Researchers have created a 3D printed ceramic resin that can withstand high temperatures, paving the way for next-generation aircraft traveling at incredible speed.

Picture a 3D printed object, and chances are you imagine something made with PLA or ABS thermoplastic filaments: they are pretty much the default. But many entrepreneurs are looking to change that, developing filaments that reuse coffee and beer grinds, even recycled, powdered wood. And pushing 3D printing to industrial applications requires a much wider range of materials than plastics.

Enter 3D printed ceramic, which is making a splash since a big reveal in Science journal last week.

In case you’re new to these parts, 3D printing is an additive process, which means that pliable material is extruded from a nozzle and forms objects by adding thin layer after thin layer. But ceramics have a very high melting point — too hot for a standard nozzle to handle. This high melting point is what is so important about ceramic as an material — but it means that ceramic objects are porous and brittle.

Ceramics can be time-consuming, expensive, and difficult to manufacture. You can easily cast or machine metal and plastic, but these techniques only work on low-melting point oxide ceramics — which aren’t durable enough for industrial applications (just think about that smashed ceramic plate and there you go). There have been some efforts to 3D print ceramic materials, but the resulting prints need to be very simple — fine details end up, well, a little blobby.

Enter HRL Laboratories in Malibu, California. They’ve invented a “pre-ceramic monomer” made from silicon carbide powder, which prints just like any other polymer filament (in a $3,000 incredibly detailed stereolithic system, but still). But when exposed to UV light, the resin cures into a silicon carbide ceramic — which is to say an extremely durable, lightweight, non-conductive material.

Other materials used for 3D printing could be re-melted at the same temperature at which they were printed, obviously. But once hit with the UV light and baked at 1,000 C, 3D printed ceramic is heat-stable even at 1,400+ degrees — a higher melting point than most metals. And, more astonishingly, these materials are non-conductive. Which means, basically, that one end of the printed ceramic part can be heated by a blowtorch to 1,000 degrees Celsius, and the other end is cool enough to hold with a bare hand.

3D Printed Ceramic could be used in Spaceships

All of which makes 3D printed ceramic perfect for high heat, high pressure applications.

The scientists at HRL foresee the use of this material where ceramics are currently used: in aerospace engineering, most famously, where ceramics’ light weight, heat-resistance, and chemical inertness makes it the perfect material for gas burner novels, probes to test fuel levels in commercial and military aircraft, turbine engine blades, race-car disk brakes, and missile nose cones.

And how do space shuttles withstand the incredible heat of re-entry into the earth’s atmosphere? Ceramic tiles.

With the ability to craft these shapes more finely through 3D printing, even more applications could be developed: for example, hypersonic cars or more efficient jet engines. As HRL senior scientist Tobias Schaedler told Discovery:

“If you go very fast, about 10 times speed of sound within the atmosphere, then any vehicle will heat up tremendously because of air friction… People want to build hypersonic vehicles and you need ceramics for the whole shell of the vehicle.”

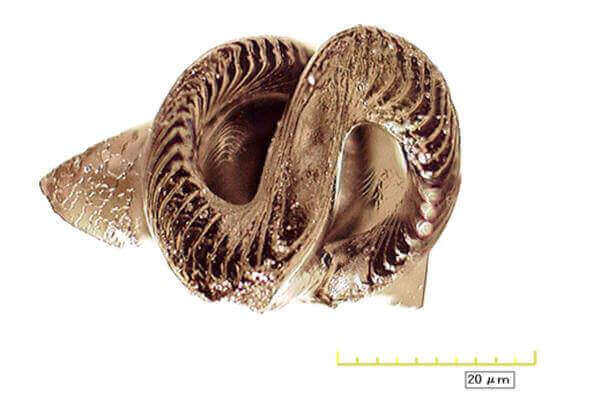

While ceramics are notoriously brittle, this silicon carbide ceramic showed to be stronger under an electron microscope than similar materials — up to ten times stronger, in fact. So these new materials are thus much less likely to crack along faults introduced in the 3D printing process. The team in California is already working to introduce fibers into the composite to strengthen the material further.

Extraordinary stuff, but it may be a while before we see the benefits for ourselves. The paper in Science, while super exciting, is also an indication that this is still very much a research material — it will be at least 5 to 10 years before commercial applications of 3D printed ceramic become available.

License: The text of "3D Printed Ceramic is Incredibly Hot Right Now" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.