CAD Greats

The CAD software market grows more crowded every year, but Dassault Systèmes’ SolidWorks and PTC’s Creo have both stood out since the beginning.

SolidWorks was created as a cheaper and simpler direct competitor to Creo in the mid-1990s. Since then, both CAD programs have expanded their features, customer base, and usage to become two of the top-rated CAD programs out there.

While they both fall under the category of CAD software, SolidWorks and Creo have several major distinctions. The biggest is that Creo focuses more on pure solid 3D modeling, while SolidWorks’ modeling approach is more parametric.

Another notable difference between the programs is their user-friendliness. SolidWorks is touted as great for novices because of its easy-to-use interface and widespread industry recognition. Meanwhile, Creo is aimed at handling complex CAD needs, offering higher-level detailed simulations, translating to a more complicated user experience.

Their software structure is also different. SolidWorks is a single design program that includes all the general design tools, while Creo is actually a suite of modules that users mix and match depending on their CAD needs.

So which is the better program for you? Our comparison below takes you through all the important details, so you can decide where best to invest your time and money.

Prices & Licensing

SolidWorks

SolidWorks offers four types of licenses based on who you are and how you plan to use the software. Each comes with specialized permissions and tools.

- Commercial: This type of license should be familiar to anyone who has bought software to conduct their business. With this license, you’re authorized to use SolidWorks to make products meant for sale and profit.

- Research: When you’re a researcher, sharing your work is key. This SolidWorks license lets you use what you create for projects, industry publications, or intellectual property paperwork (such as a patent application), all without a watermark. Just remember that it’s not intended for work that’ll directly result in a profit.

- Education: SolidWorks’ educational license offers a variety of teaching support along with the core design software. There’s a list of modules you can choose from to personalize what you need for your classroom, all ready to use with your students (but again, not for commercial use).

- Entrepreneur and start-up: This license type is designed to help small businesses who are looking for a CAD system to help them get off the ground. SolidWorks offers a free three-month trial of its software and small-business training for those who fit the following criteria: The software will be used to design products to sell (not consulting), the company has less than $1 million in funding and revenue, and it has been in business for less than three years. Note that if you’re already using any Dassault Systèmes software, you can’t switch to this type of license.

SolidWorks’ pricing system is based on tiers of usage. It includes a one-time fee for the software itself, plus an annual fee for maintenance and upgrades.

- Standard: $3,995 one time fee plus $1,295 per year

- Professional: $5,490 one time fee plus $1,495 per year

- Premium: $7,995 one time fee plus $1,995 per year

If you’re interested, you can read all the details and talk to a sales representative on the SolidWorks website.

Creo

Creo is available with two types of licenses based on how many devices should use the program:

- Locked: This is for using Creo on a single device, such as a work desktop. You can’t transfer the program to any other device, but you don’t need a licensed server to use it.

- Floating: With this license, you can use Creo on a number of devices. A licensed server is required with a floating license as a way for Creo to know how many devices are using one license (because there’s an upper limit). This is the clear choice for an office or work environment where multiple users on multiple devices can share the same Creo login.

The exact price of Creo can be hard to pin down without talking to a salesperson because PTC offers a wide variety of extras that are meant to be tailored to your specific situation. However, there are five basic service levels that have subscription pricing to start you off. All prices are per-year subscription fees.

- Design Essentials: $2,390 for locked, $2,931 for floating

- Design Advanced: $5,890 for locked, $7,299 for floating

- Design Advanced Plus: $10,300 for locked, $10,980 for floating

- Design Premium: $14,375 for locked, $15,610 for floating

- Design Premium Plus: $20,000 for locked, no floating license available

If you’re interested in trying or buying this software, you can check out Creo’s website.

System Requirements

SolidWorks and Creo both require a certain degree of computational capacity to work smoothly. Let’s break down what you’ll need to run each program.

