Why 3D Print With Wax & Castable Materials

Metalworkers have used beeswax for thousands of years, carving out models of tools or other objects by hand. The wax model is encased in a material that hardens around it, then the wax is melted away and the hardened shell becomes a mold into which liquid metal is poured.

Today, the process is called investment casting while jewelers refer to it as lost-wax casting. It hasn’t changed that much except that now it’s dramatically faster and more customizable with 3D printed wax and wax-like castable materials.

Instead of making a model or pattern via injection molding or carving, you design parts using computer-aided design (CAD) software and 3D print them directly in wax. There are software programs specifically for casting in industry, dentistry, and jewelry, so you don’t need deep design skills. You can also reverse engineer an existing part by 3D scanning it and uploading it to your CAD software.

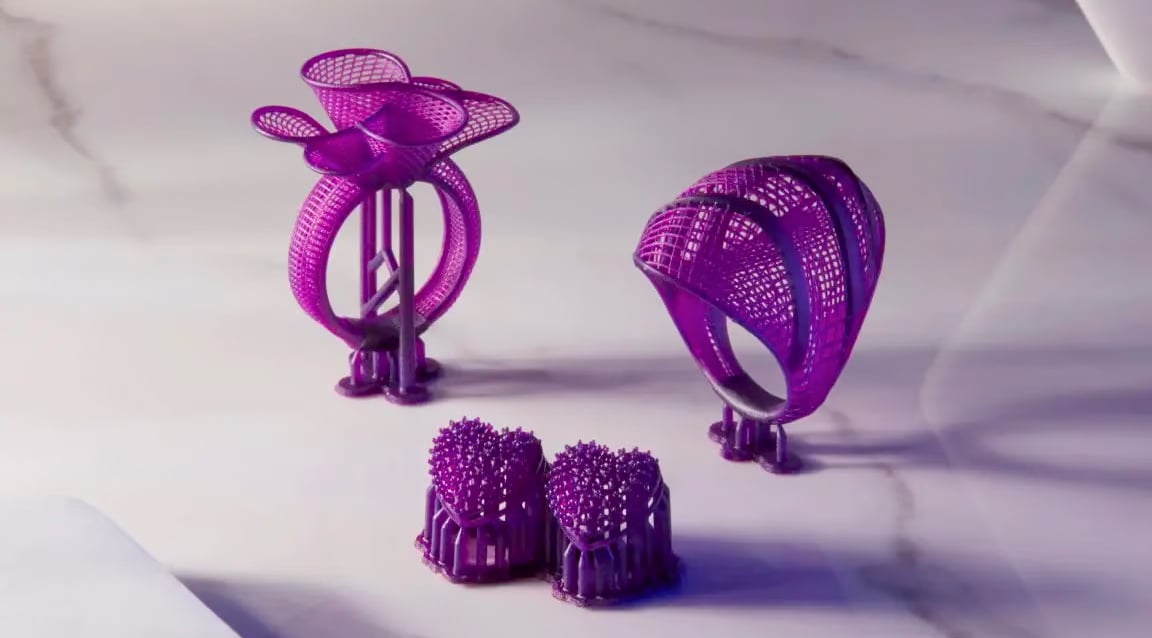

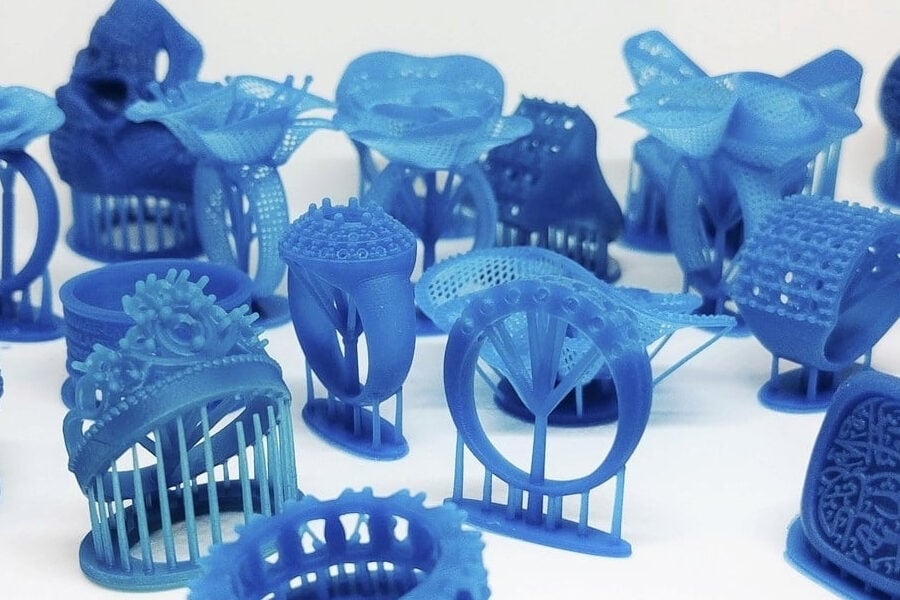

3D printing enables you to make each pattern different (without the need for new dies for the injection molding machine) and you can consolidate parts in your 3D printed pattern instead of having to assemble multiple injection-molded parts. For example, with smaller parts for jewelry, you can print an entire pattern tree at once with no assembly.

The 3D printing of wax models is becoming the preferred method in a number of industries and, the “3D Printing Jewelry Markets 2023: Market Study and Forecast” study indicates that the 3D printed jewelry market will reach $989 million by the year 2031 compared to $489 million in 2021.

Tool-Less Pattern Making

Eliminating the injection molding (or carving) step not only means you can go from digital design to the final metal part in days instead of weeks or months, but it eliminates a huge chunk of the cost. 3D printer maker 3D Systems says it reduces casting pattern costs by as much as 95%.

In addition, with the same digital file, you can produce a 3D print to also serve as a prototype for form and fit evaluation in a single day. Your 3D printer isn’t limited to making wax patterns. Depending on the model you can also manufacture tools, jigs, and aids for your shop or foundry in tough industrial-grade polymers.

