The Glass Bed

A 3D printer glass bed is arguably the best option when aiming for a flawless print bottom. Not only that, it’s also remarkably easy to remove prints from glass (providing your bed was clean before the print). In fact, within the 3D printing community, the joke goes that just knocking on the printer is enough to make it slide.

In the following, we’ll discuss what makes a glass bed so good and what to consider when buying one.

Benefits

It’s widely accepted that no one build plate is best; what’s ideal for you largely depends on what you want to print. Glass as a bed for your 3D printer, however, gives many benefits that are worth considering.

Generally speaking, what makes glass a good option is that it’s a reliably flat, stiff, dense, and cheap material. As a print bed, it therefore has a number of characteristics and advantages that you should keep in mind when in the market to replace your print bed:

- Flatness: Print beds need to be flat throughout printing to avoid running into errors. When produced properly, glass is naturally stiff and thermally stable. Therefore, it remains flat and will ensure your bed’s leveling remains consistent. After all, the tedium of leveling and calibrating is never fun.

- Smooth finish: Designers want the bottom of their prints to be as smooth as possible, and glass guarantees such a finish. It gives a mirror-like, glossy base that can’t be achieved with most other surfaces.

- Durability: A good number of surfaces can’t stand repeated use because of the heating and contraction. Plastic or acrylic bases, for example, will eventually need a replacement because the surface will start to chip, scratch, warp, or peel. Meanwhile, glass rarely needs replacing because it hardly wears. That means you can enjoy consistent high-quality prints for a long time.

- Cost: By virtue of its durability and little need for replacement, a glass bed will save you money (and time) down the road.