SolidWorks

- Operating systems: Windows 7 SP1 or 10, 64 bit

- Minimum RAM: 16 GB or more (depending on the size of renders)

- Video display: Workstation card (recommended)

- CPU: Intel Core i7 9700K or Core i9 9900K (recommended)

- Internet connection: Not required (work can be done in offline mode)

Creo

- Operating systems: Windows 7, 8, or 8.1, 32-/64-bit

- Minimum RAM: 512 MB

- Video display: 3D-capable graphics card

- CPU: Single- or dual-quad processors

- Internet connection: Required to activate (reactivation occurs every three days)

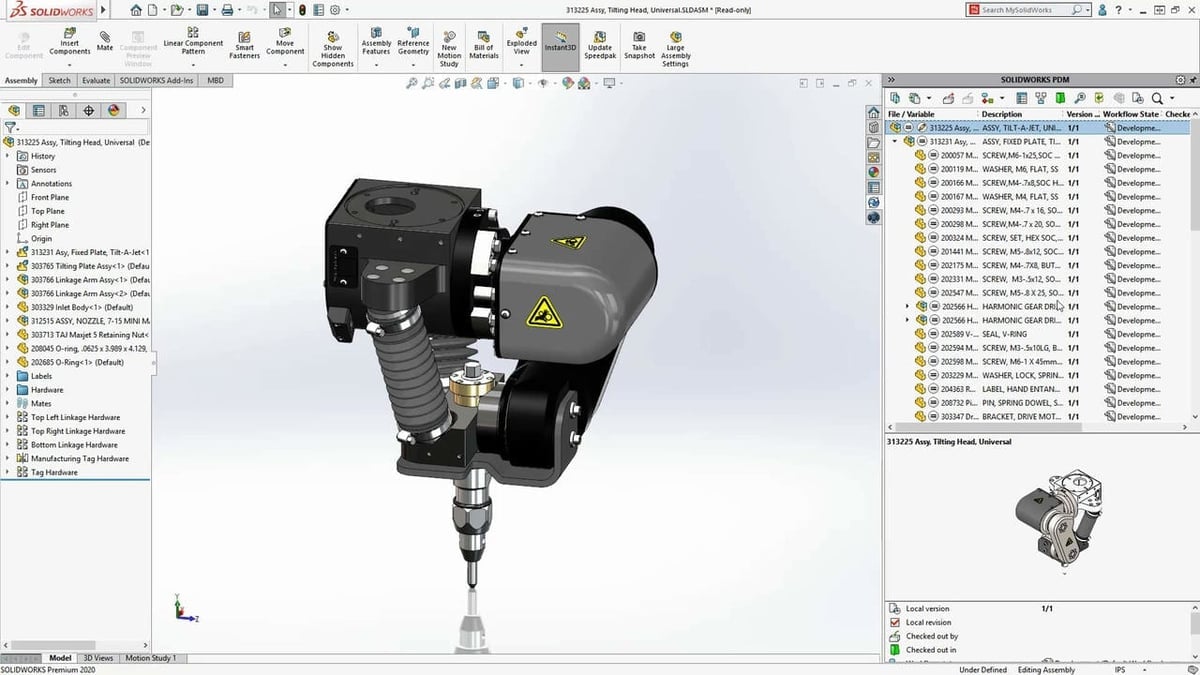

Features & Functions: SolidWorks

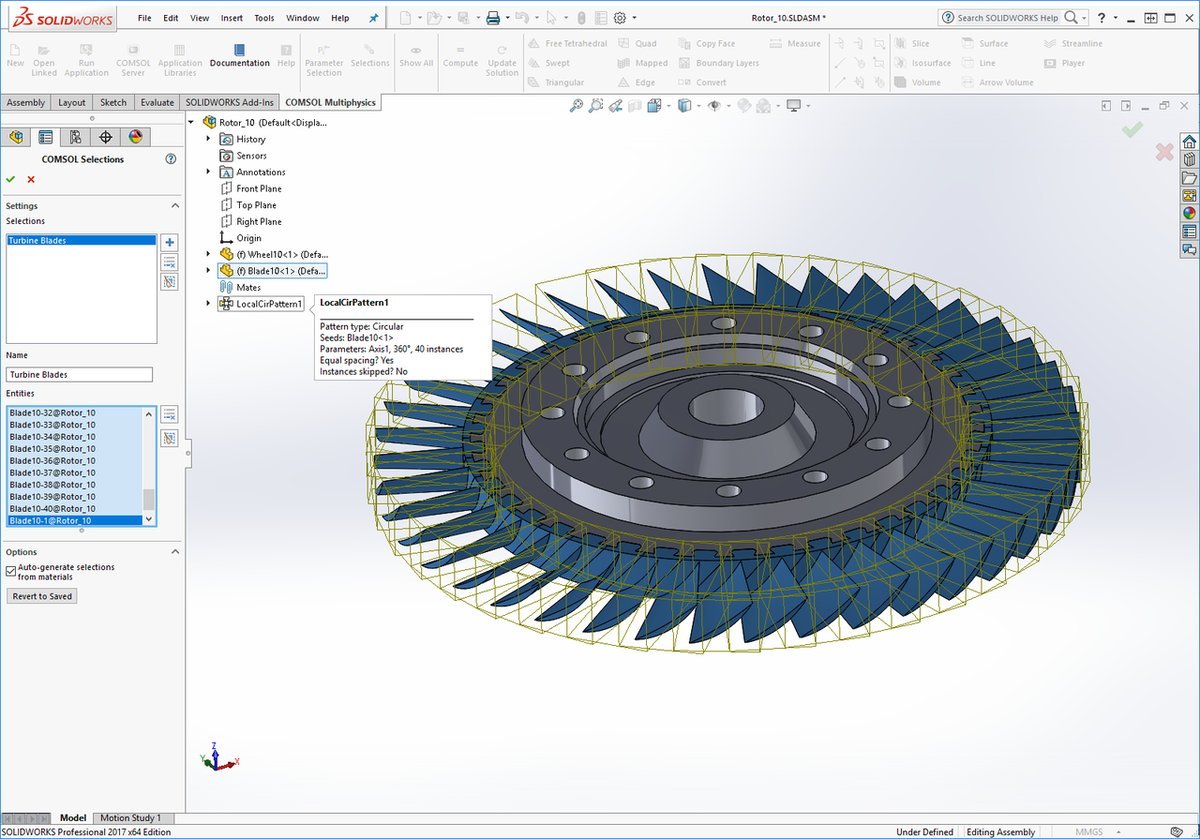

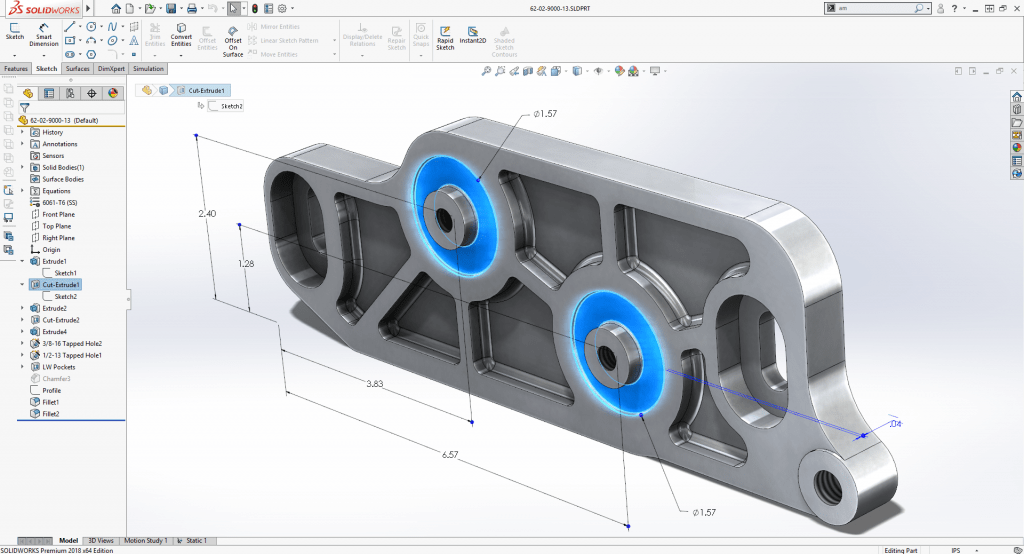

SolidWorks is CAD software that’s been on the market since 1995. It’s a solid modeler that uses a parametric feature-based approach to CAD, which means it emphasizes creating life-like renderings of objects.

While the features and functions in SolidWorks are many, we’ll highlight several that make SolidWorks’ user experience stand out.

- Command finder: If you ever find yourself lost in a maze of menu choices, SolidWorks’ command finder comes to the rescue. It’s a search function on your top ribbon that lets you find a command based on keywords, so you don’t have to remember the command’s exact title to grab and use it.

- Hide or show components: Working on a complex design means you need a way to flip between the big picture and concentrating on small details. In SolidWorks, it’s a snap to switch components between seen and hidden; all you have to do is hold down the Shift and Tab keys while highlighting a specific component, and it hides or reveals itself.

