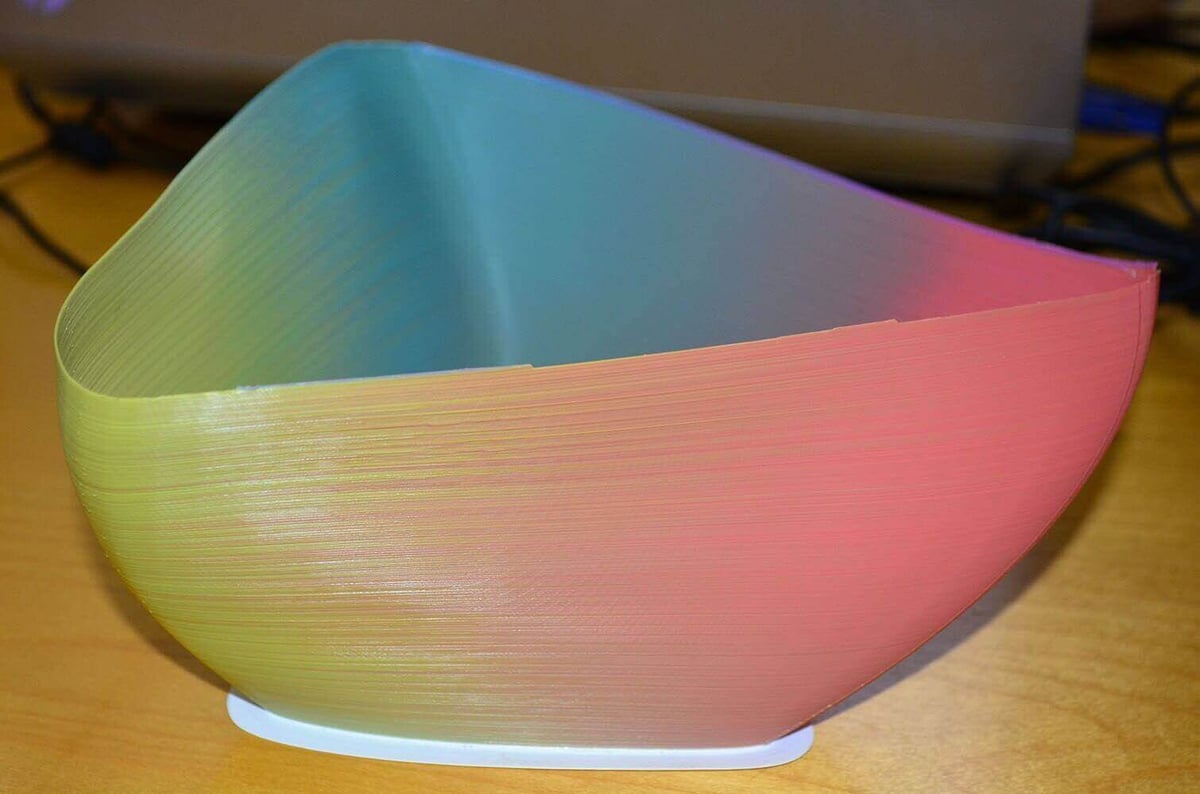

At the Midwest RepRap Festival, maker Daren Schwenke showed off his homemade Arcus 3D “true color” 3D printer.

In the makersphere, we’re seeing sophisticated hack jobs that seem capable of outdoing existing systems at their own game. One recent example is Daren Schwenke’s Arcus 3D printer.

Schwenke just demoed his creation at the Midwest RepRap Festival. His project first appeared in 2014.

Using an assemblage of spare parts and plenty of engineering know-how, he has pieced together a full-color FDM 3D printer.

The machine follows the color principles of 2d printing – that cyan, magenta, yellow and black (key) can combine to create any other color. His linear delta-style printer can print any hue. Unlike traditional 2D printing though, the absence of paper means the Arcus 3D Printer requires white filament too. Hence, CMYKW.

Over time, the machine evolved from a junkstrap build, into a “full color capable linear delta 3D printer”, described now as an “ongoing effort to perfect a reliable active mixing filament printer.”

He has posted the parts and various stages of the project in detail on Hackaday.

Building the Full Color 3D Printer

The Arcus 3D Printer is pieced together from an eclectic collection of parts. Among other things, it uses a CRAMPS board — based on BeagleBone Black, with Machinekit and custom code — plus Bowden tubes taken from an old mig welder and screen door rollers fitted with roller-blade bearings.

Perhaps most interesting of Schwenke’s build is the mixing process.

The Five filaments are drawn toward a liquid-cooled cold-end. From there, Schwenke’s project page describes the mixing:

“The all metal hot-end employs a tiny impeller located right at the melt-zone of the 5 distinct incoming plastic streams. The impeller spins at a relatively high speed and is designed such that it also generates its own extrusion pressure to feed the nozzle. This greatly reduces the feed pressure required, eliminates feeding back into idle ports, dramatically improves color change performance, and helps to mitigate ‘oozing’.”

The results certainly sound impressive. The color change occurs in 20mm of extrusion at 0.4mm. This means a full change between any ratio of mixes between the 5 loaded filaments.

Prints that use mixed color are a known entity to us at this point. Some machines print in full color from the get go. But for FDM, it has taken time to mature (though we will be seeing a lot more of mixed color FDM later in the year).

There are existing color-mixing systems, like the Kickstarted — and yet to ship —RoVa4D. But to see it from workshoppers sharing stuff on GitHub and documenting the build is pretty rad.

Source: Hackaday

License: The text of "Full Color 3D Printing: From Junkstrap to Delta CMYKW Printer" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.