Small, medium, or large has never been the ideal way to prescribe a medical device. Every patient is unique. Yet custom-fit orthotics can be expensive and time-consuming to make, and plaster casts are messy and inconvenient. All that is changing rapidly as affordable hand-held scanners and 3D printing – coupled with new software and services – are more widely available.

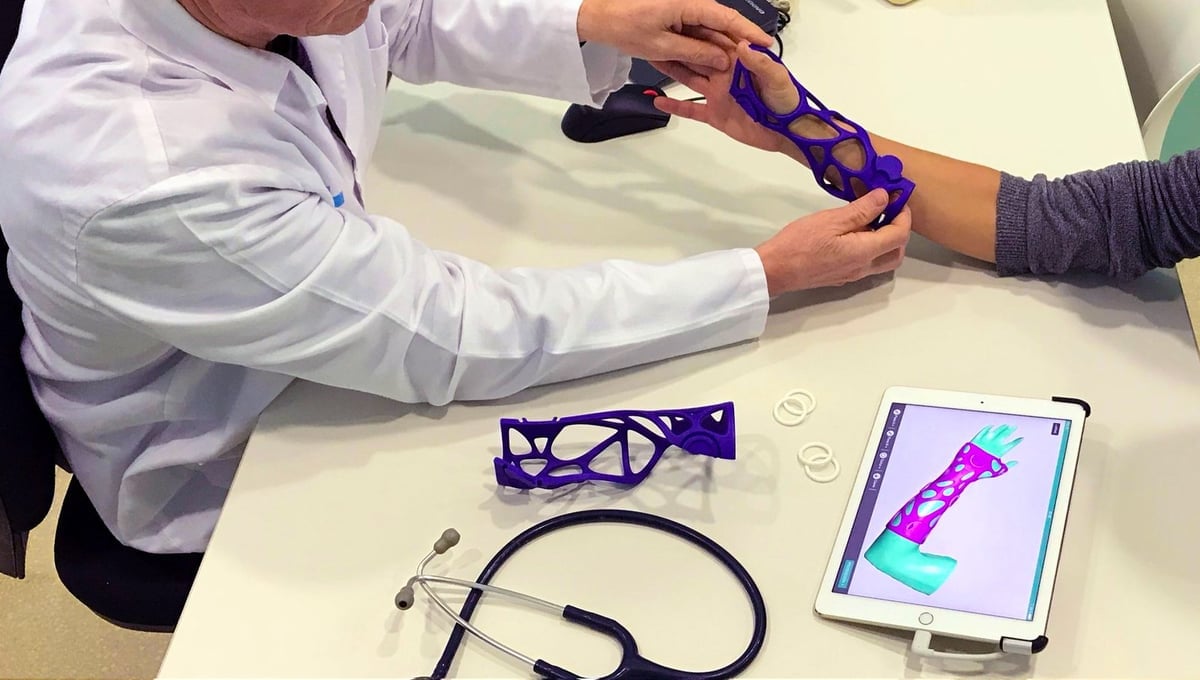

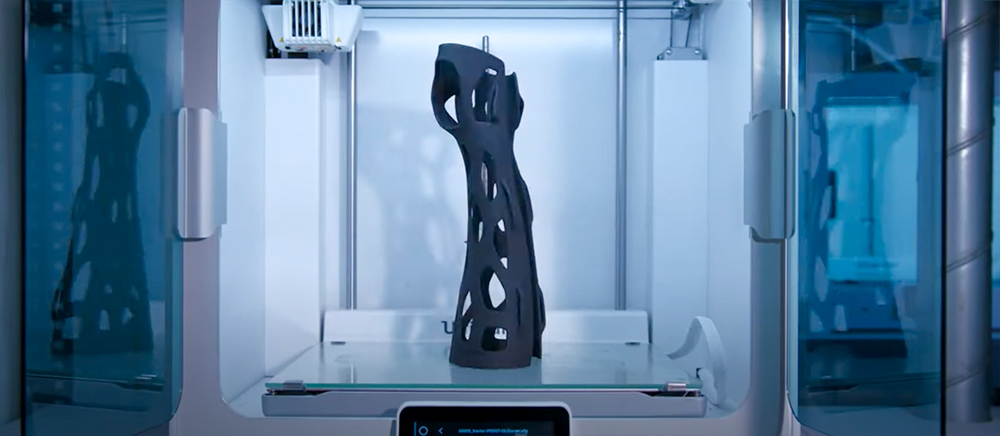

Whether it’s a wrist guard shaped to the patient’s unique injury or a post-op ankle splint designed around the wearer’s specific needs, producing custom-fit orthotics has never been easier. Why? Because a new breed of software that integrates with a wide range of available 3D scanners and 3D printers gives practitioners the ability to 3D print custom-fit products with little to no experience in design or 3D printing.