- Interference check: One of SolidWorks’ most lauded simulation features is its ability to let you know if any of your components will overlap or otherwise clash during the tests you set up for them. We don’t have to tell you how much grief this will save you if you’re able to catch this kind of interference during the design testing stage instead of halfway through manufacturing.

- Simulation-specific configuration: In order to execute certain simulations, one has to change the geometry of a design. But who wants to have to change it back once they’re done? Within SolidWorks’ simulations, you can change shapes within your design without saving them.

- Hole wizard: No need to rely on dog-eared manuals or bookmarked browser windows to figure out the specifics of the holes you’re making in your design. With its hole wizard, SolidWorks stores all the information needed within a feature containing holes so that you’re compliant and fitted with standard tools and hardware.

- Quick mates: When you hold down the Control key and select a reference, like a face, edge, or vertices, this little gem pops up. Quick mates takes the separate components of your design and puts them together based on the reference you chose. It’s an easy way for you to check your progress at any point, which can save a lot of time and headaches down the road.

- Mouse gestures: This feature is somewhat polarizing. Some users find it frustratingly less precise than keyboard commands, but others enjoy the freedom of movement and find the mouse easier to control. Wherever you fall in that debate, SolidWorks does depend a lot on mouse usage, which may take some getting used to.

- Library: Do you have shapes and details that you use constantly? Add them to your SolidWorks library so that you don’t have to recreate them every single time. It’s great for consistency in design and your sanity.

