No End to Innovation

When you think of a 3D printer, you probably imagine a standard Cartesian FDM printer, like the Creality Ender 3 or the Prusa i3 MK3S+. These types of printers move on a basic, three-dimensional coordinate grid (X, Y, Z), with components like the printhead or print bed moving along their corresponding axes.

A Bit of Background

All FDM printers can be classified by coordinate and motion systems. For coordinates, it’s those that follow the Cartesian coordinate system and those that don’t. The latter refers to some alternative coordinate systems, such as polar.

With respect to movement, the typical standard Cartesian printers fall under rectilinear motion. Within this, there are sub-categories, such as belt, CoreXY, and H-bot machines. Then there are the non-rectilinear motion styles, including delta as well as SCARA (robotic arm).

The Power of Three

Types of printers continue to grow as the 3D printing community creates unique ways to 3D print things. One such alternative is a Tripteron FDM 3D printer, originally developed in 2015 by the robotics lab at Laval University in Canada. It has since been expanded by RepRap enthusiasts worldwide but remains a novel development concept rather than a commercially available product.

The Tripteron printer falls under the Cartesian style when looking at its operating coordinate system. However, Tripteron printers are an entirely new breed with respect to their motion system, which is most similar to SCARA but still quite different.

In this article, we’ll go over how Tripteron 3D printers work, especially with respect to their motions, printing, software, and firmware. Following that, we’ll cover the pros and cons of this type of printer and then go over a few example builds. Enjoy!

How They Work

Tripteron printers are quite complex compared to standard Cartesian printers, so in this section, we’ll unpack how they move, print, and more.

Motion

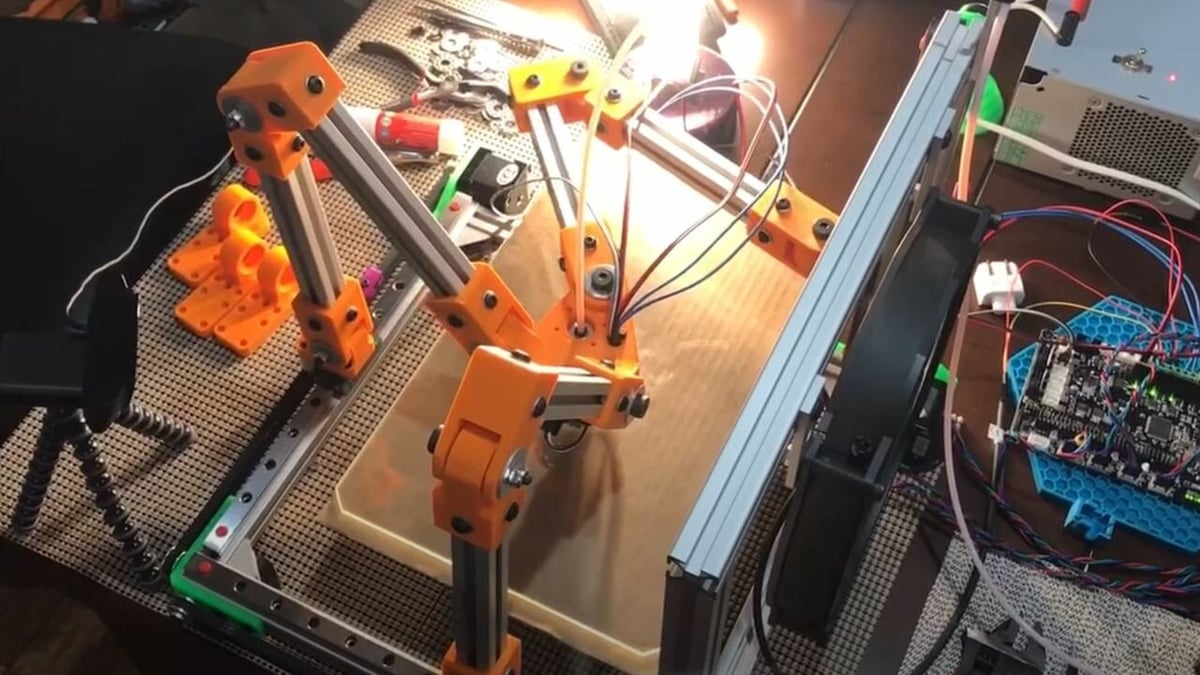

Just by looking at a Tripteron printer, you can tell it isn’t your typical machine, with its sprawling arms and linkage motion. While Tripteron machines classify as their own type of motion system, they’re most similar to SCARA and delta printers in that they use robot-like arms to control the printhead. Yet, unlike SCARA printers, Tripteron machines move each entire linkage structure (three of them) rather than using a motor on the joint (what SCARA printers have). And, well, delta printers don’t have “elbow-like” joints!

