The CEL CEO speaks exclusively to ALL3DP about the evolution of the Robox 3D printer, including plans for a print-it-yourself stylus cutter.

Robox has since become a major name in the 3D printing community, and a few months ago the CEL team returned to Vegas – this time to unveil a new dual-material print head for the Robox, opening the door to a new range of possibilities.

And now? Well, now things have the potential to get really interesting.

“It’s a really exciting time for the company,” says Elsworthy, speaking to ALL3DP from CEL’s headquarters in Bristol, UK.

“Over the last year or so we’ve laid down all the foundations for Robox, and we’ve had to work very hard on a lot of the back-end stuff that consumers don’t see, the more dull stuff — the service side of things, and the foundations for the software and hardware to improve. But right now we’re at a stage where we can start to release all these new features and functions without too much slog in the background.”

Robox to Feature Multiple Manufacturing Processes

So far, so standard. After all, few people would be expecting CEL to rest on its collective laurels at this point. Yet the exact nature of where Robox goes next may take some people aback.

“This year we hope to move the printer into other manufacturing processes, away from 3D printing,” says Elsworthy. “We want to use that same XYZ stage on people’s desks to perform new tasks, so it really will be a micro-manufacturing platform and not just a 3D printer.”

The first step in the evolution of the Robox will take the form of a stylus head, capable of holding a pen or cutting material with a knife, and will hopefully launch in the first or second quarter of next year. Unlike the recent dual-material head, however, CEL plans to release the stylus as “a less finished product” – specifically, by bringing the Robox community into the production process.

“The work we’ve done as engineers, we’re going to release that as data for consumers to be able to print their own components, bringing new functionality,” explains Elsworthy. “The first one is going to be the background work, which will allude to the style of cutting and the pen plotting, and then hopefully that will lead to a camera in the head for microscope inspection, 2D scanning of sheets so that you can cut or draw around objects in the bed.”

In short, CEL’s plans for Robox take the form of a domino effect, where the development of one new feature can feed into the next.

“The stylus head can hold a dragknife for cutting around stickers and vinyl, or cardboard or paper,” says Elsworthy. “But the mechanism to make that work will allow us to move to the next head, which may be a paste extruder or a laser engraver. Because of the mechanics of holding that head, as a factor, we might have optical sensors for picking up the way you’ve laid your paper down on the bed. It’s a very modular roadmap.”

Modularity is the Key to Longevity

Pessimists might argue that this jack-of-all-trades approach could be something of a gamble, but it’s hard not to be swept away by the ambition of this vision, not to mention the infectious enthusiasm of Elsworthy himself.

British readers with long memories may also recall that this is hardly the first time that CEL has employed such tactics: the company was founded on the success of the POWER8 Workshop – a modular cordless workstation that Elsworthy demoed on the entrepreneurial TV show Dragons Den, with triumphant results.

On a personal level, Elsworthy says he is dismayed by the tendency for manufacturers to render their own products obsolete as a means of shifting new stock. There is also, he admits, an element of practicality to CEL’s step-by-step strategy.

“It’s basically CEL ethos to build things in a modular way — and that’s for our own benefit as well, in the fact that we’re a smaller company. I guess if we had thousands of engineers all working on projects, they could be working on different aspects at the same time — but we have to focus on one thing, then bolt-on and build from there.

“It’s probably lead from me as a Lego and Meccano lover, in the fact that you can buy one thing and then another set and then another, and your money adds up to a much greater machine than if you were to buy one thing at a time.”

Bringing Robox into British Schools

Elsworthy’s appreciation for Lego and Meccano also echoes one of CEL’s other major goals for this year – namely, selling the Robox into UK schools.

As he explained in a guest editorial penned for ALL3DP last October, Robox has recently teamed up with Kitronik – a company that supplies electronic project kits to teachers, students and hobbyists all over the UK. Last year this partnership brought Robox printers to 3500 British schools.