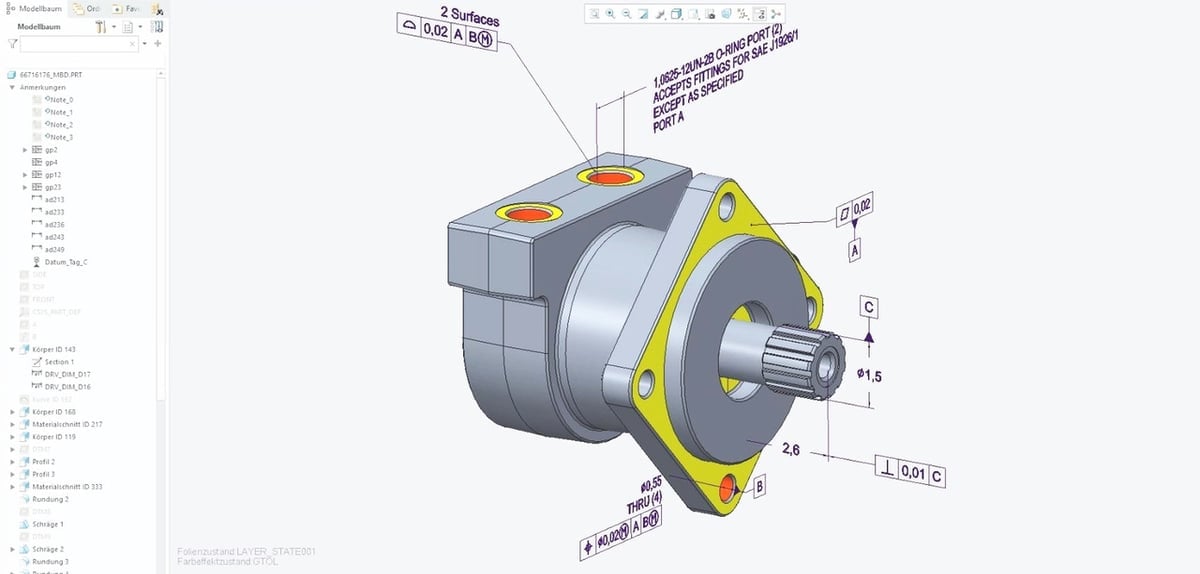

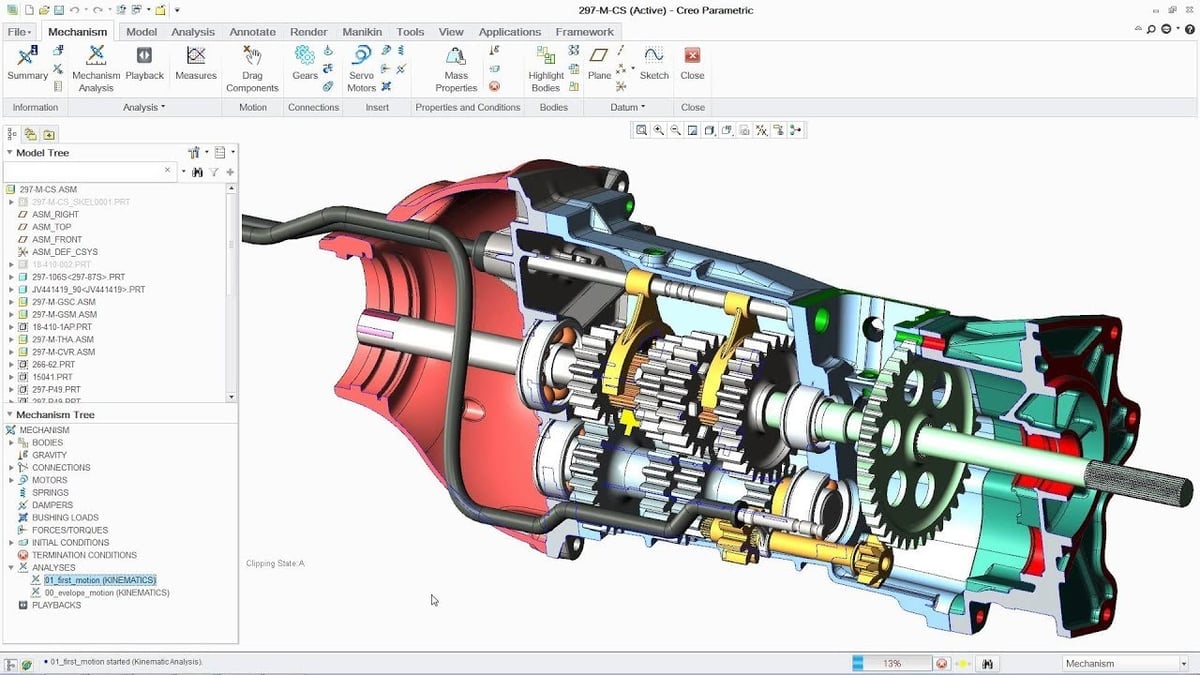

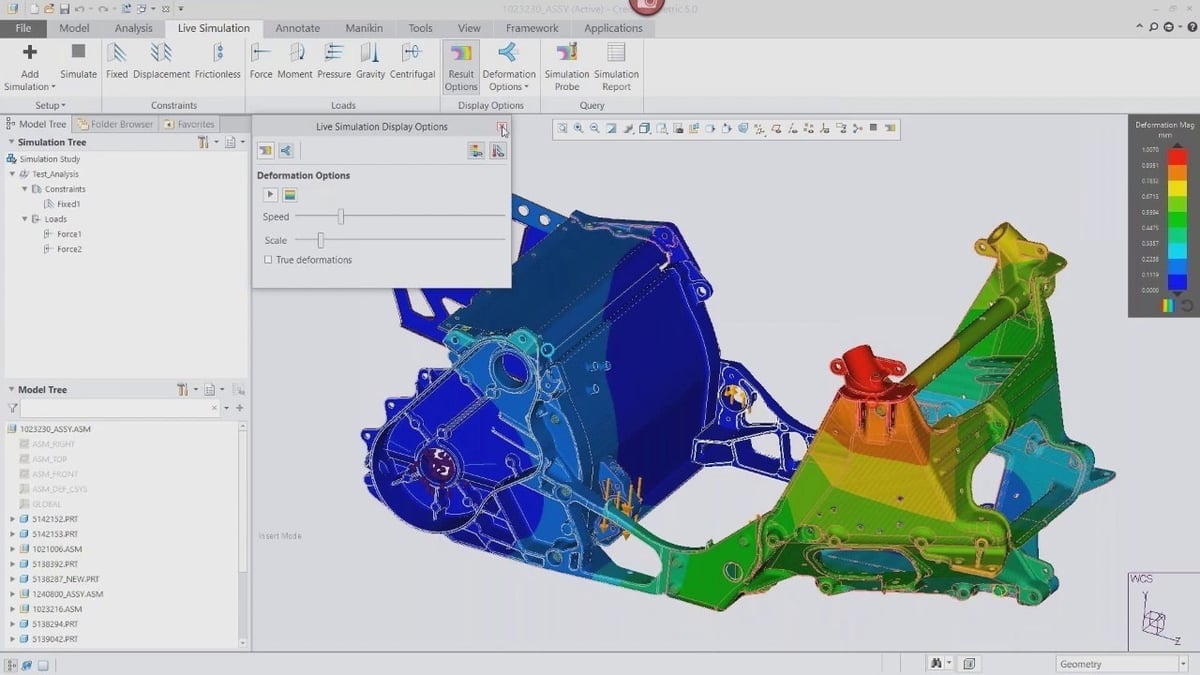

Features & Functions: Creo

Creo comes with a number of features and tools that show off its elevated level of CAD functionality. While it’s seen as less user-friendly than SolidWorks, users appreciate what Creo can help them accomplish.