If you’re looking to 3D print a cast or brace for yourself, there is a DIY section at the end. The rest of this article focuses on how doctors, physical therapists, orthopedic clinics, and hospitals across the globe have new options to offer personalized products to their patients not only to lower costs and speed up delivery but to provide a better patient experience and gain a competitive edge for their business.

In fact, patients are seeking out 3D printed cast providers because the products are lighter-weight, airy, and more comfortable. Patients can shower and swim in them, and they are more aesthetically pleasing than traditional plaster casts and orthotics, all leading to a better quality of life during recovery.

If you want to offer your customers and patients a custom fit with 3D printed orthotics and braces – or even design and develop your own – keep reading for an overview of the industry, plus the top software and services to get you started.

How to Custom-Fit 3D Printed Products

There are several approaches to creating custom-fit products, but they all begin with a digital scan of the body part. There are a wide array of scanners on the market and the best, from budget to professional, are covered in All3DP’s Guide to 3D Scanners. Some methods even enable you to use your smartphone to scan.

3D scan data is one of the most revolutionary aspects of custom-fit orthotics and braces today because it enables patients themselves to make the scans, although the preferred method is by a medical professional. Patient self-scanning enables clinics to respond faster and get braces and orthotics to patients anywhere.

In addition to standard scanners, there are some specific anatomy and healthcare 3D scanners and scanner apps from companies, such as TechMed 3D, Creaform, and Comb O&P. Regardless of your scanner or your 3D printer, the software is the key element between the two that makes the process accessible to medical professionals who are not trained in device design or 3D printing.

Before we dive into the leading software solutions, let’s look at how 3D printed custom-fit products got to where they are today.

3D Printed Model Approach

The most basic approach to creating a custom-fit product is to use a digital scan of a body part to create a digital model that is then 3D printed. An orthotic shoe or brace, for example, is then fitted or shaped around this physical model. Although rudimentary, this process still holds various benefits over traditional methods of using plaster casts to get a negative of the patient’s foot, which would then be used to mold the replica of the patient’s foot – known as a “last”. The traditional plaster cast process is often messy, time-consuming, and requires the patient to be on site.

With 3D printing, however, manufacturers can go from patient scan to model in less time with less labor and materials.

Digital Model Approach

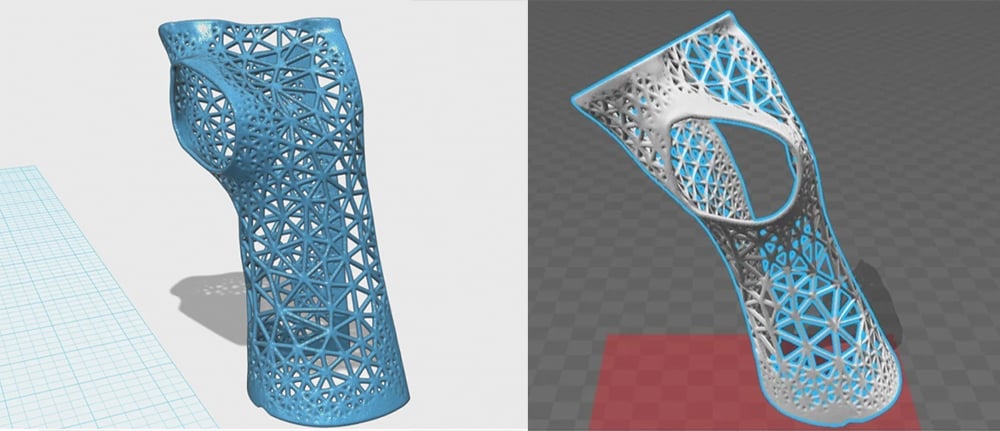

Another approach demonstrating how widely accessible and democratized 3D printing orthotics has become is the use of standard computer-aided design (CAD) software – from MeshMaker to Blender – to size an existing digital 3D model of a brace or cast, then print it. These digital files are widely available online at model libraries, such as Thingiverse. Consumers can use just about any CAD software to fit basic braces or casts.