3D Printing Technology for Patterns

There are three distinct types of 3D printing used to make wax patterns. For jewelry and small-size, low-volume 3D printing a desktop vat polymerization printer is most typical because it creates finely detailed models. By vat polymerization, we’re referring to either stereolithography (SLA), masked stereolithography (MSLA), or direct light processing (DLP). For more on this technology, its sub-categories, and the top 3D printers, check out our Guide to Jewelry 3D Printers. Vat polymerization can also be used for larger wax models for industry or sculpture with industrial-size printers. This process requires some post-processing steps and it’s critical to follow the material manufacturer’s guidelines for preparing your model for investment casting.

Material jetting is another 3D printing technology that deposits a wax-like material that’s instantly cured with UV light. It’s generally much faster than vat polymerization. One type of material jetting is called drop-on-demand (DOD). This technology uses two print heads to drop two different materials; one is the main material for the part and the other is a soluble support material that dissolves in a liquid solution leaving behind just the smooth model. This further streamlines the process as the need for manual support removal is eliminated.

Under this technology, there are industrial machines that can print dozens of models at once or very large models, such as the new ProJet MJP 2500W Plus from 3D Systems. With a maximum build envelope capacity of 294 x 211 x 144 mm, this machine is one of the fastest and most productive 3D printers specifically designed for jewelry manufacturing. And with the newly introduced ZHD printing mode, the machine is capable of printing at a layer thickness of 8 µm, achieving best-in-class surface quality.

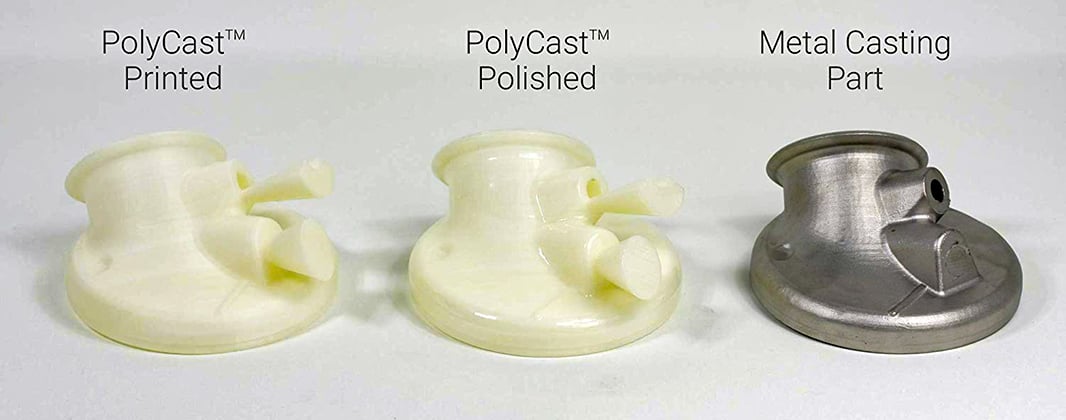

Wax-like models can also be made on a classic FDM 3D printer using a wax-like filament that enables FDM printers to produce mold castings. This is the most economical option but your models will need some post-processing, such as sanding to remove the filament layer lines.