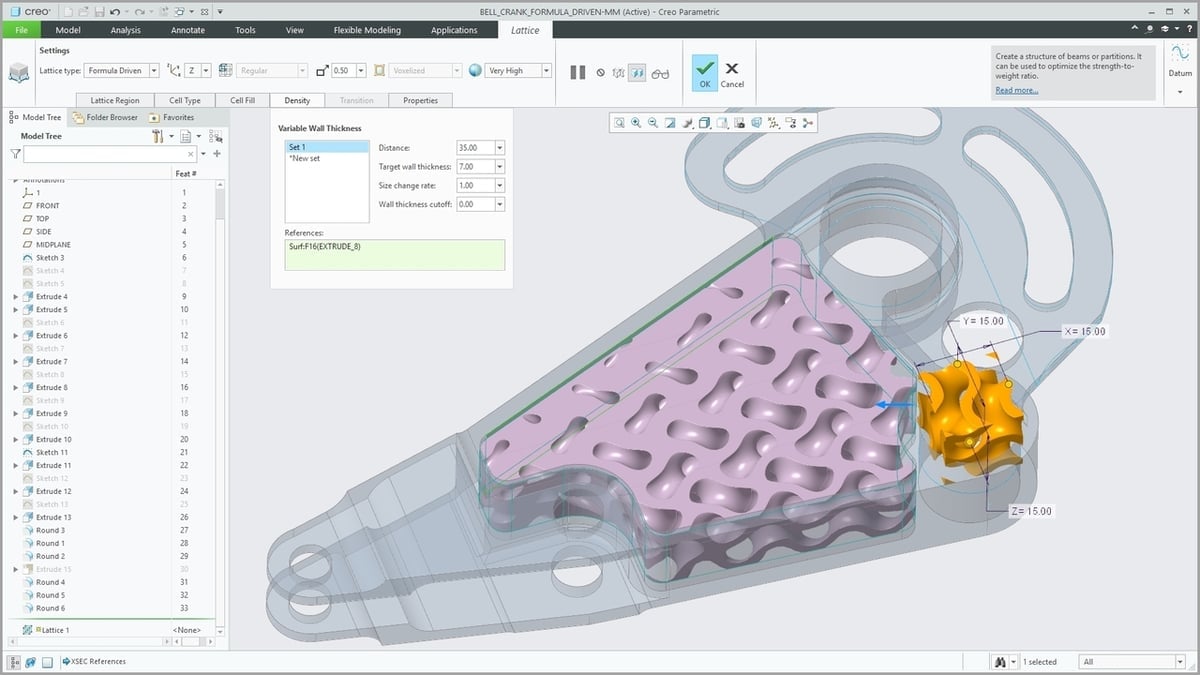

- Style features: This tool lets you create free-form curves and surfaces. You can combine limitless numbers of them into what Creo calls “super features”. Creo users love this self-contained design environment, where you can freehand and also have access to Creo’s full set of parametric tools.

- Technical and freestyle surfacing: Creo offers several ways to create surfaces and curves on your design model. Technical surfacing lets you manipulate patches of specific types of surfaces within their designated measurement constraints. Working with curve tangents that you can alter on-screen, freestyle surfacing lets you adjust the boundaries and other measurements of your surface. The underlying structure changes as the surface does, so everything stays in proportion.

- Analysis features: If you’ve got parameters, Creo can show you a number of designs created within your specifications. You can go with their option, reject it completely, or pick and choose what you want to keep. Any way you use it, you’re getting the help of an AI that’s designed to elevate your final product to its best.

- Sheet metal modeling: If you’re planning on creating a part out of sheet metal, Creo has a feature that behaves like that material’s surface while you design your model. Within the sheet metal module, you can also adjust specific dimensions and other details that help you get exactly the performance you want before bringing your design to life.

