Almost every day All3DP readers ask about Tiko 3D printer: Is the project on schedule? Will I get my Tiko in November? I missed the Kickstarter campaign – when will I be able to buy one regularly?

So we contacted TIKO 3D and arranged an interview with co-founder Matt Gajkowski.

Plus: At the end of this article we summarize the latest updates TIKO 3D sent out to their backers. An interesting read not only for Tiko backers but for everyone curious about this clever 3D printer.

Interview with TIKO 3D co-founder Matt Gajkowski

“November is right around the corner, but by the looks of it, so is Tiko!”

All3DP: So, what is the current status of the Tiko project? What are you doing right now?

Matt: “That is a simple question to which there are many answers. Tiko is a relatively complex consumer product, and there are many components that need to be prepared for manufacturing. Right now Tiko’s parts are spread throughout the readiness spectrum. Some are about to be tooled, some already have. Others are finished, and still others are off-the-shelf that we simply need to order when the time is right. Meanwhile R&D is humming along with benchmarks on the software/electronics, tests on mechanical components, and of course preparing everything for a smooth and efficient compliance testing process.

There is a tremendous amount of activity going on – it’s beautiful and glorious in all of its complexity. It takes a sophisticated planning and prioritization system to do everything correctly, as so many items are interconnected. All in all, it’s pretty remarkable how far we’ve come in just the past month alone. The whole team has been truly exceptional at hitting our milestones.”

All3DP: Will you stay on schedule and deliver the first Tikos in November?

Matt: “Everything looks great right now. Can’t say we haven’t hit any speedbumps – manufacturing something like this is no walk in the park after all – but we are so quick on our feet and so responsive to challenges that in some respects we’re doing better than we expected. November is right around the corner, but by the looks of it, so is Tiko!”

“[our backers] got us here, so it’s out duty to hold up our end of the bargain”

All3DP: Now that you are preparing for mass production: Have there been any changes to the Tiko hardware or software compared to the Tiko you presented on Kickstarter?

Matt: “Any worthwhile answer here would require divulging too many technical details, so let’s skip it.”

All3DP: What has been the greatest challenge for this project so far?

Matt: “Communication. Actions speak louder than words, and so we tend to wait for meaningful and noteworthy accomplishments to post up. At the same time, we’re quite guarded about our R&D. So, we have to strike a careful balance between saying too much and not saying enough. It feels good to have that sense of accountability, though. It can be challenging to do what you have to do while under the microscope, but every decision we make, we strive to make it “backer approved”. They got us here, so it’s out duty to hold up our end of the bargain – even if we don’t post up the day-to-day stuff.”

All3DP: What are your plans: Will there be add-ons to Tiko? Will there be a generation 2 – and when?

Matt: “3D printing is happening, and additive manufacturing, in general, is indeed the future of manufacturing. Like most new technologies it might look completely different in 20 years, but it’s happening, and if there is one thing you can count on it’s that Tiko will be on the cutting edge the entire time. Oh yes, we have plans for the next iteration of Tiko, and we have plans that go far than beyond that. However, we’ve got to keep our eye on the prize right now, and that prize is November delivery. But rest assured we’re just getting started.”

All3DP: There are a lot of people out there who were late for the Kickstarter project. When can they buy a Tiko and what will it cost?

Matt: We’ve got some pretty cool plans for that. For the time being we recommend signing up to our mailing list, because when Tiko does become available it will be swift, and it will be awesome. And, duh, affordable! 🙂

Tiko technical updates

In the July update TIKO 3D sent out to their backers they did divulge some technical details. Here is what they wrote:

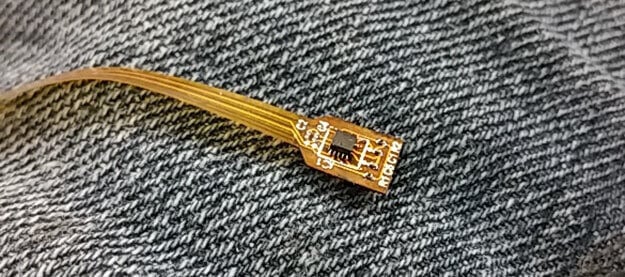

Accelerometer

Remember the photo on our campaign page of our end-effector accelerometer? Well, for a long time we yearned to put that sucker onto a flexible PCB, but we weren’t sure we could justify the added cost. But, with larger orders come lower production costs, and we used that in numerous ways to subtly improve Tiko beyond even what we had created in the prototyping phase.

In the case of the accelerometer, this new configuration brings with it a number of advantages including better signal integrity, one less connection that could fail, and a reduction in stiffness of the end-effector wiring harness.”

Stepper motor

“During the campaign a number of backers expressed concerns about the small stepper motors we’re using inside Tiko. Let’s face it, we saw it coming. We used motors that – although more suitable for a compact, lightweight, and energy efficient 3D printer like Tiko – would be compared directly against the beast-like and painfully expensive Nema-series motors used in old-school 3D printers.

The concerns were always about two factors: Speed, and motor lifespan – both of which are directly dependent on the gears inside the motor housing. So… we pounced on it!

For a little extra cost and the time it took for tooling, we worked with our motor supplier to improve these little motors just for Tiko. We came up with a customized gear ratio that significantly improves speed without affecting resolution, and we use higher quality gears with a hardened material that improves lifespan.”

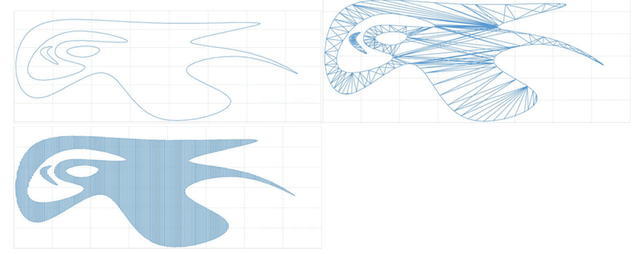

Slicing Engine

“When we think of an engine, we think of a 200lb, 19,000 RPM 2.4L V8. And it is in that image that we’ve been building Tiko’s one-of-a-kind STL file slicing engine.

It’s come a long way since its inception, with some pretty clever and efficient algorithms used to make it run like nothing we’ve seen before.

We’ve been testing a variety of edge cases, but it’s proving to be a lean, mean, slicing machine! Thus far our benchmarks indicate it could -even in it’s final production form- be an order of magnitude faster than any other slicer we’ve come across.”

Further reading: Inofficial Tiko FAQ on All3DP

And if you like to read more about the Tiko 3D printer, head over to All3DP’s inofficial frequently asked questions article on the Tiko 3D printer.

License: The text of "Tiko 3D printer: Shipping Date November Confirmed" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.