All About 3D Printable Wax

As we mention above, All3DP covers the technology, processes, and printers for mold making (for both jewelry and industry) in other guides. Here we’re talking wax, casting resin, and other materials used for casting. It’s not all the same.

You can print in pure wax, but newer materials, such as castable resins are formulated to be stronger during the casting process and burn out cleaner, among other features.

Polymethyl methacrylate (PMMA), for example, is an acrylic plastic with excellent burnout behavior that’s often used in industrial casting. These materials are not always suitable as a direct replacement for wax since some may interact negatively with phosphate-bonded and plaster-bonded investment materials. Be sure to match your casting material with your investment material.

What to Look for in Wax & Casting Materials

Your 3D printer may only be compatible with wax made by your 3D printer manufacturer as is the case with printers from Solidscape or Formlabs. If your printer is compatible with third-party materials, here’s what to look for when making a castable material purchase.

- Melt Time. How long does it take your wax or castable resin material to melt or burn out completely from your mold? Two hours, 5 hours?

- Ash Level. Low-ash or no-ash wax materials will leave little to no remaining ash or soot inside your mold after burnout, while others may require that you thoroughly clean your mold.

- Low shrinkage. All waxes and castable materials shrink a bit and you need to account for this so it’s important to know the shrinkage factor, which should be listed on the materials technical data sheet.

- Low water absorption. Most castable resins absorb moisture if left uncovered so you’ll want to start off with one with a bit of moisture resistance, then keep it in a cool, dry place.

Wax Materials for SLA, LCD & DLP 3D Printers

When shopping for a wax or castable resin look for one that your printer manufacturer recommends or one that has a print profile for your brand of printer. This will save on the amount of trial and error required to print your models with high detail and tight tolerances.

Wax Filament for FDM Printers

Wax-based and castable filaments are also available for your FDM 3D printer. These are formulated to perform better than regular PLA when used for casting molds. Although you can use low-cost PLA as we describe in our article “Lost-PLA Casting: All You Need to Know”, PLA is known to leave ash and residue behind in your mold and not melt consistently.

Top Wax Printers for Every Industry

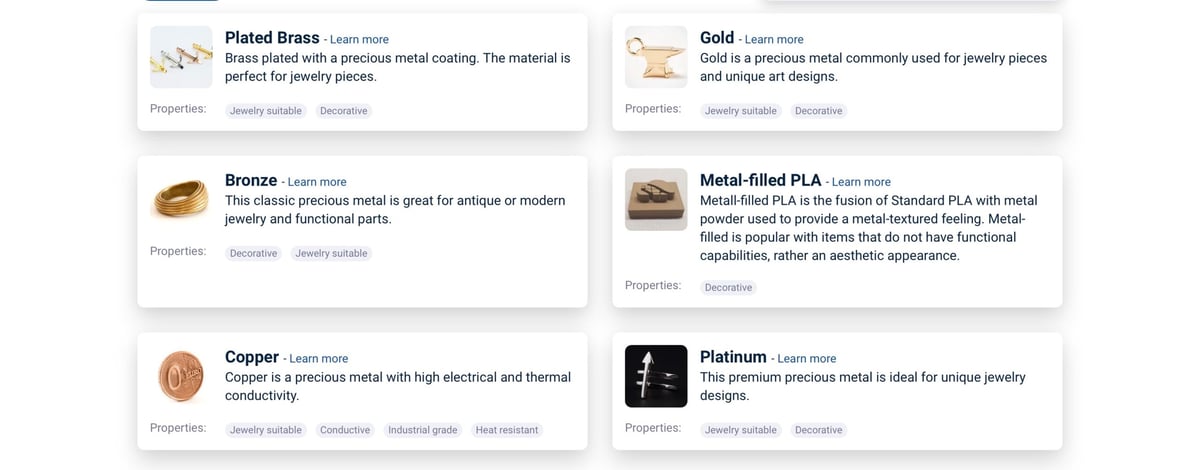

Although we have other in-depth guides to 3D printers for jewelry casting and for metal casting, this overview below will ground you in your options.