Tripteron printers use three arms, each oriented on a different axis, containing two linkage structures and a joint in the middle of it. The base (bottom) linkage in each arm is connected to a carriage that runs along either the X-, Y-, or Z-axis on the machine’s frame. However, there are other types of Tripteron motion, such as a single-rail system, as seen in one maker’s demonstration video.

The three arms meet together to hold the printhead, similar to a delta printer, and when the carriages move the linkage structures, the printhead moves around the build area. When constructed properly, this motion system can cover a large portion of the space this printer takes up.

The printhead, where the three linkage arms connect to, needs to be lightweight so that problems like ringing don’t show up in prints. Furthermore, the frame and its joints need to be tight so that motion is clean. If everything is in order, there shouldn’t be any significant dimensional accuracy problems or layer shifting.

Printing

As it’s an FDM machine, printing on a Tripteron looks familiar: An extruder pushes filament through a hot end that melts the plastic. Then the printer moves the printhead around using the motion system previously discussed to print a part layer-by-layer, rising along the Z-axis.

Like a delta printer, due to the awkward configuration of the printhead on the three-arm joint, it may be hard to utilize a direct drive configuration where the extruder is directly above the hot end. Therefore, most Tripteron printers use a Bowden system, where the extruder is separated from the hot end, and filament flows between the two entities through a Bowden tube.

Unlike some printing styles, there aren’t any specific types of models that Tripteron printers are meant for (e.g. like curved parts for non-planar printers or long prints for belt machines). However, Tripteron printers tend to be able to print larger objects than machines with the same dimensions.

Software & Firmware

The hardware isn’t the only complicated aspect of a Tripteron printer, as the digital side is also fairly complex, including the software and firmware.

For 3D printing, you need 3D slicer software, which turns 3D model files (STL, OBJ, etc.) into G-code, interpretable by your printer. Firmware is the digital program in your machine’s mainboard that translates each G-code command into activity. In other words, it controls how motors, sensors, or other features connected to the controller board react when instructed to do something.

Software applications and firmware programs have come a long way from the beginning of the RepRap project, the initiative to develop open-source 3D printing. But, for Tripteron printers, the journey has only just begun, as there are minimal firmware options meant for Tripteron printers.

For a slicer, it’s a little easier. Still, you’ll have to make a custom slicer profile with manual machine settings (build space, max temperatures, etc.).

Now that we know more about Tripteron machines, let’s see how they stand next to their cousins.

Pros & Cons

Let’s put the Tripteron under the microscope.

Pros

- Fast movement speed: Tripteron printers, much like SCARA and delta machines, are very fast, more so than standard Cartesian FDM printers. You can see a demo of how fast they are from the University of Laval’s website.

- High print-volume- to-frame space proportion: Tripteron machines are very space efficient, meaning you can print in a large volume of the frame.

- Minimal build materials: You don’t need many materials to build a Tripteron printer as they don’t require a movable print bed or a large frame.

- Can print on any surface: Tripteron printers don’t use an attached build platform as most Cartesian printers have. Instead, Tripteron machines can print on any surface put below it.

Cons

- Joints and frame need to be sturdy: As the linkage motion will exacerbate any discrepancies in the sturdiness of the frame, the structure of the frame needs to be very durable and tight. Also, the joints need to be tense enough to provide stability but loose enough to not disrupt the motion.

- Difficult to use a direct drive extruder: The three arms meet together to hold the printhead, but, similar to a delta printer, it’s difficult to attach a direct drive extruder, especially since you’re trying to minimize the weight on the printhead.

- Technology is not very popular: Tripteron printers aren’t very popular, so, naturally, there aren’t many guides or tutorials for building these printers. You’ll also have to use older firmware that could contain bugs as it’s not as current as more popular FDM printer firmware programs like Marlin.

Examples

Although Tripteron printers have their fair share of advantages, there currently aren’t any Tripteron machines available for purchase. Moreover, there hasn’t even been that much activity around Tripteron machines in the past five years. This is most likely due to the development of cheaper, more community-backed 3D printers made of more readily available components.

While there aren’t many, a few custom Tripteron printers have been developed by members of the 3D printing community. However, some of them lack evidence to show that they’re reproducible (by someone other than the designer), so be cautious if you want to build one!