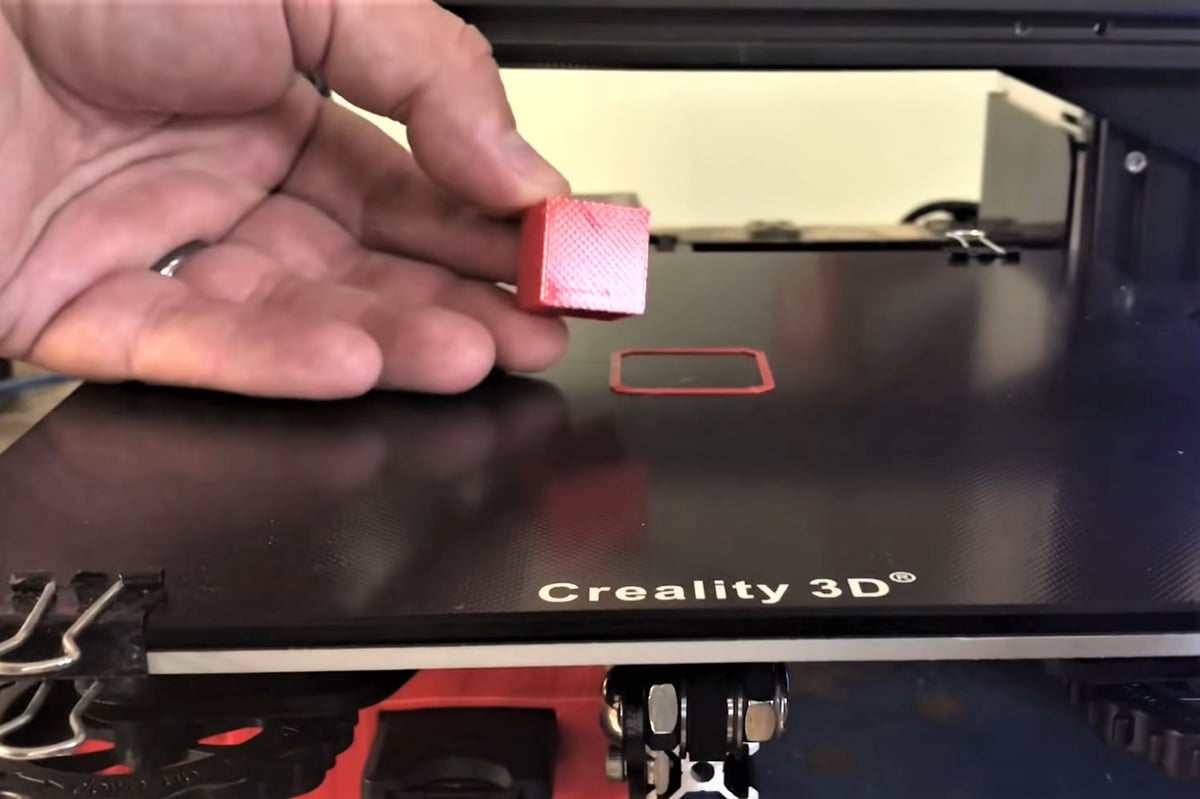

- Easy removal: No one likes using force to remove a print from a print bed. Not only is there a chance to break more fragile models, you also risk hurting yourself or damaging some component of your printer when the model does finally pop off, sending hand, scraper, and print flying. Glass print beds are famous for easily releasing prints, which makes the whole printing experience that much more enjoyable.

- Easy cleanup: Beds commonly gather grease, dust, and unwanted plastic fragments that result in an uneven and unreliably adhesive print surface. This makes cleaning a necessity, and few printer beds clean as easily as a smooth sheet of glass, again thanks to its smooth, flat, and stiff surface.

- Uniform heating: Even for materials that don’t require need it, heating the print bed can greatly improve how well a model prints. Lacking thermal conductivity, glass beds typically take longer to heat up, but they also spread heat much better than other surfaces. This can greatly help when experiencing first layer issues, as you can be sure different areas will be affected similarly.

What to Look For

Below are the main factors to consider when replacing or buying a glass bed.

Size

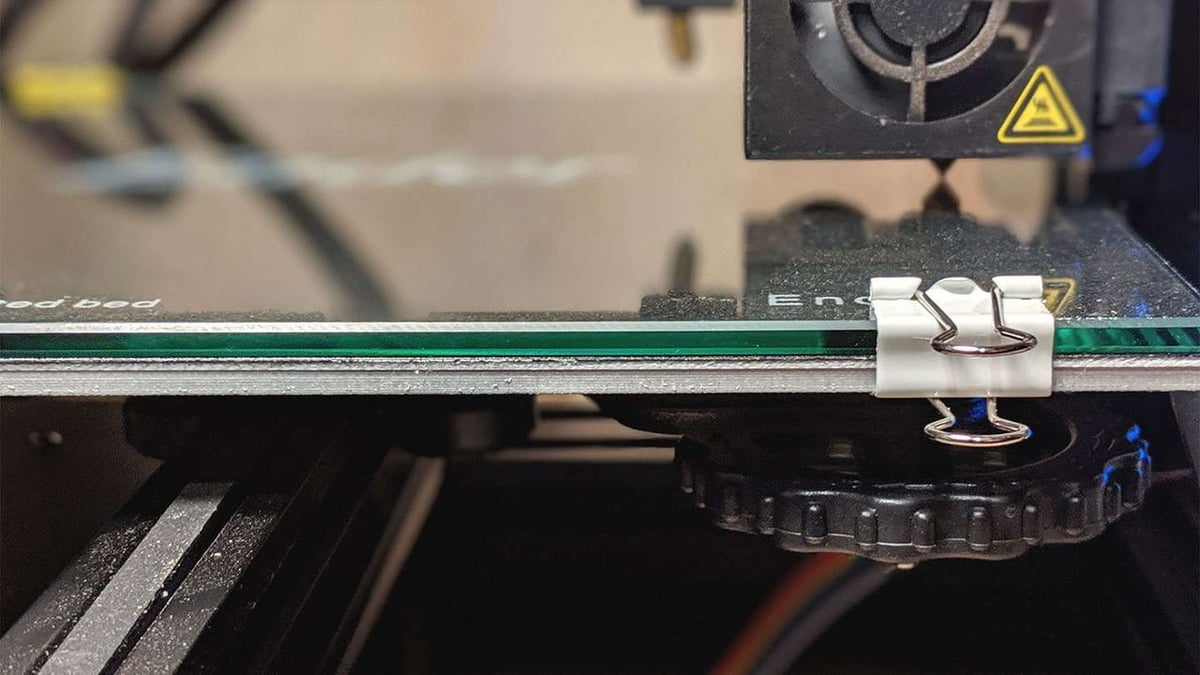

While this may sound obvious, your glass plate should match your print bed size. You want that “snug fit” between the glass plate and the print bed to avoid something that wobbles during printing. After all, how’re you going to use the build plate clamps when your glass plate is too big or too small in comparison to the print bed size?