For medical or orthopedic professionals, however, mastering CAD software can be time-consuming, while aiming for speed with a simple template could be too limiting as far as integrating special features.

These two limitations have led to the rise in specialized software that offers foolproof measurements, libraries of product templates and models, step-by-step design guidance, and automated export to 3D printers.

One category of custom-fit orthotic software that we cover below enables you to automate labor-intensive parts of the product production process without design or technical knowledge. The key here is software that doesn’t require specialized engineering or design skills.

Another category of custom-fit software enables more freedom to design and optimize the function and form of the product with a level of automation that enhances efficiency but does require some CAD design skills.

Custom-fit automation software creates an intricate and optimized product that can include special features, such as hinges and even differentiating patterns (e.g. logos) to be incorporated into the design.

When evaluating software in this area, be sure to ask about regulatory compliance and consider how and where the device will be 3D printed since some industrial methods, such as Multi Jet Fusion from HP, can produce more durable products than some other 3D printing technologies, like FDM.

Let’s take a look at the leaders in this category that are automating the process of custom-fit 3D printed orthotics, braces, and casts.

Spentys

Spentys is a 3D scanning, modeling, and printing platform for the development of custom-made immobilization devices. The company says its clinically validated workflow enables healthcare providers to create quality, patient-specific orthoses faster and at lower costs. You can make everything in-house or use Spentys’ modeling service and production facilities. In 2023, the company announced a partnership with the Arize Orthotic Solution from HP, which uses HP’s 3D printing technology to create custom foot orthoses.

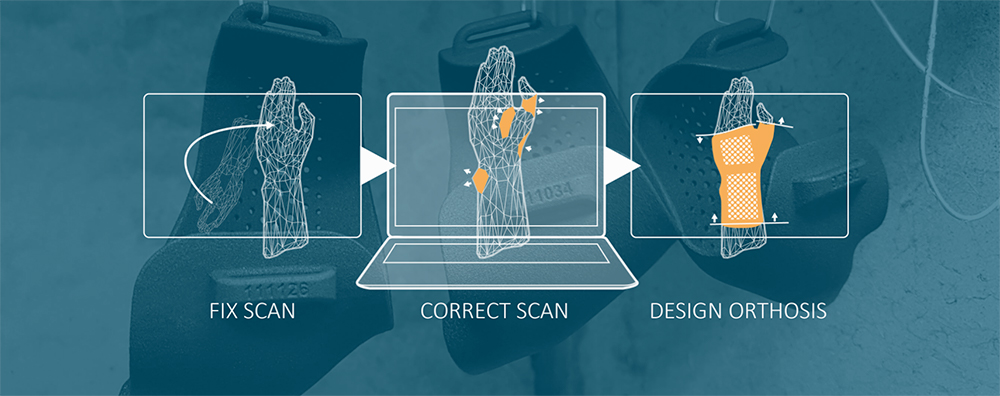

The patient scan data is reviewed by the Spentys AI-based software, which enhances it and automatically corrects imperfections in the scan. The patient’s 3D scan is stored in the cloud and can always be consulted for reimbursement justification and for device replacements or repairs.

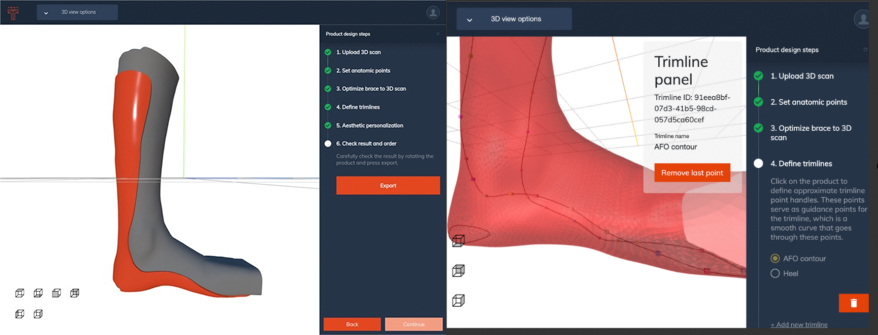

The Spentys software lets you design the orthosis directly on the patient’s scan through an easy-to-use digital interface that helps you step-by-step through the designing process.

