How Small Can You Go?

Small 3D printed objects are considered to be even more difficult to print than big ones. To succeed, every aspect has to be nicely balanced: the interplay between settings and materials, the 3D model, and the know-how of the producer to choose the right settings. If all is working nicely, 3D printers can produce amazing tiny objects.

Let’s take a look at the smallest 3D printed objects we could find.

Daniel Norée Figurine (2 cm)

Daniel Norée, who is an award-winning Swedish 3D designer, father of the popular Benchy and 3D Printing evangelist, has uploaded a 3D model of himself to Thingiverse.

Chinese company Flashforge downloaded the file and used its own Flashforge Hunter SLA 3D printer to produce the figure of Daniel. The figure measures 2 cm in height and was made using a standard Flashforge gray resin.

The layer height for the Daniel Norée figure was set to 25 microns.

It’s a fun 3D print that perfectly showcases just how good the SLA 3D printing technology is when producing details at a small scale.

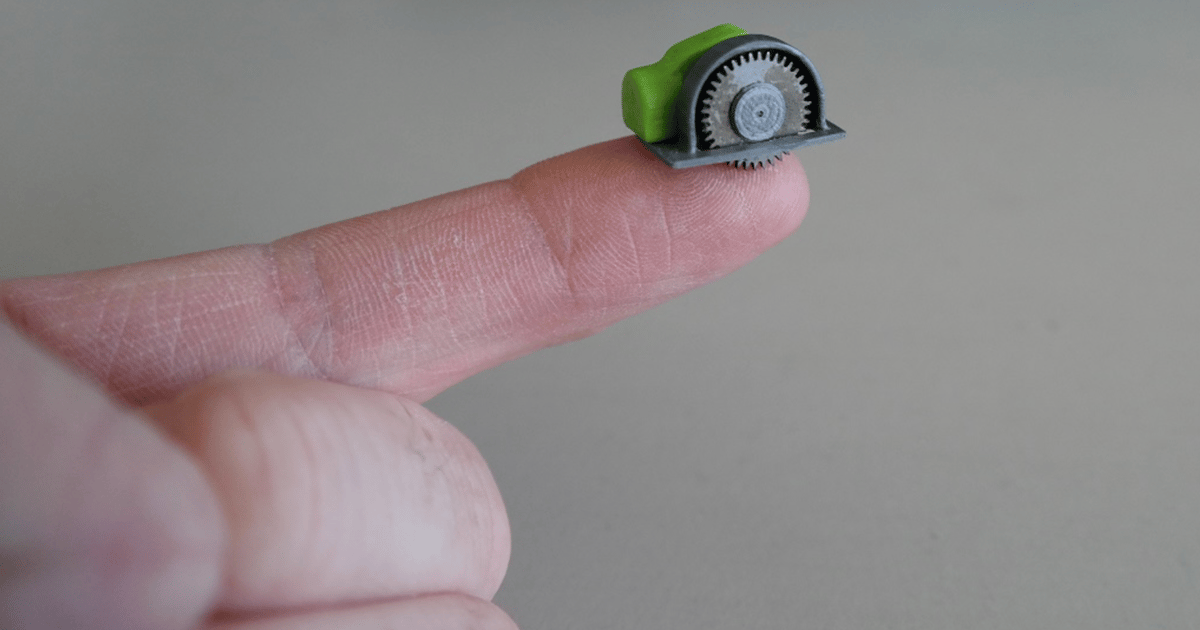

Miniature Circular Saw (1.5 cm)

A few years back, New Zealander Lance Abernethy got a lot of media attention thanks to his creation, which was the smallest working drill ever.

Abernethy 3D printed the drill’s housing and used a tiny hearing aid battery and a little motor to make the drill work.

The successor project of Lance’s to the little drill is the smallest working circular saw. Just as he did with the drill, Abernethy used his Ultimaker 2 3D printer to 3D print the parts he needed. The housing was 3D printed in two pieces, alongside a saw guard and a blade holder.

All the four parts combined were 3D printed in about an hour using PLA.

Inside the saw’s housing, there’s a small battery and a tiny motor which makes the blade spin. Although Abernethy’s 3D printed saw is not able to cut through anything, it’s definitely an amazing piece of engineering.

Tiny Towers (3 mm)

The Solus DLP 3D printer by Reify 3D is a printer capable of producing some extra small pieces.

As you can probably tell, there’s no need for a 3D printed castle as small as the smallest one pictured above, but it’s cool to see how small this printer can go. The smallest of the four castle-like 3D models shown above is about 3mm high, yet its features are still recognizable!

The particular models are used just as a showcase for the build quality of the Solus DLP 3D printer which is mainly used for creating tiny high-detailed prints, like jewelry.

Just imagine 3D printing a part this small using an FDM 3D printer — it simply would not be possible at this level of detail.

As far as small 3D prints are concerned, SLA and DLP 3D printing represent one of the best choices out there.

Miniature Marvin (2.5 mm)

As mentioned in the introduction, small 3D prints are a great way of measuring your 3D printer’s quality. The biggest challenge for 3D printers when printing extra small pieces is to keep the details in place.

Using their professional Solidscape T76+ 3D printer, Hungarian 3D printing service Basilikus 3D produced a 1/10 scaled Marvin.

In case you didn’t know, Marvin is a rather famous 3D Hubs model, which is printed by lots of people who want to test their printers’ print quality.

As you can see by looking at the photo above, the details of the Marvin are still visible on the 1/10 scale model. That’s possible thanks to the Solidscape T76+3D wax 3D printer which is a professional wax 3D printer used for making jewelry models for casting, capable of producing extremely detailed small pieces.

The print took 4.5 hours to print with a layer thickness of just 0.012 mm.

Complex Cube (2.5 mm)

This is a tiny 3D printed cube with a rather complex inner structure. The cube was 3D printed on a Unirapid 3 SLA 3D printer, capable of producing extremely small, high-quality parts.

The cube’s dimensions measure only 2.5 x 2.5 x 2.5 mm, and it took only 32 minutes to 3D print. The layer height setting for the cube was set to 0.05 mm.

The material used for making this amazing tiny cube is a high-resolution resin, called the ProtoGen18420.

The Next Step: Nano 3D Printing

Nano 3D printing was developed at the Karlsruhe Institute of Technology in Germany over a period of five years. Since then, the process has been commercialized under the German company Nanoscribe. Their minimum print size reaches far below the normal boundaries of SLA and DLP 3D printers.

The company’s Photonic Professional GT 3D printer can produce parts with layer thicknesses and detail sizes well below one micrometer. In fact, it’s claimed that the printer is able to produce parts as small as 500 nanometers.

There are many possibilities for applications of such technology. For example, nano 3D printing is a perfect solution for producing microscopic lenses for endoscopes. Endoscopes are very important for the medical industry because they can be inserted into small openings in the body to inspect without causing pain to the patient.

Nano 3D printing is also a great tool for the newest developments in the computing industry. Lastly, microscopic lenses find use in optical instruments and consumer electronics.

One of the newest big achievements for nano 3D printing was developed at the Stuttgart University, where researchers have printed microlenses onto CMOS image sensors. This makes it possible to create high-performance imaging systems.

Although these applications still only exist in labs and aren’t yet publicly available, we think there’s a bright future full of applications awaiting nano 3D printing, and we’re very excited to see what comes next!