Pick

Laser engraving from your home or office is now more accessible than ever. Once strictly the preserve of industrial manufacturers, laser engraving is being increasingly adopted by small businesses, product designers, makers, and hobbyists.

In some cases, there’s a good chance that a laser engraver might prove to be the most advantageous technology for your needs. So, before pulling out your wallet, you might want to take a peek at the laser engravers we’ve picked out below; because we think they’re the best.

Most laser-packing machines that you can buy out there in the wild are capable of engraving, but not every engraver can cut. As with any product relating to creative technology, it’s always a good idea to know exactly what you want to do with a device before purchasing.

When it comes to engraving soft materials, lower-power diode lasers will do the job just fine. Higher power diodes are now also starting to become accessible to consumers. We’ve seen manufacturers like xTool packing multiple diode lasers into one toolhead to offer a higher output strength than what was previously possible on a diode laser engraver. While these new tool heads can pack an output strength similar to something you might see from a CO2 laser, they can be quite pricey.

If you want options, there are a lot of lower-powered diode lasers and affordable open-frame devices costing, normally, somewhere in the region of $2-500. These units typically have output strengths ranging from 1-5 W, and are more than suitable for working with softer materials such as cardboard, papers, fabrics, and more. They don’t make for very good cutters, so for consistent, clean, and quick cutting, you’ll probably want something CO2-powered.

Safety is, of course, paramount when it comes to working with any kind of powerful laser device. On any laser engraver, the minimum we’d be expecting to see is a G-sensor that stops the laser immediately should the frame be disturbed, as well as adequate shielding from the potentially sight-robbing laser beam. A device that can detect potential flare-ups during work and shutdown is also heavily appreciated. Regardless, you’ll want to invest in good eye protection: the glasses that come with affordable laser cutters and engravers are often criticized as being poor quality – don’t trust them. Just pick up your own.

Lastly, so much of laser engraving’s efficiency and usability comes down to software. Some laser engraving software can be tricky to get to grips with and lack adequate signposting to help ease you into the game. LightBurn is often cited as being one of the best pieces of software out there. It’ll set you back a one-off fee of either $60 or $120 (depending on your machine), but laser engravers compatible with LightBurn tend to score extra points with users.