Spentys will print and ship the parts or you can 3D print the parts yourself. Spentys gives you the possibility to have traceability for all your prints: what printer was used, what spool was used, what material was used, when the print was launched and finished, etc. Spentys integrates with a wide range of 3D printers enabling you to pick the hardware that fits your budget and level of expertise.

ActivArmor

ActivArmor offers custom-fit and fabricated splints and orthoses designed per doctor’s orders for each patient’s unique injury or condition. As with some others on our list, ActivArmor has multiple cast designs that doctors simply fit to their patients using the company’s online portal. These colorful waterproof casts are FDA-registered and typically covered by medical insurance, including Medicare and Medicaid in the US.

Patients can approach their doctor for a prescription for an ActivArmor cast, then scan themselves with the company’s iPhone app, and receive the cast in the mail.

ActivArmor’s turnkey solution, powered by Twikit (featured below), enables any doctor to provide their patients with this immobilization option by using a free iPhone scanning app or by becoming an ActivArmor-providing clinic. Because ActivArmor devices are custom-designed and fabricated, physicians have an infinite number of unique design options, including length, thickness, cut lines, exposure of bony protrusions or incisions, adaptability for use with complementary healing technologies, such as ultrasound and bone stimulators, TENS units, biomonitors, and EMS.

Invent Medical

Invent Medical offers software to help orthotists, prosthetists, physiotherapists, podiatrists, and doctors customize orthotics for their patients.

The Invent Medical configurator is a software tool to design custom-made orthotic and prosthetic products in minutes, the company says. Simply choose the product from their library of models and follow the configuration wizard. The automated processes, including algorithms and artificial intelligence, make production faster and cheaper than traditional methods. Once your product is configured and customized based on patient data, Invent Medical will 3D print it on their industrial printers, or if you have an industrial printer, you can print products yourself.

The bespoke product is sent to you for the final patient fitting. One extra step Invent Medical takes to empower medical technicians is to provide free websites, apps, brochures, photos, and videos to help attract patients to their clinics and build trust around the process.

An off-shoot of Invent Medical, Raptor Mask 3D prints protection masks for athletes. Recently

Twikit

The Twikit software platform solution, TwikFit, is not purely focused on orthotics and sports equipment but also provides solutions for on-demand digitally manufactured personalized consumer products, such as golf club grips designed around your biometric data.

Their orthotic offering, though, is a turnkey ‘scan-to-fit solution’ enabling medical professionals to create made-to-fit orthotics in their own offices or labs. You do not need any engineering skills. It’s the software solution behind ActiveArmor, mentioned above.

Twikit has a software solution that covers the entire custom-product process from customer order to production, and unlike some other solutions, Twikfit enables your customers to participate in the design of the products according to their own needs.

Twikfit also includes order management software for your digital manufacturing so you can create, track, and manage orders printed in-house or outsourced. The template-based Twikfit solution is compatible with a wide range of scanners, 3D printers, and parts from many OEMs.

Mecuris

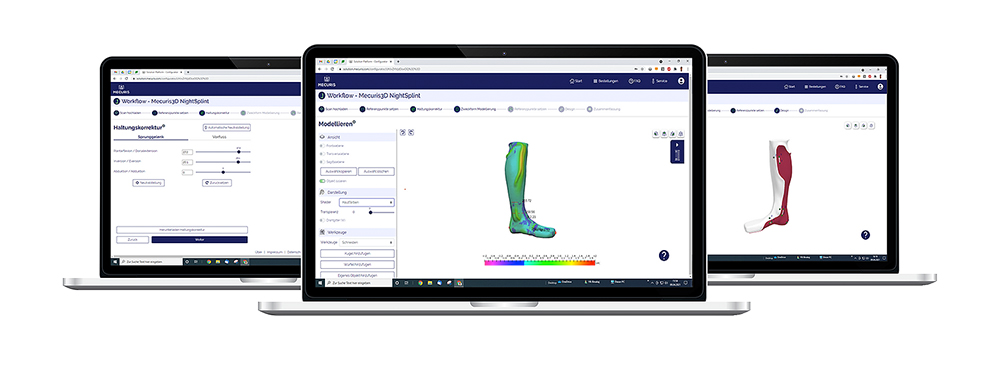

Mecuris calls its software a “digital orthotics workshop” providing tools for orthopedics, clinics, and medical supply stores to enter custom manufacturing.