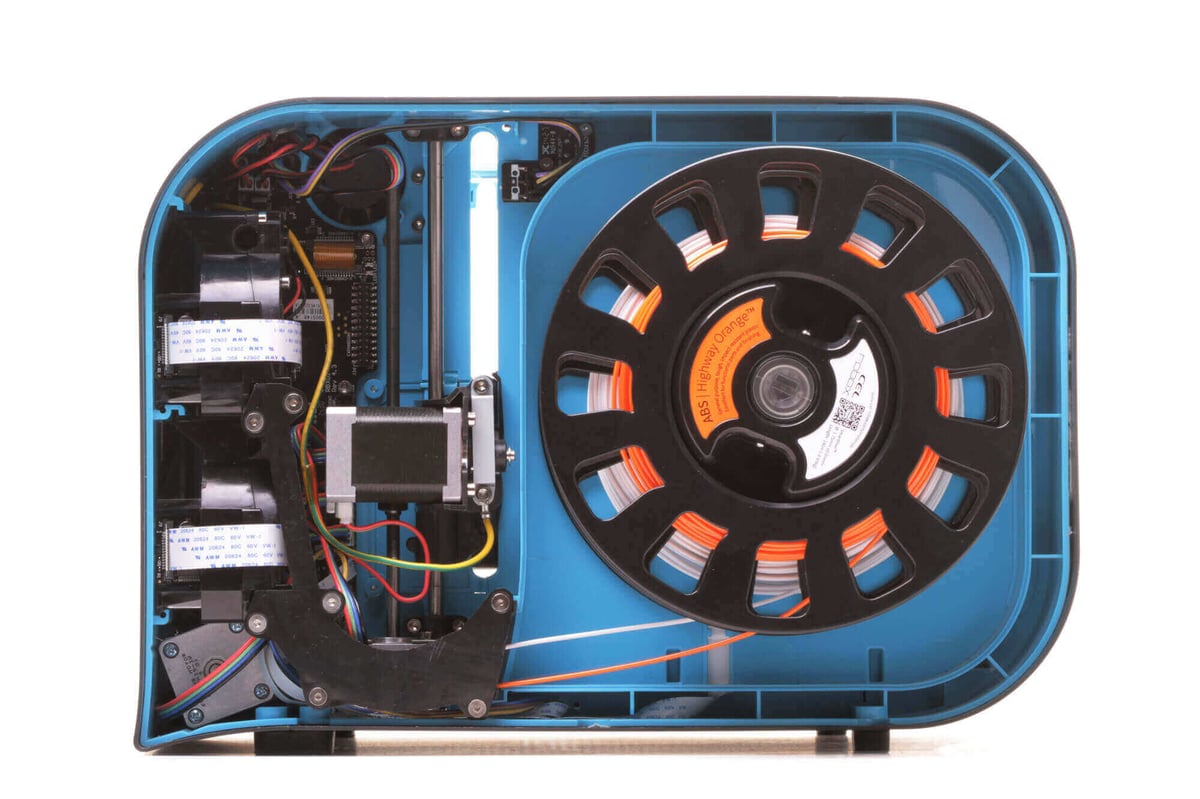

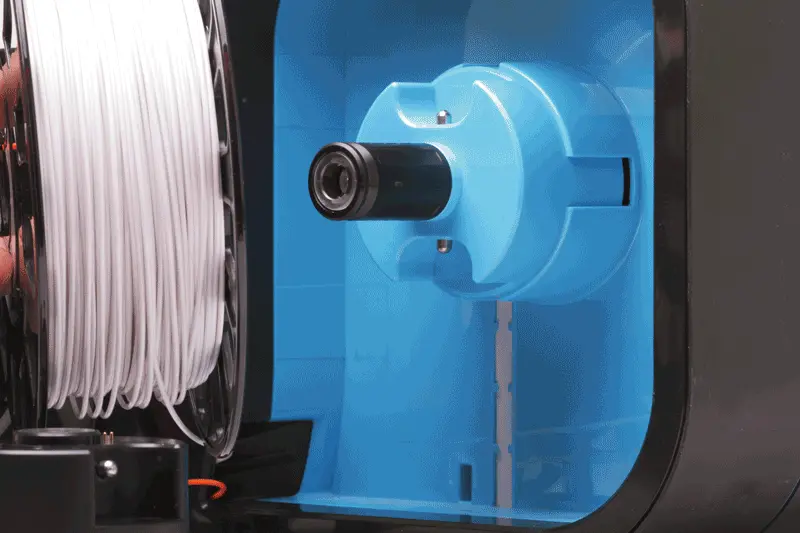

“We think the Robox is an ideal printer for school usage, for several reasons — not only can the case lock, but its still has this 360 degree view of the process of 3D printing, while hiding away the mechanics. Also, the build volume that we’ve chosen is a practical size.

“We’ve discovered that schools don’t like to leave machines running overnight. Big machines are a great idea if you want to build things in one piece, but the fact remains that it takes a long time to build a big part. For the same investment you could have four Roboxes running, printing four separate parts and completing the job in a quarter of the time. That alone is a very attractive and appealing thing for school — you can get a lot more done for every student in the class.”

It’s obvious that Elsworthy’s interest in bringing Robox to UK schools moves far beyond some cynical attempt to sell more printers. He is, quite simply, an engineer at heart, the kind of guy who takes his kids to see The Bloodhound Project — a Bristol-based collective of engineers who are attempting to smash the land speed record with a new vehicle of their own design. He admits to being frustrated by what he sees as a lack of support from the British government when it comes to engineering – both in terms of celebrating the UK’s inventor heritage, and in fostering a maker spirit among students.

“If you imagine a craft classroom, you’re thinking about blocks of wood, sanding machines, guillotines. Recently I’ve been looking at schools to send my oldest child to, and it really hasn’t moved on that far. Yes, schools are starting to buy laser cutters, but all the creative subjects are just pushed into one corner of academia. Maths, English and History have always been classed as the upper crust of education, whereas I still feel that engineering and software development, IT and making things, it’s what’s made Britain great. I would love education to go back that way.”

While CEL lacks the heft to bring about political change on its own (“we’re too small to reinvent legislation”), partnerships with the like of Kitronik and the Dyson Foundation provide an opportunity to introduce the Robox to a new generation. And while some adults may struggle to embrace the concept of making things for themselves, today’s kids will grow up more comfortable with 3D printers and other maker technologies.

“When I introduce 3D printing to young people, their imagination goes wild,” says Elsworthy. “They just get the technology, and their imagination goes wild — they’re not restrained by current manufacturing processes.

“I think it’s just a matter of time as the younger people come through and say, ‘We do this all the time, this is fine. We can make our own things, we don’t have to buy it — we can write a bit of code, or we can build and 3D print that component, because we can’t buy anything that meets that exact specification.’ Society is changing, it’s just a matter of time.”

License: The text of "The Future is Modular: Chris Elsworthy Shares Robox Roadmap" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.