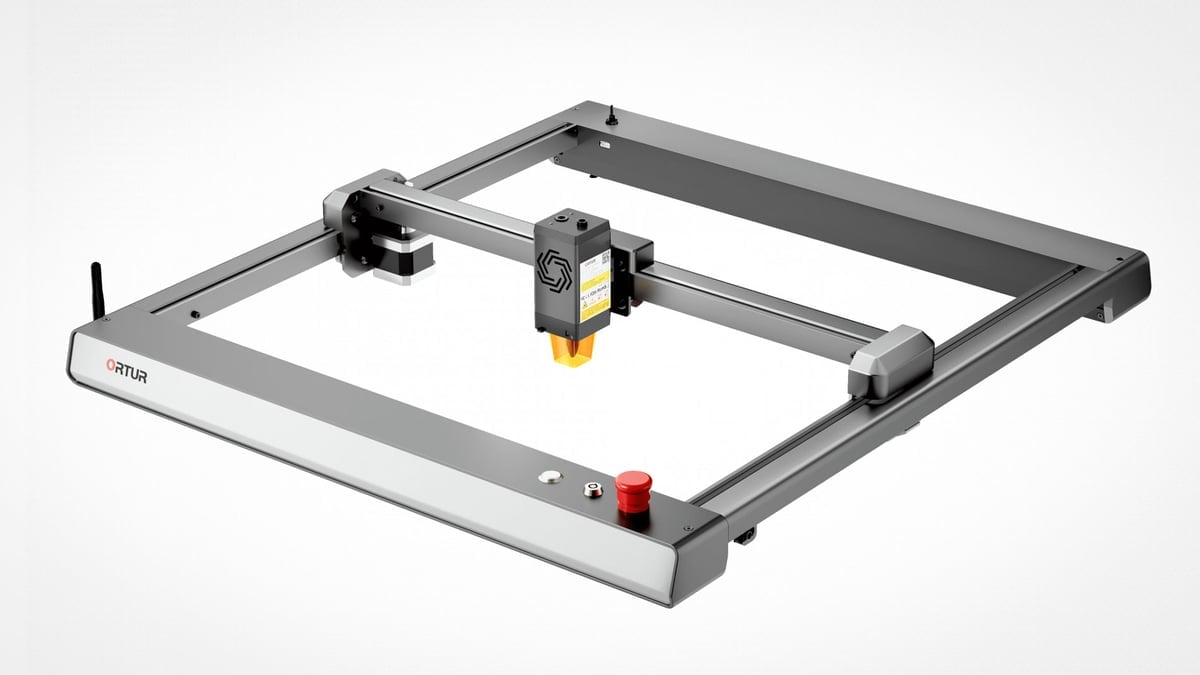

Ortur’s third-generation Laser Master is a logical choice for our Top Pick, being a more refined, advanced evolution of a machine that was already impressive. For a start, the toolhead has been upgraded, and now packs twin 5.5 W diode lasers that, via some nifty lens trickery, combine for what Ortur says is a “true” 10 W output strength. The work area is now 400 x 400 mm, a touch smaller than the Laser Master 2, but still on par with similar machines in this construction.

The resulting firepower allows for the cutting of acrylic sheets up to 30 mm thick and pine boards up to 20 mm thick. The toolhead itself is relatively small compared to some, and Ortur says the lower size (and therefore weight) allows for engraving speeds of up to 20,000 mm/m. In truth, users will be experimenting with the best speed and power settings to get the best finish on their materials. An integrated air assist port in the toolhead allows users to use an air pump to pull air away from the burn zone and possibly achieve better engraving results, and Ortur sells an air pump at $129 as an optional extra.

In terms of safety, Ortur offers several different features to try and safeguard users from its dangers. There’s a G-sensor that automatically shuts the laser off should it detect movement in the axes during work, an emergency stop button, exposure duration detection (a system that will know when a laser has been firing at one spot too long and cut the power to avoid a fire breaking out), and usefully, a key lock. The latter allows you to ensure that the laser cannot be activated without the key being inserted, so if the key is in your pocket, the LM3 will simply not function. It’s good for peace of mind.

Operation can be carried out via LightBurn, which is desirable, but the LM3 also functions with LaserGRBL (free software) and Ortur’s own Laser Explorer app that makes use of the device’s Wi-Fi connectivity; another desirable feature in a laser engraver, though connectivity can also be carried out via USB and SD card.

Priced at $699, the 10 W form of the LM3 is considerably more expensive than its predecessor, but the upgrades to performance and usability shouldn’t leave anyone feeling shortchanged. For those seeking a beefier output, a 20 W version will set you back $1,099, so be sure to think twice about how much power you really need, it might save you a few hundred bucks.

The Sainsmart Jinsoku LC-40’s intelligent design and affordable ~$250 price tag allows it to stand out among affordable laser engravers, despite a relatively low-powered 5.5 W diode laser on the base model. A 10 W version is available, but it increases the price significantly.

Sainsmart has a good reputation with consumers and products, having been a pretty prolific producer of CNC machines, laser engravers, tools, and more for quite some time now. The company is also a reseller of Creality 3D printers. Key to its positive reputation is its communication and support.

The Jinsoku LC-40 benefits from an intelligent design, integrating hidden limit switches, linear rails, Bluetooth connectivity, and a toolhead complete with a flue design that helps blow smoke away from the lens – thereby improving engraving potential. That feature alone is almost like having a built-in air assist system, and Sainsmart refers to it as “passive air assist”. But, instead of users needing to buy an air pump, it simply makes use of the cooling fan to channel air down the toolhead and vents from the “back”.

The stability of the frame is also noteworthy, being comprised of a strong aluminum alloy. Sainsmart has made sure two sides of the frame are raised, allowing for a passthrough that helps enormously when working with longer materials. Attached to the frame is a small 5 mm focusing guide; again very neatly integrated, which is a real theme of this product.

All the cabling in the Jinsoku LC-40 is beautifully arranged and sorted, a real step up when compared to much of the market alternatives, and a huge point scorer with anyone infuriated by lazy cable management.

Providing a working area of 395 × 365 mm, a bunch of clever features, and a laser just about potent enough to engrave all the necessary materials, the Jinsoku LC-40 laser engraver is an easy recommendation at its affordable price point.

xTool’s impressive P2 system remains P1 in the race to be our Upgrade Pick. Now, you could say that, for laser engraving, the xTool P2 is a bit OTT – and we hear you. However, it does offer powerful engraving potential and can comfortably dunk its face into the more demanding world of laser cutting, too.