This medtech start-up says its software is so intuitive that orthopedic technicians and physicians can get up and running with the ability to scan patients and 3D-print components in very little time.

The platform includes a correction module for patient scans, a modeling module, and a creator module that enables you to configure and design the orthotic blank. After the final design of an orthosis blank, you hand over the print file to your print service provider (see section below). The orthosis then requires finishings, such as straps and locks, and it’s ready for the patient fitting.

Like some other solutions, Mecuris enables practitioners to manipulate digital patient files to reprint parts and easily adjust for growth.

Xkelet

Although most software solutions in this market integrate with third-party scanning and printing hardware, Xkelet has taken the full ecosystem approach. The company offers a scanner that integrates with a tablet, a software platform, and it has developed its own resin 3D printer with accessories. It’s a full immobilization manufacturing solution in a box.

Xkelet says its devices solve the problems inherent with current plaster solutions, such as itching and skin irritation, enabling patients to shower. Its devices also enable medical professionals to see the condition of a wound instantly thanks to the design of windows.

Practitioners simply size the Xkelet library of patented devices, such as the XKast, to their patients.

Toolkit 3D

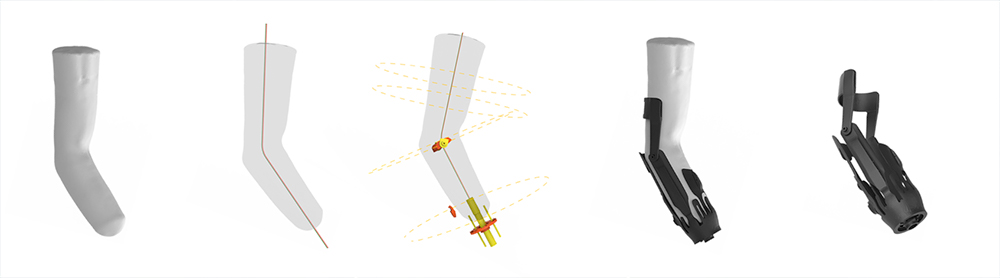

Toolkit 3D, which purchased Shapeshift 3D and its technology in 2023, specializes in software solutions aimed at digitizing and automating the customization of 3D printed products, such as high-performance medical and sports equipment from knee orthotics to sports helmets to custom insoles.

Setting itself apart from other solutions on this list is the scale of the platform and patent-pending technology powered by artificial intelligence that automatically fits a 3D product’s model to a client’s 3D scan while maintaining compliance with medical, manufacturing, functional, performance, and branding requirements, the company says.

The software enables practitioners with digital product designs to grow their portfolio of 3D printed orthotics at low cost and scale their custom-fit product line. But the amount of automation is flexible and ranges from a fully autonomous process to some steps requiring manual manipulation.

This online software platform helps O&P and sports equipment businesses simplify, streamline, and scale their custom-fit production.