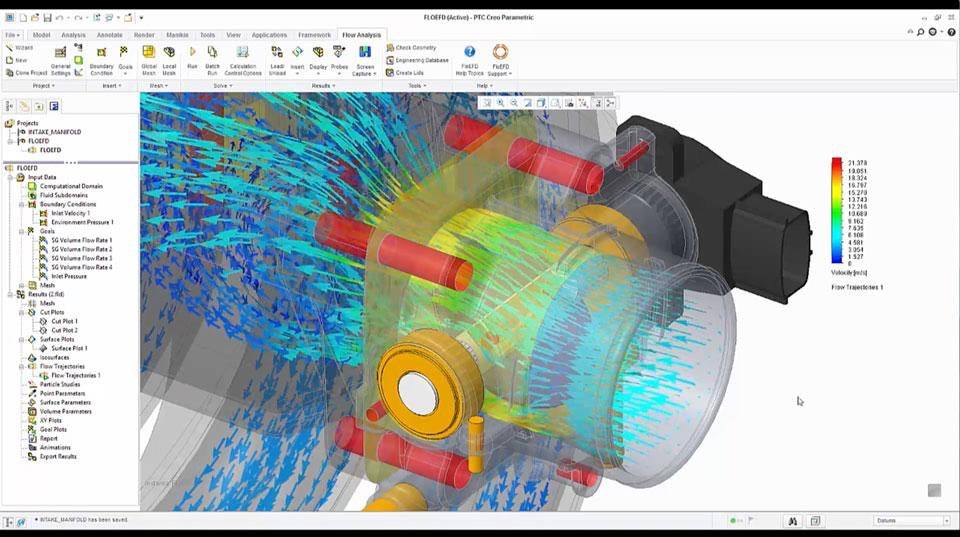

- Computational fluid dynamics: A new feature in Creo’s latest 5.0 version is computational fluid dynamics, which lets you simulate liquid and gas flow in your designs. As a bonus, users say this new tool is designed for any level of user, so you can give it a try even if you’re brand new to the software.

- Design for 3D printing: Another major advantage added to the latest version of Creo is the ability to take your design directly into its additive manufacturing stage. This is done through Materialise or other metal 3D printing services, which can save you a lot of time and money.

User Experience

SolidWorks

- Easy to learn: SolidWorks’ biggest claim to fame is how easy it is to learn, even if you’re a complete CAD beginner. Several available tutorials help you master the basics in no more than an hour. Its extensive user-led community is also there to give you tips on how to learn, practice, and become fluent in your use of CAD.

- Makes design failures transparent: When you make a mistake in your CAD design, SolidWorks doesn’t stop working; it carries that mistake into your next steps. And while that may initially sound terrible, from a creation perspective, it’s actually a good thing. SolidWorks documents how a mistake affects other aspects of your design, and you can use this to trace your misstep back to its source, giving you a better, more holistic idea of how it happened and how to correct it.

- User control over design part details: Another useful aspect of SolidWorks’ process details is how you can merge two separate designs into one. That also means you can treat two parts of your whole design as separate files before bringing them together, a feature that can help you give each section the attention to detail it deserves. SolidWorks also has a built-in feature that lets you build a weldment as one multi-body part, which is very handy if you deal with weldments on a regular basis.

Creo

- Steep learning curve: The number one complaint about Creo is how hard it is to learn. We definitely sympathize with that, as CAD software, in general, can be intimidating to beginners. It’s definitely true that the more advanced the features, the less user-friendly the software becomes. So if you’ve never worked with CAD before, Creo may not be a great place to start.

- High-end CAD functions: This is what Creo is most famous for and what it does best. It focuses on bringing advanced CAD tools, like topology optimization (which makes it possible for users to create optimized shapes directly onto geometry), for superior top-down design to creation processes. Users say they enjoy the speed and level of control Creo gives them in their work, such as the ability to stack commands, kaleidoscope features, and other advanced geometric building abilities.