This is unlike the other machines mentioned on this list, given that it’s a CO2 laser, with a powerful 55 W tube contained within: meaning it can really pack a punch, and over a relatively large 680 x 360 mm area too. xTool says you’ll be engraving trickier, harder materials such as glass and ceramic with the P2, and that the machine is capable of cutting clean through 20 mm thick acrylic in just one pass. Formidable is the word, we think.

That sort of formidableness comes with a formidable price. The xTool P2 starts a cent under $5,000. Oof. Despite that, xTool often runs promotions, so you if you can hold out you can almost certainly get it for less.

It’s possible that you may end up spending more, though, as the P2 has some pretty tempting extras available to purchase. For $459 you can add a conveyor belt system to the machine that gives you the flexibility to engrave really, really long things – if you have the space in the workshop for it. You could also be drawn to the $299 RA2 Pro rotary attachment and the $999 smoke purifier, too.

So, it isn’t cheap. And it can be even pricier if you want some of those extras. But with this puppy, you’ll be able to get engraving on a truly bountiful array of materials, cut effortlessly, work quickly, have all kinds of quality-of-life features, and have options to work with longer materials if need be. Factor in LightBurn compatibility and intelligent object detection via its built-in camera, and you’ve got yourself a pretty tempting proposition – if you can stomach the price.

Between this and the last update, there’s been a ton of new laser engraving machines released.

xTool’s D1 Pro has cemented its reputation on the engraving scene. It packs a whopper of a diode laser, offering an output of 20 W, leaving it capable of cutting pretty thick materials as well as doing quick, quality engraving work. That powerful diode comes at a cost, though, and you’ll need to be ready to drop nearly $1,300 to land yourself a 20 W D1 Pro. Lower power diode toolheads are available that don’t command such a high price tag, however.

If a powerful laser punch is really all you’re interested in, then OMTech’s K40+ Co2 laser engraver is probably the way to go. It’s an inexpensive, powerful machine, and now even features LightBurn compatibility out of the box. Priced at around $800, and with US-based support and a 2-year warranty included, this is a potent laser, albeit one that will require the extra hassle of water cooling.

Sticking with OMTech, the firm has recently released its Light B10 laser engraver, with the firm saying that it’s capable of cutting through 8 mm plywood and 5 mm black opaque acrylic with just a single pass. Its list price is a buck under $600, but at the time of writing it’s available for $320, and we’d expect it to remain comfortably under that stated $600 mark.

Lastly, what about Glowforge? Yes, the mainline models from Glowforge cost several thousand dollars, but its relatively new Aura engraver is around $1,000 and offers the Glowforge user experience that many rate so highly. It might not pack quite the same oomph as some of the other machines listed here, but Glowforge’s first diode laser engraver certainly has admirers, if nothing else, for the way it handles for the user.

Here’s how this article has changed over the months and years:

Update – February XX, 2024: Minor update for clarity and accuracy. We’re on notice for the flurry of engravers that have been released recently and could give strong competition to our existing top picks here. Watch this space.

Update – August 24, 2023: Along comes a new Upgrade Pick in the form of xTool’s exciting P2, replacing the aging Flux Beamo. As with our usual updates, we’ve also checked for pricing and availability as well as any other useful nuggets of information sitting out there in the internet’s pan. We’ve also updated the guide to laser engraving further down this page.

Update – February 9, 2023: We’ve given the guide a total overhaul to put greater focus on three key laser engraving machines that we think should be given serious consideration. In comes the Sainsmart Jinsoku LC-40, which has a growing reputation and strong performance at an affordable price. Joining it is the Ortur Laser Master 3, the next-gen of the Laser Master family and new Top Pick, replacing the now discontinued Laser Master 2. Finally, the Upgrade Pick is now the Flux Beamo. Packing a CO2 laser, great software, and great versatility, this compact, fully-enclosed CO2 laser is a logical next step from a diode laser.

