The last two years saw a number of 3D printer projects promoted on crowdfunding platforms such as Kickstarter. Almost all of them died a fast or an achingly slow death.

In comes TIKO 3D, the company that started a more than successful Kickstarter campaign for its $179 3D printer. TIKO 3D managed to convince more than 10,000 people to back its project – and there are still 13 days to go. Right now, they collected over $2 million.

There is a heated discussion on the Kickstarter forum with over 1,600 comments so far. Last week, All3DP compiled the most important questions and the answers from TIKO 3D in our unofficial FAQ (this FAQ will be updated regularly).

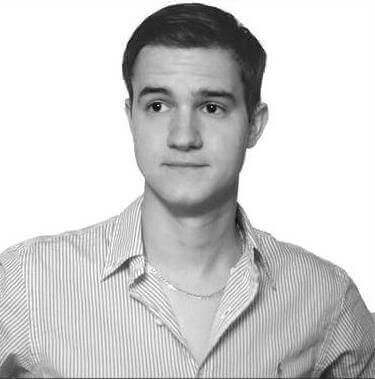

Now, we managed to get an exclusive interview with Matt Gajkowski, “the mind behind Tiko’s groundbreaking technologies”.

Status of the Tiko project

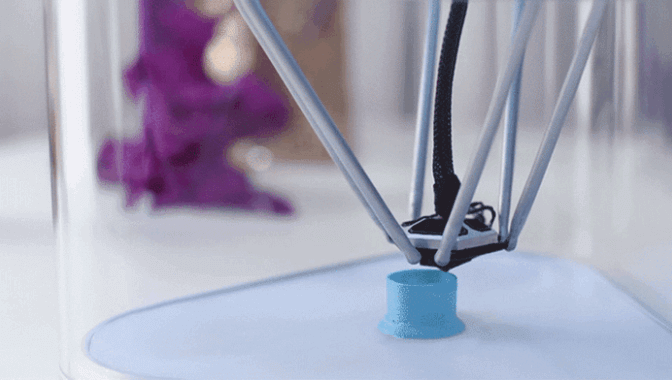

A: Tiko’s hardware works and is readily manufactureable, but there‘s a long road of refinement and endurance/torture testing ahead of us. The results of those tests will dictate how many changes we need to make. The software is still under development, because it doesn’t have hardware-like lead times. We’re exploring an API, but that will be post-delivery. Tiko’s hardware won’t require maintenance except for the occasional nozzle-change. Software/firmware will see regular updates as we explore Tiko’s potential.

We’re not planning on creating a larger Tiko, instead we’re focused on getting the most out the current exterior dimensions.

Technical questions

Q: We all know that one of the weak points of PLA printers is cooling the liquefier unit. This involves a complex construction including large fan, complex installation, noise, dust collecting in the fan. The Tiko is an enclosed unit – cooling must be an even bigger problem here. How does the passive cooled liquefier work?

A: In order to make any liquefier work with PLA, you have to go from ~200C to ~50C in a very short distance. There are two strategies to do this. One is to minimize conduction from the hot nozzle to the cold inlet, and the second is to maximize heat dissipation at the inlet. Tiko’s passive cooled liquefier achieves both of these by using a one-of-a-kind titanium nozzle, and a large heatsink that is shielded from the hot gasses rising up around the nozzle. That’s the basic premise anyway, but there is a lot more going on and it took a great deal of work to get right.

Q: How does the filament feed work? In the video, adding the filament spool seems to be simply plug&play. How does the user thread the filament into the feed pipe?

A: Tiko has a filament detection system, so loading filament is as simple as pushing the filament into the slot until Tiko detects and ‘grabs’ it, and takes it from there. Removing filament is done via the software via a single button.

Q: There have been some questions on Kickstarter regarding the 165mm filament spools – what is Tikos official take on that?

A: They’re not as common in every corner of the world as we had expected, but it’s no problem. By delivery time we’ll have a good list of approved resellers, in addition to carrying materials ourselves. At the end of the day, 10,000+ backers are going to need 165mm spools of filament – someone is going to step up to the plate and sell them.