3D wax printing can used by any industry that involves casting metal or plastic. Each has their own specifications and therefore different requirements for the machines they prefer to use. The requirements for casting metal jewelry are far different from producing medical devices or say, molds for airplane propellers. Here are some tips for selecting the best printer broken down by industry.

Jewelry

Printing jewelry requires the machine to be able to create a finely detailed master wax model or several detailed models at once. For producing different iterations quickly, speed will be essential for the machine to have, especially when it comes to mass production of your hottest selling design.

Most jewelers opt for resin-based technologies, including SLA, LCD, or DLP due to their high printing resolution and the availability of wax and castable resins that will burn out cleaning.

Material jetting is another resin technology that’s generally faster than SLA and LCD especially for large-volume production. With material jetting, like 3D System’s ProJet 2500W series 3D printers, layer thicknesses as thin as 8 microns make an extremely fine detail resolution possible. If you’re trying to decide on the best printer for your jewelry making needs, our article The Best 3D Printers for Jewelers can help you decide.

Dental

Working in the Dental Industry is a bit more complicated than other trades. Any dental practitioner or a specialist in a dental laboratory will know that there’s a world of difference between dental models for patient education and dental parts for patient use.

If your goal is to print reasonably accurate models of a patient’s mouth taken from an oral 3D scan or impression in order to, for example, explain a procedure to a patient, then there’s no need for a specialized dental printer. However, if you’re looking to print biocompatible dental parts – anything that will come in contact with a patient’s mouth or skin – you’ll need to use biocompatible materials certified by the regulatory authorities in your area, plus approved software and 3D printers.

Printers such as the Shining 3D’s AccuFab-L4D, AccuFab-D1s, Desktop Health’s Einstein Series, Carima’s IMD, and several of Rapid Shape’s DLP printers are capable of wax-ups and other dental products. The J5 DentaJet from Stratasys comes with a full range of biocompatible dental resins. Additionally, the Separator DM coats dental models automatically in order to simplify the process of separating the acrylic device from the model, and then removing the wax and residue. For more indepth information on Dental Printers, check out our article The Best Dental Printers of 2023.

3D Printing Casting Patterns for Industries

Several industries require parts to be generated through casting. From aerospace to automotive, military to medical, many industries have turned to using 3D printing to produce molds, cores, and patterns to optimize and modernize their workflow and cut costs. When it comes to wax and casting materials printers, a few 3D printer manufacturers stand out, namely 3D Systems, Voxeljet, and Eplus3D.

3D Systems makes a wax 3D printer and has bundled all of its investment casting methods and resources into what they call the Digital Foundry. Perfect for industrial pattern-making. 3D Systems also offers a process called QuickCast with a special material, Accura Fidelity, on its stereolithography (SLA) 3D printers featuring a build style available with the company’s 3D Sprint Pro additive manufacturing software. The company says this process creates complex master patterns in hours that are large yet lightweight and strong enough to perform in the investment casting process.

Foundries, such as the Walla Walla Foundry in Washington State, have turned to the casting pattern capabilities of the Voxeljet VX1000 for statues. In fact, hundreds of models out of castable material were printed to create The Embrace, a bronze statue in Boston. The artwork was a digital design printed out in parts and then cast.

Eplus3D’s EP-C7250 uses what the company calls “resin sand” to print sand molds for metal casting of parts such as engine blocks, cylinder heads, turbines, and impellers with complex structures. The printer uses selective laser sintering (SLS) and offers a huge build size and can rapidly print sand casts and molds from powdered wax, polystyrene, or resin sand to create molds for the traditional casting process.

These aren’t the only two manufacturers out there. For more in-depth information on casting, check out our article: 3D Printing Patterns, Cores & Molds for Casting Metal.

Wax Models from a 3D Printing Services

You don’t need to have a 3D printer to take advantage of all that wax and castable materials have to offer your business. A wide range of 3D printing services can print your digital model in wax and castable materials.

Here’s how these services work: Upload your digital model, choose your material, choose a surface finish like polishing, and often you can even select the 3D printing technology. You can receive your models often the next day.

3D printing service marketplaces, like Craftcloud, present quotes on your 3D printing project from several vetted services and you pick the one that best meets your needs.

Some services can connect you with companies to even cast your model or create your final metal parts.

Lead image source: All3DP

License: The text of "Wax 3D Printing – The Ultimate Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.