This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

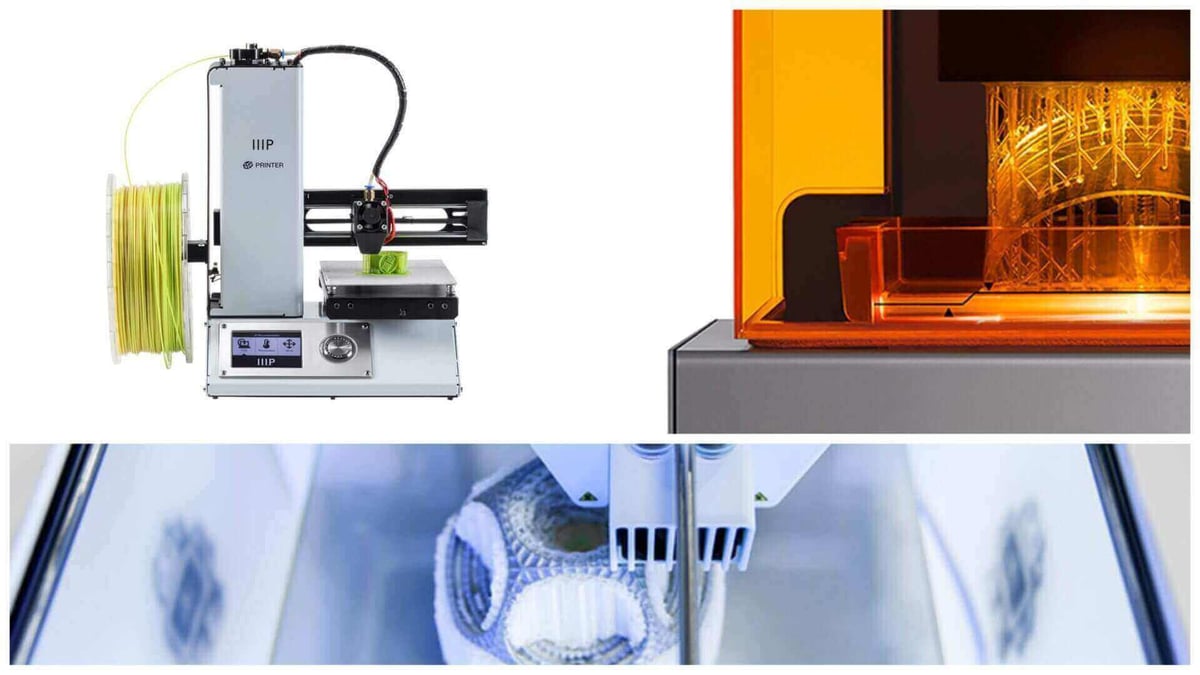

How to Buy a 3D Printer Online (Fast)

Where to Buy a 3D Printer & Which to Buy?

Where should I buy a 3D printer? Which should I buy? There is an overwhelming number of choices, so let us boil it down a bit for you.

Advertisement

Advertisement