When it comes to choosing 3D printing materials, there are a lot of factors that can help you make a decision, such as printability and strength. Of course, depending on what you’re printing, the quality you want most will differ. For example, if you’re printing a GoPro mount, you may want a filament that can withstand the elements, but when making a fun toy for your nephew, a filament that’s easy to print with would work fine.

PLA and PETG are two of the most popular filament materials available to hobbyists, both with their advantages and disadvantages regarding printability, strength, and more. In this article, we’ll review the main differences between PLA and PETG and what makes each material better suited for specific applications and purposes.

The Contenders

Before we look at the differences between PLA and PETG, it’s important to review each filament material on its own merits. So first, we’ll go over how each material is sourced, as well as the main benefits and disadvantages of each.

PLA

First up, PLA is the commonly used abbreviation for poly(lactic acid). PLA is the most popular 3D printing filament material and is also commonly used in the food packaging industry due to its food safety properties, which we’ll talk about later.

To give some background, the building blocks of PLA can be sourced from starches derived from crops like corn and sugar cane. Certain sugars are extracted from the starch, which can then be fermented to create monomers, the starting material for polymers. This chemical is polymerized to create the raw version of PLA plastic.

Perhaps the most notable aspect of PLA is how easy it is to print with. Basically, any FDM 3D printer can print with PLA due to its low melting and glass transition temperatures. Additionally, PLA isn’t super sensitive to the surrounding environment and works with a range of slicer settings, so you can achieve decent prints without too much work.

However, no material is all good, and the main downside of PLA is its lack of strength. Parts printed in PLA are known to be very brittle due to the low layer-to-layer adhesion of 3D printed models. Also, high temperatures and UV rays are known to discolor and even deform parts printed in PLA, making it a poor material choice for parts meant to be outside and under the sun.

PETG

Polyethylene terephthalate glycol-modified, or PETG, is another popular 3D printing material. PETG is a modified version of PET, the plastic you likely associate with disposable water bottles and other clear containers. The main difference between PETG and PET lies in the ‘G’, which signifies the glycol modification that lowers PETG’s melting point and makes it easier to 3D print.

Like most plastic out there, the building blocks of PETG are mainly sourced from crude oil, specifically the glycol and terephthalic acid monomers. These chemicals are extracted from the oil and then polymerized to create raw PETG plastic.

PETG is best known for its durability and strength, and the plastic is resistant to high temperatures, UV rays, water, chemical solvents, and more. All of this makes PETG an ideal filament material option for printing parts that will exist in harsh environments or have to undergo a lot of physical stress.

Unfortunately, PETG requires somewhat high printing temperatures, which means higher energy consumption. Additionally, there are a few common printing and part quality issues, like over-adhesion and stringing, that make the material more difficult to work with. Nonetheless, PETG is still a great filament material option with a lot of applications.