Update – September 16, 2022: Two more entries join our list of laser engravers worth knowing right now: the xTool D1 Pro, a powerful and popular machine with nifty features such as Wi-Fi accessibility, and the LaserPecker 2, a portable and battery-powered engraver that can be used in handheld mode and allows you to engrave on the go. We’ve also checked up on the existing entries, prices, and general availability.

Update – June 10, 2022: With this update, we welcome the Sculpfun S9, a budget laser engraver that enjoys great popularity amongst tinkerers. We also removed the FoxAlien LE-4040, as it is no longer available, and replaced it with the FoxAlien Reizer 4040. A similar, if not identical, alternative. Price-wise the market seems to have settled somewhat, although some prices are still high given the current global situation.

Update – August 11, 2021: Neje Master 2S Max drops out, as its $200 price increase since the previous update makes it simply too expensive to recommend. There are better, cheaper options out there. Unfortunately, many machines have increased in price since the last update around the turn of 2021. It could be down to recent global events. We’ve also taken time to update the guide aspect of the article in an attempt to make it more relevant to this piece and checked out all the prices to make sure it accurately reflects what you should expect to pay for any of these machines.

Two laser technologies are relevant in desktop laser engraving – diode and CO2.

Diode lasers use a semiconductor diode to convert current into light which is then focused into a beam. Generally, diode lasers are cheaper, making them a great low-cost starting point. While they are suitable for engraving most materials, they typically lack the power of stronger CO2 lasers, and their ability to cut materials is limited. That is because the maximum physical output of a laser diode is about 10 W. Note: while some manufacturers claim their diode laser engravers capable of 15-30 W, this refers to the input power. Make sure to check the actual output of a machine.

CO2 lasers are a significant step up from a diode laser, often offering several times more power. They work by passing an electrical current through a CO2-filled glass tube, which creates the light energy. Mirrors then guide this light to the focusing lens.

While powerful diode lasers exist, CO2 lasers generally offer more versatility than diode lasers and are able to cut materials that diode lasers can’t. The downside is, CO2 lasers are very delicate devices with mirrors and glass tubes that are highly susceptible to damage – especially during transport. In addition, there are consumable costs with CO2 lasers in replacement parts needed after a couple thousand hours of usage.

Laser engravers are compatible with a wide variety of materials, but a particular laser may not be compatible with the materials you would like to work with. Before you invest in a laser engraver, it’s very important you know the materials you want to work with so that you get the most appropriate laser engraver for the job.

For the short read, peruse our six-step guide. If you want to delve deeper, consult our in-depth dossiers that will help you improve your laser engraving results.

You can use both raster and vector files for laser marking, engraving, and etching. However, your intended use may impact which one you apply for your design.

Raster files (JPG, PNG, etc.) are the go-to format for large engravings like fillet letters, images, and stamps. If you want to engrave any image made with a camera, raster engraving is what you want to use. Just like on computer screens, the image is put together by gradually adding points to form any shape you can imagine. Sometimes this method is also called “area engraving.” This method is especially well suited to materials like acrylic because it lends a beautiful frosted finish with a distinct contrast. Avoid raster engraving large glass, stone, and ceramic surfaces, since the results may be visually uneven.

