about their exciting new product, they seemed to envision a world where every designer and engineer has direct access to a Method 3D printer on their desk. No matter waiting in queues to print on a bulky industrial 3D printing system, no more printing an object on a desktop machine that has different dimensions than the CAD model it’s supposed to represent. Needless to say, with the new 3D printer from MakerBot, there’s definitely a Method to the madness.

Technical Specifications

Want to see a by-the-numbers breakdown of this potentially groundbreaking machine? Here are the technical specifications for the MakerBot Method 3D printer:

- Dimensional Accuracy: ± 0.2mm / ± 0.007in 1

- Layer Resolution: 20 – 400 microns

- Product Dimensions: 43.7 x 41.3 x 64.9 cm (17.2 x 16.3 x 25.6 in)

- Weight: 29.5 kg (65 lbs)

- Maximum Build Volume:

- Single Extrusion: 19 x 19 x 19.6 cm (7.5 x 7.5 x 7.75 in)

- Dual Extrusion: 15.2 x 19 x 19.6 cm (6.0 x 7.5 x 7.75 in)

- Extruders: Dual Performance Extruders

- Build Surface: Spring Steel Build Plate with Grip Surface

- Material Storage: Dry Sealed Material Bays (plus sensors for humidity and temperature)

- Supported Materials: MakerBot Tough, MakerBot PLA, MakerBot PVA, MakerBot PETG, MakerBot PVA-M, Third-Party Materials, etc

- Connectivity: WiFi, Ethernet, USB

- Power Requirements: 100 – 240V/4A, 50-60 Hz/400 W max.

Where to Buy

The MakerBot Method 3D printer has already started shipping to the first customers. You can place an order to purchase this 3D printer from the MakerBot website.

License: The text of "MakerBot Method 3D Printer: Review the Specs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.