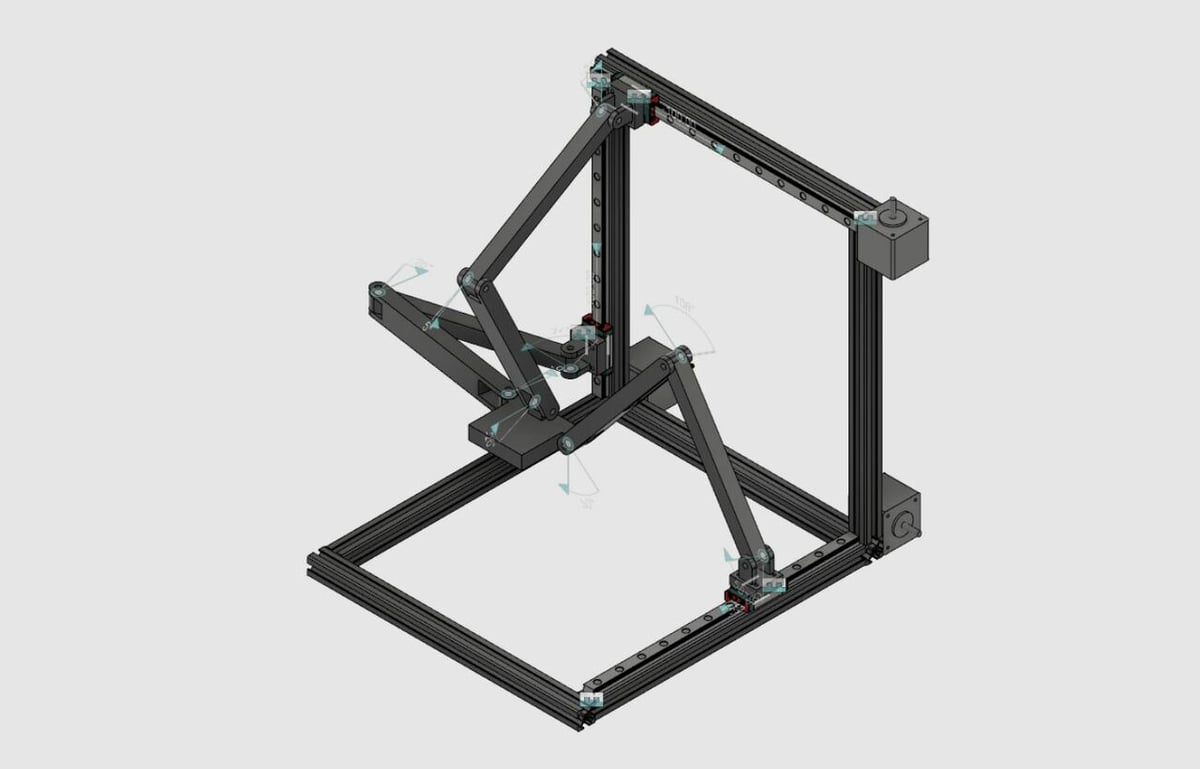

The University of Laval (Original)

This project is known as the first Tripteron machine and isn’t exactly a 3D printer, more of a test that Tripteorn motion is possible. While it wasn’t meant for 3D printing, the machine is suitable for this technology because, in testing, the school has found Tripteron machines can move fast with precision.

To turn it into a 3D printer after building the frame, all you need to do is add a hot end on the tool head carriage. The University of Laval also created a Quadrupteron printer like a Tripteron machine with a fourth axis.