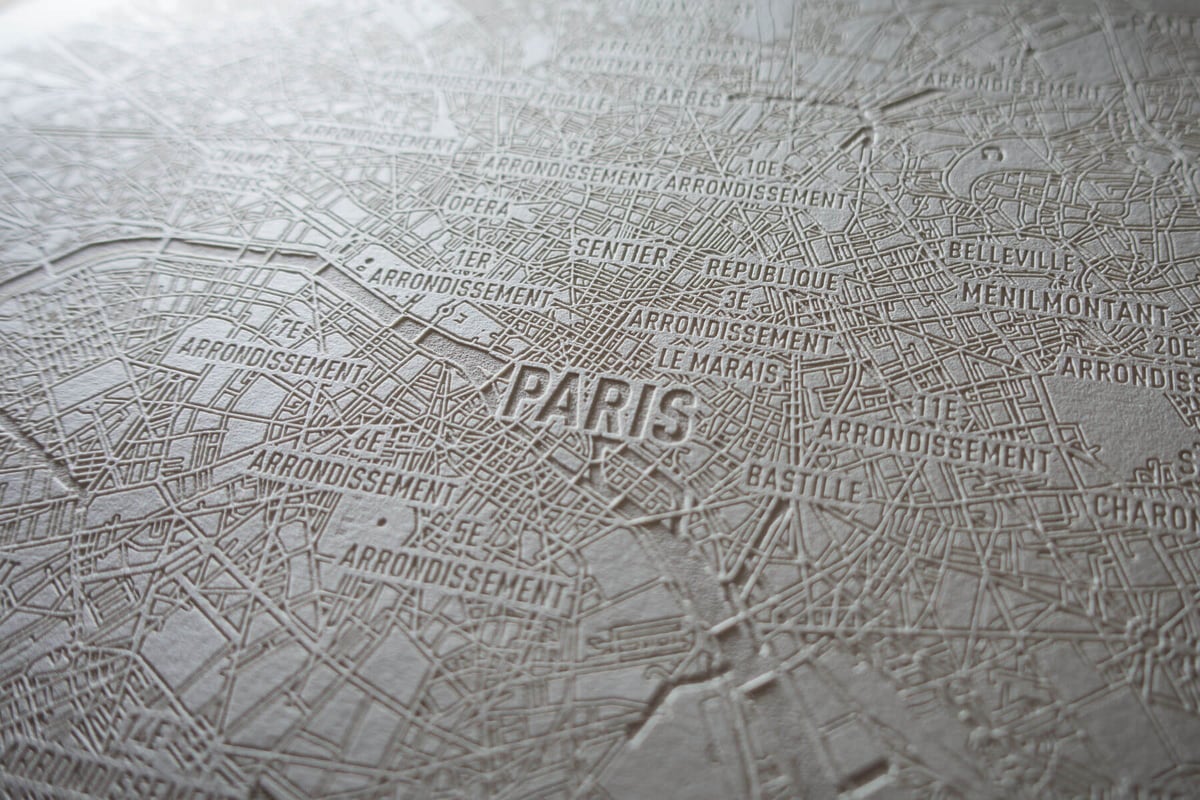

Vector files (SVG, EPS, etc.) are composed of lines that are traced onto the surface sequentially. If your design consists of fine lines and curves, then vector engraving is the appropriate method. Professionals also call this approach “scoring,” and sometimes “line engraving.” Vector engraving lends itself well to wood because the burned outline creates a stunning contrast with the warm surface of the material. It is less suitable for materials like acrylic since the melted outline is only faintly visible. The video above illustrates the strengths and weaknesses of both methods.

For the best effect, it may be worthwhile to combine both methods. The final parts feature the evenly engraved surface from raster engraving and also the crisp outline created by the vector engraving. This effect works exceptionally well on wood.

The difference between both methods can be a substantial cost saver even when you order only one piece from an online service. But how do you decide? As a rule of thumb, if your surface details consist of large, relatively simple shapes, you should opt for vector engraving, as this is the quicker and thus more economical laser engraving method. However, if the design covers a large area that contains many intricate details, you should choose the raster engraving method. However, ultimately, you should decide based on what works best for your design!

Laser engraving is so much more than fastening any material in the work area and pushing a button. Every material has its quirks and idiosyncrasies that will sometimes help you achieve your design goal and sometimes make it hard for you. The following list will guide you through the properties of the most common materials.

Since leather is a natural material, it may deform during laser engraving if too much power is applied.