Printing

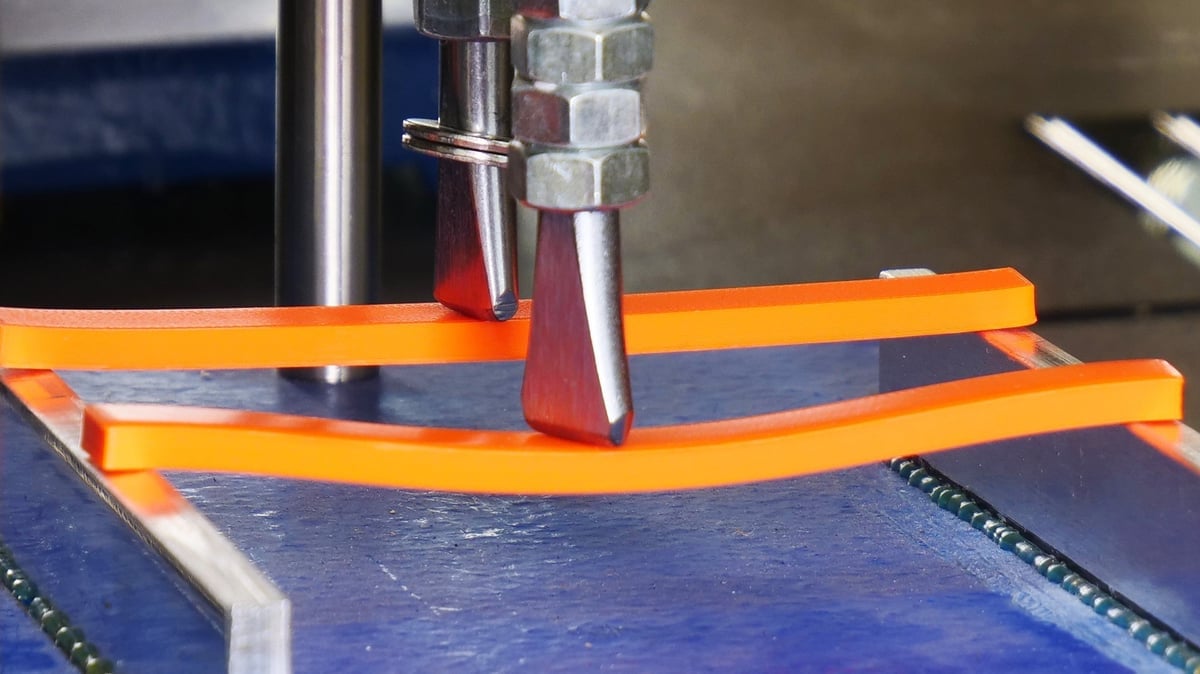

As we mentioned, PLA requires comparatively low printing temperatures. Most PLA filaments can be printed with a hot end temperature of around 210 °C and an optional bed temperature of up to 60 °C. On the other hand, PETG requires notably higher temperatures, with a suggested hot end temperature between 220 °C and 250 °C and a bed temperature around 65 °C.

PLA is also a lot less sensitive to printing factors, such as the printing environment and imperfect slicer settings, compared to PETG. It’s not uncommon to achieve high-quality prints in PLA with a default PLA printing profile.

