Survivors of landmine blasts may soon benefit from 3D printed synthetic bone thanks to a £2.8m research grant at the University of Glasgow.

Don’t Miss: 3D Printed Mine Kafon Drone Can Remove Mines Safely

A new £2.8 million regenerative medicine project at the University of Glasgow, funded by the charity Find A Better Way, could lead to synthetically grown bone for landmine blast survivors.

An estimated 4,300 people are injured or killed by landmine blasts every year. In those countries where conflict is long over, victims of landmines are often innocent children and civilians. This sobering statistic inspired football legend Sir Bobby Charlton to set up Find A Better Way in 2011.

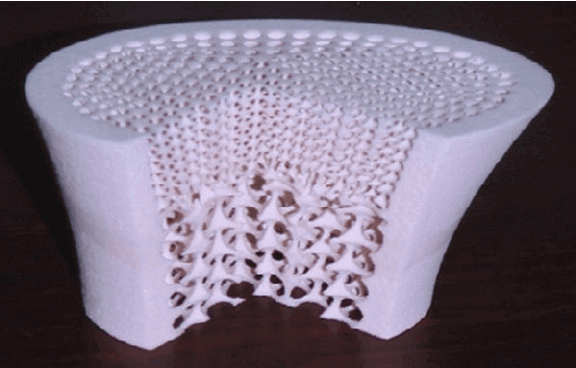

Because modern landmines are designed to maim rather than kill, there is a great need for reconstructive blast injury surgery. But the difficulty is that reconstruction is limited to how much bone can be saved from the injury. The project at the University of Glasgow hopes to improve bone regrowth chances using 3D printed scaffolds.

At the signing ceremony on 16 December, Find A Better Way CEO Lou McGrath said:

“It is hard to overestimate what an important breakthrough this could be for landmine blast survivors. Advances in reconstructive surgical techniques now encourage trauma surgeons to retain as much of a limb as possible instead of quickly amputating above the knee. In many cases, the amount of bone that can be recovered is a limiting factor in how much of a leg or arm can be salvaged. With the developments from this project, we could reach a situation where it is only the limitations of surgical techniques, not the amount of viable tissue remaining, that determines the outcome.”

3D Printed Synthetic Bone Project at University of Glasgow

How does 3D printed synthetic bone work? Scaffolds are 3D printed and then coated with nanolayers of growth factor BMP-2 and stem cells. A machine called the Nanokick shakes the bone scaffold 15 nanometers, 1,000 times per second. This stimulates stem cells and growth, allowing bone tissue to be grown on the scaffold faster.

After this, bespoke bone pieces take just 3-4 days to create. This bone tissue can be implanted in the body and will continue to grow. As a result, the scaffold is then replaced and, as it dissolves, only new bone is left behind.

In addition, small blocks of “off the shelf” synthetic bone will also be developed by the team at the University of Glasgow. Packaging is being designed to keep the bone tissue usable for up to three weeks. The blocks can then be shipped to anywhere in the world for local surgeons to use.

Theoretically, there is no limit to how much synthetic bone can used in a blast injury survivor’s surgery. This new 3D printing technology has the potential to hugely improve recovery for blast injury victims.

Project lead Professor Manuel Salmeron-Sanchez from the University of Glasgow said:

“We have been developing various types of bone-related technology at the University of Glasgow for the previous five years. Thanks to the support of Find a Better Way we can improve and combine these technologies for use in extreme situations where a significant amount of bone is needed urgently.”

The project is scheduled to begin on the first day of the New Year. A ‘first man’ study is projected to be conducted within five years.

Source: Find a Better Way

License: The text of "£2.8 Million Fund to Research 3D Printed Synthetic Bone for Landmine Survivors" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.