Sneaker giant Nike partners with Prodways on 3D printed shoes to reduce manufacturing time and cost, while enhancing performance for wearers.

Don’t Miss: Carbon & Adidas Unleash Revolutionary Futurecraft 4D Footwear

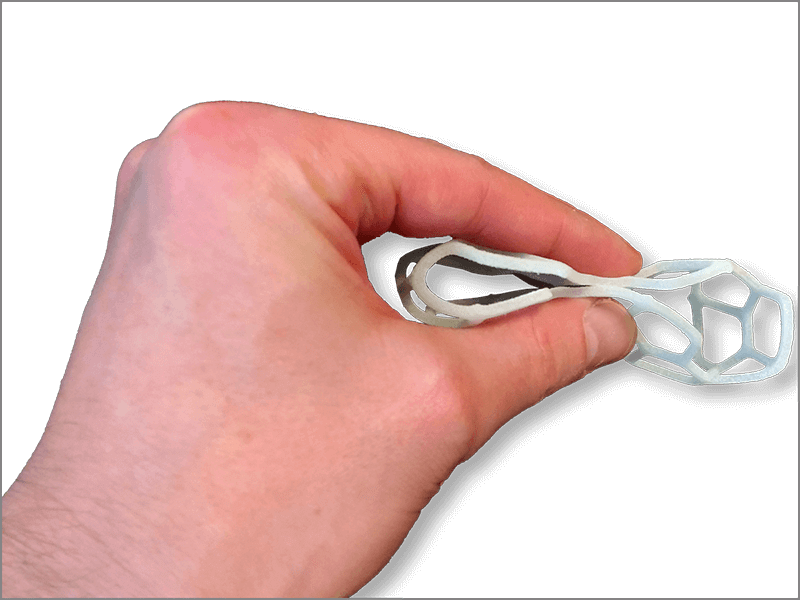

French 3D printing company Prodways has disclosed that Nike is using 3D printing to develop shoe prototypes from thermoplastic polyurethane (TPU) material.

The sneaker giant is using a selection of the 3D printed outsoles, midsoles and insoles from Prodways. The goal is to reduce manufacturing time and cost while providing a competitive advantage to wearers.

Although Nike has not officially launched 3D printed shoes in the consumer market (yet), its executives praise the quality of Prodways’ material and the speed of manufacturing the product.

According to Nike Rapid Prototyping Innovator Harleigh Doremus:

“Prodways’ TPU material has been an excellent addition to our Rapid Prototyping operations. The ease-of-processing of the TPU material has allowed us to consistently produce high quality flexible parts and is a key component in increasing the ‘speed-to-market’ of new Nike products.”

3D Printed Shoes from Nike and Prodways

Don’t Miss: Under Armour Release 3D Printed "Architect" Sneakers

While 3D printing is still a new technology in the shoe industry, Nike has some catching up to do with competitors New Balance and Adidas. Both of those brands have already released shoes with 3D printed midsoles to the public, albeit in limited quantities.

But Nike has the larger market share than its rivals. Their decision to partner with a 3D printing company indicates that a commercially available 3D printed Nike shoe is not too far off.

There are many benefits that come from the use of TPU material. As well as cutting down on manufacturing time, these products can also better aid those with orthopaedic issues. Cyrille Pailleret, the general manager of Prodways’ ScientiFeet insole division, says:

“Being able to 3D print customized soles for specific pain relief is a game-changer for orthopedic applications. 3D-printed insoles are lighter and deliver higher precision to offer a tailor-made treatment to each patient.”

The company has already printed over 5,000 pairs of ScientiFeet insoles. Nike products could soon feature its production partner’s futuristic insoles, providing increased comfort to consumers.

Source: Press Release

License: The text of "Nike Jumping into 3D Printed Shoes with Prodways" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.