Popular 3D printer maker Zortrax just launched a new larger, more powerful, and more expensive version of its resin-based Inkspire machine to target small manufacturers and attract those who may have thought tough, shop-floor parts only come from filament 3D printers.

Zortrax says its durable engineering resins from BASF Forward AM and Henkel/Loctite are functional equivalents of high-performance filaments. The result is the ability to print both prototypes and final parts using resin 3D printing only.

The Inkspire 2 features liquid-crystal display (LCD) technology that flashes complete layers of the part at the resin tank with UV light from an array of LEDs shining through the LCD screen, not a projector. The screen is a mask, revealing only the pixels necessary for the current layer and blacking out the rest. This technique is often referred to as “masked SLA” or MSLA.

Although LCD resin printing is a technology commonly found in consumer 3D printers (with some notable exceptions, such as Nexa3D), Zortrax says its light engine is powerful enough to work with high-grade engineering resins (those cured by light with 405 nm wavelength) that used to be supported only on industrial digital light processing (DLP) machines. Inkspire 2’s UV light engine is seven times more powerful than the previous Inkspire and is compatible with some DLP resins. (DLP technology uses a digital light projector and a digital micromirror device to selectively direct light.)

Developed entirely in-house by Zortrax, the proprietary light engine provides a consistent UV exposure across the entire build platform to achieve consistent print quality regardless of the position of the models, the company says. Compared to the original Inkspire, introduced in 2018, the new version boasts 40% more uniform light distribution.

The Inkspire 2 is also noticeably larger than its predecessor with four times the build volume (192 x 120 x 280 mm), while the layer height and resolution remain the same.

Professional Materials

Overall, four resin lines are dedicated to the Inkspire 2: elastomeric resins, rigid or tough resins, castable resins, and basic resins, with room for expansion in the future. Zortrax says the new materials open up the Inkspire 2 to professionals and industrial applications including 3D printing seals and gaskets with flexible material, jigs and fixtures with the rigid resin, high-load mechanical components with the tough resin, and heat-resistant final parts with the high-temperature resins.

- Zortrax Henkel Loctite Resin Pro 410

- Henkel Loctite 3D 3843 HDT60 High Toughness Matte Black

- Henkel Loctite 3172 HDT50 High Impact Grey

- Ultracur3D EL 150, 60, 4000

- Ultracur3D ST 45 B, 80, 80 B, 80 G

- Ultracur3D RG 35, 50, 1100

- Ultracur3D FL 60

- BlueCast X5, X10, and original LCD/DLP Resin,

- BlueCast X-One Resin,

- Zortrax Resin Basic, Tough

More Automation

Although Inkspire 2 is more advanced than its predecessor, it has more automated features. A resin level sensor measures the amount of resin required to 3D print each model and signals if there’s not enough liquid in the vat.

Other upgrades you’d expect on a $4,200 printer include closed air circulation, HEPA filters, blackout response system that shuts down in the event of a power outage and finishes the printing process once the power is back on. There’s an automatic wiper that prevents resin sedimentation during longer prints, and, when the printing is done, the Inkspire 2 can transfer the remaining resin back to the bottle. A sensor shuts down the UV lamps when the door is open.

Zortrax inCloud enables real-time, remote management capability over all Zortrax 3D printers. Prints can be uploaded, started, and paused on each machine connected to the inCloud account. The inCloud software has built-in staff management functionalities enabeling users to be organized into teams with assigned 3D printers.

Full Print-Wash-Cure Ecosystem

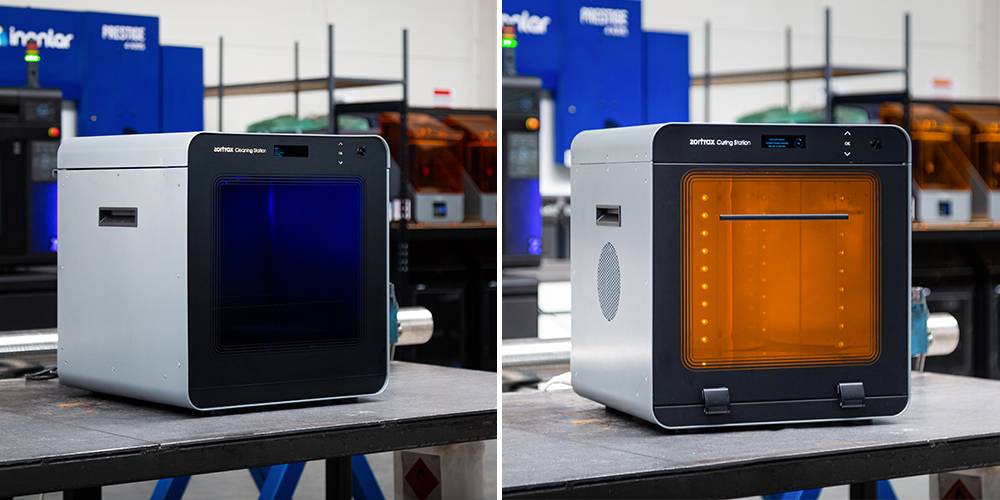

The Inkspire 2 is making its debut with new washing ($3,800) and curing ($4,400) devices to accommodate the printer’s large volume.

The Zortrax Cleaning Station has a high-volume IPA tank with a filtering system that enables the cleaning solution to be reused for multiple cleaning sessions. Its 300 x 210 x 270 mm volume can accommodate large models 3D printed on nearly any resin 3D printer on the market.

The new Zortrax Curing Station (300 x 200 x 300 mm) provides a consistent UV exposure enhanced by a rotating table and ensures that the models are free of any weak spots caused by insufficient UV exposure. The curing process is fully automated.

These devices can operate independently of the 3D printer with different technologies, such as UV LCD, DLP, and SLA.

Zortrax Move to Pro is Complete

Poland-based Zortrax is no stranger to the professional 3D printing space having launched several FDM printers focusing on engineering-grade materials. Its original Inkspire resin printer may have been the company’s last stand in the consumer/prosumer market, but the new version lands the company squarely in professional territory.

Tech Specs

- Technology: UV LCD resin

- Build volume: 192 x 120 x 280 mm

- Light source: LED panel at 405 nm wavelength

- Precision 50μm

- Min. layer height: 25μm

- Software: Z-Suite

- Price: $4,400

- Zortrax Cleaning Station: $3,800

- Zortrax Curing Station: $4,400

License: The text of "Zortrax Targets the Shop Floor With New Desktop Resin 3D Printer" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.