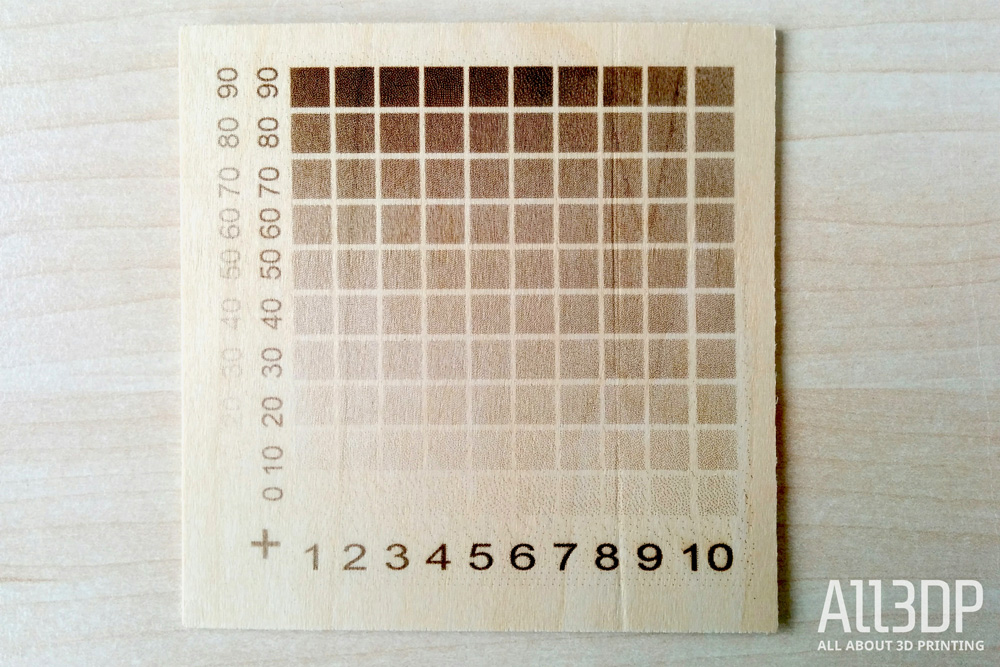

Because of the many varieties of leather, it is difficult to come up with a general rule for laser engraving. Hence, there is no way around determining the optimal laser engraving settings for each kind separately. To this end, test your machine with a grayscale matrix.

In terms of laser engraving, plywood has an additional advantage over natural wood. When cut into sheets, the latter reveals grains in alternating shades that stem from different kinds of growth during the seasons. These differences also translate into different laser engraved surfaces. Usually, the lighter areas will come out lighter, and the dark areas will be darker.

As a rule of thumb, unless the desired look of your design is zebra pattern, you will be better off using plywood that has a uniform surface.

When engraving hardwood, you should always apply higher laser power to achieve smooth results.

To determine the optimal laser engraving settings, test your machine with a grayscale matrix.

Apply a moist paper towel to achieve a smoother surface finish and a white engraving result. Take care that there are no air bubbles or overlaps because this would distort the effect. Once the engraving is finished, the paper towel can be wiped off easily.

An alternative to paper towels is application tape. Like moist paper towels, application tape is an excellent measure against surface roughening. The same caveat concerning air bubbles and overlaps applies. However, the final engraving color is not a bright white but looks grey. Once the engraving is finished, the tape residue can be easily removed.

But what to do when your laser engraver doesn’t have enough power to engrave glass? You can still achieve high-contrast designs by stenciling paint with tape! Simply mask the glass surface with tape, then engrave your design into it. Next, cover the revealed area of the tape with a thin layer of paint using a brush. After the paint has dried, peel the tape and remove the tape residue carefully.

If your results are unsatisfactory, consider changing the Z-offset value. This simple trick can significantly improve the result of your engraving. Many professional laser engravers report that hard stones are easier to process if you choose a negative Z-offset value of 1 mm or more. The physics behind this workaround is simple. The closer the surface to be engraved is to the laser, the more energy enters.

But what about when your laser engraver doesn’t have enough power to engrave stone? Or, when working with extremely hard stones that yield no satisfying results? You can still achieve high-contrast designs by stenciling paint with tape! Simply mask the glass surface with tape, then engrave your design into it. Next, cover the revealed area of the tape with a thin layer of paint using a brush. After the paint has dried, peel the tape and remove the tape residue carefully.

Files for use in raster engraving can be created in many graphic programs. In fact, if you are reading this on a Windows, macOS, or Linux PC, then you’ll have a pre-installed graphics program with the operating system that will suffice for your basic needs. But, these programs are our preferences:

If you are looking for a free alternative to Photoshop, try GIMP.