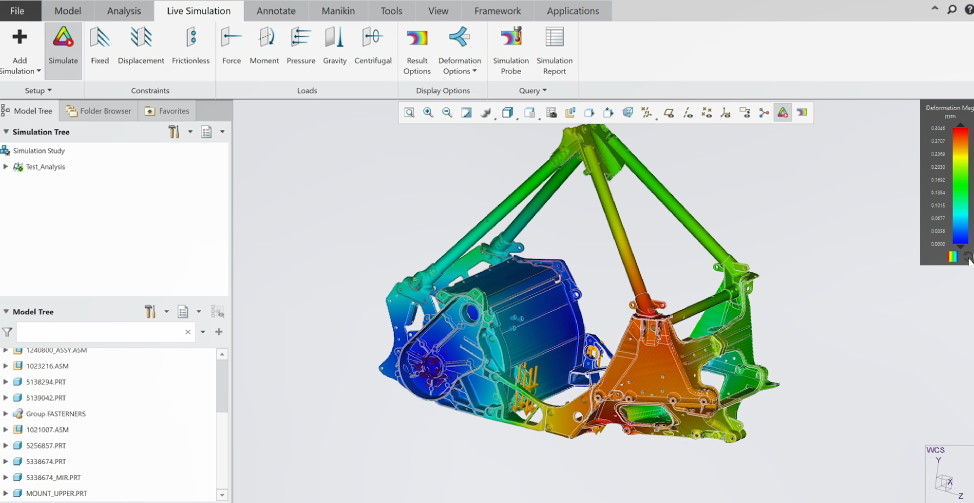

- Customization: Since Creo is a suite of CAD applications instead of one single program, you can choose highly-specific modules that you need and forget about extras you don’t need. There are a number of packages that target different CAD usages, from “Creo Interactive Surface Design” for advanced curvature and tangency tools to an extensive library of design testing in “Creo Simulate”. And those are just two of its ten comprehensive applications, so whatever your needs are with solid modeling software, Creo’s got you covered.

Use Cases & Applications

Since SolidWorks and Creo are both solid modeling CAD programs, there’s a significant overlap in their target user base. However, there are a few key differences in the details of their use, which leads each to be better-suited for different specialty applications.

SolidWorks

- Use cases: On its website, SolidWorks highlights a few of its recent customers, such as Astrobotic, CP Manufacturing, Solar Ship, and Labun Nuclear Technologies.

- Applications: SolidWorks is used in a lot of manufacturing-adjacent industries, including machinery, computer hardware, mechanical and electrical engineering, and construction. According to a user survey by Enlyft, mining and medical device fabrication are also among the top ten industries that use SolidWorks.

Creo

- Use cases: PTC’s website has in-depth case studies from a number of companies, including Fujitsu, the University of Minnesota’s solar vehicle team, and KTM.

- Applications: Creo is used in many industries and companies because of its extensive adaptability. These include automotive, aerospace, heavy machinery, and others that require robust testing and simulation of designs before they’re manufactured.

Community & Company Support

Both SolidWorks and Creo have dedicated spaces on the internet for users who want to connect, troubleshoot, and learn more. Below, we’ll highlight a few details about their individual official support systems, though the unofficial support across the web is also quite substantial.

SolidWorks

- Community: SolidWorks’ user group network is led by actual users, and they put on live meetups and streaming meetings. You can find your geographic area, specialty, and even become a group leader yourself. In addition, SolidWorks has a vast network of user-led forums on their official website.

- Company support: SolidWorks uses a centralized knowledge base to organize its company-produced education and training modules. You can go through full courses (even earning certifications for your efforts), or you can pick and choose topics for which you need help. And of course, there’s always directly contacting their support team.

Creo

- Community: PTC has a company support group page that’s based on which product of theirs you use. Plus, you can partner with their developers for questions that other users haven’t figured out yet.

- Company support: You can go through the PTC University training offerings for more formalized help. There are several ways to search available classes, which can be filtered by region and product.

Final Thoughts

Both of these CAD programs are star players in the solid modeling world. Choosing which one to use really comes down to an honest assessment of your own skill level and knowledge of what you need for your CAD projects.

We like Creo because of its higher capabilities and customization of core CAD functions. It’s more difficult to jump into than SolidWorks, but it outperforms SolidWorks in key areas, such as design speed, keyboard shortcuts, and its vast array of tools that give additional levels of detail.

On the other hand, if you’re a less-experienced modeler, or if non-specialized CAD is a part of your work but not the main function of your job, we recommend SolidWorks. In addition to being more user-friendly, it has a great user community to support whatever it is you need to design.

Lead image source: SolidWorks Blog

License: The text of "Creo vs SolidWorks: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.