Mass manufacturing

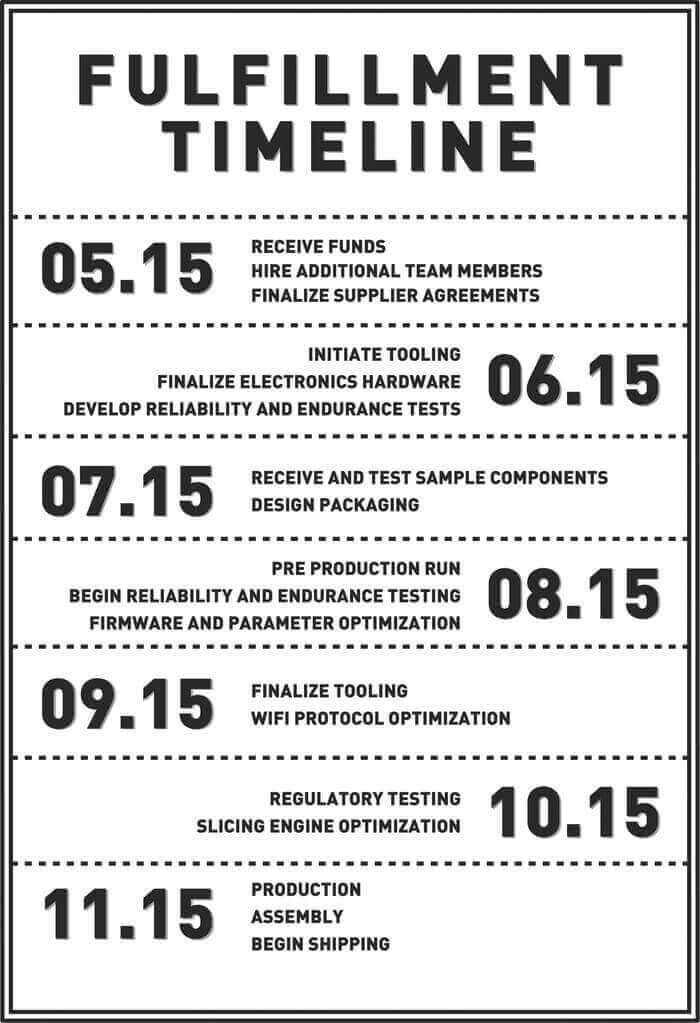

Q: You already have several thousand orders. How will you make sure you can deliver on time?

A: We don’t expect any delays as a result of the order size, as we are working with large and established manufacturers who can handle this volume. In fact, it’s the months leading up to production that are critical. As with anything, preparation is key – and we’ve already got a head start on some of tasks such as tooling of certain components. In general we’re working day and night to stay ahead of the curve.

Q: What if there is any delay? Will that eat up the financial cushion you gathered from Kickstarter?

A: We’re not planning on hiring a large team or opening up a facility, so no. It would however piss off a lot of people – and there is no cushion for that.

Q: How come you offer the Tiko at the fraction of the price of other 3D printers?

A: There’s a common misconception that advanced technology and affordability are mutually exclusive. We fundamentally believe that this untrue, and that one can be a driving force behind the other.

If you’re wondering why we didn’t set a high price even despite the low manufacturing cost, it’s because of our belief that 3D printing should be accessible to anyone.

Customer support

Q: Tiko is a closed system. What if something breaks? In other 3D printers, it is not a problem for the user to replace a broken part – what do I do when something breaks inside the Tiko?

A: The same thing you would do if any other appliance breaks – contact the people who made it. Our users can still replace part (which we’ll gladly send over), they just won’t be able to print most of them due to material/tolerance limitations. That shouldn’t stop anyone from trying, though!

Q: What is the MTBF of the motors in the Tiko? How many years of operation does that mean?

A: The MTBF of the motors we use is 5,000 hours, and we have good reason to believe they will last longer in our application. Pre-production testing will reveal the true lifespan, but even 5,000 hours would mean years for most users. To put things in perspective, over the course of 5,000 hours a single Tiko would print approximately 53 kg of filament – that’s $1,500 USD worth of plastic. So, we’re confident these motors will give your Tiko a long and happy life.

Q: Assuming you will ship 10,000 and more Tikos all over the world? How will you handle repairs and shipping?

A: On a case-by-case basis. Some cases will require parts, others a replacement printer, others still might require repair. We’re too young and small a business to promise a one-size-fits-all policy, but we look after our backers. Once we’ve put Tiko through a full endurace testing program we’ll be able to re-evaluate this.

Outlook

Q: Tiko seems to me to be what VW did with the Volkswagen/Beetle: A car for every household = a 3D printer for every household. What percentage of households in the US will have a 3D printer, in – say – 5 years?

A: The problem with this analogy is that people wanted a car and benefitted from owning one. Unfortunately, 3D printers are not (yet) useful to the average-joe consumer. They are, however, an invaluable asset for creators and innovators. When the advantages of 3D printing outweigh those of mass-manufacture, that’s when we’ll see real consumer adoption. But that’s still a ways off.

Q: What percentage of that will be Tikos?

A: We aim to be a leader in 3D printing technology. If technology and prices are indeed what’s driving the adoption of 3D printing, then we are well on our way to becoming the market leader. We’ll leave the numbers to your imagination.

Profile: Matt Gajkowski

Matt was born and raised to be an entrepeneur. He believes in simplicity and relentless progress, and he isn’t afraid to challenge established ideas. He is the mind behind Tiko’s groundbreaking technologies and the muscle that has brought them to market. Matt worked as a freelance product designer before starting Tiko. He now has a vision for the future of 3D printing and the know-how to realize it. (from the Kickstarter project page)

License: The text of "Tiko 3D: Interview with Matt Gajkowski" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.