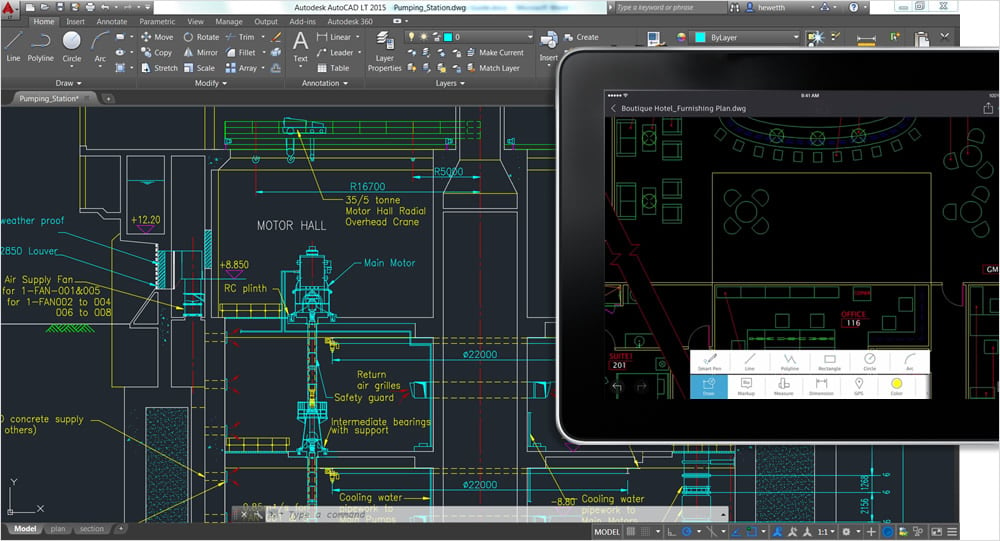

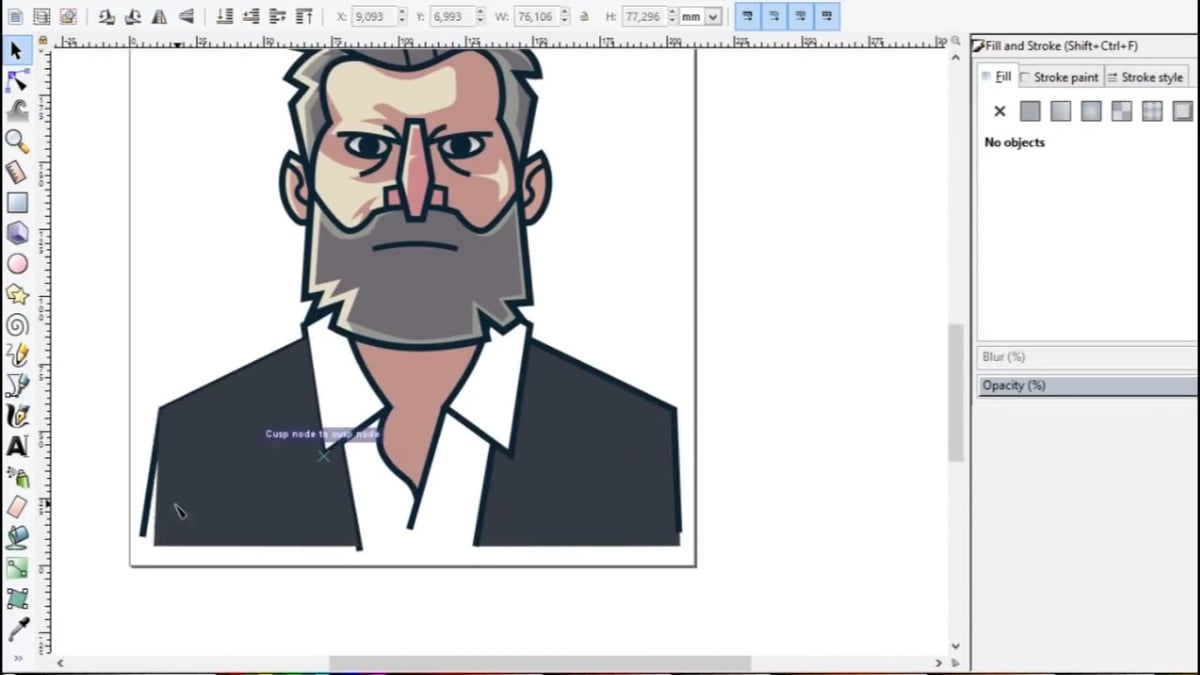

Vector engraving files are created in programs that offer support for vector formats like AI, DXF, EPS, PDF, and SVG. In general, this software comes with different tools to generate the necessary files. Depending on the machine you are using, a different setup is required. For example, if you want to combine vector engraving and raster engraving in the same design, it may be necessary to create separate files or assign different colors for each technique.

