This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Classic Comeback?

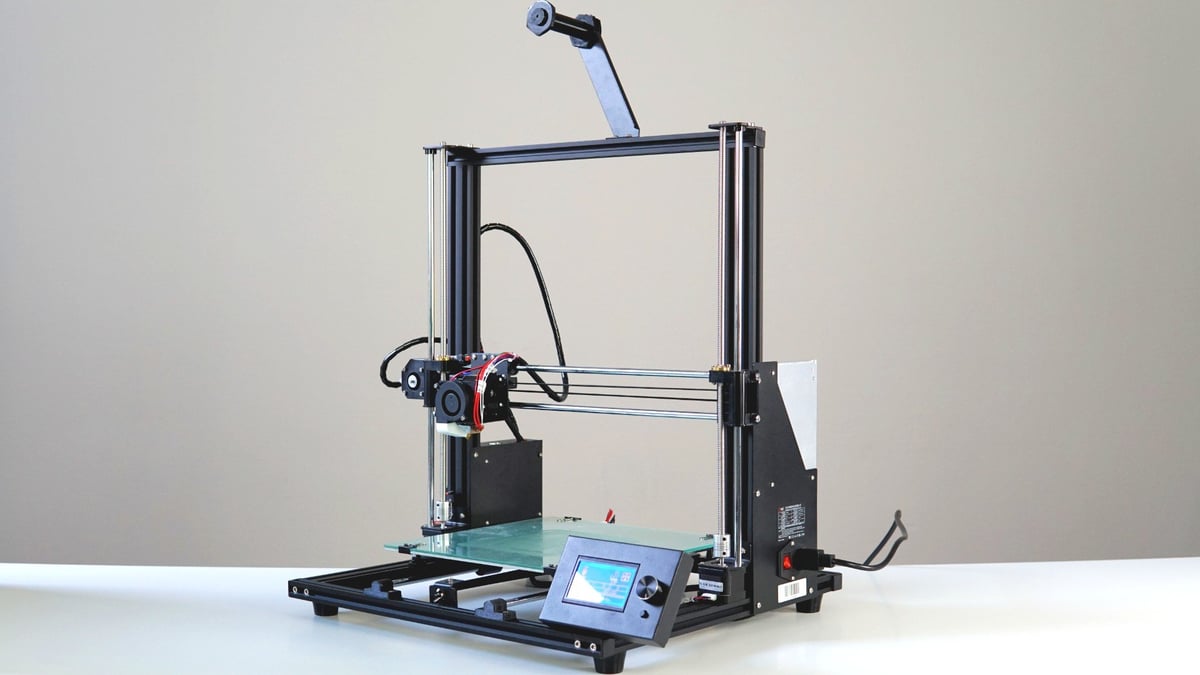

Anet A8 Plus Review: Hands On

The Anet A8 Plus 3D printer is an upgraded version of the tremendously popular Anet A8 and features a larger build volume plus a refined frame design. Read on for our hands-on review.

Advertisement

Advertisement