Optimal Thickness

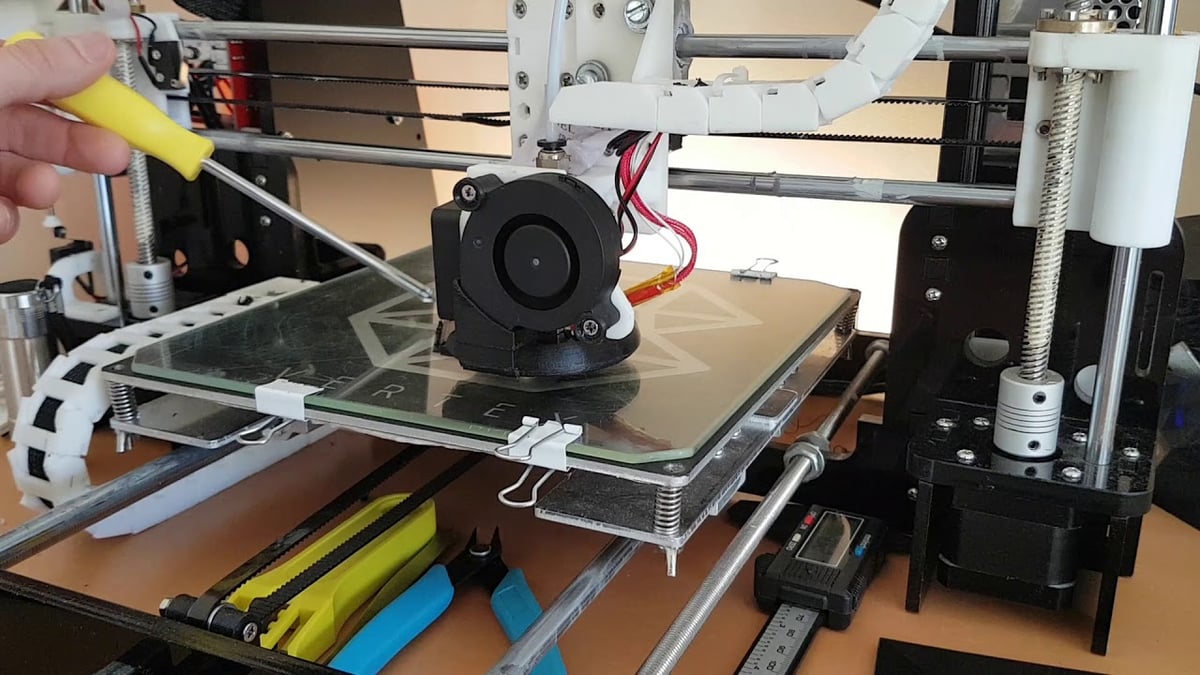

As long as glass isn’t subjected to shock, it’s actually stronger than most people think. Therefore, if you’re using a standardized bed, a 3- to 4-mm glass plate should be fine. This thickness is sufficient to maintain strength and spread heat.

If you opt for a very thin glass plate (for example, 1 mm), it’ll be vulnerable to cracking from the high temperatures or accidental contact with the hot end. Furthermore, thickness should increase with print bed size. For a massive print bed, you may want to consider something like 6 mm.

Thermal Shock Resistance

A glass print bed should be highly heat-resistant. A plate that will crack or shatter when exposed to rapid changes in temperature won’t be ideal for 3D printing. Instead, you want something that’ll retain its original shape and structure when heated up to 200 °F and plunged into 40 °F water. Such durability is known as thermal shock resistance, and it goes a long way in ensuring that a glass plate remains usable for an extended period.

If a plate can endure large temperature changes without sustaining any damage, it stands to reason that damage through 3D printing would be next to impossible. When searching for a glass print bed, keep an eye out for terms like “borosilicate” and “tempered”.

Thermal Fatigue Resistance

Repeated heating and cooling means that even tempered glass will lose its strength eventually. However, certain varieties of glass, like NeoCeram’s ceramic glass, can withstand repeated heating and cooling cycles.

Which to Buy

As was mentioned above, print beds can reach fairly high temperatures. For this reason, you’ll want a plate made of borosilicate glass. Borosilicate, which is made up of boron trioxide and silica, is resistant to thermal expansion and thermal shock, and will rarely undergo any physical changes when subjected to high temperatures.

Assuming you find the right size and thickness, borosilicate plates can be purchased from many different vendors, including Amazon and MatterHackers.

License: The text of "3D Printer Glass Bed: What to Consider & Which to Buy" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.