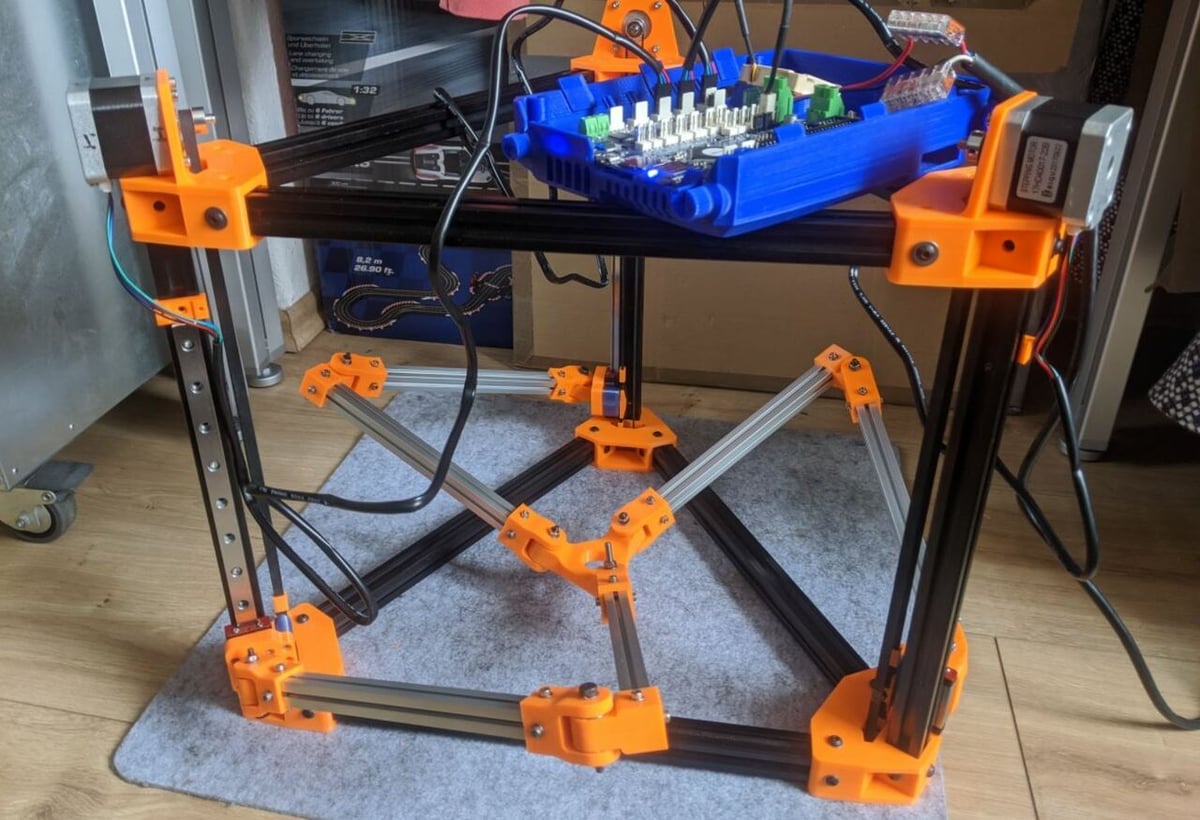

RepRap Forum Build

This project was made by a 3D printing enthusiast, Apsu, who used the University of Laval’s original design and implemented it on a 3D printer. The project page includes the basic design and some of the build log for this Tripteron printer.

There’s also an abundance of comments containing useful information if you decide to build this machine. Learn more from Apsu’s Thingiverse project and Reddit post.

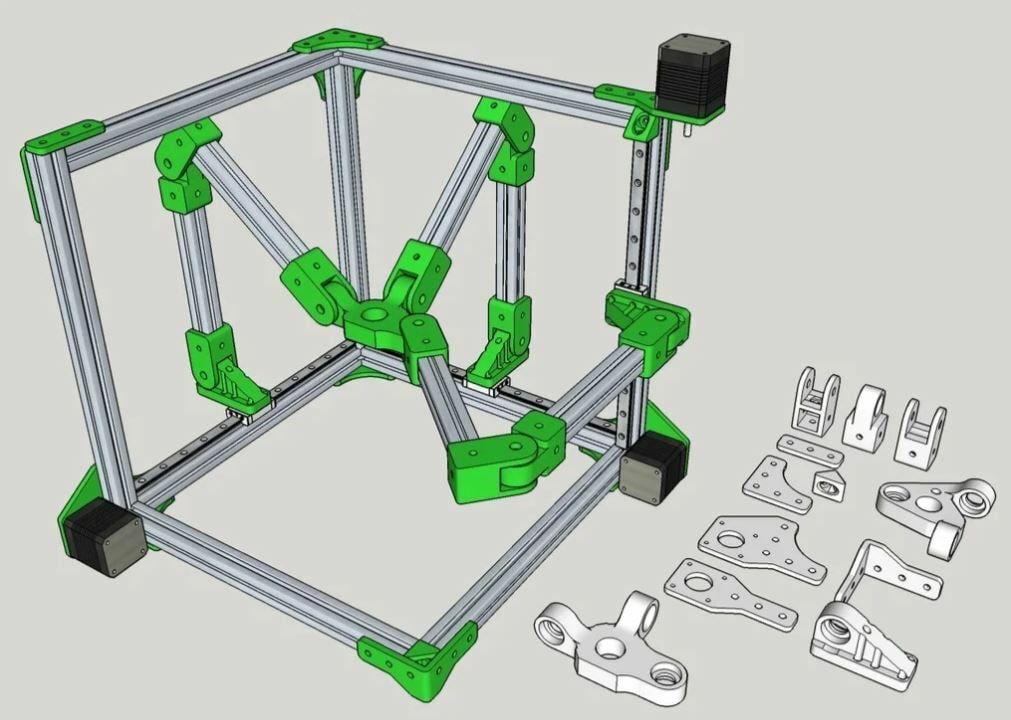

Thingiverse Build

This Thingiverse Tripteron printer project was a Remix from Apsu’s Tripteron machine, with many changes, including frame rigidity improvements, Z-axis motion, and more. Although this project has no recorded Makes or images of successful builds, the designer provided some useful information like how the printer is based on 202 extrusions and uses NEMA 11 (not NEMA 17) stepper motors.

Lead image source: Apsu via YouTube

License: The text of "Tripteron 3D Printer: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.