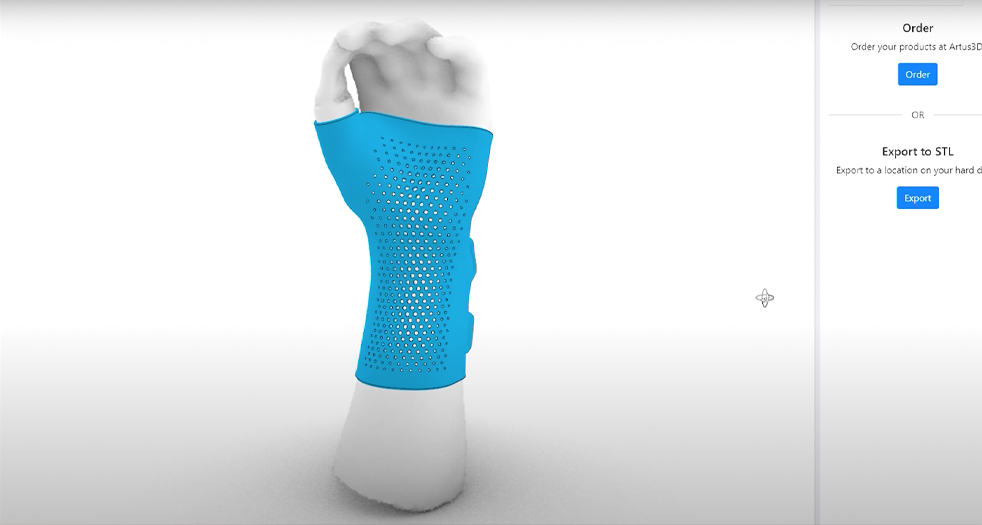

Artus3D

Artus3D software currently focuses exclusively on hand braces and full automation, although it is possible to make adjustments. The platform includes a scanning app that can scan the hand in about two minutes and send the image to the Artus3D Cloud, so it’s available for processing in another location. The software then cleans up the scan, correcting for any missing data points, and creates a final digital hand model.

The braces are then fitted to the model and adjustments can be made for straps and add-ons. Lastly, the file is sent to any 3D printer or printing service for production. In addition to design software, the company also supplies finger splints in silver and Nylon.

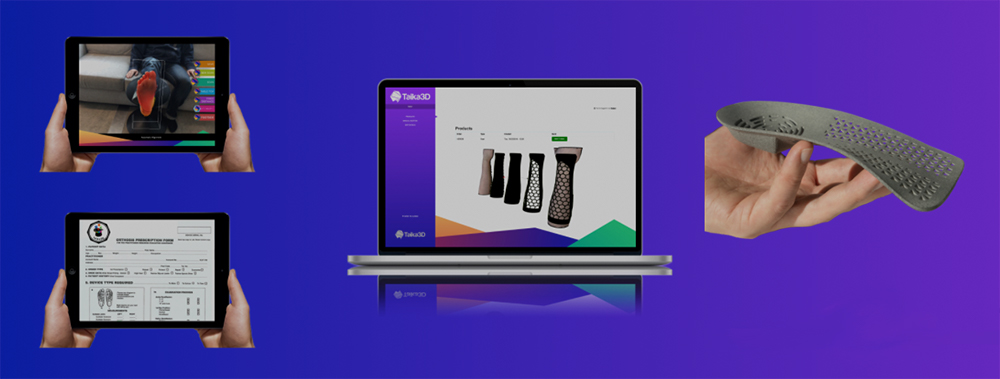

Taika3D

Software from start-up Taika3D was born out of the challenge to create complex custom designs in a fast and consistent way. The technology has been used to give orthotic and prosthetic laboratories design freedom to 3D print for mass customization. Clinicians directly model from anatomical surfaces and scale templates or create a hybrid of the two, even incorporating standard components.

The Taika Create design engine cloud platform is customized to each client’s products and processes to dramatically improve accuracy, consistency and speed of design, the company says.

The full platform includes a scanning app, but Taika also supports input from a wide variety of 3D scanners. Despite being based in Europe, Taika can advise on selecting equipment for in-house production or provide access to their network of 3D print bureaus worldwide.

Medical Regulations and Certifications

Orthotics, braces, and casts are ultimately medical devices that can cause harm if not prescribed, manufactured, and used properly. 3D printing is indeed democratizing access to these life-changing devices, but it is essential that this democratization be done by those with the required training and experience.

Although a cast is clearly a medical device, is the software to create the cast a medical device?

Software as a medical device (SaMD) is relatively new, and the regulatory environment is still evolving as regulators scramble to keep pace with innovation. The International Medical Device Regulators Forum (IMDRF), a global working group comprising representatives of the U.S. Food and Drug Administration, European Medicines Agency, and other key regulators, defines SaMD as “software intended to be used for one or more medical purposes that perform these purposes without being part of a hardware medical device.”