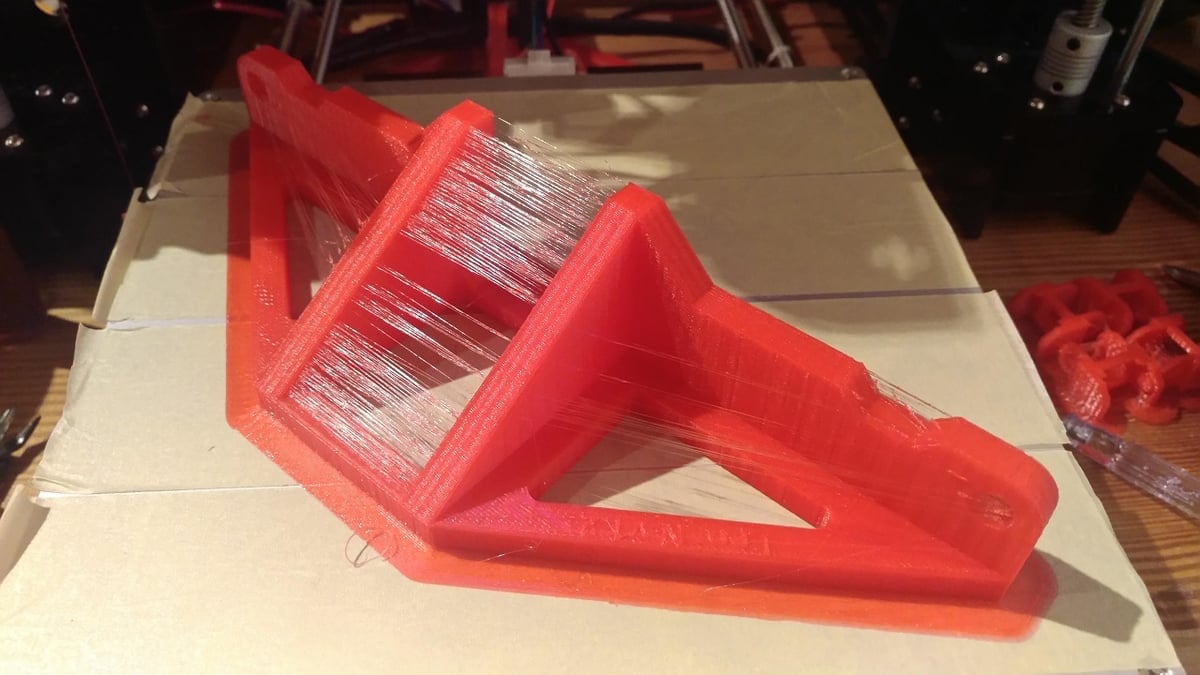

However, PETG is a little more difficult to work with. Especially if you don’t calibrate your extruder, tune your retraction settings, and find the best temperatures and speeds, you’ll likely experience stringing on your PETG prints.

If you’re unfamiliar with the problem, stringing is when extra material flows out of the nozzle when it shouldn’t, leaving small wisps of extra plastic all around your print (it’s not a good look). With PETG, you’re also more likely to have issues with bed adhesion, as some filament brands can over-adhere to some build surfaces – notably glass, BuildTak, and PEI sheets. This may make PETG prints more difficult to remove from the bed compared to PLA.

Mechanical Properties

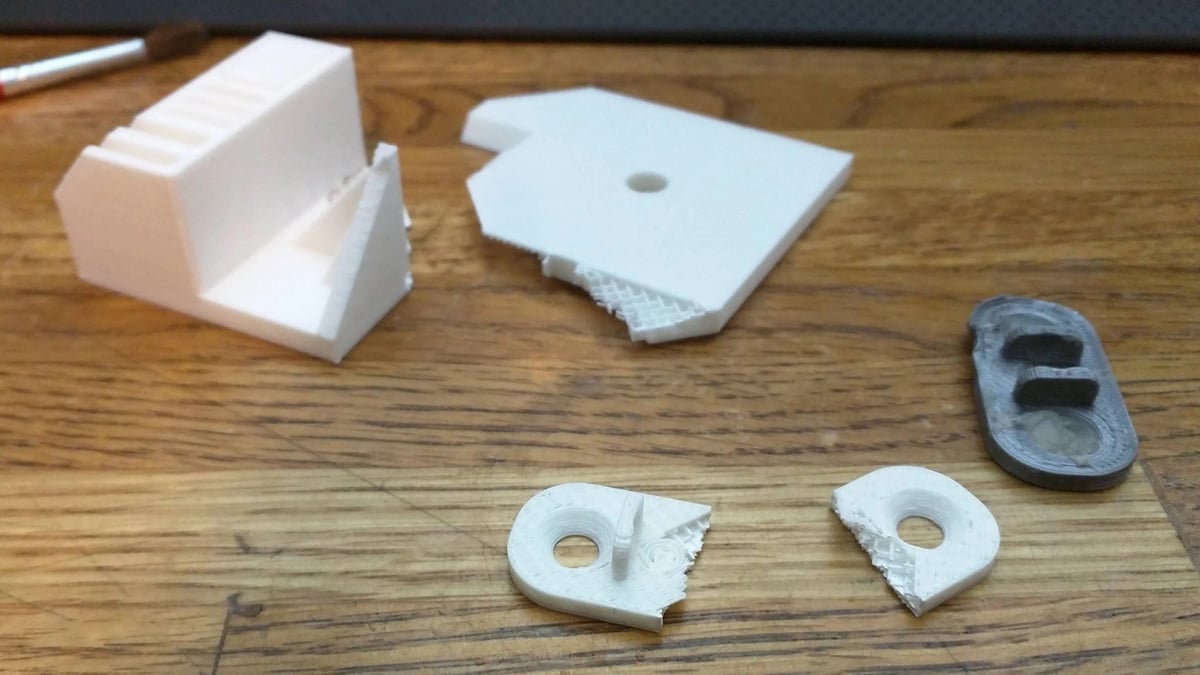

In terms of mechanical properties, PETG is well-known for its high strength, which is a result of the raw material’s natural strength combined with the increased layer-to-layer adhesion produced with the higher printing temperatures. PLA’s layer adhesion is less impressive, and PLA prints can be brittle, making this material not ideal for applications where sudden failure could result in damage or injury. PETG is favorable to PLA in the way that it will often bend before totally breaking (depending on the model and type of stress, of course). However, PLA can handle more stress than PETG before it fails.