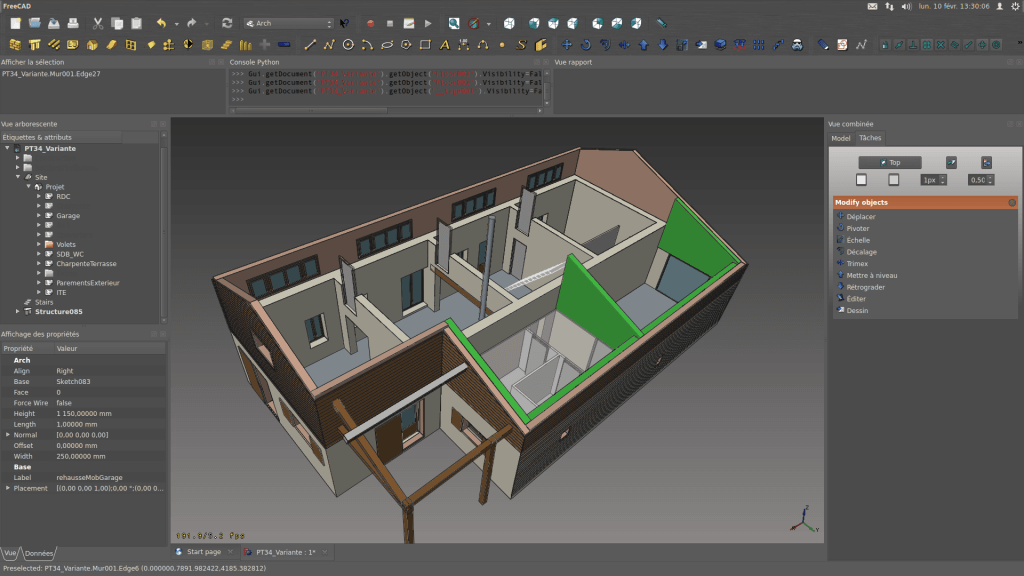

If you are looking for a free alternative to AutoCAD, try FreeCAD.

Learn more about this software for laser engraving: AutoCAD 2025: Free Download of the Full Version

Learn more about this free CAD software:

If you are looking for a free alternative to Adobe Illustrator, try InkScape.

So, you want to know how you can improve your laser engravings? Here are a few tricks that will help achieve that goal.

There are a few hacks that allow you to get you started in no time. However, if you are earnest about laser engraving, then there is no way around measuring the focal point of your laser. We suggest that you test 10 to 15 increments of 1 mm in the Z-axis. Prepare a series of files that contain a straight line and the value you are testing. Once your series of tests is complete, compare the results. You want the laser engraving with the thinnest solid line. Use this value for your future laser engravings.

The same applies to testing the intensity of colors. Modern laser engraving machines can achieve a broad spectrum of shades. However, the appearance of the final engraving cannot always be deduced by looking at the raster file. Laser engraving a grayscale matrix onto your material is an easy way to achieve predictable results, as you can “read” the intensity of shades on a scale from 0 (white) to 100 (black). Ideally, you should run this test for every material you want to laser engrave for the best possible results.

Tidiness at the workplace should be a no-brainer. However, concerning laser engraving, we’re not merely talking about courtesy towards your co-workers. Materials like wood, plastics, or rubber leave large amounts of dust that may cause unwanted results like discolorations, burnt debris, or even distortions. Be sure to install an exhaust system with the necessary capacities. It will take a lot of weight on your shoulders, but won’t clean the entire machine.

You should also be cleaning your laser engraver regularly by hand, removing the bulk of dust with a simple kitchen cloth. Pay extra attention to the machine head and the laser lens: these components should be free from dust and smut at all times to avoid laser engraving mistakes. To increase the efficiency of your exhaust when working with parts smaller than your work platform, try covering the rest of the platform with paper. It will save you a fair amount of manual cleaning.

Here are our tips for making your laser engraving process more efficient with templates:

Watch out for the volume of your workpieces. For thin objects, flat templates are sufficient to keep them in place. However, thicker and rounded objects, like pens, require thicker templates to keep them from rolling away.

In case you work with a large number of different templates, be sure to write (or laser engrave) the name of the graphics file in question onto the template, making it much easier to match your tools in your daily work. File small templates in folders to keep them safe and organized.

License: The text of "The Best Laser Engravers in 2024" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.