Louis-Philippe Broze, the co-founder of Spentys, says his software is, essentially, computer aided design software. In other words, it’s a tool for the user, just like the 3D printer is, to create the medical device – only the final splint, cast, or brace, is the medical device.

When you print medical devices in-house on your own 3D printer, you become the legal manufacturer and are therefore responsible to meet quality requirements (safety, quality and performance) and make declarations that the product conforms to the regulatory standards. What are the regulatory standards, you might ask? In Europe, refer to ISO 13485:2016, in the US, check out FDA registration of medical devices, Title 21 CFR Part 807, and elsewhere, refer to your national medical regulatory body.

When Spentys prints devices for its customers, it takes on the legal responsibility for ensuring the quality of the device. Likewise at ActivArmor, which is registered with the US FDA as a medical device manufacturer for Class I splints. It takes on responsibility for all quality tests and checks for biocompatibility and microporosity (which can trap moisture and bacteria against the skin) and assumes all warrantees. ActivArmor’s international partners work with their own regulatory bodies.

If you use other third-party 3D printing services, such as Craftcloud or Sculpteo, they will send you the device, but typically will not perform any special quality control on the product, leaving that step to you. Check with your third-party printing service to determine if they will perform quality checks and make quality declarations. The quality declaration you make or receive from the manufacturer is intended to track the cause of any problem should it occur.

Although the CAD tools and platforms used to create these devices are not regulated or standardized, there are efforts underway by associations like the Association for Orthotics and Prosthetics of America (AOPA) to develop guidelines and standards.

In the meantime, it is important to acknowledge the importance of having an appropriately certified and licensed medical professional prescribing and overviewing the care of patients, as recommended by the American Association for Orthotists and Prosthetists (AAOP).

Of course, compliance is required with patient data regulations – General Data Protection Regulation (GDPR) in Europe and the Health Insurance Portability and Accountability Act (HIPAA) is the US – to ensure the safety of the data being handled.

Where to Print Your Orthotics

Although there’s nothing to stop a consumer with a sore wrist from 3D printing a brace on their desktop printer, the 3D printing method and materials used by medical professionals have to meet certain standards. Similar to the booming market for 3D printed dental products, orthotics, and braces must be made from materials certified for short- to long-term skin contact, such as PLA or nylon (PA11).

Practitioners have three choices when it comes to the actual printing of their custom-fit product: print it themselves on their own 3D printer, have the design platform (e.g., the companies detailed above) manage the manufacturing, or take your custom-fit product’s digital file (the STL) and upload it to a third-party 3D printing service, such as Craftcloud by All3DP.

Print it yourself

There is a wide range of 3D printers you can use to manufacture orthotics in your own office. Splentys uses Ultimaker S5 and S7 machines, for example, and Invent Medical and others use an HP Multi Jet Fusion printer (which you can access at a service provider).

Nearly all of the 3D printing technologies are applicable to orthotics and braces. Your choice of printer depends on how much you plan to print, how fast you need the parts, your budget, and how much time you have to devote to post-processing and finishing. If you’re new to 3D printing, check out our guide to selecting a printer below.

Contract a third-party printer

There are a lot of advantages to outsourcing your orthotics and braces to a trusted third-party 3D printing, including their expertise, multiple finishing options, and different industrial technology to choose from depending on your part’s need. Experts at these companies can also advise you on materials and finishes and some will manage the shipping to your patients.

Some of the custom-fit solutions we detail above will manufacture your part in-house, or they’ll outsource it to their trusted third-party printer service near you. If they can’t manufacture your parts for you, many will recommend a service.

DIY Orthotic Braces

Throughout this article, we’ve highly discouraged DIY healthcare. Even in places where access to medical care is severely limited, research studies and pilot projects focusing on 3D printing as an economical way to bring orthotics to patients always include involvement by medical professionals.

The risks of 3D printing a device that is the wrong size or shape is just too high: your injury or condition could not only fail to heal but you could experience further and possibly permanent injury. Improperly printed devices at home could trap moisture and rub on the skin leading to sores, blisters, and infection. DIY casts and braces could break, warp, or bend if not 3D printed properly.

If you want to design your own brace and 3D print it yourself, discuss it with a healthcare provider who can evaluate your final printed part before you use it.

License: The text of "3D Printing Casts, Braces & Orthotics" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.