While strength is one thing, resistance to the elements is also very important for a 3D printing material. If you’ve ever printed with PLA, you’ll know that it can easily get ruined in the wrong conditions. For example, if left outside and under the sun on a hot day for more than an hour, parts printed in PLA will start to deform because the UV rays and warm temperatures are enough to soften the material.

This is not anywhere near the case for PETG, though, as this thermoplastic material is a relatively durable plastic. PETG’s got a long list of things that it’s resistant to, including UV rays, high temperatures, water, and acetone. All of this makes PETG a great option for printing any models that will be used outdoors or face harsh environments.

More Differences

It’s more than the properties of the materials and how to print them that set PLA and PETG apart. For one, there’s the environmental friendliness of the materials. PLA can be derived from renewable resources, while PETG comes from less-than-environmentally-friendly crude oil.

While producing PLA is, theoretically, less harmful than making PETG, this doesn’t consider the end-of-life for each material. Although PLA is often advertised as being compostable, the reality is that the biodegradation of bulky (and additive-filled) 3D printed PLA parts takes too long, even in industrial composting settings, and therefore will end up in the general waste stream.

Both PLA and PETG are recyclable, but you’ll have to search out specialty recyclers that handle 3D printer waste or recycle it yourself. Although PETG is related to PET, municipal recycling facilities consider PETG to be a contaminant due to its lower thermal properties.

With everything in mind, neither plastic is particularly friendly for the environment. However, if one had to be a winner, PLA would likely take the cake due to its renewable source materials.

And although it’s not a difference, it’s also important to know that both PETG and PLA are generally considered food safe. If your prints will come in contact with food or drink, it’s best to look for filaments that follow FDA or EU guidelines.

Please also keep in mind that there are other sources of contamination throughout the 3D printing process. So, in addition to printing with a certified food-safe filament, you should take precautions to reduce possible contamination during extrusion and, after printing, seal the print with a food-safe sealant.

Examples

Now that we’ve gone over the differences between the materials, you might be interested in getting some filament. There are quite a few brands offering PLA and PETG. Below, we highlight just a couple of the many options out there.

PLA Filaments

Prusament is manufactured by the well-known Prusa Research, and their PLA filament is considered to be very easy and reliable to print with. Prusament PLA comes in around 30 different colors, including marble, silky variants, and two fun polychromatic options. Prusament is known for its high-precision tolerance of just ±0.02 mm and a QR code provided on each roll that will lead you to several more quality assurance parameters the filament passed before it ended up in your hands.

Polymaker is another manufacturer of 3D printing filaments, producing an astonishing variety of PLA filaments and colors. Their PolyTerra PLA, popular for its ease of printing and environmental friendliness, has 35 different color options. They also offer a general-purpose PolyLite and a tougher PolyMax, both in a wide range of colors and effects like metallic, glow-in-the-dark, and dual-color. All filaments come on a cardboard spool and feature a diameter tolerance of ±0.02 mm or smaller.

PETG Filaments

Prusa Research’s Prusament made the top of the list again for their PETG filament. Like their PLA, you can expect top-of-the-line dimensional accuracy and even more quality assurance specs by following the QR code on each one of their PETG spools. There are 22 colors to choose from, including a popular clear variety, as well as a carbon fiber composite option.

FormFutura’s ReForm rPET is made from recycled material from their own HDglass filament production, but don’t make any judgments about its quality before you try it. It’s proven to be exceptionally easy to work with, although it can have some color variation from spool to spool. At a price point of just $20 per kg, one of their 13 color options may just be worth a shot.

License: The text of "PETG vs PLA Filament: The Main Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.